Approval of HSE Manager - PMP Project, Qatar Gas

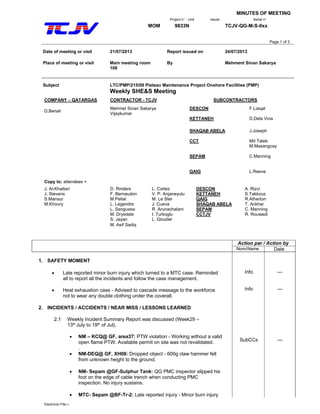

- 1. MINUTES OF MEETING Project n° - Unit Issuer Serial n° MOM 9833N TCJV-QG-M-S-0xx Page 1 of 3 Electronic File:-- Date of meeting or visit 21/07/2013 Report issued on 24/07/2013 Place of meeting or visit Main meeting room 108 By Mehment Sinan Sakarya Subject LTC/PMP/215/09 Plateau Maintenance Project Onshore Facilities (PMP) Weekly SHE&S Meeting COMPANY – QATARGAS CONTRACTOR - TCJV SUBCONTRACTORS D.Benali Mehmet Sinan Sakarya Vijaykumar DESCON F.Liaqat KETTANEH D.Dela Vina SHAQAB ABELA J.Joseph CCT Md Taleb M.Masangcay SEPAM QAIG C.Manning L.Reeve Copy to: attendees + J. Al-Khattari D. Rinders L. Cortez DESCON A. Rizvi J. Stevens F. Bernaudon V. P. Anjaneyulu KETTANEH S.Takkouz S.Mansur M.Pellat M. Le Ster QAIG R.Atherton M.Khoury L. Legendre J. Cueva SHAQAB ABELA T. Ackhar L. Sanguesa R. Arunachalam SEPAM C. Manning M. Drysdale I. Turkoglu CCTJV R. Rouwadi S. Jayan L. Gloutier M. Asif Sadiq Action par / Action by Nom/Name Date 1. SAFETY MOMENT ď‚· Late reported minor burn injury which turned to a MTC case. Reminded all to report all the incidents and follow the case management. ď‚· Heat exhaustion case - Advised to cascade message to the workforce not to wear any double clothing under the coverall. 2. INCIDENTS / ACCIDENTS / NEAR MISS / LESSONS LEARNED 2.1 Weekly Incident Summary Report was discussed (Week29 – 13th July to 19th of Jul). ď‚· NM – KCQ@ GF, area37: PTW violation - Working without a valid open flame PTW. Available permit on site was not revalidated. . ď‚· NM-DEQ@ GF, XH08: Dropped object - 600g claw hammer fell from unknown height to the ground. Ěý ď‚· NM- Sepam @GF-Sulphur Tank: QG PMC inspector slipped his foot on the edge of cable trench when conducting PMC inspection. No injury sustains. Ěý ď‚· MTC- Sepam @BF-Tr-2: Late reported injury - Minor burn injury Info Info SubCCs --- --- ---

- 2. MINUTES OF MEETING Project n° - Unit Issuer Serial n° MOM 9833N TCJV-QG-M-S-0xx Page 2 of 3 Electronic File:-- of right arm when welding slag dropped and got inside the welding gloves. ď‚· FA- DEQ @BF-Utility : Minor cut/laceration of right hand middle and index finger when hit by the rotating fan when adjusting the cage fan inside rest shelter. Ěý 3. STOP/PULSE PROGRAMS: 3.1 Reached over 473,000 SOCs, project to date. 3.2 Pulse Survey Structure was shared: Rollout will start on 13th August. 3.3 Translations of the pulse questionnaire need to be completed and submitted to TCJV Pulse team. 3.4 SubCCs to provide the breakdown numbers of their organization for Pulse survey calculations. 3.5 SubCCs to provide the names of interviewers and coordinators for Pulse Survey to Pulse team. 4. MANPOWER AND HSE RATIO (DIRECT EMPLOYEE/FIELD HSE): SubCC Manpower HSE Supervision Ratio First Aider Ratio DS NS DS NS DS NS Kettaneh 470 43 8 1 1/59 1/43 10 1/51 Descon 1970 50 44 2 1/45 1/20 65 1/31 Sepam 600 2 19 - 1/32 - 10 1/60 QAIG 1160 - 4 - 1/40 - 8 1/20 Shaqab-Abela 117 4 2 - 1/59 - 2 1/61 CCT 420 2 11 - 1/38 - 6 1/70 TOTAL 3737 101 88 3 1/42 1/34 101 1/38 4.1 TCJV requested all SubCCs to provide the valid certificates of all first aiders. (in line with project procedure: All safety officers and 1/50 of employees). 5. OTHER TOPICS: 5.1 Incident investigations process: TCJV will prepare a presentation for the investigation process and skills. 5.2 Camp walkthroughs – TCJV to distribute the action points from the Alkhor Camps walkthrough to QAIG and Sepam. New schedule for the walkthrough will be issued by TCJV. 5.3 Reported some snakes seen in TCJV Camp – TCJV to issue an alert in the camp. Shaqab Abela will place signages in the camp. 5.4 CCT rest shelter in place but has no fan. TCJV reminded until in compliance, shelter need to be closed. 5.5 TCJV requested SubCC HSE manager’s to send their updated CV. 5.6 Changes in DEQ HSE Management – Mr. Farooq promoted as DEQ HSE manager, in place of Mr.K.Khan. SubCCs Info Info KCQ/DEQ All All SubCCs TCJV TCJV SA SubCCs SubCCs Info --- --- --- 25.07.13 25.07.13 25.07.13 28.07.13 10.08.13 25.07.13 30.07.13 --- 25.07.13 ---

- 3. MINUTES OF MEETING Project n° - Unit Issuer Serial n° MOM 9833N TCJV-QG-M-S-0xx Page 3 of 3 Electronic File:-- 5.7 TCJV requested the updated org.charts from all subcons. 5.8 PMC Awareness Campaign will roll out next week. TCJV will distribute the materials. 5.9 TCJV requested SubCCs to arrange alignment sessions internally with their supervisors and safety personnel for the changes in the new Heat stress procedure (rev.04), before rolling out the new procedure. 5.10 Observed some people removing their PPE at site. Information will be passed to workforce during TI consecutive 3 days. Failure to comply is open for disciplinary action. 5.11 Anji (TCJV) is appointed as focal person for GF, until Jayan arrives. 5.12 Information regarding “Safely Finishing Strong” shared with the team. . 6. NEXT MEETING: 28th Jul 2013, 10.00 hrs, TCJV Main Conference Room # 108. Ěý SubCCs TCJV/SC SubCCs SubCCs Info Info 25.07.13 28.07.13 23.07.13 23.07.13 --- --- COMPANY considers the information contained herein as an accurate depiction of discussions during the meeting. It does not constitute instruction to change the WORK as defined in the CONTRACT. For Company For TCJV J.IERUBINO C.BAUDEL