Arduino-based-diag OBD-II_±č°ł“Ē²µ°ł²¹³¾²¹Ć§Ć£“Ē.pdf

- 1. Arduino-based OBD-II Interface and Data Logger CS 497 Independent Study Ryan Miller Advisor: Prof. Douglas Comer April 26, 2011

- 2. Arduino ā¢ Italy 2005 ā¢ ATmega328 microcontroller ā¢ 14 digital I/O pins ā¢ 16 MHz clock speed ā¢ 32 KB memory ā¢ About $30 online Arduino Hardware Automotive OBD ISO Interface Software Data Conclusions

- 3. Arduino ā¢ Program āsketchesā in Multi-platform Java- based IDE ā¢ Code in C/C++ ā¢ Serial Communication (currently USB)

- 4. Hardware ā¢ Goals of this project: ā¢ Communicate with an automotive engine control unit (ECU) via the Arduino ā¢ Gather and record instantaneous data that is reported by the vehicle Arduino Hardware Automotive OBD ISO Interface Software Data Conclusions ?

- 5. Hardware ā¢ Vehicles produced in the U.S. after 1996 are required to have an OBD-II (on-board diagnostic) connector

- 6. Hardware ā¢ OBD-II Interface ā¢ Very simple connection for most applications ā¢ Most important pins ā¢ K-Line ā¢ Ground ā¢ +12V

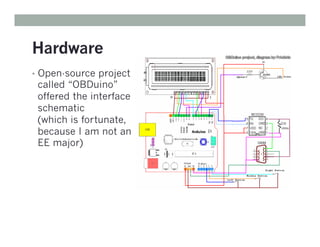

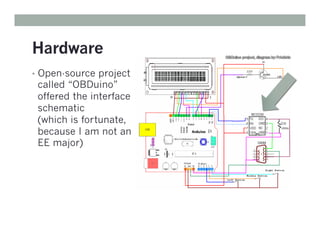

- 7. Hardware ā¢ Open-source project called āOBDuinoā offered the interface schematic (which is fortunate, because I am not an EE major)

- 8. Hardware ā¢ Open-source project called āOBDuinoā offered the interface schematic (which is fortunate, because I am not an EE major)

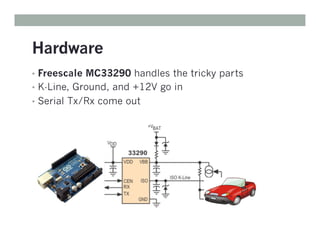

- 9. Hardware ā¢ Freescale MC33290 handles the tricky parts ā¢ K-Line, Ground, and +12V go in ā¢ Serial Tx/Rx come out

- 10. Hardware OBD-II

- 11. Software ā¢ A few functions to perform: ā¢ Initialize ISO connection ā¢ Request data from vehicleās ECU ā¢ Display the result on the LCD and record the value to retrieve later Arduino Hardware Automotive OBD ISO Interface Software Data Conclusions

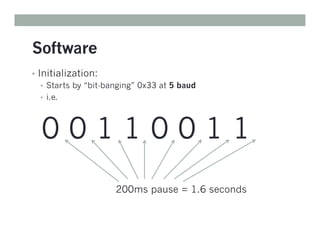

- 12. Software ā¢ Initialization: ā¢ Starts by ābit-bangingā 0x33 at 5 baud ā¢ i.e. 0 0 1 1 0 0 1 1 200ms pause = 1.6 seconds

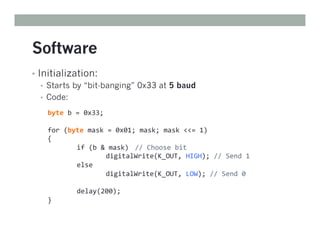

- 13. Software ā¢ Initialization: ā¢ Starts by ābit-bangingā 0x33 at 5 baud ā¢ Code: byte Ā b Ā = Ā 0x33; Ā Ā for Ā (byte Ā mask Ā = Ā 0x01; Ā mask; Ā mask Ā <<= Ā 1) Ā { Ā Ā if Ā (b Ā & Ā mask) Ā // Ā Choose Ā bit Ā Ā Ā digitalWrite(K_OUT, Ā HIGH); Ā // Ā Send Ā 1 Ā Ā else Ā Ā Ā digitalWrite(K_OUT, Ā LOW); Ā // Ā Send Ā 0 Ā Ā Ā Ā delay(200); Ā } Ā

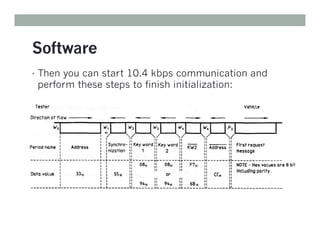

- 14. Software ā¢ Then you can start 10.4 kbps communication and perform these steps to finish initialization:

- 15. Software ā¢ Parameter IDs (PIDs) ā¢ SAE J1979 standard ā¢ Examples: PID Bytes Description Formula 0x0C 2 Engine RPM ((A*256)+B)/4 0x0D 1 Vehicle Speed (km/h) A 0x11 1 Throttle Position (%) A*100/255 0x3F 2 Catalyst Temp (B2, S2) ((A*256)+B)/10 - 40

- 16. Software ā¢ Steps: 1. Request PID with hex value 2. Continuously read data from ISO until successful checksum or timeout 3. Convert returned value with formula 4. Display / record value and repeat

- 17. Software 1. Request PID with hex value Index Value Description 0 0x68 SAE J1979 standard 1 0x6A OBD-II request 2 0xF1 Off-board tool 3 0x01 Mode 1 PIDs 4 pid Hex value for PID requested 5 Checksum Computed from message byte Ā message[6]; Ā for Ā (int Ā i Ā = Ā 0; Ā i Ā < Ā 6; Ā i++) Ā Ā iso_write_byte(message[i]); Ā

- 18. Software 2. Continuously read data from ISO until successful checksum or timeout Byte(s) Description 0 Message Header 1 1 Message Header 2 2 Source Address 3 ā 9 Data (up to 7 bytes) Final byte Checksum byte Ā buf[11]; Ā

- 19. Software 3. Convert returned value with formula ie.: PID Bytes Description Formula 0x0C 2 Engine RPM ((A*256)+B)/4 double Ā rpm; Ā Ā rpm Ā = Ā ((double)buf[0] Ā * Ā 256) Ā + Ā (double)buf[1]) Ā / Ā 4.0; Ā

- 20. Software 4. Record/display value and repeat ā¢ Displaying on an LCD screen: LiquidCrystal Ā lcd; Ā Ā lcd.print(rpm); Ā Ā

- 21. Software 4. Record/display value and repeat ā¢ Writing to an SD card: File Ā log; Ā Ā log.print(rpm); Ā Ā

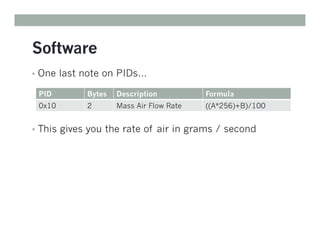

- 22. Software ā¢ One last note on PIDsā¦ ā¢ This gives you the rate of air in grams / second PID Bytes Description Formula 0x10 2 Mass Air Flow Rate ((A*256)+B)/100

- 23. Software ā¢ You can convert into ā¢ And then use vehicle speed to convert to or MPG g air s gal gasoline h miles gal gasoline

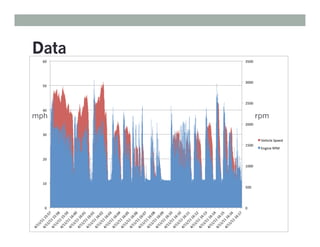

- 24. Data ā¢ Scanned four PIDs over a 20-minute interval every 1-2 seconds ā¢ Vehicle Speed ā¢ Engine RPM ā¢ Engine Coolant ā¢ Calculated MPG Arduino Hardware Automotive OBD ISO Interface Software Data Conclusions

- 25. Data mph

- 26. Data mph rpm

- 27. Data Ā°C

- 28. Data mph Ā°C

- 29. Conclusions ā¢ Embedded computing is ubiquitous ā¢ Massive amounts of data generated by everyday machines ā¢ Elec. Engineering and CS can come together to make some pretty cool things Arduino Hardware Automotive OBD ISO Interface Software Data Conclusions

- 30. Questions?

![Software

1. Request PID with hex value

Index Value Description

0 0x68 SAE J1979 standard

1 0x6A OBD-II request

2 0xF1 Off-board tool

3 0x01 Mode 1 PIDs

4 pid Hex value for PID requested

5 Checksum Computed from message

byte

Ā message[6];

Ā

for

Ā (int

Ā i

Ā =

Ā 0;

Ā i

Ā <

Ā 6;

Ā i++)

Ā

Ā iso_write_byte(message[i]);

Ā](https://image.slidesharecdn.com/arduino-basedobd-ii-240530130001-6bb5666f/85/Arduino-based-diag-OBD-II_programacao-pdf-17-320.jpg)

![Software

2. Continuously read data from ISO until successful

checksum or timeout

Byte(s) Description

0 Message Header 1

1 Message Header 2

2 Source Address

3 ā 9 Data (up to 7 bytes)

Final byte Checksum

byte

Ā buf[11];

Ā](https://image.slidesharecdn.com/arduino-basedobd-ii-240530130001-6bb5666f/85/Arduino-based-diag-OBD-II_programacao-pdf-18-320.jpg)

![Software

3. Convert returned value with formula

ie.:

PID Bytes Description Formula

0x0C 2 Engine RPM ((A*256)+B)/4

double

Ā rpm;

Ā

Ā

rpm

Ā =

Ā ((double)buf[0]

Ā *

Ā 256)

Ā +

Ā (double)buf[1])

Ā /

Ā 4.0;

Ā](https://image.slidesharecdn.com/arduino-basedobd-ii-240530130001-6bb5666f/85/Arduino-based-diag-OBD-II_programacao-pdf-19-320.jpg)