Ashutosh Gauniyal_B.Tech Mech_2.5 years PPC

Download as doc, pdf1 like280 views

Ashutosh Gauniyal has over 5.5 years of experience in operations and production engineering. He has a B.Tech in mechanical engineering and is a certified Six Sigma Black Belt. His most recent role was as a Senior Engineer at Warm Forgings Pvt. Ltd. where he was responsible for forecasting, planning production, inventory management, and maintaining ISO documents. Previously, he worked as a Production Engineer at Orient Fans, where he implemented manufacturing processes and ensured production targets were met.

1 of 3

Download to read offline

Ad

Recommended

Resume

Resumejaved ahmed

╠²

Jabed Ahmed is a mechanical engineer with over 7 years of experience in production planning and control. He is currently working as an Assistant Manager at Vidhyut Auto Industries, where he is responsible for production activities in the press shop and ensuring plan vs production targets are met. Previously, he has worked at Five Ess Precision Component and Airlink Engineers in roles with increasing responsibility. He is proficient in implementing quality management systems, lean manufacturing techniques, and equipment maintenance.RAMKUMAR Resume LEAR TVS

RAMKUMAR Resume LEAR TVSRam kumar

╠²

1. P. Ramkumar is seeking a growth-oriented career where he can contribute his knowledge and skills while enhancing his experience through continuous learning and teamwork.

2. He has a diploma in mechanical engineering and work experience at Lear Automotive India Pvt Ltd and TVS Sundaram Clayton Ltd in production and quality control roles.

3. His skills include proficiency in AutoCAD, MS Office, and knowledge of manufacturing technology and automobile engineering.Resume

ResumeNaveen Gunagi

╠²

Naveen Gunagi is a mechanical engineer with 2 years of experience seeking a challenging position. He has expertise in production, setting up lines, and operating press machines. His experience includes delegating work schedules, preparing documents, and leading teams. Currently he is a Line Leader at Exedy clutch India where he achieves targets, ensures tool and material availability, resolves issues, and improves productivity. Previously he was a trainee at BNR Exports where he supervised production tasks and implemented techniques to reduce costs and cycle times. He has a Bachelor's degree in Mechanical Engineering and has received training in processes at Exedy Thailand.S K Kalraiya -Freelance Trainer-7.7.15

S K Kalraiya -Freelance Trainer-7.7.15Sanjay Kumar Kalraiya

╠²

S K Kalraiya is a freelance trainer, consultant, and lean manufacturing practitioner based in Faridabad, India. He has over 33 years of experience working in production, maintenance, quality, product development, vendor development, and other departments for several automotive and engineering companies in India. His goal is to share his extensive industry experience by providing training to engineers, students, and managers on topics useful for their professional and personal growth. Some of his areas of expertise include lean six sigma, valuation of plant and machinery, and coordinating industrial clusters. He is eager to partner with training centers, institutions, and companies interested in upgrading their skills and developing competitiveness through lean concepts.bharat 2

bharat 2Bharat Bhushan

╠²

BharatBhushan is seeking assignments in Production, Process Enhancement, and Quality Assurance with reputed organizations. He has 1 year of experience in Quality Assurance with SUNVISORS INDIA PVT LTD in Gurgaon, where he was responsible for child parts layout preparation, testing materials, job setup, inputs in TRW, and preparing daily inspection reports. He holds a B.Tech in Mechanical Engineering and diplomas in Product Design and AutoCAD. BharatBhushan is located in Gurgaon and prefers roles in the Auto/Auto Ancillary industries.Ashwani Kumar new

Ashwani Kumar newASHWANI KUMAR

╠²

This curriculum vitae outlines Ashwani Kumar's professional experience and qualifications. He has 6 months of training in CNC machining and over 1 year of experience in production and manufacturing. His skills include machine operation, quality control, production target achievement, and software like AutoCAD. He holds an ITI qualification in production and manufacturing and is seeking a challenging position that allows continuous learning and growth.resume_new

resume_newanand kumar

╠²

This document contains a cover letter and resume from Anand Kumar Singh applying for the position of Design Engineer. In the cover letter, Anand highlights his mechanical skills and experience. His resume then outlines his educational and professional background, including a degree in Mechanical Engineering and over two years of experience in product design using CAD software like CATIA. He also lists several design projects he has worked on involving sheet metal parts, fuel tanks, air filter boxes, and more. His objective is to join a progressive organization where he can utilize his technical and functional knowledge.vinod

vinodvinod kumar

╠²

Vinod Kumar is seeking a challenging career in industry utilizing his skills and qualifications. He has a B.Tech in Mechanical Engineering and diplomas in Computer Applications and CAD drafting. He has over 5 years of work experience in roles such as workshop supervisor and production supervisor in Qatar, Oman, and India. He is proficient in AutoCAD, SolidWorks, and MS Office applications. His areas of interest include manufacturing technology and automobile engineering. He has participated in training programs, industrial visits, workshops, and extracurricular activities.cv. deepak kr. bharti

cv. deepak kr. bhartiDEEPAK KUMAR BHARTI

╠²

This resume is for Deepak Kr. Bharti, a mechanical engineer with 2 years of experience. He has a B.Tech from Manav Rachna International University with a 6.09 CGPA. His relevant work experience includes a 6-month industrial training at JBM AUTO LTD where he gained experience in tool room maintenance and planning. He seeks to contribute his skills in mechanical engineering, CAD, maintenance, and programming to an organization that offers opportunities for growth.Karthik international cv

Karthik international cvKarthik Kandasamy

╠²

This document contains the resume of Karthik A.K. It summarizes his personal details, educational qualifications, internship experiences, projects undertaken, machine handling experience, modeling software skills, languages known, leadership experience, hobbies and references. He has a BE in Mechanical Engineering and MBA in General Management. He has worked as a Production Engineer, Manufacturing Engineer and has experience in areas like PPC, new product development, tooling, fixture design and CNC programming.RES 1 (1)

RES 1 (1)padmaja pandith

╠²

This document contains the resume of Padmaja SP, who is seeking a challenging career opportunity as a design and planning engineer. She has over 2 years of experience in design engineering at GEARS AND GEAR DRIVES (I) PVT LTD and Hindustan Aeronautical Ltd. Her skills include design using AutoCAD, SolidWorks and UG NX8. She is proficient in design, modeling, assembly and drafting. She has experience designing lifting systems, screw jacks and aerospace components like the GSLV MkIII nose cap assembly jig. Padmaja holds a B.E. in Industrial Engineering and Management and is fluent in Kannada, Telugu and English.RHEINMETALL AUTMOTIVE: A Piston Manufacturing Company

RHEINMETALL AUTMOTIVE: A Piston Manufacturing CompanyAkhilesh Rathiya

╠²

This document contains information about KSPG Automotive India Private Limited, including:

1. KSPG Automotive India Private Limited manufactures auto components such as exhaust gas recirculating valves, pistons, and vacuum pumps for customers like BMW, General Motors, Volkswagen, Renault, and Mahindra.

2. The company was formerly known as Pierburg India Private Limited and is located in Pune, India, operating as a subsidiary of Pierburg GmbH.

3. KSPG Automotive India Private Limited benefits from technical support from a number of qualified engineers located in Pune, as well as a local supplier base that provides quality components globally.CV

CVImtehaj Tamboli

╠²

This curriculum vitae summarizes the qualifications and experience of Imtehaj Babulal Tamboli. It outlines his 7.8 years of experience in quality control, production, and vehicle dispatch roles at various automotive companies. His most recent role is as an Executive overseeing production and site operations at Emirates Logistics India Pvt. Ltd. He also has experience as a Supervisor at Junaid Industries and as a Junior Engineer in quality inspection and pre-delivery inspection at Ashok Leyland Ltd. in the UAE. Tamboli holds a diploma in mechanical engineering and technical qualifications in fitting.Resume - Abhishek Shah

Resume - Abhishek ShahAbhishek Shah

╠²

Abhishek Shah is a senior studying Mechanical Engineering at Kettering University in Flint, Michigan with a GPA of 3.6/4.0. He has extensive engineering experience through internships at companies in the US, Spain, and India in areas such as prototype development, metallurgical analysis, and testing. His career objective is to apply his knowledge and experience to create an engineering institute that serves as a model for societal progress and betterment. He is proficient in MS Office and CAD software, played varsity tennis and cricket, and received academic honors including being named to the Dean's list at Kettering University.Resume 22222

Resume 22222VAIBHAV PUNDIR

╠²

Vaibhav Kumar Pundir is a mechanical engineer with over 4 years of experience in production engineering roles. He currently works as a Production Executive for JBM Group, where he is responsible for daily production planning and maintenance of SAP systems. Previously he has worked for several automotive component manufacturers in roles involving production planning, press shop operations, quality control, and training of personnel. He has expertise in production, SAP, Kaizen, 5S methodology and has received training and certifications in AutoCAD, ISO and TS quality standards.aeropri_20.01.15

aeropri_20.01.15Deepak Kumar Rajput

╠²

Deepak Kumar is seeking a position as an Aerospace Engineer. He has a B.E. in Aeronautical Engineering from The Aeronautical Society of India. He currently works as a Graduate Trainee Engineer at Gas Turbine Research Establishment, where he performs tasks like 3D modeling, analysis, and sensitivity studies. He has skills in CAD software, structural analysis tools like Nastran and Patran, and the Microsoft Office suite.CURRICULUM VITAE- Elam

CURRICULUM VITAE- ElamElam paruthi

╠²

Elamparuthi M is a mechanical design engineer with over 4.5 years of experience. He currently works for JM Frictech India Pvt Ltd as an engineer in ER&D. Previously he worked as a design engineer and trainer. He has expertise in areas like oil immersed brakes, hydraulic brake and clutch actuations. Some of his projects include production improvement that led to 60% higher production and 50% cost savings. He holds a B.E in Production Engineering from St. Peter's Engineering College.vikas prajapati

vikas prajapativikas prajapati

╠²

Vikas Prajapati is seeking a position that allows him to utilize his skills in mechanical design and production coordination. He has over 3 years of experience as a Design and Production Engineer at VS International in Faridabad, where he performs tasks like mechanical drafting, maintaining stock levels, coordinating with vendors, and more. Vikas has a B.Tech in Mechanical Engineering and certifications in AutoCAD, SolidWorks, and Catia V5. He has also completed projects and internships focused on sheet metal components and engine assembly.Sai Vishwanath Goud

Sai Vishwanath GoudSai Goud

╠²

Sai Vishwanath Goud is seeking a new role to further his career growth and development. He has over 3 years of experience as a Quality & Shift Engineer at Mahindra & Mahindra Ltd, where he conducted product and process audits, ensured first time product launches, and generated quality reports. He has a B.Tech in Mechanical Engineering and is skilled in quality systems, data analysis, and automotive processes. His achievements include establishing quality plans, reducing defects and costs, and implementing lean practices.Mechanical design engineer cv

Mechanical design engineer cvJonny Deep

╠²

This document is a resume for Ankush Panchal. It includes his contact information, personal details like date of birth and marital status, languages known, career summary with over 5 years of experience in hydraulic engineering, educational qualifications including a diploma in mechanical engineering and pursuing a B.Tech, internship and plant experience, software skills, and experience working as a quality inspector, draughtsman, technical instructor, and junior design engineer for various companies. It expresses interest in drafting, designing, and the hydraulic field and declares all information provided is true and correct.satyajit

satyajitSatyajit Rout

╠²

Satyajit Rout is seeking a position that allows him to utilize his technical skills and drive organizational progress. He has a diploma in mechanical engineering with over 10 years of experience in quality control and inspection. His experience includes working for JTEKT Sona Automotive India Ltd where he ensured quality of components and facilitated problem solving. He is proficient in CAD software like AutoCAD, PRO-E, and CATIA as well as CNC programming. He also has machine operation experience and skills in using measurement instruments for inspection.Sandy's resume updated

Sandy's resume updatedSandeep Mamgain

╠²

Sandeep Mamgain is seeking a challenging position that utilizes his engineering and technical skills. He has over 5 years of experience in galvanizing process production at Bhushan Steels Ltd and 11 months of supervisory experience at Jagdamba Liquefied Steels Ltd. He has a B.Tech in Industrial Production Engineering from Dehradun Institute of Technology and is proficient in production planning, scheduling, and costing. He is self-motivated, hard-working, and has strengths in adaptability, teamwork, analytical thinking, and leadership.new AMANDEEP RESUME

new AMANDEEP RESUMEAmandeep singh bhatia

╠²

Amandeep Singh Bhatia is applying for the position of Mechanical Engineer. He has a B.E. in Mechanical Engineering from R.G.P.V Bhopal with over 4 years of experience in auto companies like Tata Motors, AAA Vehicleaders, and Maruti Suzuki. He is skilled in production planning, quality control, engine testing, and conceptualizing new product development processes. He is a hard worker with strong communication skills who is seeking a challenging role to utilize his mechanical engineering skills.vishvjeet qa cv

vishvjeet qa cvVISHVJEET YADAV

╠²

The applicant, Vishvjeet Yadav, is applying for a mechanical engineering position. He has a B.Tech in Mechanical Engineering from Rajasthan Technical University. He has over 2 years of work experience in quality control and assurance roles for automotive companies. He is proficient in quality processes like rejection analysis, corrective and preventive action planning, auditing, and documentation. He also has technical skills like tensile strength testing, heat treatment processes, and using measurement equipment. He is looking for a new challenge where he can apply his skills.AMAR VARSHNEY-12

AMAR VARSHNEY-12Amar Varshney

╠²

This document is a resume for Amar Varshney summarizing his professional experience and qualifications. He has a B.Tech in Mechanical Engineering and currently works as a Service Engineer for Star Seiki India installing robots on injection molding machines. Previously he has worked as a Maintenance Engineer and Graduate Trainee testing injection molding machines. His objective is to work in a challenging environment utilizing his strengths of a positive attitude, dedication, and team skills. He has experience maintaining various manufacturing equipment and troubleshooting issues.vishal maurya(1)(1)

vishal maurya(1)(1)Vishal Maurya

╠²

Vishal Lalmani Mourya is a Production Engineer and Internal Auditor seeking a position to contribute his skills and passion for continuous self-improvement. He has over 5 years of experience in production and maintenance roles at various steel manufacturing companies. Mourya holds a B.E. in Mechanical Engineering and has additional training in areas such as internal auditing, Total Productive Maintenance, and Overall Equipment Efficiency. He is proficient in SAP, PRO-E, and Microsoft Office applications.Atul_resume1

Atul_resume1atul khedekar

╠²

Atul N. Khedekar is seeking an opportunity as an automobile engineer. He has a B.E. in Automobile Engineering from the University of Mumbai. Currently, he works as a warranty assessor for Tata E-nxt assessing warranty claims for Jaguar Land Rover dealers globally. He has experience with Microsoft Office, CAD design software, and has participated in industrial visits to automotive plants.Pankaj sharma

Pankaj sharmaPANKAJ SHARMA

╠²

This document contains a summary of Pankaj Sharma's resume. It lists his contact information, software skills which include NX 10.0, Solid Works, Pro/E, Auto Cad, CNC Programming, and Master CAM. It details his professional qualifications including a post-graduation diploma from Fanshawe College in London, Ontario. It also outlines his industrial training and work experience at places like Daikin Air-Conditioning India Pvt. Ltd., Railway Coach Factory, and Honda Agency where he gained experience in areas such as troubleshooting, commissioning, project engineering, and service.Music video analysis 2

Music video analysis 2ramshaimran9

╠²

The music video is a narrative about a couple who are constantly pranking each other in creative ways, such as gluing a hand to a door or putting a cockroach in an engagement ring box. Though their pranks, the video shows their relationship is not affected negatively and represents a modern, fun relationship. It targets mass audiences, especially teenagers and young adults, who can relate to the couple's personalities. However, some may be offended by the portrayal of wastefulness and non-productive competition. The video features the couple in a lavish, modern home and expensive clothes to show their high social class. It uses various camera angles like close-ups to show reactions to pranks.More Related Content

What's hot (20)

cv. deepak kr. bharti

cv. deepak kr. bhartiDEEPAK KUMAR BHARTI

╠²

This resume is for Deepak Kr. Bharti, a mechanical engineer with 2 years of experience. He has a B.Tech from Manav Rachna International University with a 6.09 CGPA. His relevant work experience includes a 6-month industrial training at JBM AUTO LTD where he gained experience in tool room maintenance and planning. He seeks to contribute his skills in mechanical engineering, CAD, maintenance, and programming to an organization that offers opportunities for growth.Karthik international cv

Karthik international cvKarthik Kandasamy

╠²

This document contains the resume of Karthik A.K. It summarizes his personal details, educational qualifications, internship experiences, projects undertaken, machine handling experience, modeling software skills, languages known, leadership experience, hobbies and references. He has a BE in Mechanical Engineering and MBA in General Management. He has worked as a Production Engineer, Manufacturing Engineer and has experience in areas like PPC, new product development, tooling, fixture design and CNC programming.RES 1 (1)

RES 1 (1)padmaja pandith

╠²

This document contains the resume of Padmaja SP, who is seeking a challenging career opportunity as a design and planning engineer. She has over 2 years of experience in design engineering at GEARS AND GEAR DRIVES (I) PVT LTD and Hindustan Aeronautical Ltd. Her skills include design using AutoCAD, SolidWorks and UG NX8. She is proficient in design, modeling, assembly and drafting. She has experience designing lifting systems, screw jacks and aerospace components like the GSLV MkIII nose cap assembly jig. Padmaja holds a B.E. in Industrial Engineering and Management and is fluent in Kannada, Telugu and English.RHEINMETALL AUTMOTIVE: A Piston Manufacturing Company

RHEINMETALL AUTMOTIVE: A Piston Manufacturing CompanyAkhilesh Rathiya

╠²

This document contains information about KSPG Automotive India Private Limited, including:

1. KSPG Automotive India Private Limited manufactures auto components such as exhaust gas recirculating valves, pistons, and vacuum pumps for customers like BMW, General Motors, Volkswagen, Renault, and Mahindra.

2. The company was formerly known as Pierburg India Private Limited and is located in Pune, India, operating as a subsidiary of Pierburg GmbH.

3. KSPG Automotive India Private Limited benefits from technical support from a number of qualified engineers located in Pune, as well as a local supplier base that provides quality components globally.CV

CVImtehaj Tamboli

╠²

This curriculum vitae summarizes the qualifications and experience of Imtehaj Babulal Tamboli. It outlines his 7.8 years of experience in quality control, production, and vehicle dispatch roles at various automotive companies. His most recent role is as an Executive overseeing production and site operations at Emirates Logistics India Pvt. Ltd. He also has experience as a Supervisor at Junaid Industries and as a Junior Engineer in quality inspection and pre-delivery inspection at Ashok Leyland Ltd. in the UAE. Tamboli holds a diploma in mechanical engineering and technical qualifications in fitting.Resume - Abhishek Shah

Resume - Abhishek ShahAbhishek Shah

╠²

Abhishek Shah is a senior studying Mechanical Engineering at Kettering University in Flint, Michigan with a GPA of 3.6/4.0. He has extensive engineering experience through internships at companies in the US, Spain, and India in areas such as prototype development, metallurgical analysis, and testing. His career objective is to apply his knowledge and experience to create an engineering institute that serves as a model for societal progress and betterment. He is proficient in MS Office and CAD software, played varsity tennis and cricket, and received academic honors including being named to the Dean's list at Kettering University.Resume 22222

Resume 22222VAIBHAV PUNDIR

╠²

Vaibhav Kumar Pundir is a mechanical engineer with over 4 years of experience in production engineering roles. He currently works as a Production Executive for JBM Group, where he is responsible for daily production planning and maintenance of SAP systems. Previously he has worked for several automotive component manufacturers in roles involving production planning, press shop operations, quality control, and training of personnel. He has expertise in production, SAP, Kaizen, 5S methodology and has received training and certifications in AutoCAD, ISO and TS quality standards.aeropri_20.01.15

aeropri_20.01.15Deepak Kumar Rajput

╠²

Deepak Kumar is seeking a position as an Aerospace Engineer. He has a B.E. in Aeronautical Engineering from The Aeronautical Society of India. He currently works as a Graduate Trainee Engineer at Gas Turbine Research Establishment, where he performs tasks like 3D modeling, analysis, and sensitivity studies. He has skills in CAD software, structural analysis tools like Nastran and Patran, and the Microsoft Office suite.CURRICULUM VITAE- Elam

CURRICULUM VITAE- ElamElam paruthi

╠²

Elamparuthi M is a mechanical design engineer with over 4.5 years of experience. He currently works for JM Frictech India Pvt Ltd as an engineer in ER&D. Previously he worked as a design engineer and trainer. He has expertise in areas like oil immersed brakes, hydraulic brake and clutch actuations. Some of his projects include production improvement that led to 60% higher production and 50% cost savings. He holds a B.E in Production Engineering from St. Peter's Engineering College.vikas prajapati

vikas prajapativikas prajapati

╠²

Vikas Prajapati is seeking a position that allows him to utilize his skills in mechanical design and production coordination. He has over 3 years of experience as a Design and Production Engineer at VS International in Faridabad, where he performs tasks like mechanical drafting, maintaining stock levels, coordinating with vendors, and more. Vikas has a B.Tech in Mechanical Engineering and certifications in AutoCAD, SolidWorks, and Catia V5. He has also completed projects and internships focused on sheet metal components and engine assembly.Sai Vishwanath Goud

Sai Vishwanath GoudSai Goud

╠²

Sai Vishwanath Goud is seeking a new role to further his career growth and development. He has over 3 years of experience as a Quality & Shift Engineer at Mahindra & Mahindra Ltd, where he conducted product and process audits, ensured first time product launches, and generated quality reports. He has a B.Tech in Mechanical Engineering and is skilled in quality systems, data analysis, and automotive processes. His achievements include establishing quality plans, reducing defects and costs, and implementing lean practices.Mechanical design engineer cv

Mechanical design engineer cvJonny Deep

╠²

This document is a resume for Ankush Panchal. It includes his contact information, personal details like date of birth and marital status, languages known, career summary with over 5 years of experience in hydraulic engineering, educational qualifications including a diploma in mechanical engineering and pursuing a B.Tech, internship and plant experience, software skills, and experience working as a quality inspector, draughtsman, technical instructor, and junior design engineer for various companies. It expresses interest in drafting, designing, and the hydraulic field and declares all information provided is true and correct.satyajit

satyajitSatyajit Rout

╠²

Satyajit Rout is seeking a position that allows him to utilize his technical skills and drive organizational progress. He has a diploma in mechanical engineering with over 10 years of experience in quality control and inspection. His experience includes working for JTEKT Sona Automotive India Ltd where he ensured quality of components and facilitated problem solving. He is proficient in CAD software like AutoCAD, PRO-E, and CATIA as well as CNC programming. He also has machine operation experience and skills in using measurement instruments for inspection.Sandy's resume updated

Sandy's resume updatedSandeep Mamgain

╠²

Sandeep Mamgain is seeking a challenging position that utilizes his engineering and technical skills. He has over 5 years of experience in galvanizing process production at Bhushan Steels Ltd and 11 months of supervisory experience at Jagdamba Liquefied Steels Ltd. He has a B.Tech in Industrial Production Engineering from Dehradun Institute of Technology and is proficient in production planning, scheduling, and costing. He is self-motivated, hard-working, and has strengths in adaptability, teamwork, analytical thinking, and leadership.new AMANDEEP RESUME

new AMANDEEP RESUMEAmandeep singh bhatia

╠²

Amandeep Singh Bhatia is applying for the position of Mechanical Engineer. He has a B.E. in Mechanical Engineering from R.G.P.V Bhopal with over 4 years of experience in auto companies like Tata Motors, AAA Vehicleaders, and Maruti Suzuki. He is skilled in production planning, quality control, engine testing, and conceptualizing new product development processes. He is a hard worker with strong communication skills who is seeking a challenging role to utilize his mechanical engineering skills.vishvjeet qa cv

vishvjeet qa cvVISHVJEET YADAV

╠²

The applicant, Vishvjeet Yadav, is applying for a mechanical engineering position. He has a B.Tech in Mechanical Engineering from Rajasthan Technical University. He has over 2 years of work experience in quality control and assurance roles for automotive companies. He is proficient in quality processes like rejection analysis, corrective and preventive action planning, auditing, and documentation. He also has technical skills like tensile strength testing, heat treatment processes, and using measurement equipment. He is looking for a new challenge where he can apply his skills.AMAR VARSHNEY-12

AMAR VARSHNEY-12Amar Varshney

╠²

This document is a resume for Amar Varshney summarizing his professional experience and qualifications. He has a B.Tech in Mechanical Engineering and currently works as a Service Engineer for Star Seiki India installing robots on injection molding machines. Previously he has worked as a Maintenance Engineer and Graduate Trainee testing injection molding machines. His objective is to work in a challenging environment utilizing his strengths of a positive attitude, dedication, and team skills. He has experience maintaining various manufacturing equipment and troubleshooting issues.vishal maurya(1)(1)

vishal maurya(1)(1)Vishal Maurya

╠²

Vishal Lalmani Mourya is a Production Engineer and Internal Auditor seeking a position to contribute his skills and passion for continuous self-improvement. He has over 5 years of experience in production and maintenance roles at various steel manufacturing companies. Mourya holds a B.E. in Mechanical Engineering and has additional training in areas such as internal auditing, Total Productive Maintenance, and Overall Equipment Efficiency. He is proficient in SAP, PRO-E, and Microsoft Office applications.Atul_resume1

Atul_resume1atul khedekar

╠²

Atul N. Khedekar is seeking an opportunity as an automobile engineer. He has a B.E. in Automobile Engineering from the University of Mumbai. Currently, he works as a warranty assessor for Tata E-nxt assessing warranty claims for Jaguar Land Rover dealers globally. He has experience with Microsoft Office, CAD design software, and has participated in industrial visits to automotive plants.Pankaj sharma

Pankaj sharmaPANKAJ SHARMA

╠²

This document contains a summary of Pankaj Sharma's resume. It lists his contact information, software skills which include NX 10.0, Solid Works, Pro/E, Auto Cad, CNC Programming, and Master CAM. It details his professional qualifications including a post-graduation diploma from Fanshawe College in London, Ontario. It also outlines his industrial training and work experience at places like Daikin Air-Conditioning India Pvt. Ltd., Railway Coach Factory, and Honda Agency where he gained experience in areas such as troubleshooting, commissioning, project engineering, and service.Viewers also liked (16)

Music video analysis 2

Music video analysis 2ramshaimran9

╠²

The music video is a narrative about a couple who are constantly pranking each other in creative ways, such as gluing a hand to a door or putting a cockroach in an engagement ring box. Though their pranks, the video shows their relationship is not affected negatively and represents a modern, fun relationship. It targets mass audiences, especially teenagers and young adults, who can relate to the couple's personalities. However, some may be offended by the portrayal of wastefulness and non-productive competition. The video features the couple in a lavish, modern home and expensive clothes to show their high social class. It uses various camera angles like close-ups to show reactions to pranks.Actividad2.2 anabel lincangolincango

╠²

La tecnolog├Ła educativa como disciplina se origin├│ en la formaci├│n militar estadounidense en los 1940s y en las d├®cadas siguientes se enfoc├│ en los audiovisuales y enfoques conductistas. M├Īs tarde, adopt├│ un enfoque t├®cnico racional pero entr├│ en crisis en los 1980s con el surgimiento de las tecnolog├Łas digitales y las perspectivas postmodernas que influyen en la disciplina en el siglo 21.Mapas conceptualesCriztian Blandon

╠²

El documento habla sobre los mapas conceptuales creados por Joseph Novak. Los mapas conceptuales son diagramas que muestran conceptos y las proposiciones que los relacionan en una estructura jer├Īrquica para organizar el conocimiento de una persona o dominio. Los mapas conceptuales ayudan a ense├▒ar y aprender de manera efectiva al mostrar las relaciones entre conceptos de una manera visual estructurada.Trabajo final patricia irigoyenPatricia Irigoyen

╠²

Este proyecto busca promover el trabajo en equipo y el uso de las redes sociales como herramienta educativa entre los estudiantes. Los alumnos de 5to a├▒o actuar├Īn como monitores para los de 2do y 3er a├▒o, ayud├Īndolos a investigar y presentar contenidos acad├®micos usando aplicaciones como Tangredos, Mapas de conceptos, Youtube y Facebook. El proyecto evaluar├Ī el logro de objetivos, el trabajo individual y grupal, y el uso apropiado de la tecnolog├Ła y el vocabulario t├®cnico.ą¢ąæąŚ. ąŚą░ąĮčÅčéąĖąĄ 1.14 ąÉčĆčéąĖą║čāą╗ąĖčĆąŠą▓ą░ąĮąĖąĄ. ąĪąŠą│ą╗ą░čüąĮčŗąĄ ąĘą▓čāą║ąĖ. -ą£-

ą¢ąæąŚ. ąŚą░ąĮčÅčéąĖąĄ 1.14 ąÉčĆčéąĖą║čāą╗ąĖčĆąŠą▓ą░ąĮąĖąĄ. ąĪąŠą│ą╗ą░čüąĮčŗąĄ ąĘą▓čāą║ąĖ. -ą£-zaikaniepro

╠²

ąöąŠą║čāą╝ąĄąĮčé ą┐čĆąĄą┤čüčéą░ą▓ą╗čÅąĄčé ąĘą░ą┤ą░ąĮąĖčÅ ą┤ą╗čÅ ąĘą░ąĮčÅčéąĖčÅ ą┐ąŠ ą░čĆčéąĖą║čāą╗čÅčåąĖąĖ ąĘą▓čāą║ą░ ┬½ą╝┬╗ čü ąĖčüą┐ąŠą╗čīąĘąŠą▓ą░ąĮąĖąĄą╝ ąĘąĄčĆą║ą░ą╗ą░ ąĖ ą▓ąĖą┤ąĄąŠ. ąŻčćą░čüčéąĮąĖą║ą░ą╝ ą┐čĆąĄą┤ą╗ą░ą│ą░ąĄčéčüčÅ ąŠčüą▓ąŠąĖčéčī čāą┐čĆą░ąČąĮąĄąĮąĖčÅ ą┤ą╗čÅ ą▓čŗą┐ąŠą╗ąĮąĄąĮąĖčÅ ąĘą▓čāą║ą░ ąĖ ąĄą│ąŠ čüąŠč湥čéą░ąĮąĖą╣, ą░ čéą░ą║ąČąĄ ą┐čĆąŠčćąĖčéą░čéčī č鹥ą║čüčéčŗ čü ą░ą║čåąĄąĮč鹊ą╝ ąĮą░ ąĘą▓čāą║ ┬½ą╝┬╗. ąÆčüąĄ ąĘą░ą┤ą░ąĮąĖčÅ ą┤ąŠą╗ąČąĮčŗ ą▒čŗčéčī ąĘą░ą┐ąĖčüą░ąĮčŗ ąĮą░ ą▓ąĖą┤ąĄąŠ ąĖ ąĘą░ą│čĆčāąČąĄąĮčŗ ą▓ ą╗ąĖčćąĮčŗą╣ ą║ą░ą▒ąĖąĮąĄčé.Sete Motivosprofessorar

╠²

O documento discute sete motivos para que professores criem blogs: 1) blogs s├Żo divertidos; 2) aproximam professores e alunos; 3) permitem que professores reflitam sobre suas coloca├¦├Ąes a partir dos coment├Īrios recebidos.33 RazonesCarlos Perez

╠²

El documento proporciona 33 razones por las que el Goji deber├Ła ser tomado diariamente seg├║n el Dr. Earl Mindell. El Goji protege el cuerpo del envejecimiento prematuro debido a su poderosa acci├│n antioxidante. Tambi├®n incrementa la energ├Ła, ayuda a sentirse m├Īs joven estimulando la producci├│n de hormona del crecimiento, y mejora la salud ocular y la visi├│n. Finalmente, el Goji fortalece el sistema inmune y reduce el riesgo de c├Īncer y enfermedades card├Łacas.Monaco agenda espCarlos Perez

╠²

El documento presenta la agenda de una estad├Ła en el Hotel & Resort Monte Carlo Bay en M├│naco del 31 de marzo al 4 de abril de 2011. Incluye detalles sobre comidas, transporte y actividades como una excursi├│n tur├Łstica de Monte Carlo y una cena de gala. Todas las comidas y el transporte desde y hacia el aeropuerto/estaci├│n est├Īn incluidos en el paquete.Analisis bodas de sangremarionacastillogarcia

╠²

Este documento analiza varios s├Łmbolos clave en la obra Bodas de Sangre de Federico Garc├Ła Lorca. La luna simboliza tanto la fecundidad como la muerte y violencia. La tierra representa la fertilidad pero tambi├®n requiere sacrificios humanos. Los colores como el rojo, negro y verde tienen significados asociados a la pasi├│n, muerte y esterilidad. El azahar simboliza la pureza de la novia y el matrimonio. La sangre representa la vida pero tambi├®n la muerte y el instinto.Mapa conceptual de la Seguridad de la informaci├│nYessika Hern├Īndez

╠²

La seguridad de la informaci├│n se define como el conjunto de medidas preventivas y reactivas para proteger la informaci├│n de una organizaci├│n y sus sistemas tecnol├│gicos contra amenazas como hackers, crackers y lamers. Involucra el manejo de riesgos y el mantenimiento de la confidencialidad, disponibilidad e integridad de la informaci├│n a trav├®s de protocolos y soluciones de seguridad.Resume_surendra

Resume_surendrasurendra Kumar

╠²

This document describes an associate programmer with over 2 years of experience developing software using Java EE and middleware technologies like J2EE, XML, Java, JDBC, JSP, and Servlets. The programmer has skills in tools like Eclipse, My Eclipse, NetBeans, Apache Tomcat, Oracle, MySQL, and protocols like SFTP and FTP. Front-end skills include jQuery, JavaScript, AJAX, and HTML. The objective is to utilize skills and experience in software analysis, design, development and implementation through challenging employment opportunities.ą¢ąæąŚ. ąŚą░ąĮčÅčéąĖąĄ 1.14 ąÉčĆčéąĖą║čāą╗ąĖčĆąŠą▓ą░ąĮąĖąĄ. ąĪąŠą│ą╗ą░čüąĮčŗąĄ ąĘą▓čāą║ąĖ. -ą£-

ą¢ąæąŚ. ąŚą░ąĮčÅčéąĖąĄ 1.14 ąÉčĆčéąĖą║čāą╗ąĖčĆąŠą▓ą░ąĮąĖąĄ. ąĪąŠą│ą╗ą░čüąĮčŗąĄ ąĘą▓čāą║ąĖ. -ą£-zaikaniepro

╠²

Ad

Similar to Ashutosh Gauniyal_B.Tech Mech_2.5 years PPC (20)

C.V_Mayank_Jain_senior engineer

C.V_Mayank_Jain_senior engineerMayank Jain

╠²

This resume is for Mayank Jain, a senior mechanical engineer with over 3 years of experience working for Jindal Industries Private Limited in India. His experience includes project erection, commissioning, operation and maintenance of plant machinery. He holds a B.Tech in Mechanical Engineering and is currently pursuing an MBA. His objective is to work for a company where he can utilize his technical skills for mutual growth.Sudhir Prajapati_CV

Sudhir Prajapati_CVSudhir Prajapati

╠²

Sudhir Prajapati is seeking a challenging opportunity that utilizes his 3+ years of experience as a Design Engineer and his academic background in Mechanical Engineering. He currently works at Kruger Ventilation Industries and has also worked at Innovative Design Tech. He has experience with CAD software like CATIA V5 and AutoCAD and has completed technical training in product design. His responsibilities include 3D modeling, drawing preparation, simulation, and addressing customer queries.Ankur Resume (2)

Ankur Resume (2)ankur Ankur Ambadkar

╠²

Ankur Ambadkar is seeking a position that allows him to utilize his 3 years and 7 months of experience in production engineering. He has worked as a Production Engineer at Konecranes India Ltd. and HLM India Pvt. Ltd., where his responsibilities included production planning, quality control, and team management. He also has experience as a Junior Engineer at Sam Hi-tech Components Pvt. Ltd., where he was responsible for production planning, reducing rejection rates, and machine setup. Ambadkar has a Bachelor's degree in Mechanical Engineering, knowledge of design software like CREO and CATIA, and certifications in non-destructive testing techniques.PRAVIN RATHI RESUME (1)

PRAVIN RATHI RESUME (1)Pravin rathi

╠²

This document contains the resume of Pravin M. Rathi. It summarizes his educational qualifications including a degree in Mechanical Engineering from Jodhpur Institute of Engineering and Technology. It also outlines his over 4 years of work experience as a Production Executive at GPT Steel Industries Ltd and previously as a Shift Engineer at Uttam Galva Steels Ltd. It lists his key responsibilities in these roles and highlights his technical skills and qualifications.Prahalad Rao G Resume

Prahalad Rao G Resume Prahalad Gopal Rao

╠²

Prahalad Rao is a mechanical engineering graduate with a B.E. from Agni College of Technology, aiming to start his career as an engineer while leveraging his knowledge in quality control and refrigeration. He has completed various academic projects related to power generation and participated in workshops covering topics like renewable energy and PLC systems. Additionally, he has earned multiple accolades, including a gold medal for a design competition and has proficiency in several CAD software and languages.Mohan-PPC

Mohan-PPCMohan Natarajan

╠²

Mohan is seeking a challenging position to utilize his skills and contribute to growth. He has over 7 years of experience in production planning and control at various manufacturing companies. His responsibilities include production planning, quality control, logistics management, and ensuring delivery performance. He has a Bachelor's degree in Mechanical Engineering and skills in CAD, SAP, and Microsoft Office. He also participated in a national CAD competition project focused on process improvement.Gowtham-Final

Gowtham-FinalGowtham Prashanth

╠²

Gowtham Prashanth is seeking a job as a mechanical engineer with experience in design, manufacturing, and quality control. He has over 3 years of work experience in roles at TVS Srichakra Limited and other companies. He is proficient in AutoCAD, Solidworks, Pro-E and ANSYS software. Some of his responsibilities have included process planning, quality audits, and implementing 5S and Kaizen activities. He has participated in projects involving fixture design, glass breaking machine design, and end of line assembly systems. Gowtham holds a Bachelor's degree in Mechanical Engineering and has attended training in safety, quality, and management systems.Narender Mendiratta resume

Narender Mendiratta resumeNarender Mendiratta,PMP

╠²

Narender Mendiratta is a certified Project Management Professional with over 20 years of experience managing projects and leading teams of up to 30 people. He is seeking a challenging opportunity that utilizes his skills in project execution, management, and engineering. He has extensive experience delivering automation and control systems projects for industries such as automotive, tires, food processing, and more. His background includes planning, designing, executing, and commissioning projects with Rockwell Automation, Praia Controls, and Technofab Engineering.Narender Mendiratta resume

Narender Mendiratta resumeNarender Mendiratta,PMP

╠²

Narender Mendiratta is a Project Management Professional with over 19 years of experience managing projects in industries like automotive, tires, food processing, and more. He is seeking a challenging position that utilizes his skills in project execution, engineering, team leadership, and customer satisfaction. His experience includes managing projects worth over $2 million annually and leading teams of up to 30 people.JAI_1

JAI_1Jai Prakash

╠²

Jai Prakash is seeking a career opportunity to develop his professional and analytical skills. He has over 4 years of experience as a Design Engineer at BQB Infra Technorium Pvt. Ltd. in Gurgaon. His responsibilities include mechanical equipment design, 2D and 3D modeling, and providing engineering support. He has experience designing projects for several cement plant customers. Jai Prakash has a B.Tech in Mechanical Engineering and knows AutoCAD, Pro-E, Creo, and basic Ansys. He is proficient in English and Hindi and is looking for positions according to company norms.PRASAD RESUME_10 years.....

PRASAD RESUME_10 years.....prasad durga

╠²

This 3 page curriculum vitae summarizes S. Durga Prasad's qualifications and work experience. He has 10 years of experience in quality assurance and currently works as a Senior Quality Engineer at HBL Power Systems Limited, where he is responsible for inspection, quality reporting, implementing quality tools like FMEA and SPC, and ensuring compliance. Previously he worked as a Design Engineer and Quality Control engineer at Chiakilam Infotech and S.S. Industries, where he was involved in quality inspection, customer delivery, and supplier management. He has a Diploma in Automobile Engineering from 2003 and skills in documentation, quality systems, CAD software, and statistical process control.Centre For Hands-On Engineering Training by Verdure Infrastructure Solutions

Centre For Hands-On Engineering Training by Verdure Infrastructure SolutionsSurabhi5

╠²

The document outlines the establishment of a hands-on engineering training center aimed at bridging the gap between fresh engineering graduates and industry requirements. It highlights the importance of practical training, communication skills, and technical knowledge in increasing employability, given that a significant percentage of graduates are deemed unemployable. The center offers a comprehensive training program across various engineering specializations with a strong track record of successful placements for its trainees.Abhishek Kumar

Abhishek KumarAbhishek Kumar

╠²

Abhishek Kumar is seeking managerial assignments in production operations with over 8 years of experience. He has experience managing all aspects of production including planning, quality control, inventory management, and team leadership. He is proficient in process improvement tools like 5S, Kaizen, and lean manufacturing. Currently he works as an Assistant Manager at Escorts Ltd overseeing assembly, welding, and paint shop operations.Balaji updated resume

Balaji updated resumebala s

╠²

This document contains the resume of Balaji S. It summarizes his educational qualifications including a B.Tech in Mechanical Engineering, work experience as a Quality Supervisor at TAFE Engineering Plastics and as a Services & Sales Engineer at Wintech Hydraulics and Cool Care India Pvt Ltd, technical skills in AutoCAD and motorcycle maintenance, extracurricular activities including NCC certification and blood donation, and personal details. Balaji is looking for opportunities to develop his administrative skills and grow in his career.REHAN CV

REHAN CVREHAN BIJALI

╠²

Rehan Bijali is seeking a challenging career in the automotive industry. He has 1 year of experience at Piaggio Vehicles Pvt Ltd in chassis production and welding. At Piaggio, his roles included supervising production lines, ensuring quality control, training operators, and developing new vehicle models. He holds a Bachelor's degree in Mechanical Engineering and has completed internships in steam engineering and automotive transmission. His technical skills include CAD software and programming languages.Vivek upadhyay

Vivek upadhyayVivekUpadhyay74

╠²

Vivek Upadhyay is seeking a challenging position as a design engineer. He has 2 years of experience as an Assistant Design Engineer at Hytech Engineers Pvt. Ltd., where he performed tasks like studying customer drawings, preparing designs and drawings using AutoCAD and Creo, developing new suppliers, and ensuring implementation of quality processes. He has a Bachelor's degree in Mechanical Engineering from CDGI, Indore with 8.08 CGPA. His skills include technical drawing, project management, communication, and experience with design software. He implemented a Kaizen activity that reduced scrap collection time from CNC machines.Ppt on banco

Ppt on bancoChandni Mistry

╠²

The document discusses the objectives of a study conducted by Chandni R Mistry at Banco Products (India) Limited. The objectives are to examine the effectiveness of training, its impact on workers, changes in behavioral patterns due to training, and the cost-effectiveness of training programs. It then provides details about Banco Products such as its establishment, locations, management, products including gaskets and radiators, achievements, and an overview of its training and development programs and objectives.C.V of Prasanta

C.V of PrasantaPrasanta Gochhayat

╠²

Prasanta Kumar Gochhayat has over 10 years of experience in project management and planning roles. He currently works as a Projects Engineer for Albawardi Steel Industries in Saudi Arabia, where he is responsible for initialing projects, planning, executing, monitoring, and closing projects. Previously he has held roles as a Senior Planning Engineer and Planning Engineer for other companies in Saudi Arabia and Dubai. He has a Diploma in Mechanical Engineering and is proficient in various project management and ERP software.Ad

Ashutosh Gauniyal_B.Tech Mech_2.5 years PPC

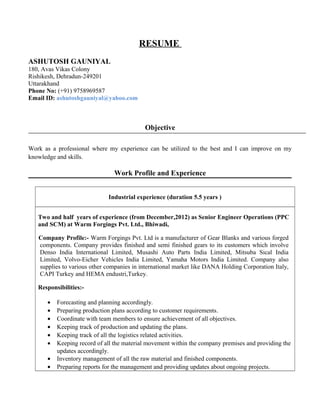

- 1. RESUME ASHUTOSH GAUNIYAL 180, Avas Vikas Colony Rishikesh, Dehradun-249201 Uttarakhand Phone No: (+91) 9758969587 Email ID: ashutoshgauniyal@yahoo.com Objective Work as a professional where my experience can be utilized to the best and I can improve on my knowledge and skills. Work Profile and Experience Industrial experience (duration 5.5 years ) Two and half years of experience (from December,2012) as Senior Engineer Operations (PPC and SCM) at Warm Forgings Pvt. Ltd., Bhiwadi, Company Profile:- Warm Forgings Pvt. Ltd is a manufacturer of Gear Blanks and various forged components. Company provides finished and semi finished gears to its customers which involve Denso India International Limited, Musashi Auto Parts India Limited, Mitsuba Sical India Limited, Volvo-Eicher Vehicles India Limited, Yamaha Motors India Limited. Company also supplies to various other companies in international market like DANA Holding Corporation Italy, CAPI Turkey and HEMA endustri,Turkey. Responsibilities:- ŌĆó Forecasting and planning accordingly. ŌĆó Preparing production plans according to customer requirements. ŌĆó Coordinate with team members to ensure achievement of all objectives. ŌĆó Keeping track of production and updating the plans. ŌĆó Keeping track of all the logistics related activities. ŌĆó Keeping record of all the material movement within the company premises and providing the updates accordingly. ŌĆó Inventory management of all the raw material and finished components. ŌĆó Preparing reports for the management and providing updates about ongoing projects.

- 2. ŌĆó Maintaining all ISO related documents. Three years of experience as a Production Engineer at Orient Fans, Lighting Division (now Orient Electric) Faridabad from June, 2009 to May 2012 (a unit of Orient Paper and Industries Ltd ). Responsibilities:- ŌĆó Implementation and control of Manufacturing Process. ŌĆó Controlling and maintaining production according to Production Plan and Schedule. ŌĆó Conducting In Process Time study. ŌĆó Involved as an internal auditor with the organization for ISO Certification. ŌĆó Involved in Quality Auditing at the supplier end. Projects:- ŌĆó Installation and commissioning of CFL capsule manufacturing line imported from Xin Xiang Lighting Machinery Limited, China. ŌĆó Defect reduction in CFL coating Process by SPC (Oct 2011 - Mar 2012) Organization: Orient Fans, Faridabad. Designation hold: Production Engineer Role: Data collection and analysis Skills Set: MINITAB, Six, SPC, Gage R&R, FMEA Academic Record Technical Skills Qualification University/Board Year of Passing Percentage B. Tech Uttar Pradesh Technical University 2009 63 Intermediate ISC Board, Delhi 2005 68 High School ICSE Board, Delhi 2003 78

- 3. ŌĆó Certified Six Sigma Black Belt from IACT Global ( A member of ASQ ) ŌĆó Well versed in MS Office and MINITAB. Extra Credentials Research paper on the topic ŌĆ£Time study model of a compact fluorescent lamp manufacturer in INDIA: a case studyŌĆØ published in ŌĆ£International journal of mechanical engineering and robotics research (IJMERR)ŌĆØ . Summer Training & Projects Industrial Training 4 Weeks summer training at BHEL, Haridwar. Completed training in Electrical machine Manufacturing department under the title Study of Process Flow System. B.Tech final year Project: Compressor Less Portable Heating & Cooling system. In this project, I had developed a prototype of the system that works on ŌĆśPeltier & Seebeck effectŌĆÖ to produce heating and cooling inside a closed environment. Personal Details FatherŌĆÖs name: Sh. K.C. Gauniyal Date of Birth: May 19, 1988 Gender: Male Nationality: Indian Languages: Hindi & English Hobbies: Cooking, Internet Browsing Current CTC 4.50 Lacs per annum Expected CTC 5.50 Lacs per annum Declaration I hereby declare that the information furnished here is true and complete to the best of my knowledge. (Ashutosh Gauniyal)