Aurora ELP Processing System Improvement Project

Download as ppt, pdf0 likes100 views

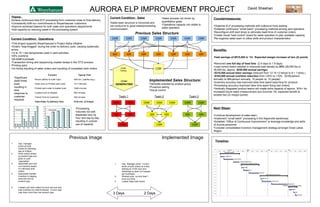

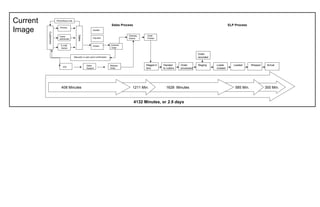

The document summarizes an initiative by Weyerhaeuser to improve the efficiency of its order-to-delivery process for engineered lumber products (ELP). Currently, the process takes an average of 2.9 days with uneven workload balance and capacity utilization. The initiative aims to achieve continuous flow processing from order to delivery through small batch processing, load control boards for sales planning, and reorganizing sales and operations teams around product groups. Initial results include removing one day from the lead time, improving load density by 25%, and reducing labor costs, overtime, and inventory issues. Next steps include expanding small batch processing and establishing an office for continuous process improvement.

1 of 2

Download to read offline

Ad

Recommended

Planning optimisation

Planning optimisationLineView Academy (was OFX Academy)

Ìę

This document provides information on production planning optimization. It explains the difference between push and pull systems and defines runners, repeaters, and strangers. It discusses determining stock levels and minimum batch sizes based on demand profiles. The goal is to match production to demand efficiently while keeping costs low by minimizing stock levels and changeover times. Both push and pull approaches are used to balance reducing warehousing costs and satisfying varying demand.Kanban Systems

Kanban SystemsAnupam Sharma

Ìę

Kanban is a system for achieving just-in-time production through continuous parts supply. It uses visual signals like cards or boards to enable workers to obtain what they need, where and when they need it. Kanban systems can be implemented manually, through software, or as a hybrid. They aim to visualize and limit workflow to lower inventory costs and improve customer service through reduced waste and variability. Kanban involves starting with the current process and making small modifications like pulling work only when there is capacity.kanban an integrated jit system

kanban an integrated jit systemSridhar Siddu

Ìę

This document provides an overview of the Just-in-Time (JIT) and Kanban systems utilized in Japanese manufacturing. It discusses the history and philosophy of JIT, how it functions utilizing a pull system, and its objectives to minimize waste and lead times. Kanban is introduced as a visual card system used to implement the pull production approach in JIT. The document outlines the different types of Kanban cards, how the Kanban system circulates between processes, and its advantages in identifying bottlenecks. Several case studies are referenced that demonstrate companies' successes in adopting aspects of Kanban to improve workflow and meet deadlines.ROI for Warehouse Management System: The Business Case for a WMS

ROI for Warehouse Management System: The Business Case for a WMSNet at Work

Ìę

The webinar focuses on enhancing warehouse management systems (WMS) with insights on efficiency, effectiveness, and productivity improvements. Key performance indicators (KPIs) are discussed, highlighting the importance of accurate inventory, order accuracy, and labor productivity in achieving a competitive advantage. Various strategies, such as slotting and pre-routing, are presented to optimize warehouse operations and improve customer service.Value stream mapping

Value stream mappingLineView Academy (was OFX Academy)

Ìę

The document describes the steps to construct a value stream map (VSM). It involves defining the current state map by gathering information on physical and information flows, cycle times, bottlenecks and defects. The future state map is then created by mapping an improved process and an implementation plan is made to achieve this. Key steps include identifying the product family, start/end points, gathering data on times, flows, inspections and linking this to create a current state map with production lead times. Future state suggestions aim to reduce changeovers and level production.ABC Analysis and Kanban . . . New Levels of Efficiency

ABC Analysis and Kanban . . . New Levels of EfficiencyThomas Cantin

Ìę

This document discusses ABC analysis and Kanban systems. It provides an overview of what a Kanban system is and why companies use them. The goals of implementing a Kanban system at one company are described as reducing overall inventory levels from over 3,500 SKUs and $1.75M to 2,000 SKUs and $600k. The document outlines steps for starting with internal Kanbans, setting signals and triggers, using historical data to analyze effectiveness, and optimizing quantities and intervals. Potential issues that could arise are also addressed.Sage Inventory Advisor for Sage 100

Sage Inventory Advisor for Sage 100Net at Work

Ìę

This webinar introduces Sage Inventory Advisor, a cloud-based inventory management solution. Sage Inventory Advisor integrates with Sage ERP systems to help optimize inventory levels, decrease working capital, improve customer service, and save time. It works by automatically extracting inventory data from the ERP system and using sophisticated forecasts to recommend order quantities and identify items needing attention. Onboarding typically takes 2-4 weeks and involves establishing the structure, integrating the systems, refining the configuration, training users, and going live. Pricing is based on a monthly fee plus a usage fee determined by inventory value.060 LEAN SUPPLY CHAIN VALUE STREAM MAPPING

060 LEAN SUPPLY CHAIN VALUE STREAM MAPPING Dr Fereidoun Dejahang

Ìę

The document discusses the Lean supply chain philosophy which aims to eliminate waste from processes. It notes that non-manufacturing tasks in the supply chain represent 50-80% of lead time but 95% of that time adds no value. Implementing Lean techniques like value stream mapping can help identify and remove waste like excess inventory, motion, transportation and rework. This will reduce costs and lead times to better meet customer needs.Advanced Warehouse Management

Advanced Warehouse Management Korcomptenz Inc

Ìę

This document summarizes a webinar about optimizing warehouse processes with Microsoft Dynamics 365 Advanced Warehouse Management. It includes an agenda that covers challenges in distribution and warehouse management, key features of Advanced Warehouse Management, and demonstrations. The key challenges discussed are high attrition, labor shortages, missed shipments, and inefficient processes. Important features highlighted are mobile device support, flexible workflows, integration capabilities, and inventory management functions. A demonstration shows examples of inbound receiving, warehouse picking, packing, and outbound shipping processes. The document concludes by stating how Korcomptenz can help with strategic assessments and proof of concepts to plan an implementation of Advanced Warehouse Management.Shivaji S_Bikale

Shivaji S_BikaleShivaji Bikale

Ìę

This document provides a summary of Shivaji S. Bikale's career profile. It summarizes his work experience of over 8 years in supply chain management, warehousing, inventory management, and logistics. It details his current role as Executive - Logistics - Supply Chain at Samsonite South Asia Pvt. Ltd., where he is responsible for warehouse operations and inventory management. It also lists his past experience with Future Supply Chains Solutions Ltd. and Kaveri Warehousing Management Service Pvt. Ltd. The document outlines his educational qualifications and technical skills in areas such as SAP, MS Office, and inventory management software.Kanban

KanbanKnoldus Inc.

Ìę

The document outlines the principles of the Kanban system and its application in software development. It discusses how to set up a Kanban board, limit work in progress, visualize workflows, and measure lead times to enhance efficiency and continuous improvement. The process aims to streamline development by replacing time-boxed iterations with a focus on continuous flow and managing bottlenecks.Kanban

KanbanAkash Patel

Ìę

Kanban is a lean production system that uses visual signals to manage and improve the flow of materials and production. It works by visually mapping out the workflow and limiting work-in-progress using cards that signal when to start and stop production. The core benefits of Kanban include reducing inventory levels by 25-75% by only producing to demand, improving workflow visibility and responsiveness, and preventing overproduction.Line balancing

Line balancingAnkur Shukla

Ìę

Line balancing is a critical optimization problem in assembly lines and work cells aimed at enhancing throughput while reducing costs and manpower. It involves assigning operations to workstations to ensure a smooth production flow, addressing bottlenecks, and maximizing resource utilization. The document discusses the importance of line balancing in the apparel industry, outlining strategies for efficient production, the impact on costs and quality, and challenges associated with balancing production lines.Tqm final case

Tqm final caseMicroGroup Lending Corporation

Ìę

The company is losing money during peak season due to inefficiencies in their manufacturing and distribution processes. They plan to use DMAIC and activity cost drivers to analyze costs. They will rearrange their warehouse using slotting and tap partnerships to increase production capacity. Key implementation strategies include utilizing cold storage facilities, rearranging truck flow, and focusing on core competencies. Process control involves senior management support, including projects in performance reviews, and taking the right measurements.Supply chain imporvement

Supply chain imporvementRohit Gothwal

Ìę

The document discusses customer service level improvements in Vardhman Special Steels' supply chain, emphasizing the importance of delivery performance indicators such as Order Fulfilment Rate (FFCOFR) and On Time In Full (OTIF). OTIF is crucial for measuring efficiency and accuracy in deliveries, requiring correct order entries and timely execution across the company's operations. It identifies root causes of delivery failures, such as internal miscommunication and inventory management issues, and suggests solutions including improved planning and communication among departments.Jit

JitShafiq Khan

Ìę

The document discusses Just-in-Time (JIT) production systems. JIT emphasizes removing waste and inefficiency through small lot sizes, high quality, and teamwork. Key elements of JIT include a steady production rate, low inventories, small lot sizes, quick setups, and a pull system. Kanban is a tool used in JIT to authorize releases in a pull system. Benefits of JIT include reduced inventories, improved quality, flexibility, and productivity. The document outlines steps to convert to JIT and potential obstacles.The Art of Replenishment

The Art of ReplenishmentSimon Roy

Ìę

The document discusses replenishment strategies for retail supply chains. There are three main types: put-away/stocked where goods are stored in a warehouse before being sent to stores; docked/flow-through where goods bypass the warehouse and are directly allocated to stores; and direct-to-store where suppliers deliver goods directly to stores. The optimal strategy depends on factors like supplier lead times, product rotation rates, available storage space, and logistics costs. Selecting and setting up the right replenishment approach is important to maximize profits, meet customer demand, and ensure efficient operations.VSM - Value Stream Mapping for made-to-order manufacturing

VSM - Value Stream Mapping for made-to-order manufacturingJessica Mitchell

Ìę

Value stream mapping (VSM) is a lean manufacturing technique used to analyze and design the flow of materials and information required to bring a product to a customer. It involves mapping both the current state and future state of the value stream. The current state map documents all steps, information flows, and delays in the production process. The future state map proposes improvements to reduce waste and enable continuous flow and pull between steps. Key aspects of VSM include identifying product families, analyzing takt time, developing continuous flow where possible, identifying the pacemaker process, and using load leveling to smooth production.Kanban - Classes of Service

Kanban - Classes of ServiceAvarteq

Ìę

The document discusses classes of service in Kanban, which divide tasks into different aspects with simplified prioritization and parallel flows. It provides examples of established classes of service like bug, standard, chore, and fixed delivery date. One company uses "virtual" swim lanes to represent standard development, support/evaluation, and extremely important tasks. Bugs and extremely important tasks take precedence and aim for a one day cycle time. Evaluations produce standard feature tasks while chores are non-urgent support and improvement tasks. It concludes that tools are needed to measure cycle times per class of service.Value Stream Mapping

Value Stream MappingMichael (Mike) Nunn

Ìę

The document outlines the process and tools for creating a Value Stream Map (VSM) to identify value and waste within business processes. It emphasizes the importance of stakeholder involvement, defining the scope, and understanding inputs and outputs for each step. Additionally, it provides guidelines for future improvements by eliminating non-value-added steps and addressing bottlenecks.ABHI perfect

ABHI perfect ABHISHEK BHATNAGAR

Ìę

This document is a curriculum vitae for Abhishek Bhatnagar. It summarizes his career objective, organizational experience, qualifications, and personal details. He has over 8 years of experience in warehouse and inventory management roles. Currently, he works as an Assistant Manager at Infibeam.com, where he oversees day-to-day warehouse operations and ensures accurate inventory levels. Previously, he worked for 5 years as a Senior Receiving Bay In-Charge at Shoppers Stop, where he managed inventory receiving and distribution. He holds an MBA in Marketing and Bachelor of Commerce degree.Joseph Scola_Resume

Joseph Scola_ResumeJoe Scola

Ìę

This document provides a summary of qualifications and work experience for Joseph P. Scola. It outlines over 29 years of management experience in retail, warehousing, and distribution. It also lists skills in Excel, Word, PowerPoint, and inventory management systems. The professional experience section details roles as an operations manager and supervisor at several companies from 2011 to the present, with responsibilities including team leadership, inventory management, and meeting production and shipping goals. Key achievements highlighted inventory accuracy rates over 99% and cost reductions through process improvements.Part one of project brown field for operational excellencies in scm integert...

Part one of project brown field for operational excellencies in scm integert...LT COLONEL VIKRAM BAKSHI ( RETD)

Ìę

The document discusses the turnaround of the Chakan facility by implementing operational excellence strategies. It describes problems at the facility like lack of organization, high costs, weak processes, and inventory issues. A turnaround plan was made to implement 5S, reduce process variation, improve on-time shipment, increase inventory turnover, reduce crane and demurrage costs, and address HR/safety issues. The plan aimed to transform the facility from a poorly functional state in 2012 to an industry standard facility by 2014 through streamlining processes, upgrading facilities, and establishing an integrated supply chain.Demand Flow Technology: learnsigma.com

Demand Flow Technology: learnsigma.comrobthompson

Ìę

This document provides an overview and introduction to Demand Flow Technology (DFT) workshop principles. It defines some key terms and concepts in DFT including:

1) DFT aims to eliminate waste and have products flow through production based on customer demand in pursuit of perfection.

2) The primary objective of DFT is to build high quality products in the shortest production time at the lowest possible cost.

3) Key advantages include minimizing non-value-added work, maintaining a continuous improvement process, and maximizing speed to market and customer responsiveness.Value stream mapping - A Simple Primer

Value stream mapping - A Simple PrimerVenkat Srinivasan

Ìę

A Value Stream Map (VSM) is a hand-drawn map that shows the flow of materials and information through a process from start to finish. It identifies the key elements of a process including customer demand, manufacturing process flow, material flow, information flow, and lead time. Drawing a VSM helps people understand the current process and identify opportunities to eliminate waste and improve flow.Value Stream Mapping (VSM)

Value Stream Mapping (VSM)Indo German Training Centre mumbai

Ìę

The document outlines the concept of value in customer service, emphasizing the importance of delivering high-quality capabilities at the right time and price. It discusses value stream mapping (VSM) as a tool to optimize processes by eliminating waste and improving productivity across design, build, and sustain phases. The text highlights the significance of continuous improvement in lean production, with examples illustrating how enhancing processes leads to a substantial increase in efficiency.Kanban Explained in 11 șĘșĘߣs

Kanban Explained in 11 șĘșĘߣsBrent Brewington

Ìę

The document provides an overview of the Kanban system, a Japanese scheduling method that enhances production efficiency by visually managing workflow and inventory. It describes various Kanban methods, including physical boards and electronic task lists, as well as best practices for implementing Kanban systems. Additionally, it highlights the benefits of Kanban in addressing common workplace problems such as bottlenecks and communication breakdowns, emphasizing its role as a tool within a broader improvement program.Lean logistics and warehousing final

Lean logistics and warehousing finalCody White

Ìę

The document outlines lean logistics and warehousing principles aimed at reducing waste and improving efficiency in fulfillment operations. It emphasizes tools and methodologies such as value stream mapping, kanban, and standardization to achieve customer demand responsiveness while minimizing costs and lead times. Key concepts include the identification and elimination of the eight types of waste, the importance of collaboration among partners, and continuous improvement through practices like PDCA and kaizen workshops.Capacity Planning of Mc Donald

Capacity Planning of Mc DonaldYamini Kahaliya

Ìę

The document discusses the capacity planning strategies of McDonald's, emphasizing the importance of aligning production capabilities with customer demand. It outlines factors affecting capacity, economies of scale, and different strategies such as lead, lag, and match strategy, with McDonaldâs primarily utilizing the lead strategy. Additionally, it provides specific details about McDonald's operations in India, including the capacity requirements for staffing and machinery needed to meet customer needs.Capacity requirement planning sure 12mt07ind019

Capacity requirement planning sure 12mt07ind019samjune

Ìę

Capacity requirements planning (CRP) is a technique that uses inputs like planned order releases, routing files, and open orders to project resource requirements and output load profiles for work centers. CRP helps identify bottleneck work centers and ensures sufficient capacity is available to meet manufacturing resource planning demands. The document discusses key CRP concepts like capacity, utilization, efficiency, load, and load percentage to determine if projected work can be completed on schedule. CRP aims to maximize capacity usage while avoiding overloading resources.More Related Content

What's hot (20)

Advanced Warehouse Management

Advanced Warehouse Management Korcomptenz Inc

Ìę

This document summarizes a webinar about optimizing warehouse processes with Microsoft Dynamics 365 Advanced Warehouse Management. It includes an agenda that covers challenges in distribution and warehouse management, key features of Advanced Warehouse Management, and demonstrations. The key challenges discussed are high attrition, labor shortages, missed shipments, and inefficient processes. Important features highlighted are mobile device support, flexible workflows, integration capabilities, and inventory management functions. A demonstration shows examples of inbound receiving, warehouse picking, packing, and outbound shipping processes. The document concludes by stating how Korcomptenz can help with strategic assessments and proof of concepts to plan an implementation of Advanced Warehouse Management.Shivaji S_Bikale

Shivaji S_BikaleShivaji Bikale

Ìę

This document provides a summary of Shivaji S. Bikale's career profile. It summarizes his work experience of over 8 years in supply chain management, warehousing, inventory management, and logistics. It details his current role as Executive - Logistics - Supply Chain at Samsonite South Asia Pvt. Ltd., where he is responsible for warehouse operations and inventory management. It also lists his past experience with Future Supply Chains Solutions Ltd. and Kaveri Warehousing Management Service Pvt. Ltd. The document outlines his educational qualifications and technical skills in areas such as SAP, MS Office, and inventory management software.Kanban

KanbanKnoldus Inc.

Ìę

The document outlines the principles of the Kanban system and its application in software development. It discusses how to set up a Kanban board, limit work in progress, visualize workflows, and measure lead times to enhance efficiency and continuous improvement. The process aims to streamline development by replacing time-boxed iterations with a focus on continuous flow and managing bottlenecks.Kanban

KanbanAkash Patel

Ìę

Kanban is a lean production system that uses visual signals to manage and improve the flow of materials and production. It works by visually mapping out the workflow and limiting work-in-progress using cards that signal when to start and stop production. The core benefits of Kanban include reducing inventory levels by 25-75% by only producing to demand, improving workflow visibility and responsiveness, and preventing overproduction.Line balancing

Line balancingAnkur Shukla

Ìę

Line balancing is a critical optimization problem in assembly lines and work cells aimed at enhancing throughput while reducing costs and manpower. It involves assigning operations to workstations to ensure a smooth production flow, addressing bottlenecks, and maximizing resource utilization. The document discusses the importance of line balancing in the apparel industry, outlining strategies for efficient production, the impact on costs and quality, and challenges associated with balancing production lines.Tqm final case

Tqm final caseMicroGroup Lending Corporation

Ìę

The company is losing money during peak season due to inefficiencies in their manufacturing and distribution processes. They plan to use DMAIC and activity cost drivers to analyze costs. They will rearrange their warehouse using slotting and tap partnerships to increase production capacity. Key implementation strategies include utilizing cold storage facilities, rearranging truck flow, and focusing on core competencies. Process control involves senior management support, including projects in performance reviews, and taking the right measurements.Supply chain imporvement

Supply chain imporvementRohit Gothwal

Ìę

The document discusses customer service level improvements in Vardhman Special Steels' supply chain, emphasizing the importance of delivery performance indicators such as Order Fulfilment Rate (FFCOFR) and On Time In Full (OTIF). OTIF is crucial for measuring efficiency and accuracy in deliveries, requiring correct order entries and timely execution across the company's operations. It identifies root causes of delivery failures, such as internal miscommunication and inventory management issues, and suggests solutions including improved planning and communication among departments.Jit

JitShafiq Khan

Ìę

The document discusses Just-in-Time (JIT) production systems. JIT emphasizes removing waste and inefficiency through small lot sizes, high quality, and teamwork. Key elements of JIT include a steady production rate, low inventories, small lot sizes, quick setups, and a pull system. Kanban is a tool used in JIT to authorize releases in a pull system. Benefits of JIT include reduced inventories, improved quality, flexibility, and productivity. The document outlines steps to convert to JIT and potential obstacles.The Art of Replenishment

The Art of ReplenishmentSimon Roy

Ìę

The document discusses replenishment strategies for retail supply chains. There are three main types: put-away/stocked where goods are stored in a warehouse before being sent to stores; docked/flow-through where goods bypass the warehouse and are directly allocated to stores; and direct-to-store where suppliers deliver goods directly to stores. The optimal strategy depends on factors like supplier lead times, product rotation rates, available storage space, and logistics costs. Selecting and setting up the right replenishment approach is important to maximize profits, meet customer demand, and ensure efficient operations.VSM - Value Stream Mapping for made-to-order manufacturing

VSM - Value Stream Mapping for made-to-order manufacturingJessica Mitchell

Ìę

Value stream mapping (VSM) is a lean manufacturing technique used to analyze and design the flow of materials and information required to bring a product to a customer. It involves mapping both the current state and future state of the value stream. The current state map documents all steps, information flows, and delays in the production process. The future state map proposes improvements to reduce waste and enable continuous flow and pull between steps. Key aspects of VSM include identifying product families, analyzing takt time, developing continuous flow where possible, identifying the pacemaker process, and using load leveling to smooth production.Kanban - Classes of Service

Kanban - Classes of ServiceAvarteq

Ìę

The document discusses classes of service in Kanban, which divide tasks into different aspects with simplified prioritization and parallel flows. It provides examples of established classes of service like bug, standard, chore, and fixed delivery date. One company uses "virtual" swim lanes to represent standard development, support/evaluation, and extremely important tasks. Bugs and extremely important tasks take precedence and aim for a one day cycle time. Evaluations produce standard feature tasks while chores are non-urgent support and improvement tasks. It concludes that tools are needed to measure cycle times per class of service.Value Stream Mapping

Value Stream MappingMichael (Mike) Nunn

Ìę

The document outlines the process and tools for creating a Value Stream Map (VSM) to identify value and waste within business processes. It emphasizes the importance of stakeholder involvement, defining the scope, and understanding inputs and outputs for each step. Additionally, it provides guidelines for future improvements by eliminating non-value-added steps and addressing bottlenecks.ABHI perfect

ABHI perfect ABHISHEK BHATNAGAR

Ìę

This document is a curriculum vitae for Abhishek Bhatnagar. It summarizes his career objective, organizational experience, qualifications, and personal details. He has over 8 years of experience in warehouse and inventory management roles. Currently, he works as an Assistant Manager at Infibeam.com, where he oversees day-to-day warehouse operations and ensures accurate inventory levels. Previously, he worked for 5 years as a Senior Receiving Bay In-Charge at Shoppers Stop, where he managed inventory receiving and distribution. He holds an MBA in Marketing and Bachelor of Commerce degree.Joseph Scola_Resume

Joseph Scola_ResumeJoe Scola

Ìę

This document provides a summary of qualifications and work experience for Joseph P. Scola. It outlines over 29 years of management experience in retail, warehousing, and distribution. It also lists skills in Excel, Word, PowerPoint, and inventory management systems. The professional experience section details roles as an operations manager and supervisor at several companies from 2011 to the present, with responsibilities including team leadership, inventory management, and meeting production and shipping goals. Key achievements highlighted inventory accuracy rates over 99% and cost reductions through process improvements.Part one of project brown field for operational excellencies in scm integert...

Part one of project brown field for operational excellencies in scm integert...LT COLONEL VIKRAM BAKSHI ( RETD)

Ìę

The document discusses the turnaround of the Chakan facility by implementing operational excellence strategies. It describes problems at the facility like lack of organization, high costs, weak processes, and inventory issues. A turnaround plan was made to implement 5S, reduce process variation, improve on-time shipment, increase inventory turnover, reduce crane and demurrage costs, and address HR/safety issues. The plan aimed to transform the facility from a poorly functional state in 2012 to an industry standard facility by 2014 through streamlining processes, upgrading facilities, and establishing an integrated supply chain.Demand Flow Technology: learnsigma.com

Demand Flow Technology: learnsigma.comrobthompson

Ìę

This document provides an overview and introduction to Demand Flow Technology (DFT) workshop principles. It defines some key terms and concepts in DFT including:

1) DFT aims to eliminate waste and have products flow through production based on customer demand in pursuit of perfection.

2) The primary objective of DFT is to build high quality products in the shortest production time at the lowest possible cost.

3) Key advantages include minimizing non-value-added work, maintaining a continuous improvement process, and maximizing speed to market and customer responsiveness.Value stream mapping - A Simple Primer

Value stream mapping - A Simple PrimerVenkat Srinivasan

Ìę

A Value Stream Map (VSM) is a hand-drawn map that shows the flow of materials and information through a process from start to finish. It identifies the key elements of a process including customer demand, manufacturing process flow, material flow, information flow, and lead time. Drawing a VSM helps people understand the current process and identify opportunities to eliminate waste and improve flow.Value Stream Mapping (VSM)

Value Stream Mapping (VSM)Indo German Training Centre mumbai

Ìę

The document outlines the concept of value in customer service, emphasizing the importance of delivering high-quality capabilities at the right time and price. It discusses value stream mapping (VSM) as a tool to optimize processes by eliminating waste and improving productivity across design, build, and sustain phases. The text highlights the significance of continuous improvement in lean production, with examples illustrating how enhancing processes leads to a substantial increase in efficiency.Kanban Explained in 11 șĘșĘߣs

Kanban Explained in 11 șĘșĘߣsBrent Brewington

Ìę

The document provides an overview of the Kanban system, a Japanese scheduling method that enhances production efficiency by visually managing workflow and inventory. It describes various Kanban methods, including physical boards and electronic task lists, as well as best practices for implementing Kanban systems. Additionally, it highlights the benefits of Kanban in addressing common workplace problems such as bottlenecks and communication breakdowns, emphasizing its role as a tool within a broader improvement program.Lean logistics and warehousing final

Lean logistics and warehousing finalCody White

Ìę

The document outlines lean logistics and warehousing principles aimed at reducing waste and improving efficiency in fulfillment operations. It emphasizes tools and methodologies such as value stream mapping, kanban, and standardization to achieve customer demand responsiveness while minimizing costs and lead times. Key concepts include the identification and elimination of the eight types of waste, the importance of collaboration among partners, and continuous improvement through practices like PDCA and kaizen workshops.Part one of project brown field for operational excellencies in scm integert...

Part one of project brown field for operational excellencies in scm integert...LT COLONEL VIKRAM BAKSHI ( RETD)

Ìę

Similar to Aurora ELP Processing System Improvement Project (20)

Capacity Planning of Mc Donald

Capacity Planning of Mc DonaldYamini Kahaliya

Ìę

The document discusses the capacity planning strategies of McDonald's, emphasizing the importance of aligning production capabilities with customer demand. It outlines factors affecting capacity, economies of scale, and different strategies such as lead, lag, and match strategy, with McDonaldâs primarily utilizing the lead strategy. Additionally, it provides specific details about McDonald's operations in India, including the capacity requirements for staffing and machinery needed to meet customer needs.Capacity requirement planning sure 12mt07ind019

Capacity requirement planning sure 12mt07ind019samjune

Ìę

Capacity requirements planning (CRP) is a technique that uses inputs like planned order releases, routing files, and open orders to project resource requirements and output load profiles for work centers. CRP helps identify bottleneck work centers and ensures sufficient capacity is available to meet manufacturing resource planning demands. The document discusses key CRP concepts like capacity, utilization, efficiency, load, and load percentage to determine if projected work can be completed on schedule. CRP aims to maximize capacity usage while avoiding overloading resources.Capacity Planning with reference to McDonlds

Capacity Planning with reference to McDonldsSai Praveen Chettupalli

Ìę

McDonald's capacity planning process involves determining production needs to meet changing demand. Key aspects include estimating total requirements based on factors like product variety and quality, estimating labor and machine needs, and comparing capacity availability to requirements. McDonald's Sonipat location has a capacity strategy of leading demand by keeping a 2-3 day inventory of buns, patties and 15 day inventory of drinks. The document also presents a hypothetical problem comparing expanding the existing location versus opening a new one, with expanding found to have a higher expected monetary value.Operation management

Operation managementMamta Karanji

Ìę

Operations management refers to administering business practices to maximize efficiency and profitability. It involves converting materials and labor into goods and services. The operations function creates and delivers products and services while evaluating quality, quantity, costs and fulfilling customer needs. Mass production and flexible production are two key production methods used. Production managers oversee resources to transform inputs into finished outputs through planning, implementing, and controlling production processes.Just in time

Just in timeshashank1220734

Ìę

Just-in-time (JIT) manufacturing is a production strategy that involves producing and delivering goods only as they are needed. This reduces waste from overproduction and shortens lead times. Key aspects of JIT include producing in small batches, minimizing inventory, and closely coordinating with suppliers. While JIT eliminates waste and reduces costs, it requires close collaboration and carries risks if production disruptions occur. Precautions like preventative maintenance and quality control help ensure smooth implementation of JIT strategies.Manish tripathi-erp-bpre

Manish tripathi-erp-bpreA P

Ìę

The document describes a case study of a precision engineering company called Tool Nation that implemented an ERP system to transform its business processes. It details Tool Nation's existing inefficient sales workflow and issues with its legacy systems. Tool Nation implemented Microsoft Dynamics NAV to automate sales ordering, integrate departments, track inventory, and improve operations. The ERP implementation helped streamline processes, increase data visibility, and improve on-time delivery to transform Tool Nation's business.Capacity requirement planning sure 12mt07ind019

Capacity requirement planning sure 12mt07ind019Akash Maurya

Ìę

Capacity requirements planning (CRP) is a technique that uses information on planned orders, routing files, and open orders to project resource requirements and generate load profiles for work centers. CRP determines if a company has sufficient capacity to meet production needs by comparing projected workload to available capacity. It helps identify bottlenecks and ensures work can be completed on schedule to avoid issues like losing customers or paying penalties.Ch3 Planning and coordinating demand and supply in a.pptx

Ch3 Planning and coordinating demand and supply in a.pptxNhatToHUYNH

Ìę

The document discusses aggregate planning in supply chain management, focusing on key operational parameters such as production rates, workforce requirements, and inventory levels. It highlights different aggregate planning strategies like chase, flexibility, and level strategies, along with the need for coordination and the impact of demand variability on costs. Additionally, it covers the importance of effective sales and operations planning (S&OP) and the obstacles to coordination within the supply chain.Kanban_230916

Kanban_230916Ram Kumar

Ìę

The document discusses Kanban, a lean manufacturing system used to limit work in progress. It begins by providing background on the competitive business environment and need for companies to be responsive, flexible, and profitable. It then explains how Toyota originally used Kanban cards to limit inventory and align production with demand. The document defines key Kanban terms and concepts like withdrawal Kanban, production Kanban, work in process, pull systems, and takt time. It also contrasts Kanban with traditional MRP systems. Overall, the summary discusses how Kanban aims to optimize workflow and align production to customer demand through visual signals and limits on work in progress.Ch11 introto business

Ch11 introto businessAjit Kumar

Ìę

This document outlines key concepts in production and operations management. It discusses the importance of effective production, including lower costs, higher quality, and responsiveness to customers. Mass, flexible, and customer-driven production systems are compared. The roles of technology in manufacturing are also examined. Other major topics covered include plant location decisions, production planning and control, inventory management, quality control, and ISO standards.15 operations, quality and productivity

15 operations, quality and productivityBeulah Heights University

Ìę

This document provides an overview of key concepts related to operations, quality, and productivity. It defines foundational terms and discusses how to classify operations systems based on factors like customer involvement, flexibility, and technology/intensity. The document also covers topics like quality, facility layout and location, capacity planning, scheduling, inventory control, supply chain management, and statistical quality control. It emphasizes that operations systems must be continually redesigned to adapt to a changing environment.Book review the goal

Book review the goaldhvani1234

Ìę

This document discusses the Theory of Constraints (TOC) developed by Eliyahu Goldratt. It introduces key concepts in TOC like bottlenecks, throughput, inventory, and operational expenses. It explains that bottlenecks limit the maximum speed of a process and must be identified and improved. The five focusing steps of TOC are identified as identifying the constraint, deciding how to exploit it, subordinating everything else to dealing with the constraint, elevating the system's constraints, and repeating the process if the constraint changes. Real-world examples are provided to illustrate how TOC can improve productivity and profitability.Working capital management

Working capital managementKapp Edge Solutions Pvt Ltd

Ìę

This document discusses working capital management. It covers elements of working capital like current assets and current liabilities. The objectives of working capital management are maintaining liquidity and maximizing profitability. It also discusses shortening the working capital cycle by reducing inventory holding periods and collection periods. The document defines overtrading and provides indicators and solutions. Finally, it discusses various working capital ratios like current ratio, quick ratio, inventory turnover ratio, debtor days, and creditor days that are used to analyze working capital.Ch8 controlling class 12 business studies

Ch8 controlling class 12 business studiesPriyanka Rao

Ìę

Controlling ensures that organizational activities are performed according to plans and resources are used efficiently to achieve goals. The controlling process involves setting standards, measuring actual performance, comparing to standards, analyzing deviations, and taking corrective actions. Traditional controlling techniques include personal observation, statistical reports, break-even analysis, and budget control. Modern techniques include return on investment, ratio analysis, responsibility accounting, management information systems, PERT/CPM, and management audits. Controlling is an essential function for accomplishing organizational goals, evaluating standards, and motivating employees.Production Planning And Control

Production Planning And ControlPVG's College of Engineering Nashik

Ìę

Production planning and control (PPC) involves coordinating activities like material control, process planning, and scheduling to systematically plan production. The objectives of PPC include meeting production targets with available resources, providing the right quality and quantity of products, and coordinating departments. PPC functions include material control, process planning, scheduling, dispatching work, and following up on production. There are different types of production systems like job shops, mass production, and batch production. Aggregate production planning coordinates with sales and marketing. Capacity planning matches resources to demand. Master production schedules convert aggregate plans into specific product schedules. Material requirements planning determines material needs. Manufacturing resource planning integrates all resource planning functions. Enterprise resource planning (ERP)ppt-project-final.ppt

ppt-project-final.pptsteel14

Ìę

This document summarizes a case study applying lean manufacturing techniques at a furniture factory in Jordan. The researchers used various lean tools to analyze sources of waste, including a current state value stream map of a two-door cabinet production process. They identified issues like long lead times, low value-add percentage, and bottlenecks. A future state map was proposed with recommendations to achieve continuous flow, balance processes, and continuously improve through techniques like 5S and kaizen. Suggestions included better production planning, utilizing CNC machines, and improving marketing.Elizabeth rubio cv-2

Elizabeth rubio cv-2Elizabeth Rubio

Ìę

The document provides a summary of Elizabeth Rubio Villalpando's work experience and qualifications. She has over 13 years of experience in production planning, scheduling, and supervision roles in manufacturing industries. Her most recent roles include Planner/Buyer at CCN Group S.A de C.V since 2017 and Master Scheduler at Placas TermodinĂĄmicas S. A. de C. V. from 2014 to 2015. Prior to that, she held several roles such as Planner Scheduler and Production Supervisor at Schlage de MĂ©xico, S. de R. L. de C. V. from 2006 to 2014. She has a Bachelor's degree in Industrial Engineering from Instituto TecCormanV5dates

CormanV5datesMichael Corman

Ìę

This document provides a summary of qualifications for Michael S. Corman, including his experience in inventory control, purchasing, and materials planning roles over 25 years. He has extensive experience managing inventories and supply chains to support production schedules for defense contractors like Lockheed Martin and Sippican. Corman also has proficiency with various ERP, MRP, and inventory management systems like SAP, MAS200, and Cabinet Vision.Lean Accounting Case Study

Lean Accounting Case StudyTIMOTHY BURKE

Ìę

The document criticizes traditional cost accounting approaches and advocates for lean accounting. Some key points:

- Traditional cost accounting focuses too much on gathering granular cost data and allocating overhead, which wastes time and can lead to bad decisions.

- In lean systems like Toyota Production System, fixed and variable costs behave differently than assumed by traditional accounting. Lean accounting focuses on tracking different metrics.

- Lean accounting aims to minimize inventory levels, track problems and quality issues instead of unit costs, and uses simple methods like calculating labor as a percentage of material costs each month. This reduces waste and provides more accurate information for decision making.Manish 13 mrp2

Manish 13 mrp2samjune

Ìę

This document discusses Manufacturing Resource Planning (MRP II), which is a method for effectively planning all resources in a manufacturing company. It incorporates financial accounting, sales, operations planning, and simulating capacity requirements. The MRP II hierarchy includes long-range planning, intermediate planning, and short-term control. Long-range planning involves functions like resource planning and aggregate planning with a time horizon of 6 months to 5 years. Intermediate planning includes production planning functions like demand management, master production scheduling, and material requirements planning. Short-term control implements the plans through functions such as job release, job dispatching, and input/output control.Ad

Aurora ELP Processing System Improvement Project

- 1. Theme: Achieve continuous-flow ELP processing from customer order to final delivery. âąConsistently fulfill our commitments to Weyerhaeuser customers âąImprove workload balance for both sales and operations departments âąAdd capacity by reducing waste in the processing system AURORA ELP IMPROVEMENT PROJECT Current Condition: Operations âąThis project supports Weyerhaeuserâs Project Alpha initiative âąOrders âleap-froggedâ during the order-to-delivery cycle, causing systematic errors. âą12 to 15 + two temporaries used in yard activities. âą25% overtime âą28,000# truckloads âąTransaction timing and sequencing creates delays in the OTD process. âąPrinting early âąUn-timely inputting of sales orders and inputting of completed work orders Function Typical Time Phone call/fax to order input 408 min. (call/fax avg.) Order entry to Printed work order 1211 Minutes Printed work order to loaded truck 1628 minutes Loaded truck to shipped 585 minutes Transit Time to Customer 300 minutes Total Order-To-Delivery Time 4132 min. (2.9 days) Current Condition: Sales âąSales team structure is horizontal and not conducive to good sales/processing communication. âąProcessing Volumes not well dispersed hour by hour and day by day, resulting in uneven use of capacity: âąSignificant dwell times exist resulting in slow response to customer requests Previous Image Implemented Image 1. Ops. manager prints all work orders for following day at 5:00pm. 2. Work orders sorted by product type and given to yard âspecialistsâ. 3. Specialists pick and cut inventory based on individual work orders. 4. Specialists transfer inventory to staging area and sort by product type. 5. Loaders pull work orders by truck and sort and load inventory by order/truckload. A truck load may have more than one product type. 1. Ops. Manager prints 1 truckâs worth of work orders at a time starting at 12:00 noon and distributes to team (2-4 people per truckload). 2. Workers pick, cut and load 1 truck at a time. 3. Loader helps load trucks. 3 Days 2 Days OSROSR OSR OSR OSR OSR OSR ISR ISR ISRISR ISR ISRISR CSR âąSales process not driven by quantitative goals. âąOperations capacity not visible to sales operation. Previous Sales Structure OSROSR OSR OSR OSR OSR OSR ISR ISR ISRISR ISRISR CSRCSR CSR Team 1 Team 2 Team 3 Implemented Sales Structure: âąVertically oriented by product group âąProactive selling âąVisual control Order Taking Order GENERATING Countermeasures: âąOrganize ELP processing methods with outbound truck loading âąEstablish continuous âsmall batchâ processing methods among yard operators âąReconfigure shift start times to eliminate dwell time of customer orders âąCreate visual âload controlâ board for sales operation to plan available capacity âąRe-organize sales team to utilize skills and product characteristics Benefits: Total savings of $615,000 in â14. Expected margin increase of two (2) points. âąRemoved one full day of lead time (2.9 days to 1.9 days) âąLoad control board resulted in improved load density by 25% (28,000 lbs to 35,000 lbs, approx. $240,000 annual savings) âą$210,000 annual labor savings (reduced from 12-15 +2 temps to 9 + 1 temp.) âą$165,000 annual overtime reduction from >25% to <10%. ($15k/person annually vs $6k/person annually, 15 people vs. 10 people) âąInventory accuracy has improved (less time spent searching for product) âąProcessing accuracy improved (less time spent fixing bad orders) âąVertically integrated product teams will create extra capacity of approx. 30%+ for increased future sales (measurement due Summer â05, expected benefit to exceed two (2) margin points) Next Steps: âąContinue development of sales team âąImplement âsmall batchâ processing in the Naperville warehouse âąEstablish âOffice of Continuous Improvementâ to leverage knowledge and skills of Aurora personnel âąConsider consolidated inventory management strategy amongst Great Lakes Region Timeline: ID 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Sales Team Facilitation Develop metrics Improve Capacity Coordinate with warehouse Small Batch Processing (Naperville Whse.) Evaluate Plan Implement Office of Continuous Improvement Select Team Train the trainer Begin projects Centralized Inventory Management Strategy Study Plan Implement 1/16 1/23 1/30 2/6 2/13 2/20 2/27 3/6 3/13 3/20 3/27 4/3 4/10 4/17 4/24 5/1 5/8 5/15 5/22 5/29 January February March April May 0 20 40 60 80 100 120 140 160 180 Mon Tue Wed Thur Fri # of work orders 0 1 2 3 4 5 6 7 8 Hour 1 Hour 3 Hour 5 Hour 7 Hour 9 Hour 11 # of work orders David Sheehan

- 2. Sales Customers Faxes distributed E-mail Queue Orders Inquiries Quotes Entered Order Odyssey Queue EDI Sales Support Release Order Manually or auto send confirmation Phone/fax/e-mail Sales Process Order Printed Staged in bins Handed to cutters Order processed Staging Order recorded Loads created ShippedLoaded ELP Process Phones Arrival 408 Minutes 1211 Min. 1628 Minutes 585 Min. 4132 Minutes, or 2.9 days 300 Min. Current Image