Automated in-line defect classification and localization in solar cells for laser-based repair

- 1. Automated in-Line Defect Classification and Localization in Solar Cells for Laser-Based Repair Jorge Rodr├Łguez ŌĆōAra├║jo, Ant├│n Garc├Ła-D├Łaz AIMEN Technology Center, Porri├▒o, Spain ISIE 2014, Istambul, 2-6-2014

- 2. www.aimen.es | aimen@aimen.es 2 Index 1. Motivation and Innovative Character. 2. Proposed Solution. 3. Diagnostic and Defect Segmentation. 4. Repair Process Decision. 5. Experimental Results. 6. Conclusions and future work. Index

- 3. www.aimen.es | aimen@aimen.es 3 Motivation and Innovative Character

- 4. 4www.aimen.es | aimen@aimen.es Motivation and Innovative Character ŌĆó Solar cells are made of silicon (156x156mm). ŌĆó Monocrystalline and Polycrystalline silicon (more common materials). ŌĆó The manufacturing process produces defects. Photovoltaic solar cells busbars front back

- 5. 5www.aimen.es | aimen@aimen.es Motivation and Innovative Character ŌĆó Electroluminescence imaging. ŌĆó Shunts and Cracks (most important).(> 50%) ŌĆó Lacks of metallization (less frequent) (< 20%). ŌĆó Finger interruptions (reduced effects). (> 58%) ŌĆó Shunts and Cracks may be repaired. ŌĆó Cutting or isolating using laser technology. ŌĆó New pieces of cells are obtained. Defects Detection

- 6. www.aimen.es | aimen@aimen.es 6 Proposed Solution

- 7. 7www.aimen.es | aimen@aimen.es Proposed Solution ŌĆó Laser Repair System (laser process). ŌĆó Defects Inspector (defects identification and laser control). ŌĆó Data Input Block (electroluminescence provider). Solar cell repair system

- 8. 8www.aimen.es | aimen@aimen.es Proposed Solution ŌĆó Cell Diagnostic (defects segmentation from EL). ŌĆó Repairing Decision (laser process decision). ŌĆó Cell Alignment (laser process correction). Defects inspector

- 9. www.aimen.es | aimen@aimen.es 9 Diagnostic and Defect Segmentation

- 10. 10www.aimen.es | aimen@aimen.es Diagnostic and Defect Segmentation ŌĆó Human experts examine EL images. ŌĆō Changes on texture. ŌĆō Changes on the shape of texture boundaries. ŌĆó Defect Diagnostic (texture based) ŌĆō Decomposition: for automatic features generation. ŌĆō Adaptation: for enhancement of features. ŌĆō Pixel level classification: for multiclass identification. Bio-inspired texture approach Texture approach Defects Log Gabor filters

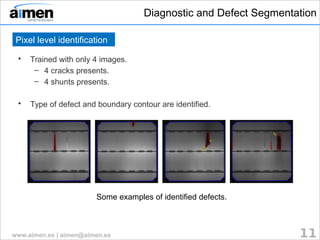

- 11. 11www.aimen.es | aimen@aimen.es Diagnostic and Defect Segmentation ŌĆó Trained with only 4 images. ŌĆō 4 cracks presents. ŌĆō 4 shunts presents. ŌĆó Type of defect and boundary contour are identified. Some examples of identified defects. Pixel level identification

- 12. www.aimen.es | aimen@aimen.es 12 Repair Process Decision

- 13. 13www.aimen.es | aimen@aimen.es Repair Process Decision ŌĆó Decision rules:. ŌĆō Isolate shunts not on a busbar. ŌĆō Cut shunts on a busbar or close to one. ŌĆō Cut pieces to remove cracks. Solar cell repair decision Examples of repair decision.

- 14. 14www.aimen.es | aimen@aimen.es Repair Process Decision ŌĆó Closing morphological operation. ŌĆó Inversion and thresholding. ŌĆó Edge detection and contour. ŌĆó Bounding box localization. Cell location and alignment Steps on cell localization.

- 15. www.aimen.es | aimen@aimen.es 15 Experimental results

- 16. Experimental Results www.aimen.es | aimen@aimen.es 16 Laser-based repair unit Camera perspective. Scanner working area. Laser repair system.

- 17. Experimental results www.aimen.es | aimen@aimen.es 17 Laser scanner calibration Galvo-scanner working area.

- 18. 18www.aimen.es | aimen@aimen.es Experimental results Calibration pictures

- 19. 19www.aimen.es | aimen@aimen.es Experimental results Processing pictures

- 20. 20www.aimen.es | aimen@aimen.es Experimental results Results pictures

- 21. 21www.aimen.es | aimen@aimen.es Experimental Results ŌĆó 47 cells considered. ŌĆó 45 cells repaired. ŌĆó 69% waste reduction. Processing results Defect type # of Defects TP FP FN Repaired Shunts 43 43 4 0 42 Cracks 38 36 6 2 36 All 81 79 10 2 45* * This value refers to the number of cells repaired.

- 22. www.aimen.es | aimen@aimen.es 22 Conclusions and Future Work

- 23. 23www.aimen.es | aimen@aimen.es Conclusions and Future work ŌĆó Defect segmentation and classification. ŌĆó In-line solar cells repair system. ŌĆó Able to isolate and cut defects. ŌĆó 69% of rejected cells reutilization. ŌĆó Discriminate more defects, like metallization. ŌĆó More complex repair strategies. ŌĆó Isolation based on efficiency estimation. Conclusions Future work

- 24. www.aimen.es | aimen@aimen.es 24 AIMEN ŌĆō Central y Laboratorios c/ Relva 27 A 36410 ŌĆō O PORRI├æO (Pontevedra) Telf.+34 986 344 000 ŌĆō Fax. +34 986 337 302 Delegaci├│n Tecnol├│gica Madrid Avda. del General Per├│n, 32, 8 A 28020 ŌĆō MADRID (Madrid) Telf.+34 687 448 915 Delegaci├│n Tecnol├│gica A Coru├▒a Fundaci├│n Mans ŌĆō Paideia Pol. Pocomaco - Parcela D-22 - Oficina 20A 15190 ŌĆō A CORU├æA (A Coru├▒a) Telf. +34 617 395 153 Thank you for your attention Jorge Rodr├Łguez Araujo | Research Engineer Ph +34 986 344 000 | jorge.rodriguez@aimen.es