Automated surface profiling

- 1. Surface Profiling of Drywalls for Automated Sanding Dony Alex Dr. Mohamed Al-Hussein Dr. Saeed Behzadipour Hole School of Construction Engineering Dept. of Civil & Environmental Engineering University of Alberta Canada June 29th, 2011

- 2. Outline ●Introduction ●Surface Profiling Techniques ●Proposed Methodology ●Algorithms ●Case Study ●Conclusion

- 3. Current Challenges in Construction ●Declining Productivity ●Hazardous Working Conditions ●Shortage of Skilled Workers ●10 -15% increase in overall productivity ●Reduce exposure to hazardous environment ●Better quality ●Higher standards of work How Automation Helps? Challenges in Construction sources: Euroconstruct, Eurostat, ACEA)

- 4. The Sanding Process ●Ensures smooth surface ●Exposure to dust - at least 10 times the Permissible Exposure Limits (PEL) ●Integration of robotics - a relatively new concept Tape Coat Drywall Tape Block Coat Skim Coat Sanding Image: http://home.howstuffworks.com/drywall4.htm

- 5. Surface Profiling ●Process of identifying the surface geometry. ●Identifies irregularities ●Currently performed manually.

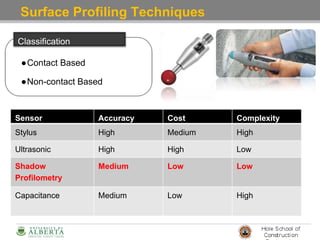

- 7. Surface Profiling Techniques Classification ●Contact Based ●Non-contact Based Sensor Accuracy Cost Complexity Stylus High Medium High Ultrasonic High High Low Shadow Profilometry Medium Low Low Capacitance Medium Low High

- 8. Shadow Profilometry ●Technique of tracing a surface profile using shadows ●When a plane of light is made to intersect with an irregular surface at an angle, the resultant intersection line follows the topography of the surface. Shadow scanner for evaluating surface smoothness in wood industry (Sandak and Tanaka, 2005).

- 11. Proposed Methodology – Test Setup Test Setup oVirtual test environment setup in 3DS Max oComprises of surface (1) , curtain (2), light source (3) and camera (4) oCaptures image of the shadow profile over the surface cross section oCaptures location at which shadow edge is formed

- 13. 1. Flat surface 2. Depression in surface 3. Elevated surface 4. Nail Hole

- 14. Proposed Methodology – Image Processing

- 15. Case Study H D1 D1 = Distance at which Shadow edge is formed. H = Height of curtain from the surface. H= 6cm Angle of Incidence (α)= 450

- 16. D H

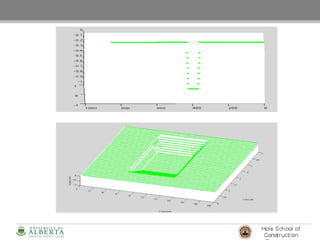

- 17. Image Resolution = 848 x 480 pixels

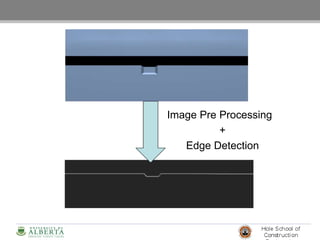

- 18. Image Pre Processing + Edge Detection

- 20. Accuracy of the reconstructed profile Maximum Error = 0.1 cm Average Error = 0.01 cm

- 21. Case Study 2 – Nail Hole Maximum Error = 0.3 cm Average Error = 0.02 cm Accuracy of the reconstructed profile

- 22. Case 3 – Curved Elevation Maximum Error = 0.1 cm Average Error = 0.04 cm Accuracy of the reconstructed profile

- 23. Conclusions - Contributions ●Introduction of shadow profilometry as a method of profiling the drywall surface ●Successful simulation of shadow profilometry for surface profiling ●Successful 3D reconstruction of the surface

- 24. Conclusion – Limitations and Future Scope ● The research treats the drywall as a single surface ●Accuracy greatly depends on sharpness of the shadow ●Experimental implementation and validation ●Robot task planning based on the surface profi ●Integration of sensor into a robotic arm Limitations Future Scope