AUTOMATIC FAN CONTROLLER USING THERMISTOR

- 1. OFF. JUHU VERSOVA LINK ROAD, VERSOVA ANDHERI (W), MUMBAI â 53, TEL.: 2670 7026 / 27 / 28 FAX: 26707026 PROJECT: AUTOMATIC DCFAN CONTROLLER USING THERMISTOR Mr. PANKAJ .M JAGDALE Under guidance of: Prof. SURENDRA SUTAR

- 2. CERTIFICATE This is to certify that report âAUTOMATIC DC FAN CONTROLLER USING THERMISTORâ, has been done by Mr.PANKAJ MARUTI JAGADALE, under my guidance and supervision for SEMESTERVI,3 rd year of BACHEOLER OF ELECTRONICS AND TELECOMMUNICATION during year 2015-2016 PROF.SURENDRA SUTAR EXAMINER PROF.K.G.SAWARKAR (H.O.D EXTC) DATE: PLACE:

- 3. ACKNOWLEDGEMENT The success and final outcome of this project required a lot of guidance and assistance from many people and we are extremely fortunate to have got this all along the completion of our project work. We are highly indebted to Ms. SURENDRA SUTAR for her guidance and constant supervision as well as providing necessary information regarding the project & also her support in completing the project. We owe our profound gratitude to all other professors of Electronics and Telecommunication Department for their proper guidance and motivation for this project. We would also thank our library staff for providing us with several books, magazines and internet usage. Our thanks and appreciations also go to our fellow colleague in developing the project and people who willingly helped us out with their abilities.

- 4. INDEX Abstract ........................................................................................ Need of projectâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶ...... Introduction ......................................................................................... Component List ...................................................................................... Major components descriptionâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶ.. Circuit diagram and its working ............................................................ Schematic diagram of circuit and PCB layout......................................... AnalysisâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶ. Specification.............................................................................................. Scopeof projectâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶ. Advantage n DisadvantagesâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶ ApplicationâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶâĶ. Conclusion ............................................................................................ References ............................................................................................

- 5. ABSTRACT The purpose of making a final project entitled Automatic Fan Control System Based with Thermistor For Temperature Controller is to allow users to adjust the fan speed automatically. So it can save and streamline the work that is usually done manually which could then work automatically and effective for humans. The study was conducted with the design and manufacture of Automatic Fan Control System. Further functional testing tools, as well as temperature sensor is used. Fan can be controlled manually by pressing on the switch button. where in this method, any change in the temperature will not give any change in the fan speed. except the usage change the speed of the fan which is manually. Over the last decade, advances in digital electronics have made computersmaller, cheaper and faster. Throughout this revolution as well, mobilecomputing environment such as PDA has been created and undoubtedly otheradvances in technology like smart home also play an important role towardsbetter life in the future. This project is about how we can control the fan basedon temperature sensor regardless of traditional thermostat. It is also part of smart home application where the fan will gradually increase the speed if thetemperature in the environment is increasing. Besides that, the component thatmade up the temperature sensor is known as thermistor. A sensor is a type oftransducer. In a broader sense, a transducer is sometimes defined as any devicethat converts energy from one form to another.There are two types of thermistor depend on the sign of k. Firstly is positive temperature coefficient (PTC). PTCthermistor works by increasing the resistance with increasing temperature. Secondly is negative temperature coefficient (NTC). NTC thermistor works bydecreasing the resistance with increasing temperature. This project will focus onNTC type of thermistor. Experiment can be followed to evaluate whether thiscircuit can save energy through the use of temperature sensor and thus promoteefficiency. Finally, after some experiments have done, the result of theexperimentation and finding can be concluded.

- 6. NEED OF PROJECT Project Background: Sometimes electric fan usage is wasting power because of human attitude. Human also mostly demands something that easily to be used without wasting energy. To minimize or reduce the power usage, this project developed an automatic fan system where speed is controlled by the room temperature. Problem Statement: Most human feels the inconvenient about changing the fan speed level manually when the room temperature changes. So, the automatic fan system that automatically changes the speed level according to temperature changes is recommended to be built for solving this problem. Project Objectives: The objectives of this project are to: i. Enable the electric fan to automatically change the speed level according to temperature changes. ii. Develop an automatic fan system that can change the speed level due to the environment temperature changes. iii. Develop an automatic fan system that can preview the status of the temperature and the speed level by using NTCThermistor. Project Scopes: The system is built using: i. IC 741 n NTC Thermistor as the main controller. ii. The temperature sensor as the input for the microcontroller. iii. The DC motor as the output for the system.

- 7. INTRODUCTION ELECTRICfan is one of the most popular electrical devices due to its costeffectiveness and low power consumption advantages. It is a common circuit and widely used in many applications. It is also one of the most sensible solutions to offer a comfortable and energy efficient. In fact, the fan has been long used and still available in the market. Nowadays, the demand for accurate temperature control and air freshening control has conquered many of industrial domains such as process heat, automotive, industrial places or office buildings where the air is cooled in order to maintain a comfortable environment for its occupants. One of the most important concerns involved in heat area consist in the desired temperature achievement and consumption optimization. So, an automatic temperature control system technology is needed for the controlling purpose in the fan speed according to the temperature changes. Many researches focusing on automatic temperature control system application in different fields will gain the benefits. For examples, an automatic temperature controller for multi element array hyperthermia systems , multi-loop automatic temperature control system design for fluid dynamics , design of automatic temperature- control circuit module in tunnel microwave heating system, the automatic temperature system with Fuzzy self-adaptive Proportional- Integral-Derivative (PID) control in semiconductor laser .

- 8. COMPONENT LIST :- R1 =4.7k R2=47Ohm NTC Thermistor = 4.7K Potentiometer (Vr) =500K OP AMP IC 741 Transistor T1=BD140 12V DC fan -Used in computer(CPU) Diode 1N4007 12V power supply

- 9. INTRODUCTION TO SEVERAL BASIC ELECTRONIC COMPONENTS: There are many electronic components that will be used during the development of temperature controlled fan circuit. There are some that we familiar with and some are rarely used. All components play its important role and interrelated between each other in completing the circuit design. THERMISTOR: According to Wikipedia.com, thermistor is a type resistor used to measureTemperature changes, relying in its resistance with changing temperature. Thermistor symbol There are two types depending on the sign of k. If k is positive, the resistance increases with increasing temperature. This is known as positive temperature coefficient (PTC) thermistor. However, if the k is negative, the resistance decreases with increasing temperature. This is known as negative temperature coefficient (NTC) thermistor. POTENTIOMETER: Wikipedia.com stated that the original meaning of the term potentiometer, which is still in use is an apparatus used to measure the potential (or voltage) in a circuit by tapping off a portion of a known voltage from a resistive slide wire and comparing it with the unknown voltage by means of a voltmeter of galvanometer. If all the three terminals are used, it can act as variable voltage divider. Potentiometer symbol The arrow represents the moving terminal, called the wiper.

- 10. CAPACITOR: A capacitor is a device that stores energy in the electric field created between a pair of conductors on which electric charges of equal magnitude, but opposite sign, have been placed. A capacitor is occasionally referred to using the older term condenser Capacitor symbols DIODE: Besides that, wikipedia.com also stated that a diode is a component that restricts the direction of movement of charge carriers. It allows an electric current to flow in one direction, but essentially block the opposite direction. Rectifiers are constructed from diodes where it used to convert alternating current (AC) into direct current (DC). Diode symbol

- 11. According to the datasheet LM741 IC is a general purpose single operational amplifier. The UA741 is a high performance monolithic operational amplifier constructed on a single silicon chip. You can find some interesting circuits here. UA741 datasheet LM741 datasheet 741 8 pin package 741 14 pin package

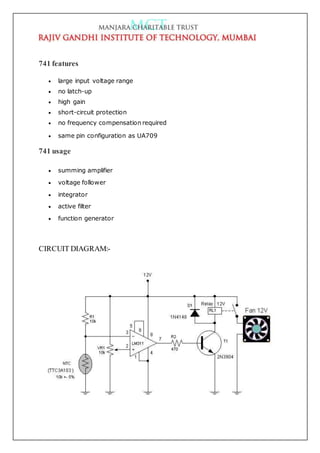

- 12. 741 features ï· large input voltage range ï· no latch-up ï· high gain ï· short-circuit protection ï· no frequency compensation required ï· same pin configuration as UA709 741 usage ï· summing amplifier ï· voltage follower ï· integrator ï· active filter ï· function generator CIRCUIT DIAGRAM:-

- 13. WORKING The basic working principle of temperature controlled DC fan is based on theworking principle of thermistor. Thermistor is component which changes its resistance as its temperature changes. There are two types of thermistor available which are NTC i.e. negative temperature coefficient and other is PTC which is positive temperature coefficient. In temperature controlled DC fan we have used a NTC type thermistor. It is called NTC because its resistance increases when its temperature decreases and vice verse. Similarly in PTC its resistance increases when temperature increases and vice verse. Op amp IC741 is used as a voltage comparator which compares the voltage between its two inputs i.e. inverting and non inverting terminals. Pin number 2 is inverting terminal which is connected to the potentiometer and pin number 3 is non inverting terminal which is connected in between thermistor and R1 which makes a voltage divider circuit. Thus the output of op amp is responsible for the speed of fan. When the temperature of surrounding increases, temperature of thermistor also increases which causes its resistance to decrease, therefore voltage divider circuit causes more voltage across pin number 3. Thus the output voltage increases causing speed of fan to increase. CFM:Unit of air flow employed in air-conditioning.A typical air-conditioner,foreg, products about 100 CFM for each ton of its cooling capacity. One CFM equals about 28.31 liters per minutes. Static pressure is resistive to flow of Air

- 14. CFM based on static pressure: CFM1=CFM2 x SqRt(SP2/SP1) RPM based on CFM: RPM2=RPM1 x (CFM2/CFM1)

- 15. SCHEMATIC OF THE CIRCUIT : PCB LAYOUT OF THE CIRCUIT :-

- 16. SPECIFICATION BRUSHLESS FAN: ï Normal Voltage:- 12V ï CFM(Cubic FeetPerminute)=42.02 ï Speed: 3600RPM ï Pressure type:0.217H2O NTC Thermistor: ï Max power:- 250mW ï Operating temperature Range:-40C to +125C ï current:- 0.46mA ï Power dissipation :- 1mW/C ï SCOPE OF THE PROJECT The focus of this research will be on the implementation of sensor that controls the speed of the fan. Scopes of this research are: a) The project will concentrate on electric standing fan rather than other type of fan such as ceiling fan PROJECT SIGNIFICANCE a) To monitor the environments that is not comfortable, or possible, for humans to monitor, especially for extended periods of time b) Prevents waste of energy when itâs not hot enough for a fan to be needed c) To assist people who are disabled to adjust the fan speed automatically

- 17. Advantages & Disadvantages of Temperature controlled Fan: ïž Advantages of Temperature Controlled Fan: ï· It is very economical and easy to handle by the user. ï· Speed varies automatically, so that it controls the speed without using it manually. ï· It is help full to disabled people. ï· It is very easy to install in offices, houses etc. ï· Save energy by slowing down its speed in low temperature. ïž Disadvantages of Temperature Controlled Fan ï· Micro controller is the heart of the circuit, if controller is damaged the whole system will be interrupted. ï· Speed control is independent of individual preference. APPLICATION Typical applications include automotive, telecom equipment, laptops, server, and many other portable and non-portable electronic devices. Sometimes you could find fans used in conjunction with a heatsink to increase overall airflow. This is known as a forced air system. CONCLUSION: ïķ This circuit is very simple and easy to build. ïķ This paper elaborates the design and construction of fan speed control system to control the room temperature. The temperature sensor was carefully chosen to gauge the room temperature. Moreover, the fan speed will increase automatically if the temperature room is increased. As conclusion, the system which designed in this work was perform very well, for any temperature change and can be classified as automatic control.

- 18. REFERENCES:- ï http://www.electronic-lab.com ï http://www.circuitgallery.com ï http://www.classbook.com ï www.wikipedia.com ï www.EstimatingWizard.com