Automobile components

- 2. INTRODUCTION Prem Industries introduce ourselves as an ISO/TS-16949 – 2009 certified company along with ISO 9001: 2008 certification for machining and manufacturing of high precision engineering and automobile components with sophisticated CNC machines operated by professional and well- qualified engineers, technicians, designers, CNC programmers and knowledgeable management.

- 3. We pride our service on : ÔÉò Customer satisfaction ÔÉò Exceptional quality ÔÉò On-time delivery ÔÉò Domestic and international sectors ÔÉò Improved operational efficiency.

- 4. QUALITY POLICY We are committed to process & supply components  which meets the requirements agreed with our customer  to ensure his satisfaction We are committed to comply with the requirements and continually improve the effectiveness and efficiency of Quality Management Systems in all the areas

- 5. PROCESS OBJECTIVES  Marketing Process o Increase the Sale o Increase Number of Customers.  Process Design & Development o Reduce the cycle time / process cost of various components  Production & Maintenance Process o Achieve the Production Targets. o Reduce the Rejection of components. o On-time delivery performance o Reduce the Breakdown of machines.

- 6. PROCESS OBJECTIVES  Quality Assurance Process o Reduce the customer complaints.  Purchase & Store Process o Reduce the cost of Purchase o Improve the Supplier’s performance.  Dispatch Process o Dispatch as per customer schedule.  Management Process (MR) o Conduct of IQA/ MRM as per plan  No repetition of Non conformity.  Training Process o Conduct of Training as per plan.

- 7. PRODUCTS PINIONS: DIA. 150 & Length 400mm

- 8. PRODUCTS Drive Shafts / Shafts/ Transmission Parts (Length 780 mm)

- 9. PRODUCTS Speed Gears, Worm Wheel (Dia 250mm) Crown Wheels (Dia. 500mm)

- 11. PRODUCTS Flywheel for Trade-mill (Dia. 210 mm)

- 12. PRODUCTS Adaptor plate for Generator Cluster Gears

- 13. PRODUCTS Stator body for Motor Disc Hub Spindle Flange Springs

- 15. PRODUCTS CON- Rod Burner Pot

- 16. OUR ESTEEMED CLIENTS  M/s. Pulse Power System, CA92630 USA  M/s. CYBEX, Owatonna , USA  M/s Ceejay Precision Engineering, Western Australia  M/s SMN Engineering, Western Australia  M/s. Bharat Gears Ltd., Thane, India.  M/s. Volvo-Eicher Commercial Engineering, Thane, India.  M/s. Paras Industries, Thane, India.  M/s. S S Natu Plastics & Metals Pvt. Ltd, Thane, India.  M/s. Star Precision works (I) Pvt. Ltd., Thane, India.  M/s. Hercules Hoists Ltd, Mumbai, India.  M/s. Rud-India P. Ltd. (German MNC), Thane, India.  M/s. Quality Engineers (China MNC) Mumbai, India.  M/s. Anihas Castings (Non Ferrous Div), Thane, India.  M/s. RPG Raychem (German MNC), Mumbai, India  M/s. YG-1- India, Thane, India.  M/s KHK Scaffoldings, Dubai

- 17. CRITICAL MACHINES A cost effective CNC turning center, this machine is ideally suited for most jobs. It has highspeed bi- directional tool turret, with 8 tools and latest numeric controls.

- 18. CRITICAL MACHINES This is a Vertical Machining Center for steel, aluminum & cast iron components. It’s an unique armless tool changer with bi- directional turret type carousel for 12 tools and a pallet changer.

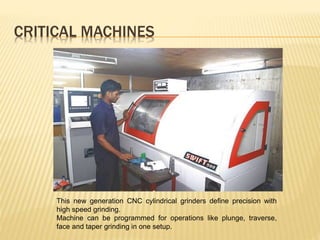

- 19. CRITICAL MACHINES This new generation CNC cylindrical grinders define precision with high speed grinding. Machine can be programmed for operations like plunge, traverse, face and taper grinding in one setup.

- 20. CRITICAL MACHINES This German Gear Hobbing machine proves very useful in maintaining the lead and profile of a job during gear hobbing.

- 21. LIST OF MACHINES (Prem Industries and Allied Group of Companies) 1. CNC Lathe Machine a) Jobber XL (Ace) 10 Nos. b) Super Jobber 500 03 No. c) LT – 20 XL 02 No. d) LT – 20 Classic (Ace) 01 No. e) STC – 250 (Jyoti) 01 No. f) Goodway (Taiwan) 01 No. g) Ikegai (Japan) 01 No. h) Daewoo (dia 400 x 700 mm) 01 Nos 2. V.M.C. with Pallet Changer a) MCV – 300 (Ace) 02 Nos. b) MCV – 400 02 Nos 3. CNC Cylindrical Grinding Machine with TESPA inprocess gauge a) Swift – 500 (Hi-Life) dia 200x500L 02 Nos. 4. Gear Hobbing 1. Stahnley : dia 200x 400L , module: 6.0 02 Nos. 2. Cugir – FD 400, Dia 450 , module :8.0 x 300L 01 No 3. Stankoimport: 53A20, Module:4.0 , dia 200 x 230L 01 No 4. Pfouter – P 600 01 No

- 22. LIST OF MACHINES (Prem Industries and Allied Group of Companies) 5. Gear Shaping machine 1. CUGIR - ROMANIA , module: 8.0 dia 200 01 No 6. Facing & Centering Machine a) F & C Machine 03 Nos. b) Centering & Plunging Machine 01 No. 7. Conventional Machines a) Center Lathes 18 Nos. b) Lathe with Coping attachment 02 Nos. c) Coping Lathe (Transpilot) 01 No. d) Piller Drills 03 Nos. e) Hacksaw Machine 02 Nos. f) Bendsaw Machine 06 No. g) Automatic Bendsaw Machine 01 No. g) Milling Machine 01 No. 8. Trivalent Trichrome Zn Plating Plant & M/c 1 set 9. Bore Grinding Machine – Out sourced 02 Nos. 10. Broaching Machine – Out Sourced – 5T X 1320 MM 03 Nos. 11. Centerless Grinding M/c – Out sourced 03 Nos. 12. Heat Treatment

- 23. ORGANISATION LAYOUT TOP MANAGEMEN T MKTG SALES (LOCAL + EXPORT) DESPATCH COSTING DESIGN COMMERCIA L PURCHASE VENDORING / STORES FINANCE ACCOUNTS ADMIN MANUFACTURING PLANNING PRODUCTION MAINHTENANCE HUMAN RESOURCES M.R.

- 25. ISO 9001: 2008 CERTIFICATE

- 26. CONTACT DETAILS:  Address: B 1/1, 27 Acre Kothari Compound Manpada, Thane (W) – 400 607 Phone : 022 2589 8146 Mobile : 9820 592 064 Email : dftl_241@rediffmail.com : dftl241@gmail.com : ceo@premindustries.co

- 27. THANK YOU