Automobile Engineering.ppt

- 2. UNIT-1 • Introduction: Types of automobiles, vehicle construction and layouts, chassis, frame and body, IC engines- components, function and materials, Turbo charging- WGT, VGT and supercharging Crankcase ventilation, Engine service, reboring, Decarburization, Nitriding of crankshaft. • Performance of automobiles: Taxable Power, Power and Torque Curves, Resistances to a Moving vehicle, Rolling Resistance, Wind or Air Resistance, Gradient Resistance, Total Resistance, Power required to propel a vehicle. 2

- 3. • Types of automobiles, • Vehicle construction and layouts, chassis, frame and body, • IC engines- components, function • Turbo charging- WGT, VGT • supercharging • Crankcase ventilation, • Engine service, reboring, Decarburization, Nitriding of crankshaft. 3

- 4. Performance of automobiles: • Taxable Power, Power and Torque Curves, • Resistances to a Moving vehicle, • Rolling Resistance, • Wind or Air Resistance, • Gradient Resistance, • Total Resistance, • Power required to propel a vehicle. 4

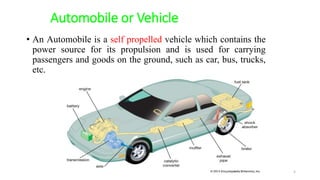

- 5. Automobile or Vehicle • An Automobile is a self propelled vehicle which contains the power source for its propulsion and is used for carrying passengers and goods on the ground, such as car, bus, trucks, etc. 5

- 6. On the Basis of Load a) Heavy transport vehicle (HTV) or heavy motor vehicle (HMV), e.g. trucks, buses, etc. b) Light transport vehicle (LTV), e.g. pickup, station wagon, etc. 6

- 7. On the Basis of Load c) Light motor vehicle (LMV), e.g. cars, jeeps, etc. 7

- 8. On the Basis of Wheels a. Two wheeler, for example: Scooter, Motorcycle, Scooty, etc. b. Three wheeler vehicle, for example: Autorickshaw, three wheeler scooter for handicaps and tempo, etc. c. Four wheeler vehicle, for example: Car, jeep, trucks, buses, etc. d. Six wheeler vehicle, for example: Big trucks with two gear axles. 8

- 9. On the basis of Fuel used a) Petrol vehicle, e.g. motorcycle, scooter, cars, etc. b) Diesel vehicle, e.g. trucks, buses, etc. c) Electric vehicle which use battery to drive. d) Gas vehicle, e.g. LPG and CNG vehicles e) Hybrid Vehicles, e.g. LPG/CNG and Gasoline 9

- 10. On the basis of Transmission a) Manual transmission b) Semi-automatic c) Automatic 10

- 11. Drive •Driven sitting towards right or left side •Left hand drive •Right hand drive •Driving Axle •Front wheel drive •Rear wheel drive •All wheel drive - USA - India – Volkswagen Passat, Chevrolet Cruze, Hyundai Sonata, Toyota Camry,…… – All Indian Vehicles – Jeep 11

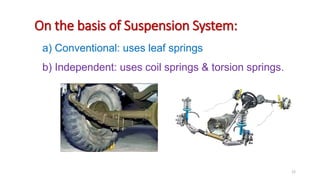

- 12. a) Conventional: uses leaf springs b) Independent: uses coil springs & torsion springs. On the basis of Suspension System: 12

- 13. Position of Engine a) Engine in Front • Most of the vehicles have engine in the front. • Example : most of the cars, buses, trucks in India. b) Engine in the Rear Side • Very few vehicles have engine located in the rear. • Example: Volkswagen Beetle 13

- 14. 14

- 15. 15

- 16. 16

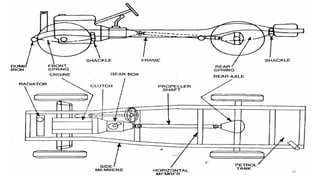

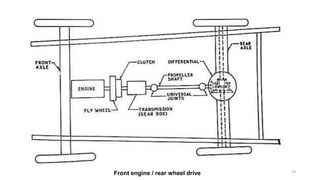

- 17. LAYOUT OF AUTOMOBILE & TYPES OF DRIVES OF AUTOMOBILES • The main parts of automobile are mounted on the chassis. • The layout of these components on the chassis are different in different types of vehicles, i.e., cars, jeeps, trucks, buses, etc. • The main difference in the layout of this chassis is the position of the engine. • The engine is located at the front of the vehicle, followed by a clutch, gear box, propeller shaft, universals joints, differential, rear axle, etc. • The radiator is located in front of the engine. Various other parts of the vehicle are dynamo, horn, steering box, fan, timing gear, carburetor, air filter, gear control, steering wheel, cylinder, petrol tank, rear axle, front axle. 17

- 18. 18

- 19. FUNCTIONS OF THE CHASSIS FRAME: 1. To carry load of the passengers or goods carried in the body. 2. To support the load of the body, engine, gear box etc., 3. To withstand the forces caused due to the sudden braking or acceleration 4. To withstand the stresses caused due to the bad road condition. 5. To withstand centrifugal force while cornering 19

- 20. TYPES OF CHASSIS FRAMES: There are three types of frames • Conventional frame • Integral frame • Semi-integral frame Conventional frame: It has two long side members and 5 to 6 cross members joined together with the help of rivets and bolts. The frame sections used are generally. a. Channel Section - Good resistance to bending b. Tabular Section - Good resistance to Torsion c. Box Section - Good resistance to both bending and Torsion 20

- 21. 21

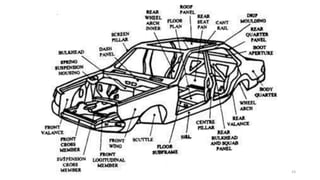

- 22. Integral Frame: • This frame is used now a days in most of the cars. • There is no frame and all the assembly units are attached to the body. • All the functions of the frame carried out by the body itself. • Due to elimination of long frame it is cheaper and due to less weight most economical also. • Only disadvantage is repairing is difficult. 22

- 23. 23

- 24. Semi - Integral Frame: In some vehicles half frame is fixed in the front end on which engine gear box and front suspension is mounted. It has the advantage when the vehicle is met with accident the front frame can be taken easily to replace the damaged chassis frame. This type of frame is used in FIAT cars and some of the European and American cars. 24

- 25. VARIOUS LOADS ACTING ON THE FRAME: ÔÉò Short duration Load - While crossing a broken patch. ÔÉò Momentary duration Load - While taking a curve. ÔÉò Impact Loads - Due to the collision of the vehicle. ÔÉò Inertia Load - While applying brakes. ÔÉò Static Loads - Loads due to chassis parts. ÔÉò Over Loads - Beyond Design capacity. 25

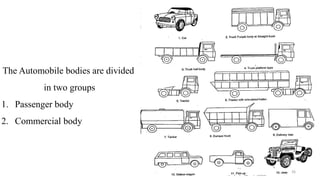

- 26. The Automobile bodies are divided in two groups 1. Passenger body 2. Commercial body 26

- 27. REQUIREMENTS OF BODIES FOR VARIOUS TYPES OF VECHILE: 1. The body should be light. 2. It should have minimum number of components. 3. It should provide sufficient space for passengers and luggage. 4. It should withstand vibrations while in motion. 5. It should offer minimum resistance to air. 6. It should be cheap and easy in manufacturing. 7. It should be attractive in shape and colour. 8. It should have long fatigue life 9.It should provide good vision and ventilation. 27

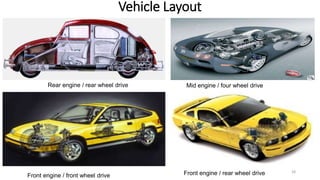

- 28. Vehicle Layout Rear engine / rear wheel drive Mid engine / four wheel drive Front engine / front wheel drive Front engine / rear wheel drive 28

- 29. Front engine / rear wheel drive 29

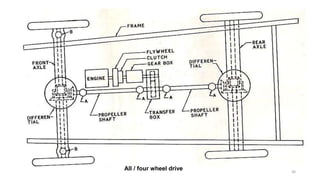

- 30. All / four wheel drive 30

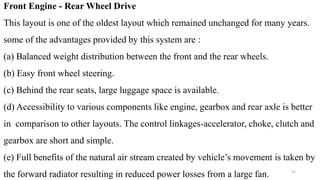

- 31. Front Engine - Rear Wheel Drive This layout is one of the oldest layout which remained unchanged for many years. some of the advantages provided by this system are : (a) Balanced weight distribution between the front and the rear wheels. (b) Easy front wheel steering. (c) Behind the rear seats, large luggage space is available. (d) Accessibility to various components like engine, gearbox and rear axle is better in comparison to other layouts. The control linkages-accelerator, choke, clutch and gearbox are short and simple. (e) Full benefits of the natural air stream created by vehicle’s movement is taken by the forward radiator resulting in reduced power losses from a large fan. 31

- 32. Rear Engine-Rear Wheel Drive • This arrangement eliminates the necessity for a propeller shaft when the engine is mounted adjacent to the driven wheels. • The engine-clutch-gear box-final drive form a single unit in this layout.. • Compared to FWD it has a simpler drive shaft layout. Further, the weight of rear engine on the driving wheels provides excellent traction and grip. • very effective rear wheel braking is possible. • Due to the absence of the propeller shaft the obstructed floor space is reduced. The front of the vehicle can, therefore, be designed for good visibility and smooth air flow. 32

- 33. • Natural air cooling is not possible, it requires a powerful fan. • Long linkage required for the engine, clutch and the gear box controls. • The rearward concentration of weight causes the vehicle to be more affected by side winds at high speeds. this makes the vehicle unstable resulting in over steering and turning very sharply into a curve. 33

- 34. Front Engine-Front Wheel Drive • This layout provides optimum body-luggage space and a flat floor • Provides good grip and good road holding on curves due to major weight at the front and chance of skidding on slippery surface is very much reduced. • when the vehicle is to be ‘steered in’ to the curve, it provides ‘understeer’ characteristics always preferred by drivers. • This requires special universal joints and a more complicated assembly. 34

- 35. Four Wheel Drive/ All Wheel Drive • Offer Excellent traction - both on dry pavement and in poor weather • Offer double the traction that is offered by 2WD systems • More weight and cost • Requires special service and maintenance • Braking distance is more because of more weight 35

- 36. Types of engines: Mainly engines are of two types. External Combustion Engines: The External Combustion Engines are those in which the combustion takes place outside the engine cylinder. E.g.: Steam Engine. Internal Combustion Engines: In the Internal Combustion Engines the combustion of fuel takes place inside the engine cylinder. E.g.: All Automobile Engines. Functions of I.C. Engine: Engine is that kind of prime mover which converts chemical energy of fuel into mechanical energy. The fuel on burning changes to gas which impinges upon the piston and pushes it to change into reciprocating motion. The reciprocating motion of piston is then converted to rotary motion of crank shaft with the help of slider mechanism involving connecting rod and crank shaft. 36

- 37. Classifications of I.C. Engines The I.C. Engine can be classified on the basis of 1. Working cycle: a. Otto cycle Engine or Spark Ignition Engine (S.I. Engine) b. Diesel Cycle Engine or Compression Ignition engine (C.I. Engine) 2. Number of strokes: a. Two Stroke engine, b. Four Stroke engine. 3. Fuel used: a. Liquefied petrol engines, b. Diesel engines, c. Gasoline or petrol, b. d. Compressed Natural gas engines, e. Methane or ethanol engines. 4. Fuel supply system: a. Fuel supply through carburetor, b. Fuel injected by Fuel injecting pump. 37

- 38. 5. Method of ignition: a. battery or coil ignition, b. Magneto ignition, c. Electronic ignition 6. Method of cooling: i) Air cooled, ii) Water cooled 7. Cylinder Arrangement: i) in line type, ii)V type, iii) Opposed cylinder type, iv)Radial type 8. Valve operating system: i) Overhead, ii) Side valve type 38

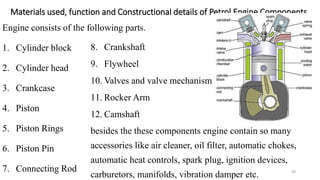

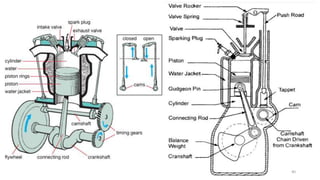

- 39. Materials used, function and Constructional details of Petrol Engine Components Engine consists of the following parts. 1. Cylinder block 2. Cylinder head 3. Crankcase 4. Piston 5. Piston Rings 6. Piston Pin 7. Connecting Rod 8. Crankshaft 9. Flywheel 10. Valves and valve mechanism 11. Rocker Arm 12. Camshaft besides the these components engine contain so many accessories like air cleaner, oil filter, automatic chokes, automatic heat controls, spark plug, ignition devices, carburetors, manifolds, vibration damper etc. 39

- 40. 40

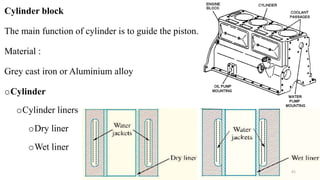

- 41. Cylinder block The main function of cylinder is to guide the piston. Material : Grey cast iron or Aluminium alloy oCylinder oCylinder liners oDry liner oWet liner 41

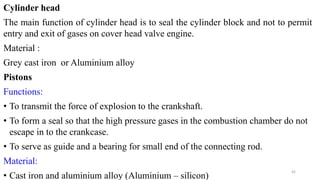

- 42. Cylinder head The main function of cylinder head is to seal the cylinder block and not to permit entry and exit of gases on cover head valve engine. Material : Grey cast iron or Aluminium alloy Pistons Functions: • To transmit the force of explosion to the crankshaft. • To form a seal so that the high pressure gases in the combustion chamber do not escape in to the crankcase. • To serve as guide and a bearing for small end of the connecting rod. Material: • Cast iron and aluminium alloy (Aluminium – silicon) 42

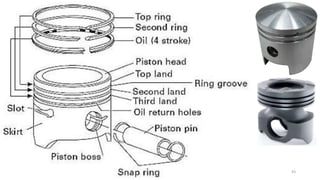

- 43. 43

- 44. Piston rings Functions: • Prevention of leakage of gas into the crank case. • Prevention of lubricating oil film • Prevention of lubricant entry into the combustion chamber above the piston head. • Easy transmission of heat from piston to cylinder wall. • Piston rings are made of cast iron of fine grain and high elastic material which is not affected by the working heat. Sometimes it is made by alloy spring steel. 44

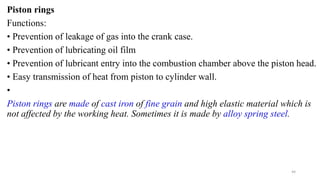

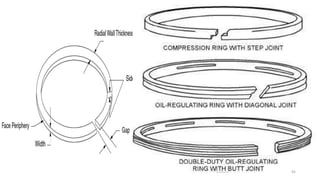

- 45. 45

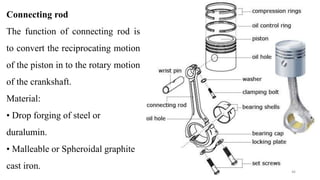

- 46. Connecting rod The function of connecting rod is to convert the reciprocating motion of the piston in to the rotary motion of the crankshaft. Material: • Drop forging of steel or duralumin. • Malleable or Spheroidal graphite cast iron. 46

- 47. Crank shaft The function of crank shaft is receives the efforts or thrust supplied by piston to the connecting rod and converts the reciprocating motion of piston into rotary motion of crankshaft Material: • Forging steel • Spheroidal graphitic • Nickel alloy castings 47

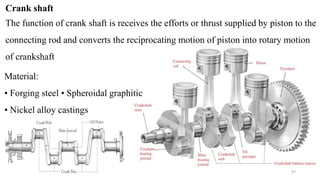

- 48. Crankcase (or) Oil sump (or) Oil pan The main body of the engine to which the cylinder are attached and which contains the crankshaft and crankshaft bearing is called crankcase. Function: • To store the oil for the engine lubricating system. • To collect the return oil draining from the main bearings or from the cylinder walls. • To serve as a container in which any impurities or foreign matter. • To provide for cooling of the hot oil in the sump by transfer of heat to the outside air stream. Material: • Pressed steel sheet or Aluminium alloy 48

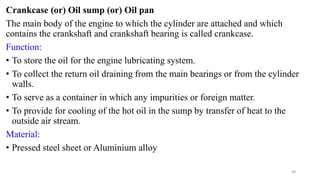

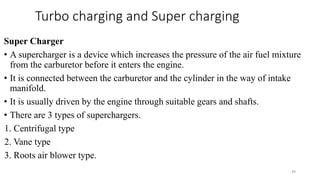

- 49. Turbo charging and Super charging Super Charger • A supercharger is a device which increases the pressure of the air fuel mixture from the carburetor before it enters the engine. • It is connected between the carburetor and the cylinder in the way of intake manifold. • It is usually driven by the engine through suitable gears and shafts. • There are 3 types of superchargers. 1. Centrifugal type 2. Vane type 3. Roots air blower type. 49

- 50. Purpose of supercharging • To reduce the weight per horsepower of the engine. • To minimize the space occupied by the engine. • To maintain the power of the engine even at high altitudes. • To improve power in a racing car. 50

- 51. Effects of Supercharging • A supercharger produces better mixing of the air-fuel mixture. • The temperature of the charge is raised as the charge is compressed in the supercharger. • The higher temperature tends to lessen the density of the charge. Also, the chances for detonation are highly increased. • Power is required to drive the supercharger. This power is usually supplied by the engine. Therefore, some of the gain in power due to supercharging is utilized by the supercharger. 51

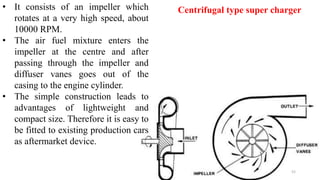

- 52. • It consists of an impeller which rotates at a very high speed, about 10000 RPM. • The air fuel mixture enters the impeller at the centre and after passing through the impeller and diffuser vanes goes out of the casing to the engine cylinder. • The simple construction leads to advantages of lightweight and compact size. Therefore it is easy to be fitted to existing production cars as aftermarket device. Centrifugal type super charger 52

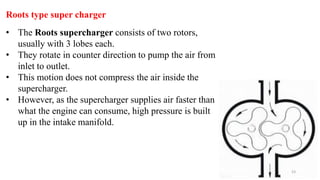

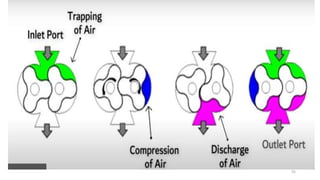

- 53. • The Roots supercharger consists of two rotors, usually with 3 lobes each. • They rotate in counter direction to pump the air from inlet to outlet. • This motion does not compress the air inside the supercharger. • However, as the supercharger supplies air faster than what the engine can consume, high pressure is built up in the intake manifold. Roots type super charger 53

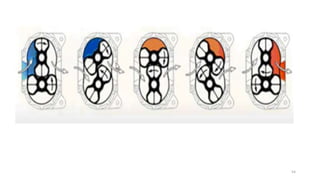

- 54. 54

- 55. 55

- 56. 56

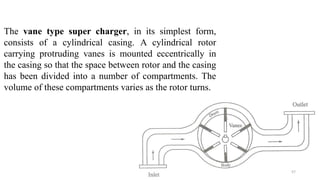

- 57. The vane type super charger, in its simplest form, consists of a cylindrical casing. A cylindrical rotor carrying protruding vanes is mounted eccentrically in the casing so that the space between rotor and the casing has been divided into a number of compartments. The volume of these compartments varies as the rotor turns. 57

- 58. 58

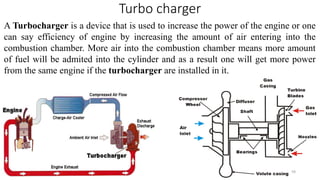

- 59. Turbo charger A Turbocharger is a device that is used to increase the power of the engine or one can say efficiency of engine by increasing the amount of air entering into the combustion chamber. More air into the combustion chamber means more amount of fuel will be admited into the cylinder and as a result one will get more power from the same engine if the turbocharger are installed in it. 59

- 60. • A turbocharger mainly consists of two main sections: the turbine and the compressor. • The turbine consists of turbine wheel and the turbine housing whose purpose is to guide the exhaust gases into the turbine wheel. • The kinetic energy of the exhaust gases gets converted into the mechanical energy after striking the turbine blades. • The exhaust outlet helps the exhaust gases to exit from the turbine. • The compressor wheel in turbocharger is attached to a turbine with the help of steel shaft. • As the turbine turns the compressor wheel, it draws the high-velocity, low pressure air stream and convert it into high-pressure, low –velocity air stream. • This compressed air is pushed into the engine with the more quantity of fuel and hence produce more power. 60

- 61. 61

- 62. 62

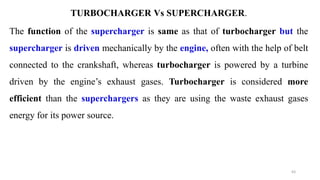

- 63. TURBOCHARGER Vs SUPERCHARGER. The function of the supercharger is same as that of turbocharger but the supercharger is driven mechanically by the engine, often with the help of belt connected to the crankshaft, whereas turbocharger is powered by a turbine driven by the engine’s exhaust gases. Turbocharger is considered more efficient than the superchargers as they are using the waste exhaust gases energy for its power source. 63

- 64. Engine lubrication Objects of lubrication 1. To reduce friction between the moving parts. 2. To reduce wear of the moving parts. 3. To act as cooling medium for removing heat. 4. To keep the engine parts clean 5. To form a good seal between piston rings and cylinder walls. 64

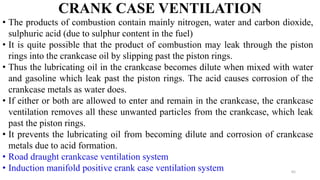

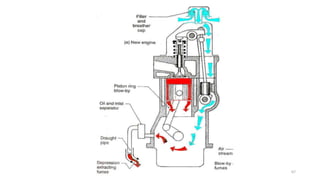

- 65. CRANK CASE VENTILATION • The products of combustion contain mainly nitrogen, water and carbon dioxide, sulphuric acid (due to sulphur content in the fuel) • It is quite possible that the product of combustion may leak through the piston rings into the crankcase oil by slipping past the piston rings. • Thus the lubricating oil in the crankcase becomes dilute when mixed with water and gasoline which leak past the piston rings. The acid causes corrosion of the crankcase metals as water does. • If either or both are allowed to enter and remain in the crankcase, the crankcase ventilation removes all these unwanted particles from the crankcase, which leak past the piston rings. • It prevents the lubricating oil from becoming dilute and corrosion of crankcase metals due to acid formation. • Road draught crankcase ventilation system • Induction manifold positive crank case ventilation system 65

- 66. • To remove gases and vapors from the crankcase and prevent their release into the environment. • such as unburned fuel and blow-by gases, can leak past the piston rings and enter the crankcase. These gases can contain harmful substances like hydrocarbons, carbon monoxide, and nitrogen oxides. 66

- 67. 67

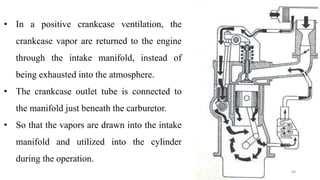

- 68. • In a positive crankcase ventilation, the crankcase vapor are returned to the engine through the intake manifold, instead of being exhausted into the atmosphere. • The crankcase outlet tube is connected to the manifold just beneath the carburetor. • So that the vapors are drawn into the intake manifold and utilized into the cylinder during the operation. 68

- 69. SERVICING OF ENGINE • Engine servicing is a method of engine reconditioning. In this method the old and worn engines are dismantled completely, repair and reassemble all the parts, Rebuild the engine, rebore the cylinders etc., and refit the engine. • For Servicing of an Engine, the following points are to be attended. 1. Cleaning the Engine, Reconditioning of Engine by Valve Servicing, Cylinder reboring, Crankshaft turning etc. 2. Servicing of Cooling System 3. Servicing of Lubrication System 4. Servicing of Fuel Supply System etc 69

- 70. • Degreasing /cleaning • A layer of oil, grease and dirt gets coated to the engine parts with passage of time and usage. The unwanted layer of grease dist etc., should be removed. • This can be done by hand cleaning or by means of certain cleaning methods. • For degreasing of smaller parts, the parts are being brushed or scrubbed with a stiff bristle brush to get rid of hard deposits. • Other dirty parts are placed in a large perforated tray or wire basket and exposed within a tank to the vapour of the heated Trichloroethylene. 70

- 71. • Decarbonization • Carbon is deposited in the cylinder due to rich mixture supply, use of wrong grade oil, unnecessary idling, poor fitted piston and piston rings. • Deposition of carbon causes Engine knockings,burnt value resulting in loss of power. • These are in general three methods of decarbonizing or decoking. 1) Scrapping method 2) Oxygen decarbonizing method 3) Chemical method of decarbonizing 71

- 72. Scrapping method : • The scrapping of the carbon is done by hand scrapping with the help of tools. • To remove the carbon quickly, carbon removing brushes may be fixed in the chuck of an electric portable drill. • To clean valve grinder, valve stems etc., special wire brushes may also be used. 72

- 73. Oxygen De-carbonizing method: • It is the process of removing carbon from the inside of the cylinder and head of the piston without removing cylinder head by means of an oxygen flame. • The equipment consists of an oxygen tank fitted at an initial pressure of 156 kg/cm² and an adjustable reducing valve for bringing the pressure down to 0.7 to 1.4 kg/cm². • The oxygen is applied to the combustion space by inserting a flexible delivery jet through a valve by slightly bending it. • The oxygen flame will burn away all the carbon deposits completely. 73

- 74. Chemical Method of De-carbonizing: • A special chemical is injected into the spark plug or injector hole in liquid form. The engine should be in warm condition so that the liquid can act more efficiently. • After twelve hours the carbon in loosened, so that upon starting the engine it is blown out of the exhaust pipe. 74

- 75. Chemical Cleaning: • Chemical cleaners can be used to dissolve carbon deposits in the engine. • These cleaners are typically added to the fuel or sprayed directly into the intake manifold or combustion chamber. • The chemicals react with the carbon, breaking it down and allowing it to be burned off during normal engine operation. 75

- 76. RECONDITIONING OF CYLINDER: • After prolonged usage of the engine, the cylinder of the engine will get maximum taper wear and ovality wear. • The Taper and Ovality wear will occur only after 40000 to 60000 kms run. • Generally the maximum permissible ovality is specified as 0.01 mm and taper as 0.25 mm. • Cylinder bores with less than 0.01 mm Ovality need not be rebored. They should only be Honed. 76

- 77. CYLINDER REBORING: • Reboring is done by the reboring machine in which a single point cutter which is set to exact diameter required with special micrometer. • The cutter blade shaft is mounted inside a column which moves up and down its housing in the fixed part of the machine for tool feeding purpose. • The top surface of the cylinder block is thoroughly cleaned and the boring bar set at one of the cylinder bores. • After completing boring the cylinder must be washed thoroughly to remove all abrasive particles. 77

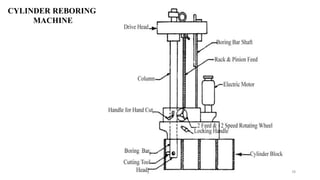

- 79. CYLINDER HONING METHOD: • After Reboring, Honing is required to finish the bore to smooth finish. • It removes minor imperfections and glaze. A hone consists of four or six narrow, narrow graded grinding stones mounted in cage around a spindle which rotated by an electric motor. • Place the Hone in the cylinder and expand the stones until the assembly can just be turned by hand and machine started. • Move the Hone up and down slowly with the first cut rough Hone up and down slowly with the first cut rough stones, but more rapidly with the finish cut five stones. 79

- 80. Honing 80

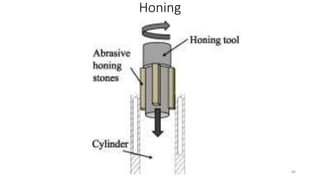

- 81. Nitriding of crank shaft • It is a surface modification processes developed industrially to improve the wear, corrosion and fatigue resistance of a steel. • Machine components such as crankshaft are subjected to alternating stresses and thus there is a requirement of good toughness but very hard and wear resistant surface. • To achieve this a process known as Nitriding is performed in which Nitrogen content is increased on the surface and hard nitrides are formed • The component is exposed to nitrogenous atmosphere or dipped into Nitriding salt bath • Some notable characteristics of the process are • No quenching is required • The component is needed to be heat treated before Nitriding is performed 81

- 82. • The cleaned crankshaft is placed in a sealed chamber, often referred to as a nitriding furnace or retort, which is capable of providing a controlled atmosphere for the process. • The crankshaft is heated to an elevated temperature, typically in the range of 500 to 600 degrees Celsius (932 to 1112 degrees Fahrenheit), in the presence of a nitrogen-rich atmosphere. This temperature range promotes the diffusion of nitrogen into the surface layer of the crankshaft material. 82

- 83. • During the heating process, nitrogen atoms diffuse into the surface layer of the crankshaft material. The nitrogen reacts with certain alloying elements, such as chromium and aluminum, present in the material, forming nitrides. These nitrides contribute to the increased hardness and wear resistance of the treated surface. • After the desired nitriding time has elapsed, the crankshaft is slowly cooled to ambient temperature within the nitriding chamber. Controlled cooling helps prevent distortion or cracking of the component. 83

Editor's Notes

- #2: An automobile is a wheeled vehicle carrying its own motive power unit

- #11: Conventional vehicles with manual transmission, e.g. car with 5 gears. In automatic transmission, gears are not required to be changed manually. It is automatically changes as per speed of the automobile.

- #12: Toyota Avalon, Volkswagen Passat, Chevrolet Cruze, Hyundai Sonata,Toyota Camry

- #14: if we look at high performance sports car,we can see most of their engines at rear portion but as usual cars we see engines at front portion.........except from normal cars what kind of benefit do the rear engine cars give us?????........like lamborghini,audi r8,posche 911,bugatti veyron Rear Wheel drive: Weight over the drive wheels - Benefit is increased traction, especially while accelerating Since the engine is typically the heaviest component of the car, putting it near the rear axle usually results in more weight over the rear axle than the front, commonly referred to as a rear weight bias. The farther back the engine, the greater the bias. Typical weight bias for an FR (front engine, rear drive), is 55/45 front/rear; for MR, 45/55; for RR, 35/65. Rear weight bias reduces forwardÃ˝weight transferÃ˝under braking, and increases rear weight transfer under acceleration. The former means that traction is more evenly distributed among all four wheels under braking, resulting in shorter stopping times and distances. The latter means that the driven wheels have increased traction when accelerating, allowing them to put more power on the ground and accelerate faster.

- #33: To reduce the ‘overhang’ distance between the wheel centres and the front of the engine, the final drive is generally placed between the clutch and the gear box.