Autonomous Maintenance Presentation

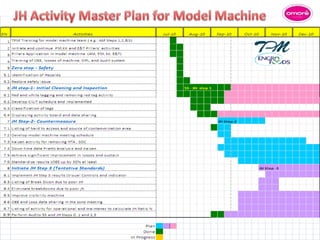

- 1. Autonomous Maintenance Step- 1 Activity on Model Machine Implementation of JH step-1 Initial Cleaning and Red Tagging in progress

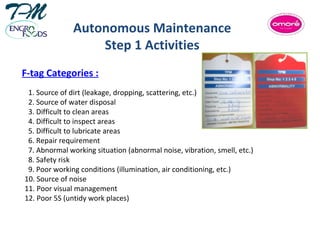

- 5. F-tag Categories : 1. Source of dirt (leakage, dropping, scattering, etc.) 2. Source of water disposal 3. Difficult to clean areas 4. Difficult to inspect areas 5. Difficult to lubricate areas 6. Repair requirement 7. Abnormal working situation (abnormal noise, vibration, smell, etc.) 8. Safety risk 9. Poor working conditions (illumination, air conditioning, etc.) 10. Source of noise 11. Poor visual management 12. Poor 5S (untidy work places) Autonomous Maintenance Step 1 Activities

- 6. ActivityActivity Autonomous Maintenance Step- 1 Activity Tags List and Machine Map Red Tag Map

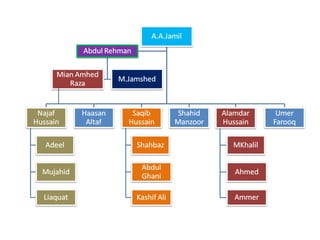

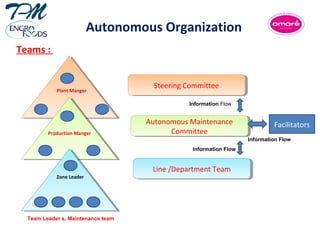

- 7. Teams : Autonomous Organization Steering CommitteeSteering Committee Plant Manger Production Manger Zone Leader Autonomous Maintenance Committee Autonomous Maintenance Committee Line /Department TeamLine /Department Team Information Flow Information Flow Facilitators Information Flow Team Leader s, Maintenance team

- 8. Autonomous Maintenance Step- 1 Red Tags Activity