Autosteering for RTG Cranes

- 1. SERVICE MACHINE TOOL SERVICE LIGHT LIFTING INDUSTRIAL CRANES PROCESS CRANES PORT CRANES LIFT TRUCKS YARD IT AutoSteering Always on the right track Autosteering for RTG Cranes

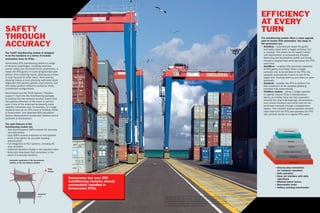

- 2. Efficiency at every Safety turn through The AutoSteering module offers a clean upgrade accuracy path for further RTG automation. Key steps to full automation are: ŌĆó utoStop ŌĆō automatically stops the gantry A and trolley travel when a target container slot The YardIT AutoSteering module is designed is reached. This allows for full speed motion to be the backbone in a series of modular until deceleration is automatically initiated. automation tools for RTGs. Optimizing the deceleration profile and timing through a programmed ramp decreases the RTG Konecranes RTG autosteering delivers a range cycle time. of decisive advantages, including improved ŌĆó utoMove ŌĆō enables fully automatic operation A worker safety and increased driver productivity. It of RTG gantry and trolley. When a target keeps the RTG gantry on a pre-programmed path container slot is transmitted to the RTG, the without driver steering inputs, allowing your driver spreader automatically moves on top of the to stay focused on other tasks. More precise target slot. Hoisting (both up and down) is semi- steering means a more precisely optimized stack automatic. alignment that permits greater stack density and ŌĆó utoGrab ŌĆō enables the RTG to perform the A also helps prevent collisions caused by loose, final movement of the spreader grabbing unpredicted configurations. container fully automatically. ŌĆó eleMove module ŌĆō allows a single operator T Konecranes has the RAAS feature (ŌĆ£Shadow- to operate several RTGs in teleoperation. supportŌĆØ) built into the AutoSteering-package. Gantry and trolley travel are fully automatic, In practice the two-antenna solution means that whereas the final hoist-lowering, micromotions, the position/direction of the crane is not lost lock/unlock functions and initial hoist lift are even if one of the antennae temporarily loses performed manually through a teleoperation satellite connection due, for example, to a large station. The remotely located operator receives obstacle such as an STS crane or building. RAAS video feed from the RTG and operates the RTG is KonecranesŌĆÖ own patented GPS-calculation with controls similar to a regular RTG cabin. feature (ReAcquisition Accelerator System) and is exclusive to Konecranes. The main features of the AutoSteering module are: ŌĆó win dual-frequency DGPS receiver for accuracy T Fully Automated and redundancy ŌĆó ual DGPS receiver antennas on the opposite D Remote Operation ends of the gantry for accurate heading determination AutoGrab ŌĆó ull integration to PLC systems, including AC F drive encoders AutoMove ŌĆó raphical deviation display in the operator cabin G ŌĆó Automatic slow-down/fast ramp-down in the AutoStop (Gantry & Trolley) event of excessive deviation TOS Interface Geometric superiority of the two-antenna solution vs the one-antenna solution AutoSteering Base ŌĆó Step-by-step automation station for container operators ŌĆó Safe operation ŌĆó Does not interfere with daily Konecranes has over 200 operations AutoSteering modules already ŌĆó Minimal labour issues successfully installed in ŌĆó Reasonable costs Konecranes RTGs. ŌĆó Utilizes existing investments Accuracy ┬▒ 1ŌĆØ This publication is for general informational purposes only. Konecranes reserves the right at any time, without notice, to alter or discontinue the products and/or specifications referenced herein. This publication creates no warranty on the part of Konecranes, express or implied, including but not limited to any implied warranty or merchantability or fitness for a particular purpose.

- 3. SERVICE MACHINE LIGHT INDUSTRIAL PROCESS PORT LIFT YARD IT TOOL LIFTING CRANES CRANES CRANES TRUCKS SERVICE Konecranes is a world-leading group of Lifting Businesses, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity-enhancing lifting solutions as well as services for lifting equipment and machine tools of all makes. In 2008, Group sales totaled EUR 2,103 million. The Group has 9,900 employees, at more than 485 locations in 43 countries. Konecranes is listed on the NASDAQ OMX Helsinki Ltd ┬Ā(symbol: KCR1V). ┬® 2009 Konecranes. All rights reserved. ŌĆśKonecranesŌĆÖ, ŌĆśLifting BusinessesŌĆÖ and ŌĆē ŌĆē are registered trademarks of Konecranes. VS 127D ATOMI/Kirjapaino ├¢hrling 7/2009 www.konecranes.com