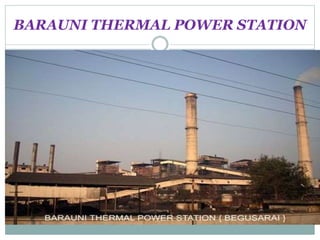

Barauni thermal power station

ŌĆóDownload as PPTX, PDFŌĆó

2 likesŌĆó1,372 views

this is a ppt based on Barauni thermal power station

1 of 20

Downloaded 223 times

Recommended

Barauni thermal power station

Barauni thermal power stationGulshan Singh

╠²

Barauni Thermal Power Station (BTPS) is a 320 megawatt coal-fired power plant in Begusarai, Bihar, India. It was established in 1962 through Russian collaboration. BTPS currently has 7 generating units, with 2 operating and producing 220 MW total, while units 5 and 7 undergo renovation. Coal is supplied from local mines and the plant is expanding to increase capacity to 500 MW in the next 5 years. BTPS converts the chemical energy of coal into electrical energy through steam turbines, and generates power for distribution in North Bihar.Training Report on Barauni Thermal Power Station

Training Report on Barauni Thermal Power StationGulshan Singh

╠²

This document provides details about a training report submitted by Gulshan Kumar Nirala at the Barauni Thermal Power Station in Begusarai, Bihar, India from July 2-31, 2014. It includes an introduction to the power station, which has a total generation capacity of 865 MW across various units commissioned between 1977-2013. It also discusses the site selection criteria for the power station including its location on the banks of the Ganga River near key transportation routes, the land acquired, and planned coal linkage. The report further describes the various systems at the power station including the coal handling plant, ash handling plant, boiler, steam turbine, turbo generator, cooling system, and main control room.AFBC Boilers, Losses discussions

AFBC Boilers, Losses discussionsManohar Tatwawadi

╠²

The presentation throws light on the AFBC boilers about the problems faced in the AFBC boilers, the fluidised bed problems and fuel partical sizing with the more overlooked air ingress losses.THERMAL POWER STATION PPT.

THERMAL POWER STATION PPT.Anish Anand

╠²

Barauni Thermal Power Station is a 320 megawatt coal-fired power station in Begusarai district, Bihar, India. It was established in 1962 through Russian collaboration. The power station currently has two operational units producing 220 MW total, while two new 500 MW units are under construction. Coal is supplied from nearby mines and the generated electricity is supplied to North Bihar. The power station aims to increase total capacity to 500 MW in the next five years through renovations.Power plant

Power plantShubham Gupta

╠²

The document summarizes the key components and mechanisms of a coal-based thermal power plant. The plant works on the basic Rankine cycle where coal is burned to produce steam that drives a turbine connected to a generator, producing electricity. The main components are the boiler, steam turbine, condenser, pumps, heaters, and other ancillary equipment. Coal is burned in the boiler to heat water and produce high-pressure steam to spin the turbine, which drives the generator and produces electricity. After working the turbine, the steam is condensed in the condenser and recycled to the boiler to repeat the process.Water steam Circuit in Supercritical Boiler for 660MW Power Plant

Water steam Circuit in Supercritical Boiler for 660MW Power PlantHareesh VS

╠²

An animated presentation over Complete water steam circulation in a super critical boiler with flow chart. The water-steam path through various Systems (High pressure & Low pressure systems) in boiler for a 660MW thermal power plat, and also indicates the temperature and pressure variations after flowing through individual systems. Watch Live Presentation on YouTube: http://youtu.be/snIVrTmI4bMNtpc report

Ntpc report vipinchaudhary45

╠²

This document provides an overview of NTPC Ltd Tanda power plant located in Uttar Pradesh, India. It thanks various individuals for their support during a training program at the plant. It then provides details about the plant's history, operations, equipment, and processes. The 440MW plant uses coal to produce steam that spins turbines to generate electricity, which is then transmitted to various locations. The document outlines the basic thermal power generation process and describes the key components and subsystems used at the Tanda plant.1st scm hw

1st scm hwshinyeonjae

╠²

scm ņ▓½ ļ▓łņ¦Ė Ļ│╝ņĀ£ļĪ£ ņŖżĒīīĻ▓īĒŗ░ ņżæ 1ņ£ä ĻĖ░ņŚģņØĖ ļ░öļ”┤ļØ╝ņé¼ņØś ĒśäĒÖ®Ļ│╝ ļ¼ĖņĀ£ņĀÉ ļ░Å ĒĢ┤Ļ▓░ ļ░®ņĢłņØä ņĀ£ņŗ£ĒĢ┤ļ┤żņŖĄļŗłļŗż.BHEL Project

BHEL ProjectSiddhartha singh jadaun

╠²

This document provides a summary report on a summer training project at Bharat Heavy Electricals Limited (BHEL) focusing on pneumatic braking systems. It includes an introduction to BHEL, acknowledgments, contents, and sections on locomotive brakes, pneumatic functions, equipment, air systems, and specific brake valves. BHEL is one of the largest engineering companies in India that manufactures power and industrial equipment. The report examines pneumatic braking systems used on locomotives produced at the BHEL facility in Jhansi. It provides technical details on the components, operation, and functions of the pneumatic braking system.6 weeks it on ntpc

6 weeks it on ntpc Uttam Kumar

╠²

The document provides an overview of the coal handling plant (CHP) at the Nabinagar Power Generating Company located in Bihar, India. The CHP processes 5 million tonnes of coal per year received via wagons to supply coal bunkers for boiler operations at the power plant. The CHP includes a wagon tippler, crushers, conveyor belts, vibrating screens, and bunkers to receive, crush, transport, and store coal prior to feeding the coal mills and furnaces. The document also discusses the transportation, storage, grading, and utilization of coal in thermal power plants in India.High pressure boilers 050,18,48

High pressure boilers 050,18,48Maharshi Soni

╠²

Steam boiler is a closed vessel in which heat produced by the combustion of fuel is utilized to generate steam from water, at desired temperature and pressure

Mini project ppt on working of steam turbine and its auxiliaries

Mini project ppt on working of steam turbine and its auxiliariesjyotishmathi college

╠²

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884. Heat & Mass Balance PPT in cement industry version 2.0.pdf

Heat & Mass Balance PPT in cement industry version 2.0.pdfNITIN ASNANI

╠²

Updated the Heat & Mass balance module regarding cement Industry

Useful For:-

1) Energy Auditors

2) Process Engineers

3) Chemical Engineers

Combustion in a CFBC Boiler

Combustion in a CFBC BoilerTapash Nag

╠²

The presentation deals with the most complex and fundamental process in a CFBC boiler. i.e., Combustion. Provides an insight into the various features in a CFBC boilers which are incorporated to enhance cpmbustion.Coal Handling Plant

Coal Handling PlantVIVEK TOMAR

╠²

Coal is the primary fuel for electricity production in India, accounting for over 60% of installed generation capacity. Coal is transported to power plants by rail, road, or conveyor belt and stored in stockyards to ensure continuous supply to boilers. The Talwandi Sabo Power Limited plant has an installed capacity of 4,620 MW and a coal handling system designed to receive, stockpile, and feed 2500 tons of coal per hour to the boilers. The system includes wagon tipplers, several types of conveyors, transfer towers, crushers, screens, a stacker-reclaimer, samplers, and other components to efficiently transport and store the 10 lakh ton coal capacity needed to power the plantSeal Oil System.pptx

Seal Oil System.pptxSaravananKumar264695

╠²

The document discusses the need for and components of a seal oil system for generators cooled with hydrogen. The key points are:

1) Seal oil systems use oil to maintain pressure higher than hydrogen pressure to prevent hydrogen leakage from generator shafts.

2) The system includes oil pumps, filters, regulating valves, tanks, and other equipment to circulate oil between the generator seals and vacuum/holding tanks where gas is extracted from the oil.

3) Proper operation and maintenance of the seal oil system is important to ensure differential pressure is maintained between the oil and hydrogen inside the generator.Design of cannal by Kennedy Theory full problem solved

Design of cannal by Kennedy Theory full problem solvedEr. Gurmeet Singh

╠²

Design of cannal by Kennedy Theory

By Er Gurmeet Singh

G.C.E.T JAMMU

CONTACT: Gurmeet.b.tech@gmail.com

Studio Apartment- Concept and Planning Requirements.pptx

Studio Apartment- Concept and Planning Requirements.pptxSamirsinh Parmar

╠²

Studio Apartment;

Micro Apartment;

Convertible Apartment;

Concept of Studio Apartment;

Planning requirements;

Building components: Studio;

Studio apartment components;

Studio apartment requirements;

Innovation possible;

Smart furniture design;

Foldable furniture;

Unit2_Linear Regression_Performance Metrics.pdf

Unit2_Linear Regression_Performance Metrics.pdfRAMESHWAR CHINTAMANI

╠²

Linear Regression, Logistic Regression, Ridge Regression, Lasso Regression,

Polynomial Regression Types of Regression, performance metrics Mean Squared Error

(MSE), Root Mean Squared Error (RMSE), Mean Absolute Error (MAE), R2 (R-

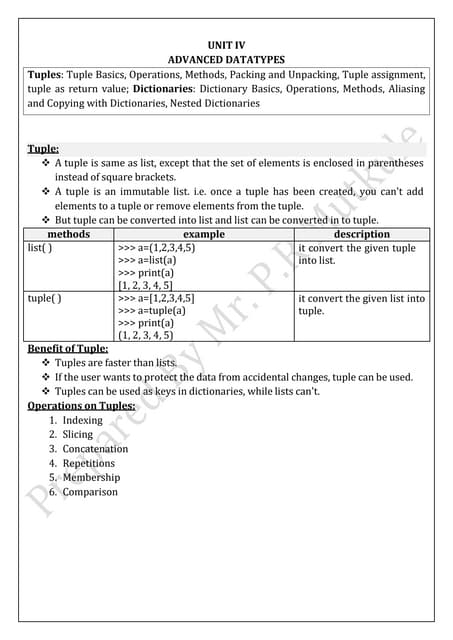

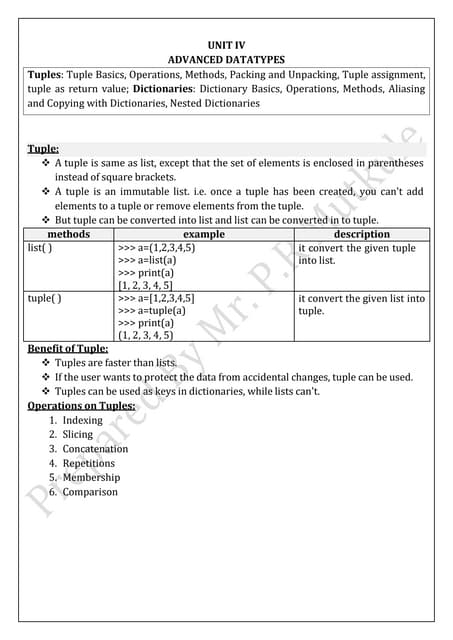

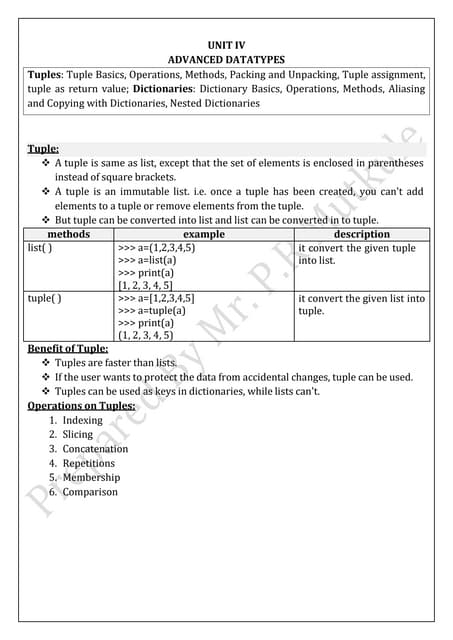

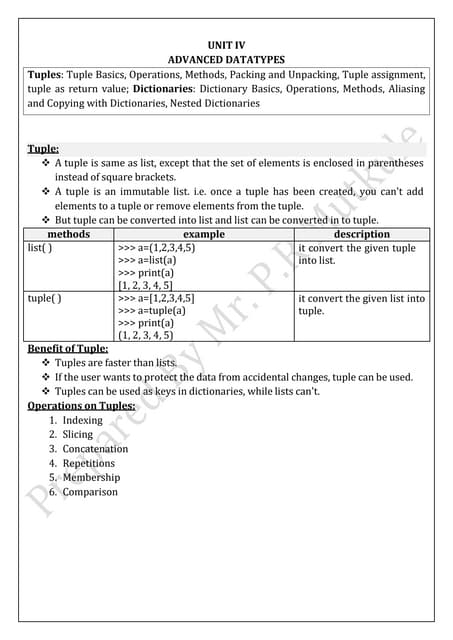

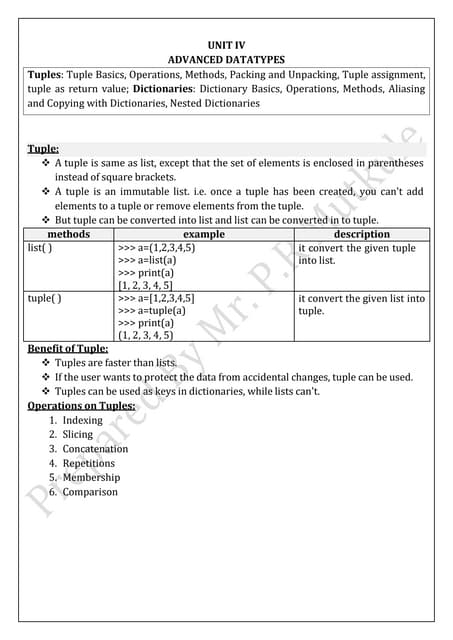

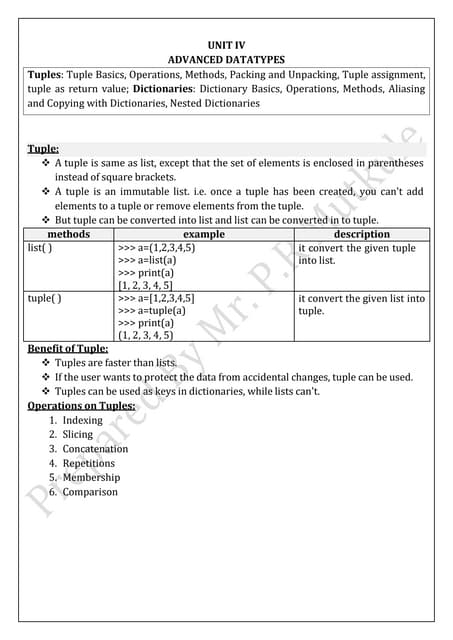

Squared)ESIT135 Problem Solving Using Python Notes of Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-3prasadmutkule1

╠²

ESIT135 Problem Solving Using Python Notes of Unit-3 Thermal Insulation In Residential Buildings.pptx

Thermal Insulation In Residential Buildings.pptxSamirsinh Parmar

╠²

Thermal Isulation;

Thermal Insulation materials;

Types of thermal insulation;

methods of thermal insulation;

materials for thermal insulation;

Various treatments- thermal insulating;

Bivariate Random Variable Correlation Analysis

Bivariate Random Variable Correlation Analysisshyamalaseec

╠²

Correlation analysis measures the strength and direction of a linear relationship between two quantitative variables. It produces a correlation coefficient (e.g., Pearson's r) that ranges from -1 to +1, indicating the degree to which the variables change together. A positive correlation implies variables increase or decrease in tandem, while a negative correlation suggests they move inversely. ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2prasadmutkule1

╠²

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2Defining the Future of Biophilic Design in Crete.pdf

Defining the Future of Biophilic Design in Crete.pdfARENCOS

╠²

Biophilic design is emerging as a key approach to enhancing well-being by integrating natural elements into residential architecture. In Crete, where the landscape is rich with breathtaking sea views, lush olive groves, and dramatic mountains, biophilic design principles can be seamlessly incorporated to create healthier, more harmonious living environments.

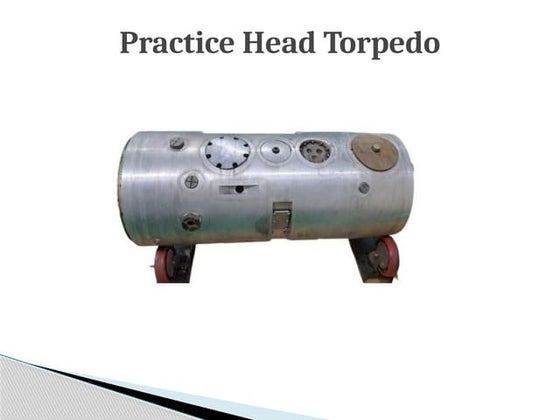

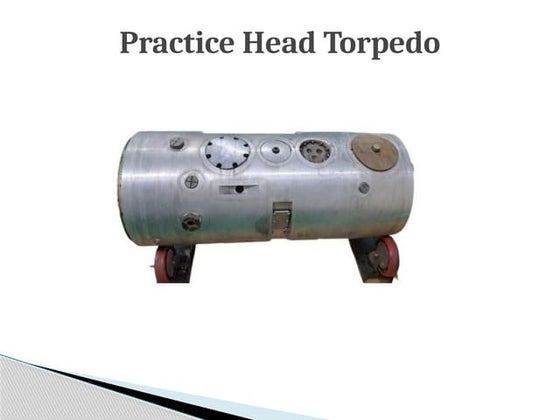

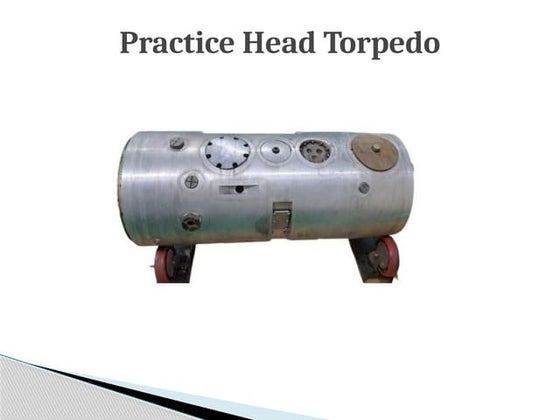

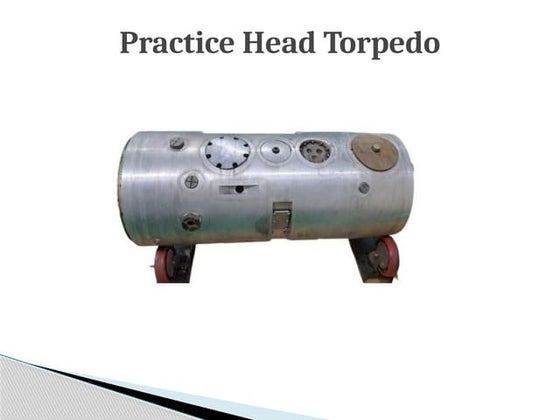

Practice Head Torpedo - Neometrix Defence.pptx

Practice Head Torpedo - Neometrix Defence.pptxNeometrix_Engineering_Pvt_Ltd

╠²

About

Practice Head is assembled with Practice Torpedo intended for carrying out exercise firings. It is assembled with Homing Head in the forward section and oxygen flask in the rear section. Practice Head imparts positive buoyancy to the Torpedo at the end of run. The Practice Head is divided into two compartments viz. Ballast Compartment (Houses Light Device, Depth & Roll Recorder, Signal Flare Ejector, Discharge Valve, Stop Cock, Water discharge Valve, Bellow reducing Valve, Release Mechanism, Recess, Bypass Valve, Pressure Equalizer, Float, Sinking Plug etc.) which provides positive buoyancy at the end of run by discharging water (140 ltrs.) filled in the compartment and Instrument compartment (dry), houses (safety & recovery unit and its battery, combined homing and influence exploder equipment, noise maker, bollards & safety valve etc.) The recess in Ballast compartment houses the float which gets inflated at the end of run to provide floatation to the surfaced Torpedo. Several hand holes/recesses are provided on the casing/shell of Practice Head for assembly of the following components:-

a) Signal Flare Ejector Assembly

b) Depth and Roll Recorder Assembly

c) Light Device

d) Pressure equalizer

e) Drain/Discharge Valve assembly

f) Bollard Assembly

g) Holding for Floater/Balloon Assembly

h) Sinking Valve

i) Safety Valve

j) Inspection hand hole

Technical Details:

SrNo Items Specifications

1 Aluminum Alloy (AlMg5)

Casing Body Material: AlMg5

ŌĆó Larger Outer Diameter of the Casing: 532.4 MM

ŌĆó Smaller Outer Diameter of the Casing: 503.05 MM

ŌĆó Total Length: 1204.20 MM

ŌĆó Thickness: 6-8 mm

ŌĆó Structural Details of Casing: The casing is of uniform outer dia for a certain distance from rear side and tapered from a definite distance to the front side. (Refer T-DAP-A1828-GADWG-PH- REV 00)

ŌĆó Slope of the Tapered Portion: 1/8

ŌĆó Mass of Casing (Without components mounting, but including the ribs and collars on the body): 58.5 kg

ŌĆó Maximum External Test Pressure: 12 kgf/cm2

ŌĆó Maximum Internal Test Pressure:-

i. For Ballast Compartment: 2 kgf/cm2

ii. For Instrument Compartment: 1 kgf/cm2

ŌĆó Innerspace of casing assembly have 2 compartments:-

i. Ballast Compartment and

ii. Instrument Compartment

ŌĆó Cut outs/ recesses shall be provided for the assembly of following components.

a) Signal Flare Ejector Assembly

b) Depth and Roll Recorder Assembly

c) Light Device

d) Pressure Equalizer

e) Drain/ discharge valve assembly

2 Front Side Collar Material: AlMg5

ŌĆó Maximum Outer Diameter: 500 MM

ŌĆó Pitch Circle Diameter: 468 MM

ŌĆó All Dimensions as per drawing T-DAP-A1828-MDWG-C&R-REV-00

Application:

In a torpedo, the ballast components and instrument compartment play crucial roles in maintaining stability, control, and overall operational effectiveness. The ballast system primarily manages buoyancy and trim, ensuring that the torpedo maintains a stable trajectory underwater.More Related Content

What's hot (9)

BHEL Project

BHEL ProjectSiddhartha singh jadaun

╠²

This document provides a summary report on a summer training project at Bharat Heavy Electricals Limited (BHEL) focusing on pneumatic braking systems. It includes an introduction to BHEL, acknowledgments, contents, and sections on locomotive brakes, pneumatic functions, equipment, air systems, and specific brake valves. BHEL is one of the largest engineering companies in India that manufactures power and industrial equipment. The report examines pneumatic braking systems used on locomotives produced at the BHEL facility in Jhansi. It provides technical details on the components, operation, and functions of the pneumatic braking system.6 weeks it on ntpc

6 weeks it on ntpc Uttam Kumar

╠²

The document provides an overview of the coal handling plant (CHP) at the Nabinagar Power Generating Company located in Bihar, India. The CHP processes 5 million tonnes of coal per year received via wagons to supply coal bunkers for boiler operations at the power plant. The CHP includes a wagon tippler, crushers, conveyor belts, vibrating screens, and bunkers to receive, crush, transport, and store coal prior to feeding the coal mills and furnaces. The document also discusses the transportation, storage, grading, and utilization of coal in thermal power plants in India.High pressure boilers 050,18,48

High pressure boilers 050,18,48Maharshi Soni

╠²

Steam boiler is a closed vessel in which heat produced by the combustion of fuel is utilized to generate steam from water, at desired temperature and pressure

Mini project ppt on working of steam turbine and its auxiliaries

Mini project ppt on working of steam turbine and its auxiliariesjyotishmathi college

╠²

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884. Heat & Mass Balance PPT in cement industry version 2.0.pdf

Heat & Mass Balance PPT in cement industry version 2.0.pdfNITIN ASNANI

╠²

Updated the Heat & Mass balance module regarding cement Industry

Useful For:-

1) Energy Auditors

2) Process Engineers

3) Chemical Engineers

Combustion in a CFBC Boiler

Combustion in a CFBC BoilerTapash Nag

╠²

The presentation deals with the most complex and fundamental process in a CFBC boiler. i.e., Combustion. Provides an insight into the various features in a CFBC boilers which are incorporated to enhance cpmbustion.Coal Handling Plant

Coal Handling PlantVIVEK TOMAR

╠²

Coal is the primary fuel for electricity production in India, accounting for over 60% of installed generation capacity. Coal is transported to power plants by rail, road, or conveyor belt and stored in stockyards to ensure continuous supply to boilers. The Talwandi Sabo Power Limited plant has an installed capacity of 4,620 MW and a coal handling system designed to receive, stockpile, and feed 2500 tons of coal per hour to the boilers. The system includes wagon tipplers, several types of conveyors, transfer towers, crushers, screens, a stacker-reclaimer, samplers, and other components to efficiently transport and store the 10 lakh ton coal capacity needed to power the plantSeal Oil System.pptx

Seal Oil System.pptxSaravananKumar264695

╠²

The document discusses the need for and components of a seal oil system for generators cooled with hydrogen. The key points are:

1) Seal oil systems use oil to maintain pressure higher than hydrogen pressure to prevent hydrogen leakage from generator shafts.

2) The system includes oil pumps, filters, regulating valves, tanks, and other equipment to circulate oil between the generator seals and vacuum/holding tanks where gas is extracted from the oil.

3) Proper operation and maintenance of the seal oil system is important to ensure differential pressure is maintained between the oil and hydrogen inside the generator.Recently uploaded (20)

Design of cannal by Kennedy Theory full problem solved

Design of cannal by Kennedy Theory full problem solvedEr. Gurmeet Singh

╠²

Design of cannal by Kennedy Theory

By Er Gurmeet Singh

G.C.E.T JAMMU

CONTACT: Gurmeet.b.tech@gmail.com

Studio Apartment- Concept and Planning Requirements.pptx

Studio Apartment- Concept and Planning Requirements.pptxSamirsinh Parmar

╠²

Studio Apartment;

Micro Apartment;

Convertible Apartment;

Concept of Studio Apartment;

Planning requirements;

Building components: Studio;

Studio apartment components;

Studio apartment requirements;

Innovation possible;

Smart furniture design;

Foldable furniture;

Unit2_Linear Regression_Performance Metrics.pdf

Unit2_Linear Regression_Performance Metrics.pdfRAMESHWAR CHINTAMANI

╠²

Linear Regression, Logistic Regression, Ridge Regression, Lasso Regression,

Polynomial Regression Types of Regression, performance metrics Mean Squared Error

(MSE), Root Mean Squared Error (RMSE), Mean Absolute Error (MAE), R2 (R-

Squared)ESIT135 Problem Solving Using Python Notes of Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-3prasadmutkule1

╠²

ESIT135 Problem Solving Using Python Notes of Unit-3 Thermal Insulation In Residential Buildings.pptx

Thermal Insulation In Residential Buildings.pptxSamirsinh Parmar

╠²

Thermal Isulation;

Thermal Insulation materials;

Types of thermal insulation;

methods of thermal insulation;

materials for thermal insulation;

Various treatments- thermal insulating;

Bivariate Random Variable Correlation Analysis

Bivariate Random Variable Correlation Analysisshyamalaseec

╠²

Correlation analysis measures the strength and direction of a linear relationship between two quantitative variables. It produces a correlation coefficient (e.g., Pearson's r) that ranges from -1 to +1, indicating the degree to which the variables change together. A positive correlation implies variables increase or decrease in tandem, while a negative correlation suggests they move inversely. ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2prasadmutkule1

╠²

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2Defining the Future of Biophilic Design in Crete.pdf

Defining the Future of Biophilic Design in Crete.pdfARENCOS

╠²

Biophilic design is emerging as a key approach to enhancing well-being by integrating natural elements into residential architecture. In Crete, where the landscape is rich with breathtaking sea views, lush olive groves, and dramatic mountains, biophilic design principles can be seamlessly incorporated to create healthier, more harmonious living environments.

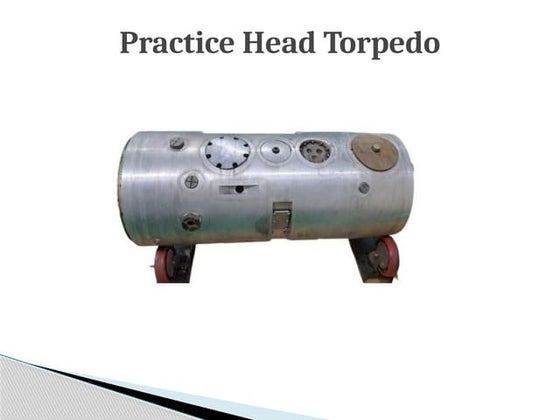

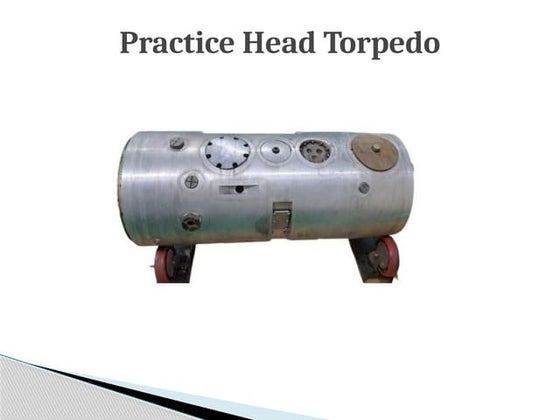

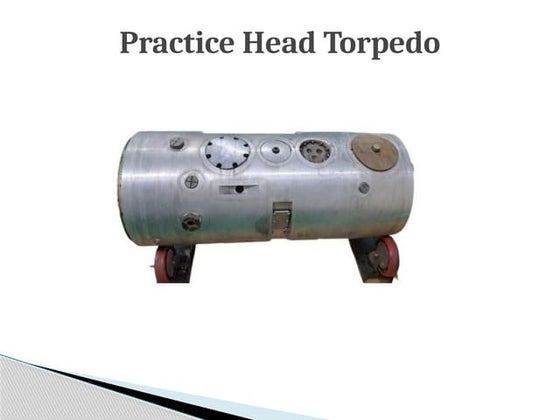

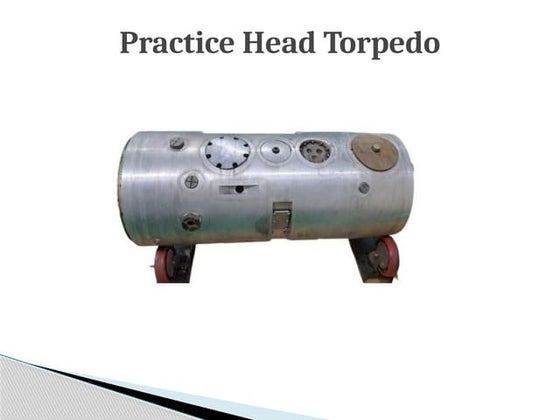

Practice Head Torpedo - Neometrix Defence.pptx

Practice Head Torpedo - Neometrix Defence.pptxNeometrix_Engineering_Pvt_Ltd

╠²

About

Practice Head is assembled with Practice Torpedo intended for carrying out exercise firings. It is assembled with Homing Head in the forward section and oxygen flask in the rear section. Practice Head imparts positive buoyancy to the Torpedo at the end of run. The Practice Head is divided into two compartments viz. Ballast Compartment (Houses Light Device, Depth & Roll Recorder, Signal Flare Ejector, Discharge Valve, Stop Cock, Water discharge Valve, Bellow reducing Valve, Release Mechanism, Recess, Bypass Valve, Pressure Equalizer, Float, Sinking Plug etc.) which provides positive buoyancy at the end of run by discharging water (140 ltrs.) filled in the compartment and Instrument compartment (dry), houses (safety & recovery unit and its battery, combined homing and influence exploder equipment, noise maker, bollards & safety valve etc.) The recess in Ballast compartment houses the float which gets inflated at the end of run to provide floatation to the surfaced Torpedo. Several hand holes/recesses are provided on the casing/shell of Practice Head for assembly of the following components:-

a) Signal Flare Ejector Assembly

b) Depth and Roll Recorder Assembly

c) Light Device

d) Pressure equalizer

e) Drain/Discharge Valve assembly

f) Bollard Assembly

g) Holding for Floater/Balloon Assembly

h) Sinking Valve

i) Safety Valve

j) Inspection hand hole

Technical Details:

SrNo Items Specifications

1 Aluminum Alloy (AlMg5)

Casing Body Material: AlMg5

ŌĆó Larger Outer Diameter of the Casing: 532.4 MM

ŌĆó Smaller Outer Diameter of the Casing: 503.05 MM

ŌĆó Total Length: 1204.20 MM

ŌĆó Thickness: 6-8 mm

ŌĆó Structural Details of Casing: The casing is of uniform outer dia for a certain distance from rear side and tapered from a definite distance to the front side. (Refer T-DAP-A1828-GADWG-PH- REV 00)

ŌĆó Slope of the Tapered Portion: 1/8

ŌĆó Mass of Casing (Without components mounting, but including the ribs and collars on the body): 58.5 kg

ŌĆó Maximum External Test Pressure: 12 kgf/cm2

ŌĆó Maximum Internal Test Pressure:-

i. For Ballast Compartment: 2 kgf/cm2

ii. For Instrument Compartment: 1 kgf/cm2

ŌĆó Innerspace of casing assembly have 2 compartments:-

i. Ballast Compartment and

ii. Instrument Compartment

ŌĆó Cut outs/ recesses shall be provided for the assembly of following components.

a) Signal Flare Ejector Assembly

b) Depth and Roll Recorder Assembly

c) Light Device

d) Pressure Equalizer

e) Drain/ discharge valve assembly

2 Front Side Collar Material: AlMg5

ŌĆó Maximum Outer Diameter: 500 MM

ŌĆó Pitch Circle Diameter: 468 MM

ŌĆó All Dimensions as per drawing T-DAP-A1828-MDWG-C&R-REV-00

Application:

In a torpedo, the ballast components and instrument compartment play crucial roles in maintaining stability, control, and overall operational effectiveness. The ballast system primarily manages buoyancy and trim, ensuring that the torpedo maintains a stable trajectory underwater.Indian Soil Classification System in Geotechnical Engineering

Indian Soil Classification System in Geotechnical EngineeringRajani Vyawahare

╠²

This PowerPoint presentation provides a comprehensive overview of the Indian Soil Classification System, widely used in geotechnical engineering for identifying and categorizing soils based on their properties. It covers essential aspects such as particle size distribution, sieve analysis, and Atterberg consistency limits, which play a crucial role in determining soil behavior for construction and foundation design. The presentation explains the classification of soil based on particle size, including gravel, sand, silt, and clay, and details the sieve analysis experiment used to determine grain size distribution. Additionally, it explores the Atterberg consistency limits, such as the liquid limit, plastic limit, and shrinkage limit, along with a plasticity chart to assess soil plasticity and its impact on engineering applications. Furthermore, it discusses the Indian Standard Soil Classification (IS 1498:1970) and its significance in construction, along with a comparison to the Unified Soil Classification System (USCS). With detailed explanations, graphs, charts, and practical applications, this presentation serves as a valuable resource for students, civil engineers, and researchers in the field of geotechnical engineering. Renewable-Energy-Powering-Mozambiques-Economic-Growth.pptx

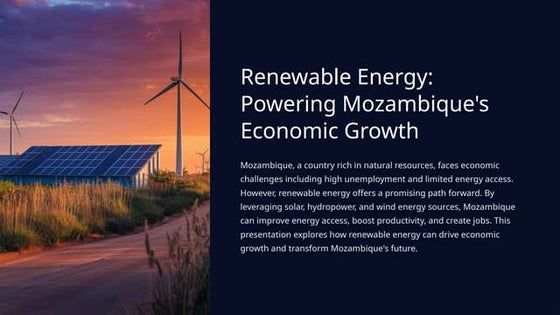

Renewable-Energy-Powering-Mozambiques-Economic-Growth.pptxRofino Licuco

╠²

Mozambique, a country with vast natural resources and immense potential, nevertheless faces several economic challenges, including high unemployment, limited access to energy, and an unstable power supply. Underdeveloped infrastructure has slowed the growth of industry and hampered peopleŌĆÖs entrepreneurial ambitions, leaving many regions in the darkŌĆöliterally and figuratively.

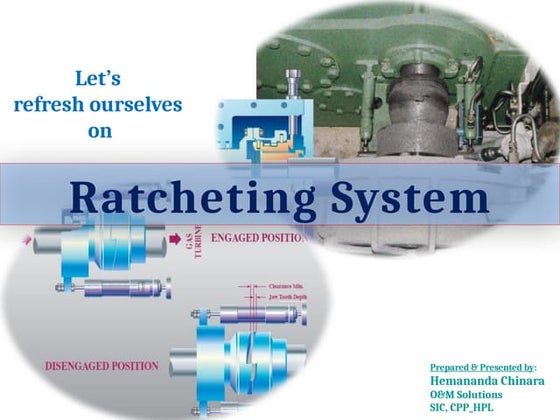

https://www.rofinolicuco.net/blog/how-renewable-energy-can-help-mozambique-grow-its-economyGE 6B GT Ratcheting Animation- Hemananda Chinara.ppsx

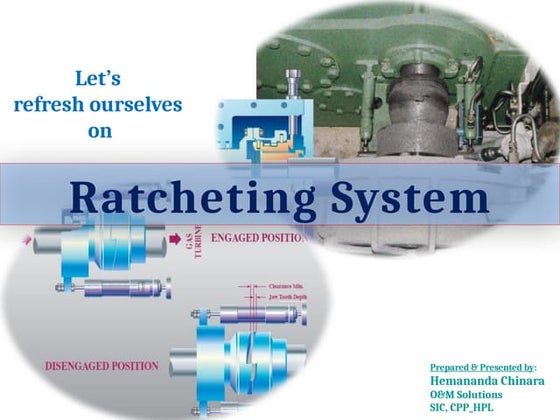

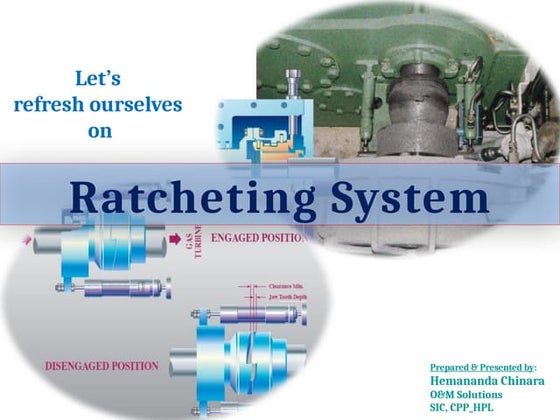

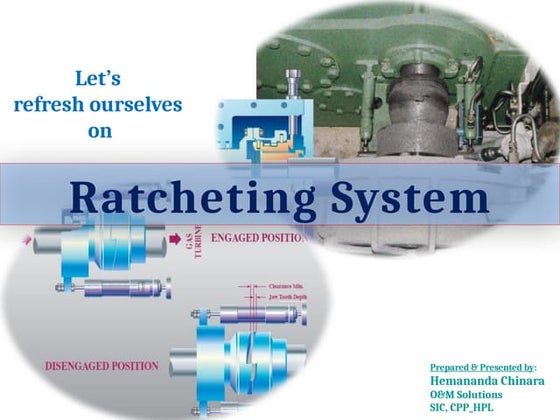

GE 6B GT Ratcheting Animation- Hemananda Chinara.ppsxHemananda Chinara

╠²

GE 6B Gas Turbine Ratcheting Mechanism Animation made by Hemananda Chinara, SIC, CPP, HPL.slides of Fluid Mechanics for Chemical Engineers

slides of Fluid Mechanics for Chemical Engineerszaidullahkhan2003

╠²

fluid for chemical engineering introduction lectureDesign and Analysis of Algorithms Unit 5

Design and Analysis of Algorithms Unit 5sureshkumara29

╠²

Algorithm design techniques include:

Brute Force

Greedy Algorithms

Divide-and-Conquer

Dynamic Programming

Reduction / Transform-and-Conquer

Backtracking and Branch-and-Bound

Randomization

Approximation

Recursive Approach

What is an algorithm?

An Algorithm is a procedure to solve a particular problem in a finite number of steps for a finite-sized input.

The algorithms can be classified in various ways. They are:

Implementation Method

Design Method

Design Approaches

Other Classifications

In this article, the different algorithms in each classification method are discussed.

The classification of algorithms is important for several reasons:

Organization: Algorithms can be very complex and by classifying them, it becomes easier to organize, understand, and compare different algorithms.

Problem Solving: Different problems require different algorithms, and by having a classification, it can help identify the best algorithm for a particular problem.

Performance Comparison: By classifying algorithms, it is possible to compare their performance in terms of time and space complexity, making it easier to choose the best algorithm for a particular use case.

Reusability: By classifying algorithms, it becomes easier to re-use existing algorithms for similar problems, thereby reducing development time and improving efficiency.

Research: Classifying algorithms is essential for research and development in computer science, as it helps to identify new algorithms and improve existing ones.

Overall, the classification of algorithms plays a crucial role in computer science and helps to improve the efficiency and effectiveness of solving problems.

Classification by Implementation Method: There are primarily three main categories into which an algorithm can be named in this type of classification. They are:

Recursion or Iteration: A recursive algorithm is an algorithm which calls itself again and again until a base condition is achieved whereas iterative algorithms use loops and/or data structures like stacks, queues to solve any problem. Every recursive solution can be implemented as an iterative solution and vice versa.

Example: The Tower of Hanoi is implemented in a recursive fashion while Stock Span problem is implemented iteratively.

Exact or Approximate: Algorithms that are capable of finding an optimal solution for any problem are known as the exact algorithm. For all those problems, where it is not possible to find the most optimized solution, an approximation algorithm is used. Approximate algorithms are the type of algorithms that find the result as an average outcome of sub outcomes to a problem.

Example: For NP-Hard Problems, approximation algorithms are used. Sorting algorithms are the exact algorithms.

Serial or Parallel or Distributed Algorithms: In serial algorithms, one instruction is executed at a time while parallel algorithms are those in which we divide the problem into subproblems and execute them on different processors. PPT of Interpolation for Newtons forward.pptx

PPT of Interpolation for Newtons forward.pptxshyamalaseec

╠²

Newton's forward interpolation is a method for estimating values within a range of discrete data points. It uses forward differences to construct a polynomial that approximates the function represented by the data. This polynomial is then used to interpolate values at points between the given data points, particularly useful for estimations near the beginning of the dataset.Barauni thermal power station

- 1. BARAUNI THERMAL POWER STATION