Base plate heavy steel structure

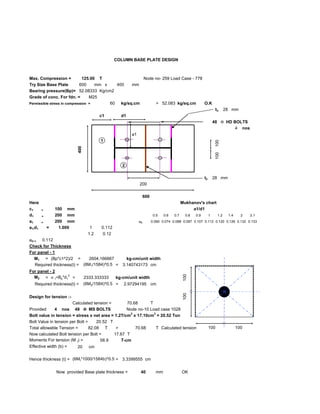

- 1. Max. Compression = T Try Size Base Plate mm x mm Bearing pressure(Bp)= Kg/cm2 Grade of conc. For fdn. = M25 Permissible stress in compression = kg/sq.cm > kg/sq.cm O.K t3 mm c1 d1 F HD BOLTS nos a1 1 2 t2 mm Here c1 = mm d1 = mm a1 = mm a1/d1 = a3 = Check for Thickness For panel - 1 M1 = (Bp*c1^2)/2 = kg-cm/unit width Required thickness(t) = (6M1/1584)^0.5 = cm For panel - 2 M2 = a 3*Bp*d1 2 = kg-cm/unit width Required thickness(t) = (6M2/1584)^0.5 = cm Design for tension :- Calculated tension = T Provided nos F MS BOLTS Node no-10 Load case 1028 Bolt Value in tension per Bolt = T Total allowable Tension = T > T Calculated tension Now calculated Bolt tension per Bolt = T Moments For tension (M t) = T-cm Effective width (b) = cm Hence thickness (t) = (6Mt*1000/1584b)^0.5 = cm Now provided Base plate thickness = mm 400 52.08333 60 52.083 28 48 COLUMN BASE PLATE DESIGN 125.00 Node no- 259 Load Case - 778400 100100 4 600 200 0.5 0.6 0.7 28 200 100 a1/d1 600 Mukhanov's chart 0.133 1.000 1 0.112 0.112 0.1200.074 0.088 2.10.9 0.097 0.107a3 0.060 1.4 21 1.2 0.112 200 0.126 0.132 0.8 2604.166667 1.2 0.12 100 70.68 4 48 3.140743173 100 2333.333333 2.97294195 100 17.67 58.9 20.52 82.08 70.68 100 Bolt value in tension = stress x net area = 1.2T/cm 2 x 17.10cm 2 = 20.52 Ton 20 3.3399555 40 OK

- 2. Design for stiffner t2 = Moment = M2*d1 = kg-cm provide 400 mm depth for Using thickness = mm each stiffener Depth = cm Design for stiffner t3 = Moment = M2*(c1+d1/2) = kg-cm Using thickness = mm Depth = cm Design for Shear :- at Calculated Shear(S) = T Effective Shear = T * considering m =0.3 Considering depth of Shear key(d) = mm Considering width of Shear key (b) = mm So that bearing pressure = < kg/cm2 Now bending moment (M) = kg-cm at Required (Z) = (M/1584) = cm3 Using thickness (at) = mm hence Ixx = cm4 Z = > cm3 Required Z Bending Stress s bc,cal = kg/cm2 Area(A) = 2*b*at = cm2 Now shear Stress tv= (T/A) = kg/cm2 < kg/cm2 So,Combind Stress= (s bc,cal )2 +(t av)2 = mm < 0.9fy = kg/cm2 Design for welding :- Vertical load (p)= T Shear(s) = T kg/cm2 Provided weld thickness (w)= mm Welding length = cm d ac,cal = (p/(L*w*0.707) = kg/cm2 zshear, cal = (s/(L*w*0.707) = kg/cm2 Combind stress = (d ac,cal 2 + 3*zshear, cal 2 ) 0.5 = kg/cm2 < allowable stress 1100 kg/cm2 46666.66667 28 7.785 46666.66667 21.35 200 250 250 28 7.785 21.35 Node 10 load case 276 56.93333 60 320250 50 202.178 25 3287.76 263.0208 202.18 1217.584 1.700032641 290.37 502.930802 8 250 125 170.8 1000 21.35 200 130 1229.505672 2250 mm 125.00 56.933

- 3. -21.35 -70.68 -11.49 222 DL+LL+EL+DWL+X+MR 4+TL 20.92 103.57 19.19 223 DL+LL+EL+DWL+X+MR 5+TL 10 121 DL+LL+EL+MR 1+TL -7.33 4.03 3.73 224 DL+LL+EL+DWL+X+MR 6+TL 122 DL+LL+EL+MR 2+TL -7.32 5.16 3.78 225 DL+LL+EL+DWL+X+MR 7+TL 123 DL+LL+EL+MR 3+TL -7.37 3.84 3.76 226 DL+LL+EL+DWL+Z+MR 1+TL 124 DL+LL+EL+MR 4+TL -7.34 3.78 3.79 227 DL+LL+EL+DWL+Z+MR 2+TL 125 DL+LL+EL+MR 5+TL -7.34 3.77 3.8 228 DL+LL+EL+DWL+Z+MR 3+TL 126 DL+LL+EL+MR 6+TL -7.34 4.38 3.64 229 DL+LL+EL+DWL+Z+MR 4+TL 127 DL+LL+EL+MR 7+TL -7.35 4.02 3.74 230 DL+LL+EL+DWL+Z+MR 5+TL 128 DL+LL+EL+(WL +X)+MR 1+TL -8.06 16.3 0.03 231 DL+LL+EL+DWL+Z+MR 6+TL 129 DL+LL+EL+(WL +X)+MR 2+TL -8.05 17.15 0.07 232 DL+LL+EL+DWL+Z+MR 7+TL 130 DL+LL+EL+(WL +X)+MR 3+TL -8.09 16.16 0.05 233 DL+LL+EL+DWL+Z+MR 1+TL 131 DL+LL+EL+(WL +X)+MR 4+TL -8.07 16.12 0.08 234 DL+LL+EL+DWL+Z+MR 2+TL 132 DL+LL+EL+(WL +X)+MR 5+TL -8.07 16.1 0.08 235 DL+LL+EL+DWL+Z+MR 3+TL 133 DL+LL+EL+(WL +X)+MR 6+TL -8.07 16.56 -0.04 236 DL+LL+EL+DWL+Z+MR 4+TL 134 DL+LL+EL+(WL +X)+MR 7+TL -8.07 16.29 0.04 237 DL+LL+EL+DWL+Z+MR 5+TL 135 DL+LL+EL+(WL +X)+MR 1+TL -7.44 9.28 2.1 238 DL+LL+EL+DWL+Z+MR 6+TL 136 DL+LL+EL+(WL +X)+MR 2+TL -7.43 10.12 2.14 239 DL+LL+EL+DWL+Z+MR 7+TL 137 DL+LL+EL+(WL +X)+MR 3+TL -7.46 9.13 2.12 240 DL+LL+EL+DWL-X+MR 1+TL 138 DL+LL+EL+(WL +X)+MR 4+TL -7.44 9.09 2.14 241 DL+LL+EL+DWL-X+MR 2+TL 139 DL+LL+EL+(WL +X)+MR 5+TL -7.44 9.08 2.15 242 DL+LL+EL+DWL-X+MR 3+TL 140 DL+LL+EL+(WL +X)+MR 6+TL -7.44 9.53 2.03 243 DL+LL+EL+DWL-X+MR 4+TL 141 DL+LL+EL+(WL +X)+MR 7+TL -7.45 9.26 2.11 244 DL+LL+EL+DWL-X+MR 5+TL 142 DL+LL+EL+(WL +Z)+MR 1+TL -6.56 16.46 -0.29 245 DL+LL+EL+DWL-X+MR 6+TL 143 DL+LL+EL+(WL +Z)+MR 2+TL -6.55 17.3 -0.24 246 DL+LL+EL+DWL-X+MR 7+TL 144 DL+LL+EL+(WL +Z)+MR 3+TL -6.59 16.31 -0.26 247 DL+LL+EL+DWL-X+MR 1+TL 145 DL+LL+EL+(WL +Z)+MR 4+TL -6.57 16.27 -0.24 248 DL+LL+EL+DWL-X+MR 2+TL 146 DL+LL+EL+(WL +Z)+MR 5+TL -6.57 16.26 -0.23 249 DL+LL+EL+DWL-X+MR 3+TL 147 DL+LL+EL+(WL +Z)+MR 6+TL -6.57 16.71 -0.35 250 DL+LL+EL+DWL-X+MR 4+TL 148 DL+LL+EL+(WL +Z)+MR 7+TL -6.57 16.45 -0.28 251 DL+LL+EL+DWL-X+MR 5+TL 149 DL+LL+EL+(WL +Z)+MR 1+TL -5.95 9.47 1.77 252 DL+LL+EL+DWL-X+MR 6+TL 150 DL+LL+EL+(WL +Z)+MR 2+TL -5.94 10.31 1.82 253 DL+LL+EL+DWL-X+MR 7+TL 151 DL+LL+EL+(WL +Z)+MR 3+TL -5.97 9.32 1.8 254 DL+LL+EL+DWL-Z+MR 1+TL 152 DL+LL+EL+(WL +Z)+MR 4+TL -5.95 9.28 1.82 255 DL+LL+EL+DWL-Z+MR 2+TL 153 DL+LL+EL+(WL +Z)+MR 5+TL -5.96 9.27 1.83 256 DL+LL+EL+DWL-Z+MR 3+TL 154 DL+LL+EL+(WL +Z)+MR 6+TL -5.95 9.72 1.71 257 DL+LL+EL+DWL-Z+MR 4+TL 155 DL+LL+EL+(WL +Z)+MR 7+TL -5.96 9.46 1.79 258 DL+LL+EL+DWL-Z+MR 5+TL 156 DL+LL+EL+EQX (+X)+MR 1+TL -8.52 13.71 2.57 259 DL+LL+EL+DWL-Z+MR 6+TL 157 DL+LL+EL+EQX (+X)+MR 2+TL -8.51 14.55 2.61 260 DL+LL+EL+DWL-Z+MR 7+TL 158 DL+LL+EL+EQX (+X)+MR 3+TL -8.54 13.56 2.59 261 DL+LL+EL+DWL-Z+MR 1+TL 159 DL+LL+EL+EQX (+X)+MR 4+TL -8.52 13.52 2.61 262 DL+LL+EL+DWL-Z+MR 2+TL 160 DL+LL+EL+EQX (+X)+MR 5+TL -8.53 13.51 2.62 263 DL+LL+EL+DWL-Z+MR 3+TL 161 DL+LL+EL+EQX (+X)+MR 6+TL -8.53 13.96 2.5 264 DL+LL+EL+DWL-Z+MR 4+TL 162 DL+LL+EL+EQX (+X)+MR 7+TL -8.53 13.7 2.58 265 DL+LL+EL+DWL-Z+MR 5+TL 266 DL+LL+EL+DWL-Z+MR 6+TL 163 DL+LL+EL+EQX (-X)+MR 1+TL -2.48 -7.66 3.02 267 DL+LL+EL+DWL-Z+MR 7+TL 164 DL+LL+EL+EQX (-X)+MR 2+TL -2.47 -6.81 3.06 268 DL+WLX 1+TX 165 DL+LL+EL+EQX (-X)+MR 3+TL -2.51 -7.81 3.04 269 DL+WLX 2+TX 166 DL+LL+EL+EQX (-X)+MR 4+TL -2.49 -7.84 3.07 270 DL+WLZ 3+TX 167 DL+LL+EL+EQX (-X)+MR 5+TL -2.49 -7.86 3.07 271 DL+WLZ 4+TX 168 DL+LL+EL+EQX (-X)+MR 6+TL -2.49 -7.4 2.95 272 DL+WLX 1A+TX 169 DL+LL+EL+EQX (-X)+MR 7+TL -2.49 -7.67 3.03 273 DL+WLX 2A+TX 170 DL+LL+EL+EQX (+Z)+MR 1+TL -6.94 27.21 -1.39 274 DL+WLZ 3A+TX 171 DL+LL+EL+EQX (+Z)+MR 2+TL -6.93 28.06 -1.35 275 DL+WLZ 4A+TX

- 4. 172 DL+LL+EL+EQX (+Z)+MR 3+TL -6.97 27.06 -1.37 276 DL+DIAGONAL WLX 1+TX 173 DL+LL+EL+EQX (+Z)+MR 4+TL -6.95 27.02 -1.35 277 DL+DIAGONAL WLX 2+TX 174 DL+LL+EL+EQX (+Z)+MR 5+TL -6.95 27.01 -1.34 278 DL+DIAGONAL WLZ 3+TX 175 DL+LL+EL+EQX (+Z)+MR 6+TL -6.95 27.47 -1.46 279 DL+DIAGONAL WLZ 4+TX 176 DL+LL+EL+EQX (+Z)+MR 7+TL -6.95 27.2 -1.38 280 DL+DIAGONAL WLX 1A+TX 177 DL+LL+EL+EQX (-Z)+MR 1+TL -4.06 -21.16 6.98 281 DL+DIAGONAL WLX 2A+TX 178 DL+LL+EL+EQX (-Z)+MR 2+TL -4.04 -20.31 7.02 282 DL+DIAGONAL WLZ 3A+TX 179 DL+LL+EL+EQX (-Z)+MR 3+TL -4.08 -21.31 7 283 DL+DIAGONAL WLZ 4A+TX 180 DL+LL+EL+EQX (-Z)+MR 4+TL -4.06 -21.35 7.03 284 DL+EQX+TX 181 DL+LL+EL+EQX (-Z)+MR 5+TL -4.06 -21.36 7.03 285 DL+EQZ+TX 182 DL+LL+EL+EQX (-Z)+MR 6+TL -4.06 -20.9 6.91 286 DL+EQX+TX 183 DL+LL+EL+EQX (-Z)+MR 7+TL -4.07 -21.17 6.99 287 DL+EQZ+TX 184 DL+LL+EL+(WL -X)+MR 1+TL -4.23 7.34 0.21 321 DL+LL+EL+MR 1-TL 185 DL+LL+EL+(WL -X)+MR 2+TL -4.22 8.18 0.26 322 DL+LL+EL+MR 2-TL 186 DL+LL+EL+(WL -X)+MR 3+TL -4.26 7.19 0.24 323 DL+LL+EL+MR 3-TL 187 DL+LL+EL+(WL -X)+MR 4+TL -4.24 7.15 0.26 324 DL+LL+EL+MR 4-TL 188 DL+LL+EL+(WL -X)+MR 5+TL -4.24 7.14 0.27 325 DL+LL+EL+MR 5-TL 189 DL+LL+EL+(WL -X)+MR 6+TL -4.24 7.59 0.15 326 DL+LL+EL+MR 6-TL 190 DL+LL+EL+(WL -X)+MR 7+TL -4.24 7.33 0.22 327 DL+LL+EL+MR 7-TL 191 DL+LL+EL+(WL -X)+MR 1+TL -3.53 -0.09 2.31 328 DL+LL+EL+(WL +X)+MR 1-TL 192 DL+LL+EL+(WL -X)+MR 2+TL -3.52 0.76 2.35 329 DL+LL+EL+(WL +X)+MR 2-TL 193 DL+LL+EL+(WL -X)+MR 3+TL -3.55 -0.24 2.33 330 DL+LL+EL+(WL +X)+MR 3-TL 194 DL+LL+EL+(WL -X)+MR 4+TL -3.53 -0.27 2.36 331 DL+LL+EL+(WL +X)+MR 4-TL 195 DL+LL+EL+(WL -X)+MR 5+TL -3.54 -0.29 2.36 332 DL+LL+EL+(WL +X)+MR 5-TL 196 DL+LL+EL+(WL -X)+MR 6+TL -3.54 0.17 2.24 333 DL+LL+EL+(WL +X)+MR 6-TL 197 DL+LL+EL+(WL -X)+MR 7+TL -3.54 -0.1 2.32 334 DL+LL+EL+(WL +X)+MR 7-TL 198 DL+LL+EL+(WL -Z)+MR 1+TL -5.16 -6.02 4.84 335 DL+LL+EL+(WL +X)+MR 1-TL 199 DL+LL+EL+(WL -Z)+MR 2+TL -5.15 -5.18 4.89 336 DL+LL+EL+(WL +X)+MR 2-TL 200 DL+LL+EL+(WL -Z)+MR 3+TL -5.19 -6.17 4.86 337 DL+LL+EL+(WL +X)+MR 3-TL 201 DL+LL+EL+(WL -Z)+MR 4+TL -5.17 -6.21 4.89 338 DL+LL+EL+(WL +X)+MR 4-TL 202 DL+LL+EL+(WL -Z)+MR 5+TL -5.17 -6.22 4.9 339 DL+LL+EL+(WL +X)+MR 5-TL 203 DL+LL+EL+(WL -Z)+MR 6+TL -5.17 -5.77 4.77 340 DL+LL+EL+(WL +X)+MR 6-TL 204 DL+LL+EL+(WL -Z)+MR 7+TL -5.17 -6.03 4.85 341 DL+LL+EL+(WL +X)+MR 7-TL 205 DL+LL+EL+(WL -Z)+MR 1+TL -4.54 -12.82 6.87 342 DL+LL+EL+(WL +Z)+MR 1-TL 206 DL+LL+EL+(WL -Z)+MR 2+TL -4.53 -11.97 6.91 343 DL+LL+EL+(WL +Z)+MR 2-TL 207 DL+LL+EL+(WL -Z)+MR 3+TL -4.56 -12.96 6.89 344 DL+LL+EL+(WL +Z)+MR 3-TL 208 DL+LL+EL+(WL -Z)+MR 4+TL -4.54 -13 6.91 345 DL+LL+EL+(WL +Z)+MR 4-TL 209 DL+LL+EL+(WL -Z)+MR 5+TL -4.55 -13.02 6.92 346 DL+LL+EL+(WL +Z)+MR 5-TL 210 DL+LL+EL+(WL -Z)+MR 6+TL -4.54 -12.56 6.8 347 DL+LL+EL+(WL +Z)+MR 6-TL 211 DL+LL+EL+(WL -Z)+MR 7+TL -4.55 -12.83 6.88 348 DL+LL+EL+(WL +Z)+MR 7-TL 212 DL+LL+EL+DWL+X+MR 1+TL -15.88 36.22 -0.93 349 DL+LL+EL+(WL +Z)+MR 1-TL 213 DL+LL+EL+DWL+X+MR 2+TL -15.87 37.07 -0.88 350 DL+LL+EL+(WL +Z)+MR 2-TL 214 DL+LL+EL+DWL+X+MR 3+TL -15.9 36.08 -0.9 351 DL+LL+EL+(WL +Z)+MR 3-TL 215 DL+LL+EL+DWL+X+MR 4+TL -15.88 36.04 -0.88 352 DL+LL+EL+(WL +Z)+MR 4-TL 216 DL+LL+EL+DWL+X+MR 5+TL -15.89 36.03 -0.87 353 DL+LL+EL+(WL +Z)+MR 5-TL 217 DL+LL+EL+DWL+X+MR 6+TL -15.89 36.48 -0.99 354 DL+LL+EL+(WL +Z)+MR 6-TL 218 DL+LL+EL+DWL+X+MR 7+TL -15.89 36.21 -0.91 355 DL+LL+EL+(WL +Z)+MR 7-TL 219 DL+LL+EL+DWL+X+MR 1+TL -9.64 13.01 2.38 356 DL+LL+EL+EQX (+X)+MR 1-TL 220 DL+LL+EL+DWL+X+MR 2+TL -9.63 13.85 2.42 357 DL+LL+EL+EQX (+X)+MR 2-TL 221 DL+LL+EL+DWL+X+MR 3+TL -9.67 12.86 2.4 358 DL+LL+EL+EQX (+X)+MR 3-TL

- 5. -9.65 12.82 2.42 367 DL+LL+EL+EQX (-X)+MR 5-TL 7.28 -14.03 8.88 359 DL+LL+EL+EQX (+X)+ -9.65 12.81 2.43 368 DL+LL+EL+EQX (-X)+MR 6-TL 7.28 -13.58 8.76 360 DL+LL+EL+EQX (+X)+ -9.65 13.26 2.31 369 DL+LL+EL+EQX (-X)+MR 7-TL 7.27 -13.84 8.83 361 DL+LL+EL+EQX (+X)+ -9.65 12.99 2.39 370 DL+LL+EL+EQX (+Z)+MR 1-TL 2.82 21.03 4.41 362 DL+LL+EL+EQX (+X)+ -10.64 30.63 -1.79 371 DL+LL+EL+EQX (+Z)+MR 2-TL 2.83 21.88 4.45 363 DL+LL+EL+EQX (-X)+M -10.63 31.48 -1.75 372 DL+LL+EL+EQX (+Z)+MR 3-TL 2.8 20.88 4.43 364 DL+LL+EL+EQX (-X)+M -10.67 30.49 -1.77 373 DL+LL+EL+EQX (+Z)+MR 4-TL 2.82 20.84 4.46 365 DL+LL+EL+EQX (-X)+M -10.64 30.45 -1.74 374 DL+LL+EL+EQX (+Z)+MR 5-TL 2.81 20.83 4.46 366 DL+LL+EL+EQX (-X)+M -10.65 30.43 -1.74 375 DL+LL+EL+EQX (+Z)+MR 6-TL 2.81 21.29 4.34 -10.65 30.89 -1.86 376 DL+LL+EL+EQX (+Z)+MR 7-TL 2.81 21.02 4.42 -10.65 30.62 -1.78 377 DL+LL+EL+EQX (-Z)+MR 1-TL 5.71 -27.34 12.79 -4.5 9.1 0.91 378 DL+LL+EL+EQX (-Z)+MR 2-TL 5.72 -26.49 12.83 -4.49 9.94 0.95 379 DL+LL+EL+EQX (-Z)+MR 3-TL 5.68 -27.48 12.81 -4.52 8.95 0.93 380 DL+LL+EL+EQX (-Z)+MR 4-TL 5.7 -27.52 12.83 -4.5 8.91 0.96 381 DL+LL+EL+EQX (-Z)+MR 5-TL 5.7 -27.53 12.84 -4.51 8.9 0.96 382 DL+LL+EL+EQX (-Z)+MR 6-TL 5.7 -27.08 12.72 -4.51 9.35 0.84 383 DL+LL+EL+EQX (-Z)+MR 7-TL 5.7 -27.35 12.8 -4.51 9.09 0.92 384 DL+LL+EL+(WL -X)+MR 1-TL 5.53 1.16 6.02 -11.47 15.35 2.1 385 DL+LL+EL+(WL -X)+MR 2-TL 5.54 2.01 6.06 -11.46 16.2 2.15 386 DL+LL+EL+(WL -X)+MR 3-TL 5.5 1.01 6.04 -11.5 15.2 2.13 387 DL+LL+EL+(WL -X)+MR 4-TL 5.52 0.97 6.06 -11.48 15.16 2.15 388 DL+LL+EL+(WL -X)+MR 5-TL 5.52 0.96 6.07 -11.48 15.15 2.16 389 DL+LL+EL+(WL -X)+MR 6-TL 5.52 1.42 5.95 -11.48 15.61 2.04 390 DL+LL+EL+(WL -X)+MR 7-TL 5.52 1.15 6.03 -11.48 15.34 2.11 391 DL+LL+EL+(WL -X)+MR 1-TL 6.23 -6.26 8.11 -5.54 -6.57 5.15 392 DL+LL+EL+(WL -X)+MR 2-TL 6.25 -5.42 8.16 -5.53 -5.72 5.2 393 DL+LL+EL+(WL -X)+MR 3-TL 6.21 -6.41 8.13 -5.57 -6.72 5.18 394 DL+LL+EL+(WL -X)+MR 4-TL 6.23 -6.45 8.16 -5.55 -6.76 5.2 395 DL+LL+EL+(WL -X)+MR 5-TL 6.23 -6.46 8.17 -5.55 -6.77 5.21 396 DL+LL+EL+(WL -X)+MR 6-TL 6.23 -6.01 8.04 -5.55 -6.31 5.09 397 DL+LL+EL+(WL -X)+MR 7-TL 6.22 -6.27 8.12 -5.55 -6.58 5.17 398 DL+LL+EL+(WL -Z)+MR 1-TL 4.6 -12.2 10.65 -2.65 -1.29 2.14 399 DL+LL+EL+(WL -Z)+MR 2-TL 4.61 -11.35 10.69 -2.64 -0.44 2.18 400 DL+LL+EL+(WL -Z)+MR 3-TL 4.58 -12.35 10.67 -2.67 -1.44 2.16 401 DL+LL+EL+(WL -Z)+MR 4-TL 4.6 -12.39 10.69 -2.65 -1.48 2.18 402 DL+LL+EL+(WL -Z)+MR 5-TL 4.59 -12.4 10.7 -2.66 -1.49 2.19 403 DL+LL+EL+(WL -Z)+MR 6-TL 4.59 -11.94 10.58 -2.66 -1.03 2.07 404 DL+LL+EL+(WL -Z)+MR 7-TL 4.59 -12.21 10.66 -2.66 -1.3 2.15 405 DL+LL+EL+(WL -Z)+MR 1-TL 5.23 -18.99 12.67 3.4 -23.38 5.17 406 DL+LL+EL+(WL -Z)+MR 2-TL 5.24 -18.15 12.71 3.41 -22.53 5.22 407 DL+LL+EL+(WL -Z)+MR 3-TL 5.2 -19.14 12.69 3.38 -23.53 5.2 408 DL+LL+EL+(WL -Z)+MR 4-TL 5.22 -19.18 12.72 3.4 -23.57 5.22 409 DL+LL+EL+(WL -Z)+MR 5-TL 5.22 -19.19 12.72 3.39 -23.58 5.23 410 DL+LL+EL+(WL -Z)+MR 6-TL 5.22 -18.74 12.6 3.4 -23.12 5.11 411 DL+LL+EL+(WL -Z)+MR 7-TL 5.22 -19 12.68 3.39 -23.39 5.18 412 DL+LL+EL+DWL+X+MR 1-TL -6.12 30.05 4.88 -10.92 39.51 -9.06 413 DL+LL+EL+DWL+X+MR 2-TL -6.1 30.89 4.92 -10.09 30.14 -6.3 414 DL+LL+EL+DWL+X+MR 3-TL -6.14 29.9 4.9 -8.92 39.72 -9.48 415 DL+LL+EL+DWL+X+MR 4-TL -6.12 29.86 4.92 -8.1 30.39 -6.73 416 DL+LL+EL+DWL+X+MR 5-TL -6.12 29.85 4.93 -5.82 27.56 -8.81 417 DL+LL+EL+DWL+X+MR 6-TL -6.12 30.3 4.81 -4.88 17.66 -6.02 418 DL+LL+EL+DWL+X+MR 7-TL -6.13 30.04 4.89 -7.06 9.74 -2.64 419 DL+LL+EL+DWL+X+MR 1-TL 0.12 6.83 8.18 -6.22 0.68 0.06

- 6. -21.35 66.07 -10.33 -13.03 35.11 -5.93 -14.36 58.62 -11.49 -6.17 29.9 -7.89 -15.47 38.24 -6.29 -7.56 9.01 -2.23 -3.7 16.05 -6.25 4.36 -13.4 -2.2 -11.53 36.05 -5.67 -9.43 54.05 -10.96 -3.48 7.56 -5.07 -5.58 -10.44 0.21 5.69 -4.2 11.46 5.7 -3.07 11.52 5.65 -4.4 11.49 5.68 -4.45 11.53 5.68 -4.47 11.53 5.68 -3.86 11.37 5.67 -4.22 11.48 1.7 10.13 5.83 1.71 10.97 5.88 1.68 9.98 5.86 1.7 9.94 5.88 1.7 9.93 5.89 1.7 10.38 5.77 1.69 10.12 5.84 2.33 3.1 7.9 2.34 3.95 7.94 2.3 2.95 7.92 2.32 2.91 7.95 2.32 2.9 7.95 2.32 3.36 7.83 2.32 3.09 7.91 3.2 10.28 5.52 3.21 11.13 5.56 3.18 10.13 5.54 3.2 10.09 5.56 3.19 10.08 5.57 3.2 10.54 5.45 3.19 10.27 5.53 3.82 3.29 7.58 3.83 4.14 7.62 3.79 3.14 7.6 3.81 3.1 7.62 3.81 3.09 7.63 3.81 3.55 7.51 3.81 3.28 7.59 1.25 7.53 8.37 1.26 8.38 8.41 1.22 7.38 8.39

- 7. 1.24 7.34 8.42 1.24 7.33 8.42 1.24 7.79 8.3 1.24 7.52 8.38 7.28 -13.83 8.82 7.29 -12.99 8.87 7.26 -13.98 8.85 7.28 -14.02 8.87