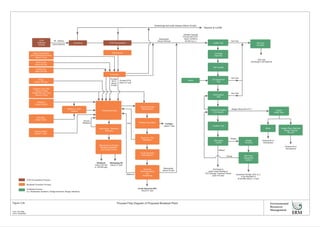

Biodiesel Process Flow Diagr.

- 1. Screenings and solid residue (About 33 tpd) Disposal at Landfill (Design Capacity 515 tpd with COD - Wastewater About 15,000 to GTW off - loading (About 450 tpd) -1 40,000 mg L ) Vent Gas Collection Screening GTW Pre-treatment Buffer Tank Vent Gas Vehicles (About 606 tpd) Scrubber Steam Condensate Trap Grease Oil-Water from Purification Process Separator (About 11 tpd) Vent Gas WCO Crude Discharge to atmosphere (About 50 tpd) DAF System Animal Fats (About 20 tpd) Purification Vent Gas PFAD Purified pH Adjustment WCO Purified GTW NaOH (About 167 tpd) Tank (About (About 91 tpd) 45 tpd) Sulphuric acid, 96% (About 3.5 tpd) Phosphoric acid, 75% Vent Gas (About 0.3 tpd) Recirculation Tank Methanol (About 34 tpd) Glycerine Phase Methanol - KOH Neutralization Internal Circulation Biogas (About 80 m3hr-1) Catalyst Transesterification Biogas (IC) Reactor Buffer Tank KOH 88% (About 5 tpd) Excess Methanol FFA Fertilizer Separation Fertilizer (about 7 tpd) Aeration Tank Methylester - Methanol Boiler Biogas Flare (Standby) Recovery Design Capacity Process Water 3 -1 (About 11 tpd) 150 m hr Glycerine - FFA Sludge Separation Secondary Sludge Exhaust Air to Clarifier Thickener Atmosphere Methylester Purification Exhaust Air to Biodiesel Distillation Atmosphere and Quality Control Effluent Crude Glycerine Neutralisation Belt Press Filtrate Dewatering System Biodiesel Bioheating Oil (About 303 tpd (About 27 tpd) or 100,000 tpa) Glycerine Wastewater Discharge to Demethanolising (About 30 tpd) public sewer leading to Methanol and TKO Sewage Treatment Works Dewatered Sludge (30% d.s.) Dewatering (upto 515 tpd) to be disposed of at landfills (About 1.3 tpd) GTW Pre-treatment Process Biodiesel Production Process Anxillaries Process Crude Glycerine 80% (i.e. Wastewater treatment, Sludge treatment, Biogas utilisation) (About 21 tpd) Figure 3.2b Process Flow Diagram of Proposed Biodiesel Plant Environmental Resources FILE: 0077089j Management DATE: 05/08/2008