Bogota 2013 gotsick v1.5

- 1. The Effect of Flexo Dot Geometry on Print Performance: Theoretical and Empirical Models of Dot Gain Mechanisms Timothy Gotsick May 28, 2013 MacDermid Printing Solutions

- 2. A little bit about myself 2 In my natural habitat, waiting for a delayed flight. Timothy Gotsick, VP Technology  R&D  Application Development  Based in Atlanta, GA  10 years with MacDermid  Background in organic chemistry  Still being tutored in print technology  Management of new product development in chemical industries  Strong interest in understanding print fundamentals

- 3. Outline ÔÇó What is Print Gain? ÔÇó Why and where is it a problem? ÔÇó What causes Print Gain? ÔÇó The effect of shoulder angle on print gain ÔÇó Case Study: Corrugated Postprint ÔÇ£FlutingÔÇØ ÔÇó Case Study: Highlight dot gain ÔÇó Further work: Effects of dot shape on ink distribution

- 4. 4 Print is made of 2-D dots

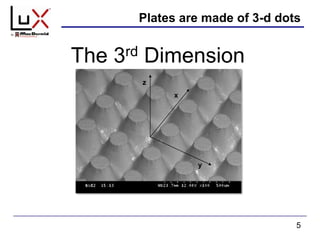

- 5. 5 Plates are made of 3-d dots x y z The 3rd Dimension

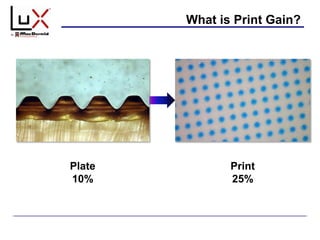

- 6. What is Print Gain? Plate 10% Print 25%

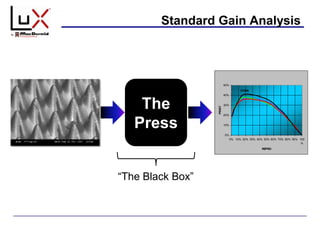

- 7. Standard Gain Analysis CYAN 0% 10% 20% 30% 40% 50% 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100 % REPRO PRINT The Press ÔÇ£The Black BoxÔÇØ

- 8. But where does print gain come from?

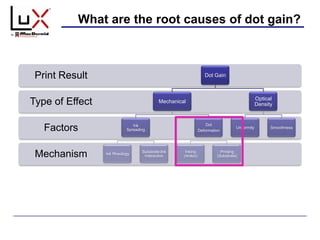

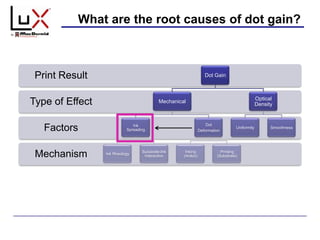

- 9. What are the root causes of dot gain? Mechanism Factors Type of Effect Print Result Dot Gain Mechanical Ink Spreading Ink Rheology Substrate-Ink Interaction Dot Deformation Inking (Anilox) Printing (Substrate) Optical Density Uniformity Smoothness

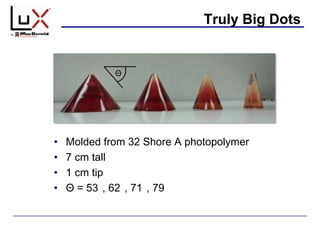

- 10. Truly Big Dots ÔÇó Molded from 32 Shore A photopolymer ÔÇó 7 cm tall ÔÇó 1 cm tip ÔÇó ╬ÿ = 53 , 62 , 71 , 79 ╬ÿ

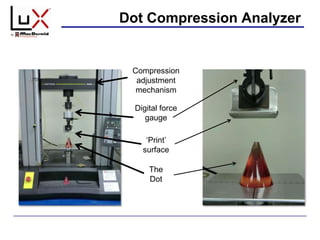

- 11. Dot Compression Analyzer Digital force gauge Compression adjustment mechanism The Dot ÔÇ×PrintÔǃ surface

- 15. Contact Patch Growth 50 100 150 200 250 300 350 400 450 500 0 2 4 6 8 10 12 14 16 18 20 ContactPath,mm2 Compression, mm Contact Patch vs Compression by Angle 79 71 62 53

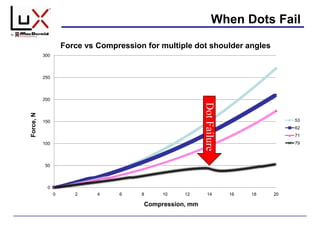

- 16. Dot Force vs Compression 0 50 100 150 200 250 300 0 2 4 6 8 10 12 14 16 18 20 Force,N Compression, mm Force vs Compression for multiple dot shoulder angles 53 62 71 79

- 19. The Problem

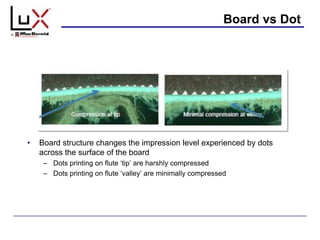

- 20. Board vs Dot ÔÇó Board structure changes the impression level experienced by dots across the surface of the board ÔÇô Dots printing on flute ÔÇ×tipÔǃ are harshly compressed ÔÇô Dots printing on flute ÔÇ×valleyÔǃ are minimally compressed

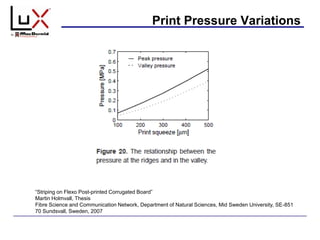

- 21. Print Pressure Variations ÔÇ£Striping on Flexo Post-printed Corrugated BoardÔÇØ Martin Holmvall, Thesis Fibre Science and Communication Network, Department of Natural Sciences, Mid Sweden University, SE-851 70 Sundsvall, Sweden, 2007

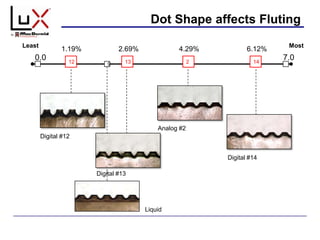

- 24. Dot Shape affects Fluting Liquid 12 13 2 14 0.0 1.19% Least Most 9 6.12%4.29%2.69% Digital #14 Digital #12 Digital #13 Analog #2 7.0

- 25. Light Compression in Valleys 50 100 150 200 250 300 350 400 450 500 0 2 4 6 8 10 12 14 16 18 20 ContactPath,mm2 Compression, mm Contact Patch vs Compression by Angle 79 71 62 53

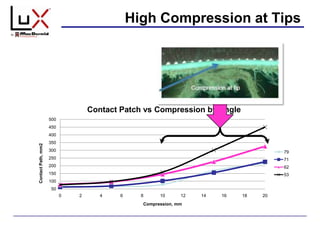

- 26. High Compression at Tips 50 100 150 200 250 300 350 400 450 500 0 2 4 6 8 10 12 14 16 18 20 ContactPath,mm2 Compression, mm Contact Patch vs Compression by Angle 79 71 62 53

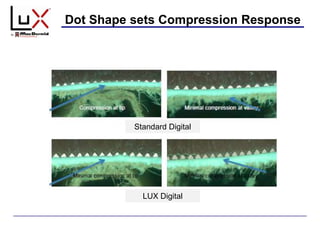

- 27. Dot Shape sets Compression Response Standard Digital LUX Digital

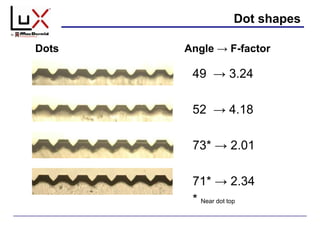

- 28. Dot shapes Dots Angle  F-factor 49  3.24 52  4.18 73*  2.01 71*  2.34 * Near dot top

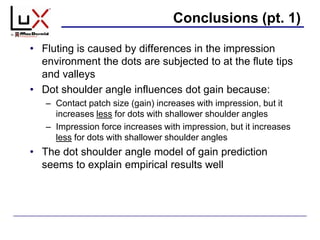

- 29. Conclusions (pt. 1) ÔÇó Fluting is caused by differences in the impression environment the dots are subjected to at the flute tips and valleys ÔÇó Dot shoulder angle influences dot gain because: ÔÇô Contact patch size (gain) increases with impression, but it increases less for dots with shallower shoulder angles ÔÇô Impression force increases with impression, but it increases less for dots with shallower shoulder angles ÔÇó The dot shoulder angle model of gain prediction seems to explain empirical results well

- 30. HIGHLIGHT DOT STABILITY Case Study

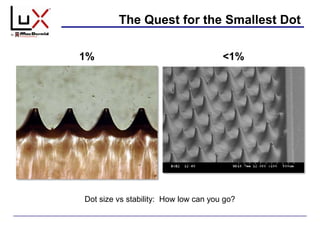

- 31. The Quest for the Smallest Dot 1% <1% Dot size vs stability: How low can you go?

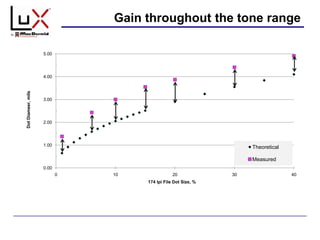

- 32. Gain throughout the tone range 0.00 1.00 2.00 3.00 4.00 5.00 0 10 20 30 40 DotDiameer,mils 174 lpi File Dot Size, % Theoretical Measured

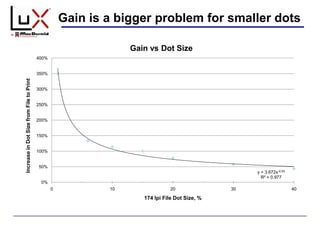

- 33. Gain is a bigger problem for smaller dots y = 3.672x-0.53 R┬▓ = 0.977 0% 50% 100% 150% 200% 250% 300% 350% 400% 0 10 20 30 40 IncreaseinDotSizefromFiletoPrint 174 lpi File Dot Size, % Gain vs Dot Size

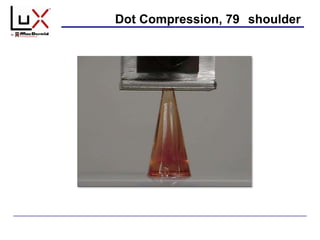

- 34. Dot Compression, 79 shoulder

- 35. When Dots Fail 0 50 100 150 200 250 300 0 2 4 6 8 10 12 14 16 18 20 Force,N Compression, mm Force vs Compression for multiple dot shoulder angles 53 62 71 79 DotFailure

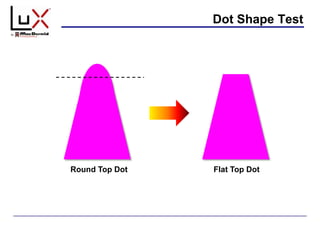

- 36. Round Top Dot Flat Top Dot Dot Shape Test

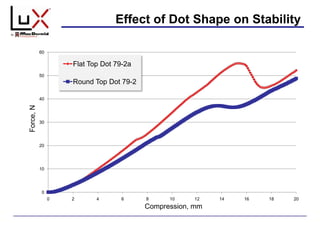

- 37. Effect of Dot Shape on Stability 0 10 20 30 40 50 60 0 2 4 6 8 10 12 14 16 18 20 Flat Top Dot 79-2a Round Top Dot 79-2 Compression, mm Force,N

- 38. DOT SHAPE EFFECTS ON PRINTING PRESSURE Further Work

- 39. What are the root causes of dot gain? Mechanism Factors Type of Effect Print Result Dot Gain Mechanical Ink Spreading Ink Rheology Substrate-Ink Interaction Dot Deformation Inking (Anilox) Printing (Substrate) Optical Density Uniformity Smoothness

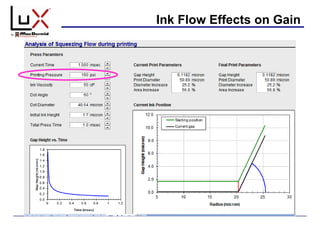

- 40. Ink Flow Effects on Gain

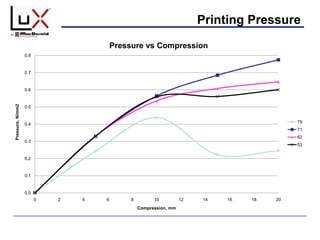

- 41. Printing Pressure 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0 2 4 6 8 10 12 14 16 18 20 Pressure,N/mm2 Compression, mm Pressure vs Compression 79 71 62 53

- 42. Industry Perspective in 2013 Flat top dots are important, but 1.Are they all the same? 2.What is the best way to make them? 42

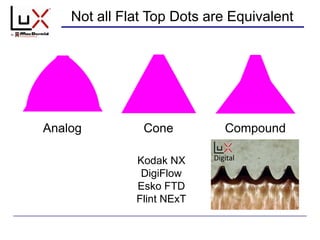

- 43. ConeAnalog Compound Not all Flat Top Dots are Equivalent DigitalKodak NX DigiFlow Esko FTD Flint NExT

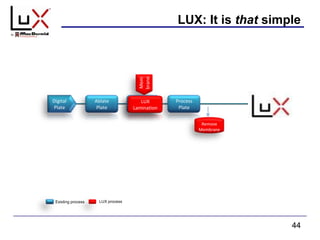

- 44. 44 LUX: It is that simple Existing process LUX process Ablate Plate Digital Plate Expose Process Plate Standard Digital Plate Mem brane Remove Membrane LUX Lamination

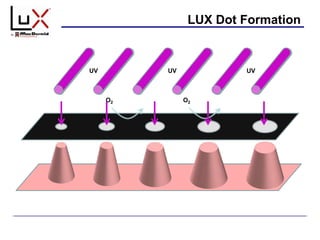

- 45. LUX Dot Formation UV UV UV O2 O2

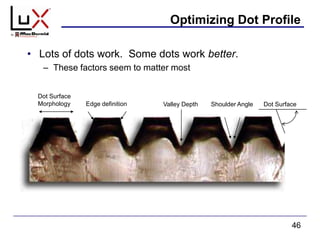

- 46. Optimizing Dot Profile ÔÇó Lots of dots work. Some dots work better. ÔÇô These factors seem to matter most 46 Dot Surface Morphology Shoulder AngleValley DepthEdge definition Dot Surface

- 47. Thank You 47 Timothy Gotsick VP Technology, MacDermid Printing Solutions tgotsick@macdermid.com http://www.macdermid.com/printing Follow us on:

Editor's Notes

- #11: Although I previously showed pictures of dots actually undergoing impression, it is actually quite hard to visually observe dot deformation under real-world conditions. You can imagine how nervous printers get when we start asking them to remove all the safety shielding so we can try and poke microscopes inside their press! As an alternative to this perilous and messy situation, we went the other direction and made a collection of macroscopic dots. Ironically, we are much better at making millions of 70 ╬╝m x 500 ╬╝m dots (which we produce every day) than we are at making 1 cm by 7 cm dots, which required some creativity on the part of our researchers. But we did succeed in creating these macro dots from the same photopolymer used in our commercial plates, and with a variety of dot shoulder angles, as shown above.

- #12: A bit more creativity gave us a test environment where we could ÔÇÿprintÔÇÖ these dots in a controlled fashion using an instrument that can precisely control the distance and rate of compression while measuring the force generated during the dotÔÇÖs compression.

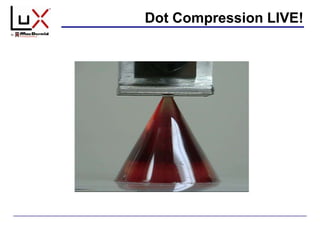

- #13: This is a video of the instrument in action, in this case compressing the 7 cm tall dot by 2 cm. Watch closely, there is a lot going on.

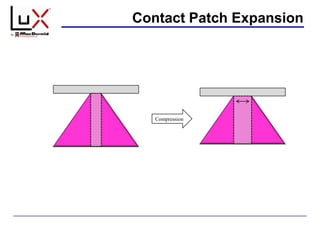

- #14: One of the effects you probably noticed in the video was that as the dot was compressed, the top of the dot was pressed into the ÔÇÿsubstrateÔÇÖ and thus the ÔÇÿcontact patchÔÇÖ grew in size. This is not surprising, and you would be correct in thinking that this is likely a major cause of gain. However, we wanted to be able to understand how this contact patch expansion proceeded with compression.

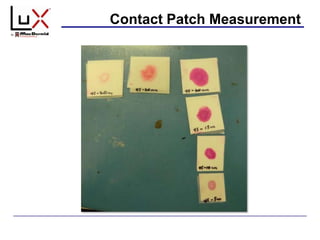

- #15: To do so, we located some pressure sensitive material that allowed us to visualize the contact patch at varying levels of impression. As shown in this slide, the material changes color as pressure is applied to it, revealing the actual size of the contact patch. Furthermore, this visualization technology can actually detect differences in pressure across the contact interface, as shown in the top row of samples. We are currently studying the distribution of force across the contact patch, although this work does not include such detail.

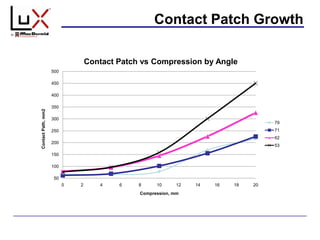

- #16: Here is the result. This graph shows the growth in the contact patch of four different dots at multiple impression levels. The four dots differed only in the angle of their shoulders, with the 53┬░ dot having the broadest profile and the 79┬░ dot having the narrowest profile. The most important things we learned were the following:1. All dots showed two ÔÇÿregionsÔÇÖ in their response to compression. At relatively low compression levels, contact patch increased relatively slowly, but at higher compression levels (between 8 and 10 mm in this graph), the contact patch growth accelerated. The onset and magnitude of this acceleration was dependent on dot shoulder angle. Broader dots (e.g. 53┬░) hit their inflection point at lower compression levels and the contact patch growth was faster once it did. In contrast, dots with steeper shoulders (e.g. 79┬░) showed less change in contact patch at all compression levels and their transition to the ÔÇÿaccelerated growthÔÇÖ portion of the curve occurred later in the compression cycle.

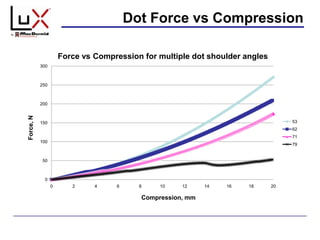

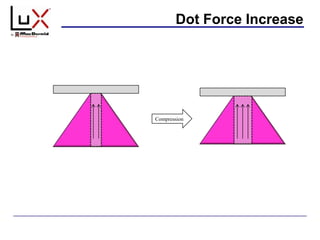

- #17: In addition to the contact patch, we also studied the change in force of the same dots during compression. Again, there were major differences in the behavior of dots with different shoulders angles. The broader the dot, the faster the growth in force during compression. What was also interesting to note was the non-linear growth in force, which actually follows a second order polynomial growth curve. This is in contrast to the expected behavior of a mechanical spring system, where force rises in direct proportion to the compression distance.

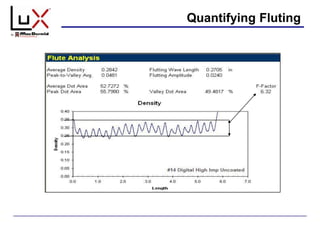

- #18: The reason for this non-linearity can be understood by considering the simultaneous expansion in contact patch that occurs during dot compression. The force rises exponentially because the contact patch increases; not only is the material being compressed more, but more material is being compressed. This is an especially relevant finding for the study of fluting. As you may recall from my description of HolmvallÔÇÖs work, the print density on corrugated board rose non-linearly with pressure/force. This means that at certain portions of the print process, both print density (through force) and dot gain (through contact patch growth) are increasing exponentially at the same time.

- #21: Here is a close-up view of what is at the heart of fluting ÔÇô two very different print environments experienced on the same print surface, with predictably different effects on the plateÔÇÖs dots.

- #22: However, even with the use of thick, soft plates, the pressure experienced by the plates in the micro-environments of the flute peaks and valleys can be quite different, and this difference becomes even more pronounced with increasing print squeeze or impression, as shown here.

- #26: Now letÔÇÖs tie all this together and explain fluting once and for all. In the ÔÇÿvalleysÔÇÖ of the corrugated board, the contact patch growth (and the force growth) is operating in this region of the curve, where gain is minimized and relatively stable.

- #27: But at the flute tips, the dots are operating in this region of the graph, where contact patch and force growth are both higher and on a much steeper slope. More gain and more print density. Also, note that the problems in this region are very different for dots with different shoulder angles ÔÇô the broadest dot studied (53┬░) had a contact patch twice as large as the narrower dots (71┬░ and 79┬░) at many compression levels.

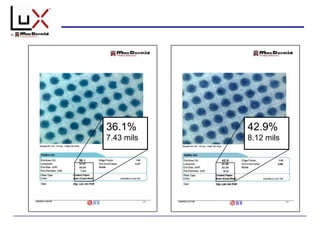

- #28: The results can be seen in print and in actual observation of dots on board. Steeper shoulder angles give a dot that tolerates compression better, giving print density that is similar at the flute tips and valleys and reducing the unwanted visual effects that density variations bring.

- #30: In conclusion, I hope that I have provided a strong case for three statements.First, fluting is caused by differences in the impression that dots printing on the tips of the flutes receive compared to those printing in the valleys of the flutes.Second, that the dot shoulder angle is an important determinant of print gain behavior, becauseThe contact patch of broader dots increases faster with impression compared to narrower dots.The impression force generated by broader dots increases faster with impression compared to narrower dots.And third, the exposure technology used to make dots can have a large and beneficial effect on the shoulder angle, with new flat-topped dot technologies creating not only flat tops, but steep shoulder angles throughout the tone range, not just at the highlights, which allows corrugated plates made with this technique to print with an unprecedentedly low level of fluting AND more consistently so.