Boiler Accidents Part III for education.ppt

- 2. B.G. Shirke Const. Technology Ltd., Shirwal, Dist: Satara. MR/10895 - 1983

- 3. B.G. Shirke Const. Technology Ltd., Shirwal, Dist: Satara. AP/152 - 1937

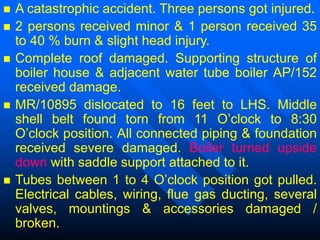

- 4. ? A catastrophic accident. Three persons got injured. ? 2 persons received minor & 1 person received 35 to 40 % burn & slight head injury. ? Complete roof damaged. Supporting structure of boiler house & adjacent water tube boiler AP/152 received damage. ? MR/10895 dislocated to 16 feet to LHS. Middle shell belt found torn from 11 OˇŻclock to 8:30 OˇŻclock position. All connected piping & foundation received severe damaged. Boiler turned upside down with saddle support attached to it. ? Tubes between 1 to 4 OˇŻclock position got pulled. Electrical cables, wiring, flue gas ducting, several valves, mountings & accessories damaged / broken.

- 5. ? AP/152 ¨C Water tube boiler received secondary damages. Steam drum & Mud drum along with supporting structure got displaced to 4.5 feet. Furnace got totally collapsed, complete refractory got damaged. ? Several tubes uprooted from tube holes. ? Steam distribution header got severe damage. Various standpipes got uprooted. Entire piping collapsed.

- 6. Photo shows failure of long seam of middle belt.

- 7. Photo shows failure of long seam of middle belt.

- 8. Photo shows failure of long seam of middle belt.

- 9. Photo shows the sequence of how boiler turned upside down. S.Structure of AP/152

- 10. Photo shows front & rear sides.

- 11. Photo shows internal details

- 12. Photo shows internal details

- 13. Photo shows shell plate of middle belt

- 14. Photo shows shell plate of middle belt

- 15. Photo shows boiler upside down

- 16. Photo shows damages to boiler

- 17. Photo shows damages to surrounding area

- 18. Photo shows damages to surrounding area

- 19. Photo shows damages to S. Distribution Header

- 20. Photo shows damages to Safety valve & Feed check Valve

- 21. Photo shows damages to Electrical Panel & External Furnace

- 22. Photo shows damages to AP/152

- 23. Photo shows damages to AP/152

- 24. Photo shows damages to AP/152

- 25. Photo shows damages to AP/152

- 26. Photo shows damages to AP/152

- 27. Photo shows damages to AP/152

- 28. Analysis ? Visual Inspection:- a) Heavy reinforcement on both sides of weld. b) Weld of the long seam was found with undercuts and cracks running through the HAZ. ? X- Ray Inspection:- a) Reveals that cracks and undercuts at fusion line of the weld were present, running throughout the length of weld & were of serious nature. ( Gross defect)

- 29. Analysis ? Macro Analysis:- a) Excesive reinforcement on both sides of weld. b) Weld of the long seam was found with undercuts and cracks running through the HAZ throughout the fusion line. c) Instead of single V (as per makersˇŻ drgs) double V preparation with heavy gouging done for sealing run found. d) Carbon segregation noticed. e) Columnar structure on both side of weld indicating use of heavy electrode size observed.

- 30. Analysis ? Micro Analysis:- a) Heavy banded ferrite & pearlite observed with top run of both sides having columnar structure. b) Cracks & undercuts noticed at fusion line & HAZ (forming notch effect) which propagated the cracks during operation because of thermal fatigue ¨C frequent on & off cycle.

- 33. Photo shows weld defects

- 34. Photo shows weld defects Original Thk = 14 mm Weld Thk = 22.5 mm

- 35. Photo shows weld defects

- 36. Concept & Design by Sanjay M. Sarode, Dy. Director, Steam Boilers, Maharashtra State.