BROCHURE_SKLP

- 1. Keep Your Trust MINING INDUSTRY OIL AND GAS CEMENT INDUSTRY PULP & PAPER POWER PLANT PETRO CHEMICAL REFINARY PT. SUMBER KARYA LESTARI PRATAMA Jl. Patriot No. 116 C, Jakasampurna Bekasi 17145 Telp. (021) 889 56466 Fax. (021) 889 56467 Email : sales@sklp.co.id marketing@sklp.co.id Website : www.sklp.co.id

- 2. PT. Sumber Karya Lestari Pratama Was estabilished in 2009 in Jakarta as private company with company registration number: AHU-07249.AH.01.02 and NPWP No. 02.885.719.1-034.000 We offer comprehensive, Cost effective high solutions as a general contractor/ Pipe- Flange-Fitting-Valve supplier in Indonesia, Focusing on Oil and Gas, Petrochemical, Cement Industry, Power Plant and Pulp & Paper. VISION Strengthen our service quality by improving, implementing, evaluating, and maintaining the qulity management system improvement and strive in excellent for best practice. MISSION • To Provide quality product and service while meeting customer requirements. • To Provide competitive price and commited for on time delivery services. MINING INDUSTRY OIL AND GAS CEMENT INDUSTRY PUPL AND PAPER POWER PLANT PETROCHEMICAL REFINARY Email : sales@sklp.co.id marketing@sklp.co.id Website : www.sklp.co.id SUPPLY PRODUCTS Fitting, Valve, Pipe Duplex Supply Customer: CONOCOPHILLIPS Valve’s Supply Customer: SAE Belt Brush Conveyor Customer: RAPP Casting Filter Oil Casting Customer: BPSA Fabrication Generator Base Customer: BPSA Heat Exchanger Part Customer: SELDAVINTO Valve’s Supply Customer: PT. SAE Gate Valve Recondition 48”#150 Customer: Geothermal Brake Container Crane Customer: RAPP Port Buatan Rebuild Conveyor Screw Customer: TelPP Loose Gear Box Crane Customer: RAPP Recondition Gearbox Agitator Customer: Kujang Adjuster Bolt HDG Customer: Berau Coal Roll Pulley SBR Customer : PKN Kaltim

- 3. PROJECT This PRESS MACHINE is a machine that has a very good quality and have optimal performance. This machine offers a minimum price but maximum result, so it can provide substansial benefit for customer. This machine made by experts and designed very carefully according to ASME standard. (KICI Indonesia) FOUNDATION RAIL is the cradle for the engine generator made with a standard based on ASME. Created by experts and has the strength and assurance of high quality products. Combining raw material between carbon steel and wear resistance plate material, and process welding by FCAW complete with WPS, PQR and ITP documentation. Machinery process by CNC HBM then produce high precision products. (BPSA / PLN Lombok) Casting, machining and assembly of CRUSHER SCREEN. Made from manganese casting to improve quality and add optimal performance. Diamond type HEAD PULLEY, shell of pulley made from seamless pipe, flanges from material carbon steel grade S45C, and shaft material alloy grade 4340. Covered by SBR shore 60 for finish.

- 4. As an agent EDV Valves of UK we capable to supply ball valve, check valve, globe valve with range of size 1”-24” ASME #150-#2500 with various of connection and we concentrated on F51 / F55 Duplex and super duplex NACE MR 0175 With full support from our principal in Europe SKLP capable and widely supply of : - Fittings (elbow, tees, cap,etc) - Bar material - Branch fitting (weldolet, sockolet, threadolets, plug, etc.) - Flange (WN, SO, SW, threaded, bleeder type) to ASME and API std. Duplex and Super Duplex UNS Grade S31803-S32205-S32750 FLANGES & FITTINGFLANGES & FITTINGFLANGES & FITTINGFLANGES & FITTING As an agent Petropipe International of UK, SKLP already widely supply seamless and welded pipe with range of size 1”-12” DSS SMLS A790 UNS Duplex and Super Duplex UNS Grade S31803-S32205-S32750 NACE MR 0175 PIPEPIPEPIPEPIPE DUPLEX VALVEDUPLEX VALVEDUPLEX VALVEDUPLEX VALVE PROJECT

- 5. ID FAN Made from wear resistance materials with grade 400, rolling process use special methods, welding by FCAW and finishing by CNC Vertical Milling EQUALIZING BIN TANK SPROCKET DECK Made from carbon steel and wear resistance plate grade 500. diameter 4000 mm and high 5200mm. It used for wood chipper storage. Made from forging materials 17CrMo6 and threatment surface induction after machining process, the sprocket cut into two parts by CNC wirecut. Installed on slasher deck and used to pull the woods to barking drum. PROJECT DISC CHIPPER Recondition disc chipper and replacement shaft. Rebuild disc by FCAW and welding wire which compatible specification. Re- tapped and install recoil on bolting holes. GATE VALVE Recondition flanges facing, rebuild by FCAW and machining gate disc on VTL CNC machine. Replace new rod screw by allow steel material and finishing grinding.

- 6. PROJECT VESSEL GEAR BOX Maker various type of gears and recondition gearbox : SOP of reconditon : • Propose recommendation • Recondition housing • Recondition bearing seat • Machining gears • Grinding gears • Treatment • Assembling • Testing without load • Proper packaging As PHE agent which complete with U, S & US ASME certification we capable to make various of Vessel & tank : • Vessel non pressure • Pressure Vessel • Heat Exchangers • Column, chimney • Ducting • etc.

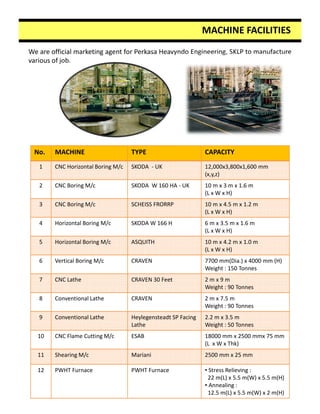

- 7. We are official marketing agent for Perkasa Heavyndo Engineering, SKLP to manufacture various of job. MACHINE FACILITIES No. MACHINE TYPE CAPACITY 1 CNC Horizontal Boring M/c SKODA - UK 12,000x3,800x1,600 mm (x,y,z) 2 CNC Boring M/c SKODA W 160 HA - UK 10 m x 3 m x 1.6 m (L x W x H) 3 CNC Boring M/c SCHEISS FRORRP 10 m x 4.5 m x 1.2 m (L x W x H) 4 Horizontal Boring M/c SKODA W 166 H 6 m x 3.5 m x 1.6 m (L x W x H) 5 Horizontal Boring M/c ASQUITH 10 m x 4.2 m x 1.0 m (L x W x H) 6 Vertical Boring M/c CRAVEN 7700 mm(Dia.) x 4000 mm (H) Weight : 150 Tonnes 7 CNC Lathe CRAVEN 30 Feet 2 m x 9 m Weight : 90 Tonnes 8 Conventional Lathe CRAVEN 2 m x 7.5 m Weight : 90 Tonnes 9 Conventional Lathe Heylegensteadt SP Facing Lathe 2.2 m x 3.5 m Weight : 50 Tonnes 10 CNC Flame Cutting M/c ESAB 18000 mm x 2500 mmx 75 mm (L x W x Thk) 11 Shearing M/c Mariani 2500 mm x 25 mm 12 PWHT Furnace PWHT Furnace • Stress Relieving : 22 m(L) x 5.5 m(W) x 5.5 m(H) • Annealing : 12.5 m(L) x 5.5 m(W) x 2 m(H)

- 8. MACHINE FACILITIES Located in Cengkareng, West Jakarta and Bekasi West Java where our supporting workshop are dedicated to running the activities No . TOOLS NAME BRAND SIZE 1 CMM PORTABLE CIMCORE 2800 mm 2 HIGH GAUGE (DIGIMARE CX1) MAHR 24” 3 HARDNESS TESTER GNEHM HRD 150 4 HARDNESS TESTER PORTABLE TIME HRC/HRB 5 VERNIER CALIPER MITOTUYO 0-1500 mm 6 DEPTH CALIPER MITOTUYO 0-200 mm 7 OUTSIDE MICRO MITOTUYO 0-400 mm 8 INSIDE MICRO MITOTUYO 8-100 mm 9 MODUL RADIUS MITOTUYO 8-100 mm 10 BORE GAUGE MITOTUYO 160-235 mm 11 MEASURING PROJECTOR CARMAR 50x150 mm TOOLS FACILITIES No . MACHINE TYPE CAPACITY 1 CNC Turning TURN 20 - Japan 200 x 500 mm 2 Vertical Machining Center WF3-12K -Germany 750 x 1200 x 2000mm 3 CNC Wire Cut AQ 325 L - Japan 220 x 250 x 350 mm 4 CNC EDM CM 434 C - Taiwan 250 x 300 x 400 mm 5 Horizontal Lathe Geminis – Germany 1500 x 1200 mm 6 Surface Grinding TODH3 - Germany 600 x 2000 mm 7 Cylinder Grinding Naxos Union - Germany 500 x 3000 mm 8 Planner Milling R1200 - Taiwan 1200 x 4000 mm 9 Horizontal Shapping Dainichi - Japan 600 x 400 mm 10 Universal Frais / Mill Sajo/ Strong - Sweden 300 x 1250 mm