Bulldozers

- 1. GROW MORE FACULTY OF ENGINEERING PRESENTS PPT ON Bulldozer

- 2. WHAT IS BULLDOZER ’éó Machines designed preliminary for cutting & pushing material relatively short distance. ’éó Consist of a tractor with a front mounted blade controlled by hydraulic cylinders use for different cut for different depth & leveling as per condition of land.

- 4. CRAWLER DOZERS ’éó It is equipped with special clearing blades which are excellent machine for loud clearing. ’éó Heavy ripping of rock is accomplished by crawler dozers with use of rippers which are mounted rear of dozers.

- 6. PURPOSE OF BULLDOZER ’éó Clear site of work ’éó Leveling of land ’éó Prepare roads on hilly areas as well as hard ground ’éó Excavate the material and haul in between 100 meters distance. ’éó Spreading earth ’éó Backfilling trenches ’éó Maintaining haul roads

- 7. CLASSIFICATION OF BULLDOZERS: ’éó It may either cable controlled or hydraulic controlled. ’éó Depending upon mountings bulldozers classified as I. crawler tractor mounted bulldozers II. Wheel tractor mounted bulldozers

- 8. WHEEL TRACTOR MOUNTED BULLDOZERS

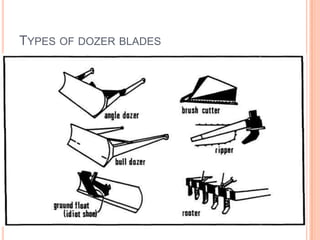

- 10. CLASSIFICATION OF BULLDOZERS: ’éó Depending on nature of blade: I. Front casting dozer II. Angle dozer ’éó In case of front casting dozer blade is fixed perpendicular to the direction of travel. ’éó In case if Angle dozer the blade is fixed at an angle with the direction of travel.

- 11. TYPES OF DOZER BLADES

- 13. ANGLE DOZER

- 14. COMPARISON : ’éó In case of front casting dozer it moves earth in the forward direction. ’éó In case of Angle dozer it moves earth one side in the forward direction. ’éó Due to this different types of blades it can converted in two types.

- 15. SIZE & OUTPUT OF BULLDOZER ’éó Size of bulldozer indicated by the dimensions of blade & its output depends upon its operating condition. ’éó Each blade has a capacity of hauling a particular type of earth & knowing the number of turns a bulldozer can be estimated. ’éó Output of all the earth moving machinery depends on given factors.

- 16. FACTORS AFFECT OUTPUT OF MACHINERY a. Efficiency of operator b. Nature of soil c. Topography of area d. Type of equipment e. Weather

- 17. UTILITY OF A BULLDOZER ’éó By suitable attachments to the bulldozer, it can be utilized to remove trees,rocks,boulders etc. ’éó In order to increase output two bulldozers working side by side with their blades in contact , can be used. ’éó It can be used on wet ground and all types of weather conditions.

- 18. ADVANTAGES OF CRAWLER MOUNTED DOZER ’éó It delivers greater attractive effort especially when operating soft grounds as loose or muddy soil. ’éó Capacity to travel over muddy surface. ’éó Work on different type of soil. ’éó Ability to travel on rough surface, which may reduce the cost of maintaining the hauling roads.

- 19. ADVANTAGES OF CRAWLER MOUNTED DOZER ’éó Greater flotation due to the lower pressure under the track. ’éó Good for short distance jobs. ’éó Greater use in different type of jobs. ’éó Can push large blade loads. ’éó Speed is slow about 8 to 16 kmph.

- 20. ADVANTAGES OF WHEEL MOUNTED DOZER ’éó Provide higher travel speed from 13 to 42 kmph on the job or from one job to another job. ’éó Eliminates the necessity of hauling equipment required to transport the dozer to the job. ’éó Greater output, especially when considerable travel is necessary. ’éó Less fatigue to operator.

- 21. ADVANTAGES OF WHEEL MOUNTED DOZER ’éó It is good for long distance. ’éó It can travel on paved highways without damaging the surface. ’éó It is best for handling loose soil. ’éó It can push moderate blade load.

- 22. BLADES OF DOZER ’éó Made from mold boards which having concave profile. ’éó Blades are connected with dozer with the help of push arms and tilt cylinders or a C frame. ’éó Based on different type of work application the size of blade is varies.

- 23. WHAT IS TILT ? ’éó In some machines either end of the blade can be raised or lowered in the vertical plane of the blade called Tilt. ’éó The movement takes place within the vertical plane of the blade. ’éó Tilting enables the concentration of dozer driving power on a limited portion of the length of the blade.

- 25. WHAT IS PITCH? ’éó The top of the blade can pitched forward or backward varying the angle of attack of the cutting edge. it is known as pitch. ’éó This is pivotal movement about the point of connection between the dozer and blade. ’éó When top of blade pitch forward, the bottom edge moves back. This increase the angle of cutting edge attack.

- 27. WHAT IS ANGLING? ’éó Blades which are mounted on a C frame can be turned from the direction of travel. It is known as angling. ’éó This features are not applicable for all blades. ’éó Turning the blade in such a way that it is not perpendicular to the direction of the travel of the dozer is known as angling. ’éó Angling causes the pushed material to roll off the traveling end of trailing end of blade. ’éó This process of rolling material off one end of the blade is known as side casting.