BUSINESS PLAN FOR SHIFTING WAREHOUSE OR TAKE NEW DISTRIBUTION CENTER

- 1. Presented By: Daipayan Adhikari BUSINESS PLAN FOR WAREHOUSE SHIFTING OR TAKING A NEW DISTRIBUTION CENTER BUSINESS PLAN FOR WAREHOUSE SHIFTING OR TAKING A NEW DISTRIBUTION CENTER

- 2. 6. WAREHOUSE OPERATIONS - RESOURCES6. WAREHOUSE OPERATIONS - RESOURCES 5. WAREHOUSE RACKING DESIGN5. WAREHOUSE RACKING DESIGN 3. SQUARE FOOTAGE & CBM PLANNING3. SQUARE FOOTAGE & CBM PLANNING 1. EXECUTIVE SUMMARY1. EXECUTIVE SUMMARY 2. WAREHOUSE SITE SELECTION2. WAREHOUSE SITE SELECTION 4. WAREHOUSE SETUP4. WAREHOUSE SETUP 7. BEST PRACTICES7. BEST PRACTICES Table of ContentsTable of Contents

- 3. EXECUTIVE SUMMARYEXECUTIVE SUMMARY The planning is based on receiving 90-100 containers per month and overall storage capacity of 550-600 containers. Average inventory holding period is considered 4 mons. Objective of creating the warehouse and Distribution Center of Excellence is :- ÔÇó Perfect Orders ÔÇó On time Deliveries ÔÇó Inventory Accuracy ÔÇó Order cycle time ÔÇó Workforce Utilization ÔÇó Shipping accuracy ÔÇó Order fill rate ÔÇó Optimize labor productivity ÔÇó Organized workstations ÔÇó Improved picking methodology

- 4. Selecting a warehouse is a major decision and choosing the right location of a warehouse can make all the difference in the company's ability to compete and effectively serve customers. WAREHOUSE SITE SELECTIONWAREHOUSE SITE SELECTION The Major 6 criteria while selecting the best possible warehouse location. 1. Rent Rates1. Rent Rates 2. Work force Availability, Labor Skills & Cost2. Work force Availability, Labor Skills & Cost 3. Roads & Traffic Flow3. Roads & Traffic Flow 4. Proximity to Ports4. Proximity to Ports 5. Markets & Local environment factors5. Markets & Local environment factors 6. Building availability & Utility Cost6. Building availability & Utility Cost

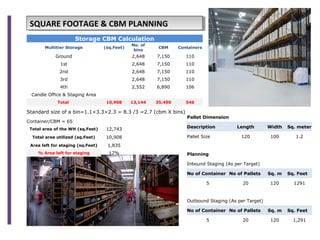

- 5. SQUARE FOOTAGE & CBM PLANNINGSQUARE FOOTAGE & CBM PLANNING Storage CBM Calculation Multitier Storage (sq.Feet) No. of bins CBM Containers Ground ╠² 2,648 7,150 110 1st ╠² 2,648 7,150 110 2nd ╠² 2,648 7,150 110 3rd ╠² 2,648 7,150 110 4th ╠² 2,552 6,890 106 Candle╠²Office╠²&╠²Staging╠²Area ╠² ╠² ╠² ╠² Total 10,908 13,144 35,490 546 Standard╠²size╠²of╠²a╠²bin=1.1├ù3.3├ù2.3╠²=╠²8.3╠²/3╠²=2.7╠²(cbm╠²X╠²bins) Container/CBM╠²=╠²65╠² Total area of the WH (sq.Feet) 12,743 Total area utilized (sq.Feet) 10,908 Area left for staging (sq.Feet) 1,835 % Area left for staging 17% Pallet Dimension Description Length Width Sq. meter Pallet╠²Size 120 100 1.2 ╠² Planning Inbound╠²Staging╠²(As╠²per╠²Target) No of Container No of Pallets Sq. m Sq. Feet 5 20 120 1291 ╠² Outbound╠²Staging╠²(As╠²per╠²Target) No of Container No of Pallets Sq. m Sq. Feet 5 20 120 1,291

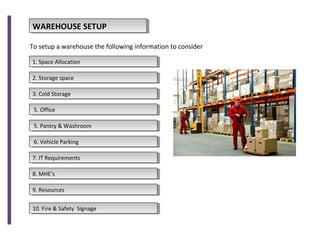

- 6. WAREHOUSE SETUPWAREHOUSE SETUP To setup a warehouse the following information to consider 1. Space Allocation1. Space Allocation 2. Storage space2. Storage space 3. Cold Storage3. Cold Storage 7. IT Requirements7. IT Requirements 5. Pantry & Washroom5. Pantry & Washroom 6. Vehicle Parking6. Vehicle Parking 5. Office5. Office 8. MHEÔÇÖs8. MHEÔÇÖs 9. Resources9. Resources 10. Fire & Safety Signage10. Fire & Safety Signage

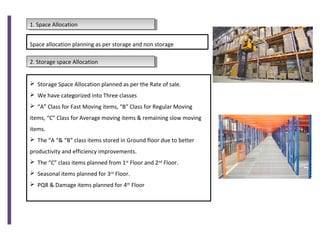

- 7. 1. Space Allocation1. Space Allocation ´âÿ Storage Space Allocation planned as per the Rate of sale. ´âÿ We have categorized into Three classes ´âÿ ÔÇ£AÔÇØ Class for Fast Moving items, ÔÇ£BÔÇØ Class for Regular Moving items, ÔÇ£CÔÇØ Class for Average moving items & remaining slow moving items. ´âÿ The ÔÇ£A ÔÇ£& ÔÇ£BÔÇØ class items stored in Ground floor due to better productivity and efficiency improvements. ´âÿ The ÔÇ£CÔÇØ class items planned from 1st Floor and 2nd Floor. ´âÿ Seasonal items planned for 3rd Floor. ´âÿ PQR & Damage items planned for 4th Floor 2. Storage space Allocation2. Storage space Allocation Space allocation planning as per storage and non storage

- 9. RESOURCES FOR WAREHOUSE OPERATIONSRESOURCES FOR WAREHOUSE OPERATIONS 1. Receiving / Inbound1. Receiving / Inbound 2. Putaway2. Putaway 3. Picking3. Picking 4. Inventory Management4. Inventory Management 5. Shipping5. Shipping 6. Office staffs6. Office staffs

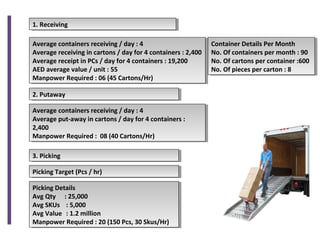

- 10. 1. Receiving1. Receiving Average containers receiving / day : 4 Average receiving in cartons / day for 4 containers : 2,400 Average receipt in PCs / day for 4 containers : 19,200 AED average value / unit : 55 Manpower Required : 06 (45 Cartons/Hr) Average containers receiving / day : 4 Average receiving in cartons / day for 4 containers : 2,400 Average receipt in PCs / day for 4 containers : 19,200 AED average value / unit : 55 Manpower Required : 06 (45 Cartons/Hr) 2. Putaway2. Putaway Average containers receiving / day : 4 Average put-away in cartons / day for 4 containers : 2,400 Manpower Required : 08 (40 Cartons/Hr) Average containers receiving / day : 4 Average put-away in cartons / day for 4 containers : 2,400 Manpower Required : 08 (40 Cartons/Hr) 3. Picking3. Picking Picking Target (Pcs / hr)Picking Target (Pcs / hr) Picking Details Avg Qty : 25,000 Avg SKUs : 5,000 Avg Value : 1.2 million Manpower Required : 20 (150 Pcs, 30 Skus/Hr) Picking Details Avg Qty : 25,000 Avg SKUs : 5,000 Avg Value : 1.2 million Manpower Required : 20 (150 Pcs, 30 Skus/Hr) Container Details Per Month No. Of containers per month : 90 No. Of cartons per container :600 No. Of pieces per carton : 8 Container Details Per Month No. Of containers per month : 90 No. Of cartons per container :600 No. Of pieces per carton : 8

- 11. 4. Inventory Management4. Inventory Management Cycle Count Audit (Bins/Day)Cycle Count Audit (Bins/Day) Bin Details Avg Bins/Day : 270 No of Days : 90 No of Times/Year : 03 Manpower Required : 02 Bin Details Avg Bins/Day : 270 No of Days : 90 No of Times/Year : 03 Manpower Required : 02 5. Shipping5. Shipping Average trips / day : 10 Avg replenishment cartons / day for 10 stores: 3,125 Avg replenishment in PCs / day for 10 stores : 25,000 Manpower Required : 05 Average trips / day : 10 Avg replenishment cartons / day for 10 stores: 3,125 Avg replenishment in PCs / day for 10 stores : 25,000 Manpower Required : 05

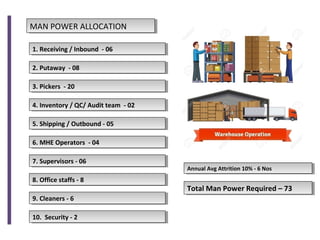

- 12. MAN POWER ALLOCATIONMAN POWER ALLOCATION 1. Receiving / Inbound - 061. Receiving / Inbound - 06 2. Putaway - 082. Putaway - 08 3. Pickers - 203. Pickers - 20 4. Inventory / QC/ Audit team - 024. Inventory / QC/ Audit team - 02 5. Shipping / Outbound - 055. Shipping / Outbound - 05 8. Office staffs - 88. Office staffs - 8 7. Supervisors - 067. Supervisors - 06 6. MHE Operators - 046. MHE Operators - 04 9. Cleaners - 69. Cleaners - 6 10. Security - 210. Security - 2 Total Man Power Required ÔÇô 73Total Man Power Required ÔÇô 73 Annual Avg Attrition 10% - 6 NosAnnual Avg Attrition 10% - 6 Nos

- 13. MHEÔÇÖs & PDTÔÇÖsMHEÔÇÖs & PDTÔÇÖs Reach Trucks - 2Reach Trucks - 2 PDTÔÇÖS - 40PDTÔÇÖS - 40 Hand lift trucks - 30Hand lift trucks - 30 BOPT - 2BOPT - 2 Fork lifts - 2Fork lifts - 2

- 14. Fire & Safety SignageFire & Safety Signage

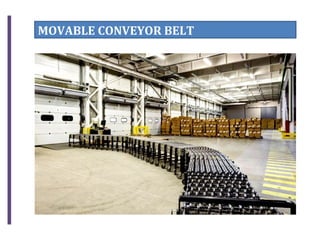

- 15. BEST PRACTICES FOR WAREHOUSE AND DISTRIBUTION CENTER OF EXCELLENCE BEST PRACTICES FOR WAREHOUSE AND DISTRIBUTION CENTER OF EXCELLENCE

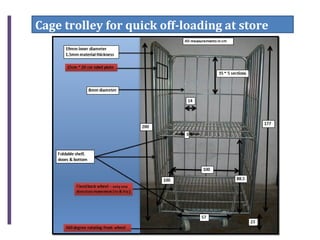

- 18. Cage trolley for quick off-loading at store

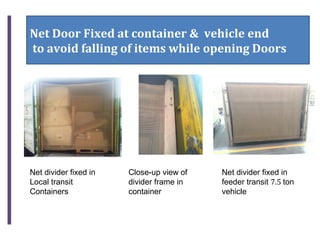

- 19. Net Door Fixed at container & vehicle end to avoid falling of items while opening Doors Net divider fixed in Local transit Containers Close-up view of divider frame in container Net divider fixed in feeder transit 7.5 ton vehicle

- 20. Box Pallet to Protect fragile items Box Pallet to protect mirrors and fragile items from in-transit damages. Box Pallet with removal led.

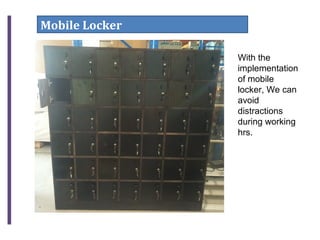

- 21. Mobile Locker With the implementation of mobile locker, We can avoid distractions during working hrs.

- 22. LED Industrial high bay light Lighting DonÔÇÖt use Industrial High bay Light with Bulb Power - 400w Use LED Industrial High bay Light Power ÔÇô 150w

- 23. Staking height indicator Staking height indicator should be fixed in bins for identification of maximum height of the bin while put away as per par norms.

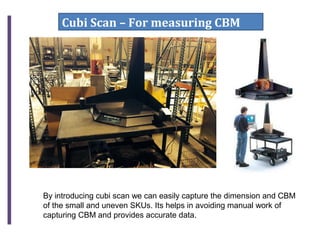

- 24. Cubi Scan ÔÇô For measuring CBM By introducing cubi scan we can easily capture the dimension and CBM of the small and uneven SKUs. Its helps in avoiding manual work of capturing CBM and provides accurate data.

- 25. PDT Cover By introducing PDT covers for pickers, put away team and shippers its will improve their productivity and reduces the chances of PDT getting damage during work.

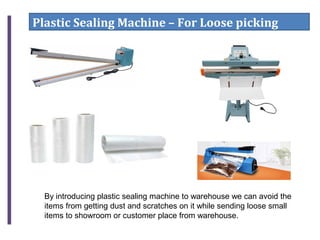

- 26. Plastic Sealing Machine ÔÇô For Loose picking By introducing plastic sealing machine to warehouse we can avoid the items from getting dust and scratches on it while sending loose small items to showroom or customer place from warehouse.

- 27. SUGGESTION FOR STORAGE We can use pallet boxes for storing case pick items (Small SKUÔÇÖs) and shifting fragile items to stores and other territories. It will protect the items from getting dust on it and also from damage.

- 28. SUGGESTION FOR LOADING We can use reusable pallet straps or cargo net for loading and sending items to other territories. It will protect the items from falling and saves cost for masking tape.