Butyl Tape Datasheet.pdf

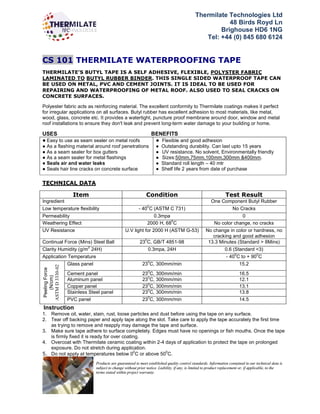

- 1. Thermilate Technologies Ltd 48 Birds Royd Ln Brighouse HD6 1NG Tel: +44 (0) 845 680 6124 CS 101 THERMILATE WATERPROOFING TAPE THERMILATE’S BUTYL TAPE IS A SELF ADHESIVE, FLEXIBLE, POLYSTER FABRIC LAMINATED TO BUTYL RUBBER BINDER. THIS SINGLE SIDED WATERPROOF TAPE CAN BE USED ON METAL, PVC AND CEMENT JOINTS. IT IS IDEAL TO BE USED FOR REPAIRING AND WATERPROOFING OF METAL ROOF. ALSO USED TO SEAL CRACKS ON CONCRETE SURFACES. Polyester fabric acts as reinforcing material. The excellent conformity to Thermilate coatings makes it perfect for irregular applications on all surfaces. Butyl rubber has excellent adhesion to most materials, like metal, wood, glass, concrete etc. It provides a watertight, puncture proof membrane around door, window and metal roof installations to ensure they don't leak and prevent long-term water damage to your building or home. USES BENEFITS ● Easy to use as seam sealer on metal roofs ● As a flashing material around roof penetrations ● As a seam sealer for box gutters ● As a seam sealer for metal flashings ● Seals air and water leaks ● Seals hair line cracks on concrete surface ● Flexible and good adhesion ● Outstanding durability. Can last upto 15 years ● UV resistance. No solvent, Environmentally friendly ● Sizes:50mm,75mm,100mm,300mm &400mm. ● Standard roll length – 40 mtr ● Shelf life 2 years from date of purchase TECHNICAL DATA Item Condition Test Result Ingredient One Component Butyl Rubber Low temperature flexibility - 40 0 C (ASTM C 731) No Cracks Permeability 0.3mpa 0 Weathering Effect 2000 H, 68 0 C No color change, no cracks UV Resistance U.V light for 2000 H (ASTM G-53) No change in color or hardness, no cracking and good adhesion Continual Force (Mins) Steel Ball 23 0 C, GB/T 4851-98 13.3 Minutes (Standard > 8Mins) Clarity Humidity (g/m 2 24H) 0.3mpa, 24H 0.6 (Standard <3) Application Temperature - 40 0 C to + 90 0 C Peeling Force (N/cm) ASTM D 3330-02 Glass panel 23 0 C, 300mm/min 15.2 Cement panel 23 0 C, 300mm/min 16.5 Aluminum panel 23 0 C, 300mm/min 12.1 Copper panel 230 C, 300mm/min 13.1 Stainless Steel panel 23 0 C, 300mm/min 13.8 PVC panel 230 C, 300mm/min 14.5 Instruction 1. Remove oil, water, stain, rust, loose particles and dust before using the tape on any surface. 2. Tear off backing paper and apply tape along the slot. Take care to apply the tape accurately the first time as trying to remove and reapply may damage the tape and surface. 3. Make sure tape adhere to surface completely. Edges must have no openings or fish mouths. Once the tape is firmly fixed it is ready for over coating. 4. Overcoat with Thermilate ceramic coating within 2-4 days of application to protect the tape on prolonged exposure. Do not stretch during application. 5. Do not apply at temperatures below 0 0 C or above 50 0 C. Products are guaranteed to meet established quality control standards. Information contained in our technical data is subject to change without prior notice. Liability, if any, is limited to product replacement or, if applicable, to the terms stated within project warranty.