Capsule

- 1. By MR. DILIP O. MORANI

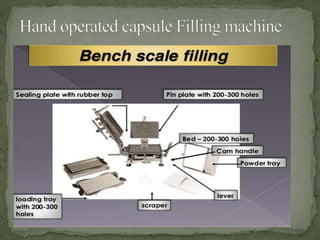

- 3. ï A bed with 200-300 holes ï A loading tray with 200-300 holes ï Powder tray ï A pin plate with 200-300 holes ï Lever ï Cam handle ï Sealing plate with rubber top ï Scraper

- 5. ï Most widely used of its kind in pharmaceutical industry. ï Small and reliable for small units. ï Speedy and efficient operations. ï Output- 6000 capsules/hour. ï Simple and sturdy machine. ï Made from high grade of stainless steel. ï All operations are manual.

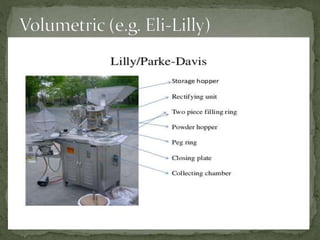

- 6. 1) Eli Lilly & Co. 2) Park-davis 3) Farmatic 4) Hofliger and Karg 5) Macofar 6) mG2 7) Osaka 8) Perry 9) Zanasi

- 7. 1) Volumetric- Powder is filled to the upper surface of body containing ring. 2) Dosator- Piston exert amount of force that compacts powder together and results in a slug that capsule filling machine later delivers into capsule. 3) Tamping-have several pins (5). It has a dosing disc with several holes on its surfaces.

- 9. ï Fill is volumetric. ï Powder is filled to the upper surface of body containing ring. ï Output- 2,00,000 capsules/hour. ï Filling rate-1200 capsules/minute. ï Maximum total fill weights are achieved with highest turntable speed and lowest rotational speed.

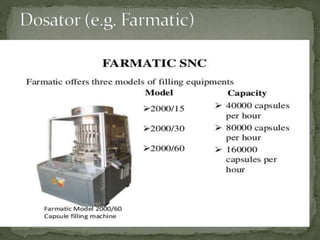

- 11. ï Machine feature continuous motion with dosator type powder feeding units. ï Totally enclosed for dust and noise control. ï Adjustable vacuum is used for separating the capsules after rectification. ï Dosator measure and deliver the powder as a slug to the capsules.

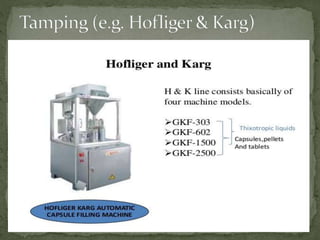

- 13. ï All models can be modified to accept powders, pellets or tablets. ï Powder is auger fed from hopper to filling chamber. ï Tamping of powder into holes of filling disc is performed at five successive stations. ï Tamps are externally adjustable at each individual station while machine is in operation. ï Additional station is available for insertion of tablets or pellets, so that mixed fills can be achieved.

- 14. THANK YOU