Case Study_Omax Autos

- 1. ENERGY CONSERVATION & RENEWABLE ENERGY An OMAX case study

- 5. Overview Amongst top three companies in Automotive Stamping and two wheeler & Commercial vehicle Chassis manufacturing- (Process 85k Tons Steel pa) Largest Sprocket manufacturing capacity (11 Million pa) in South East Asia. Facilities Largest Tri Nickel Chrome Plating facility (120 Million DM2) Largest & full spectrum welding facility in India with robots & 800 MIG welding sets (100 Km welding capacity per day) Largest consolidated Piston Rod manufacturing facility with super finishing capability catering to Europe & United States.

- 6. ONE STOP SOLUTION: Designing Automotive Stampings Two Wheel & Commercial Vehicle Chassis manufacturing Process Capability Machined Parts – Sprockets/ Piston Rods/ Oil Pumps/ Transmission Shafts Full spectrum welding process- Robotic MIG, spot and friction Powder Coating & Liquid Painting Zn Plating, Tri Nickel Chrome Painting & Hard Chrome Plating

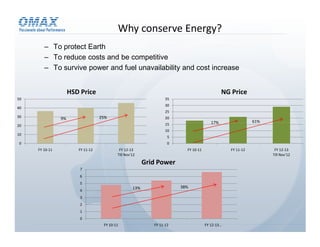

- 7. Why conserve Energy? – To protect Earth – To reduce costs and be competitive – To survive power and fuel unavailability and cost increase HSD Price NG Price 50 35 30 40 25 30 9% 25% 20 17% 61% 20 15 10 10 5 0 0 FY 10-11 FY 11-12 FY 12-13 FY 10-11 FY 11-12 FY 12-13 Till Nov'12 Till Nov'12 Grid Power 7 6 5 13% 38% 4 3 2 1 0 FY 10-11 FY 11-12 FY 12-13…

- 8. Why conserve energy? Power & Fuel Cost Power & Fuel Cost would be almost double!! Actual If unattended FY 08-09 FY 09-10 FY 10-11 FY 11-12 FY 12-13… Daily Average Power Cut Hours 14 12 ~ 6 hrs of power cut 10 everyday (25%) 8 6 Daily Average Power 4 Cut Hours 2 0 Apr-12 May-12 Jun-12 Jul-12 Aug-12 Sep-12 Oct-12

- 9. Energy Conservation Strategy Energy Saving Strategy PHASE I PHASE II PHASE III Move towards Reduce Energy Reduce Energy Renewable Consumption Cost Energy Energy Audits and Reduction in Contract Demand Optimization Rooftop Solar Power Trading Waste Heat Recovery Cheaper Alternate Fuel Saver Devices Fuels Monitoring and (Pet coke, Rice husk, briquettes Future Plan Management 1 MW Rooftop Solar for etc.) Captive Power

- 10. Power Factor • P is the Active power (kW) • S is the apparent power (kVA) • Q is the reactive power • Reactive power is necessary to generate the magnetic field needed to run certain types of loads like lighting, induction motors, electric furnaces • But it also tends to increase the difference between P and S. If PF is not close to 1, we will be paying for more power than we actually use. Dharuhera 0.99 Speedomax 0.98 Binola 0.99 Manesar 0.99

- 11. Conventional vs Waste Heat Recovery Exhaust HRU Steam generation Air Conditioning Exhaust DG SET DG SET FUEL FUEL Jacket Water Jacket Water Air Conditioning Cooling Tower

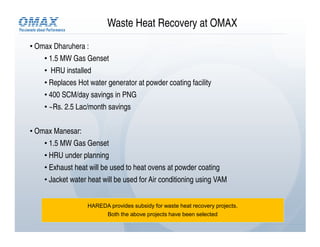

- 12. Waste Heat Recovery at OMAX • Omax Dharuhera : • 1.5 MW Gas Genset • HRU installed • Replaces Hot water generator at powder coating facility • 400 SCM/day savings in PNG • ~Rs. 2.5 Lac/month savings • Omax Manesar: • 1.5 MW Gas Genset • HRU under planning • Exhaust heat will be used to heat ovens at powder coating • Jacket water heat will be used for Air conditioning using VAM HAREDA provides subsidy for waste heat recovery projects. Both the above projects have been selected

- 13. Fuel Saving Techniques Catalytic Fuel Saver device • Installed at the diesel line inlet of DG, burners • Simple catalytic device • Results in savings of about 6 - 9% in fuel consumption Diesel Additive • 250 ml of additive for every 1000 ltr of Diesel • Improves the fuel properties • Results in savings of 5 -10%

- 14. Technology Upgrade • Modular type IGBT rectifier to replace old technology rectifiers in Electroplating • Approx 20% higher efficiency • Easy to maintain and upgrade Innovative Day-lighting system • Innovative method to utilize Sun’s visible light indoors • No heat addition • project in process

- 15. WATERLESS URINAL • Water and Energy are inter linked • Saving water saves energy and reduces cost • Savings by means of reduction in: • Pumping power • Treatment cost

- 16. Omax Renewable Energy • 2 x 100 kWp rooftop solar power plants have been installed for captive use • 2 x 1.25 MW Grid Connected, Wind Turbine Generators have been commissioned at Jaisalmer, Rajasthan in 2012. • Further 1 MW Rooftop Solar has been planned in FY 13-14 for captive use across our manufacturing units.

- 17. Omax Renewable Energy 2.5 MW 200 kWp

- 18. Mega Watt scale Solar Projects • Omax is venturing into the Solar EPC sector • Installation of MW scale rooftop Solar Power Plants for Captive use • Easy to adapt financial model • Long term hedging against power cost increase • Added benefits through Renewable Energy Certificates (REC). CLEAN ENERGY GREEN ENERGY

- 19. Gallery SOLAR 100 kWp SOLAR 100 kWp LED FUEL SAVER HRU LED

- 20. Gallery Powerless exhaust VFD on compressors Timers Servo Voltage Stabilizer

- 21. NEED OF THE HOUR ACTION!! Thank you!! Save Energy Save Earth