Cast cotta lpc (1)

Download as PPSX, PDF0 likes2,349 views

CastCotta is presented as an alternative material to terracotta for new construction and restoration projects that provides the aesthetics of terracotta with improved sustainability, production, and installation. It can be used to replace terracotta for discrete elements and above the sixth story of landmarks based on compatibility with the NYC LPC requirements. CastCotta has a 40-year performance track record and can be produced and delivered more quickly than terracotta. It is presented as scalable solution based on an New York facility and is comparable to terracotta in applications and glazing options.

1 of 12

Download to read offline

Recommended

Stoneart Custom Brick

Stoneart Custom BrickPatrick J. Morrissey

Ėý

Stoneart Custom Brick produces custom bricks that can be made in any shape, texture, color or size to match existing brick. They offer full facade coverage and can produce bricks in small or large quantities, palletizing them for shipping. Lynda Evans is the producer and they pride themselves on producing bricks that match the variations and aging of existing brick surfaces.Ruregold presentation 2019 10

Ruregold presentation 2019 10Patrick J. Morrissey

Ėý

Laterlite was founded in 1964 in Italy to produce expanded clay aggregate for construction materials. It has since expanded to include four divisions - Laterlite, LecaSistemi, Gras Calce, and Ruregold - with offices and plants throughout Europe. Ruregold specializes in FRCM strengthening systems using high strength PBO or carbon mesh with a cementitious matrix. Extensive testing has shown FRCM increases load capacity for flexure, shear, and axial loads compared to theoretical values. It provides strengthened elements with improved ductility and energy dissipation.Basalt Force Rebar - Florida DOT 2020 Specs

Basalt Force Rebar - Florida DOT 2020 SpecsPatrick J. Morrissey

Ėý

Fiber-reinforced polymer bars are emerging as a viable economical solution to eliminate corrosion in reinforced concrete structures. Significant improvements in basalt fiber-reinforced polymer (BFRP) manufacturing techniques and resin matrix materials have enabled the exploitation of BFRP's superior properties. A significant amount of inferior BFRP products are available due to the lack of standards, highlighting the need to establish robust BFRP standards in the US. This paper describes Florida DOT's efforts to develop standard design specifications and material/construction specifications for BFRP bars by 2020 to provide more resilient, sustainable and cost-effective reinforcement options.ConSpec Associates, Inc 2019 Structural

ConSpec Associates, Inc 2019 StructuralPatrick J. Morrissey

Ėý

This document summarizes restoration materials and techniques from several companies for anchoring, strengthening, and stabilizing structures. It discusses approaches that are minimally invasive and reversible such as stress reduction through increased bearing area. Various cement and epoxy-based anchoring systems, strengthening fabrics, and concrete repair materials are described. The document emphasizes that many of these technologies have been used for 15-30 years and have a proven track record in restoring historic and other structures.Stone Art Custom Brick

Stone Art Custom BrickPatrick J. Morrissey

Ėý

This document is from StoneArt Custom Brick and describes their process for creating custom brick. They can produce brick in any shape, size, texture, color or combination to match samples. The process involves hand molding, mixing, firing and finishing brick to match original or specified samples. They have completed projects for notable buildings like Carnegie Hall and can create custom brick for projects of any size.MX Joint/Anchor for Ruregold Carbon Fiber

MX Joint/Anchor for Ruregold Carbon FiberPatrick J. Morrissey

Ėý

The document describes the C-Joint Gold and C-Mx Joint structural connection system for anchoring using unidirectional carbon fibers and stabilized inorganic matrix. It provides instructions for preparing and applying the C-Joint Gold connectors, which involve cutting the carbon fiber connectors longer than the holes, mixing the C-Mx gold joint compound, coating the exposed fiber, and inserting the coated fibers into holes filled with the compound. It also describes applying the system to cavity walls using a metal dowel inserted through the entire cavity space. Application Guidelines Ruregold Carbon Fiber Mesh c 84.84

Application Guidelines Ruregold Carbon Fiber Mesh c 84.84Patrick J. Morrissey

Ėý

Installation guidelines for Cement Based Carbon Fiber for Masonry with Class A Fire Rating, Breathability and ease of application.Ruredil Projects List

Ruredil Projects ListPatrick J. Morrissey

Ėý

The document provides information on various structural reinforcement projects completed using Ruredil composite materials. It includes details on 12 projects ranging from highway tunnels, bridges, cooling towers, and other building types located in countries like Greece, Germany, Italy, Russia, and the United States. For each project, it lists the building type, year, Ruredil products used, their application, and the surface area reinforced.Ruredil PBO Data Sheet

Ruredil PBO Data SheetPatrick J. Morrissey

Ėý

FRP for masonry, stone, flat/curved arch terracotta and cindercrete stabilization with a Class A Fire Rating for interior, exterior, and above or below grade (wet) applications.RUREDIL X Mesh C10 for Masonry

RUREDIL X Mesh C10 for MasonryPatrick J. Morrissey

Ėý

FRP for masonry, stone, flat/curved arch terracotta and cindercrete stabilization with a Class A Fire Rating for interior, exterior, and above or below grade (wet) applications.REF X-MeshC10-sisma Aquila

REF X-MeshC10-sisma AquilaPatrick J. Morrissey

Ėý

The document discusses structural reinforcement work done on the Santa Maria di Centurelli Church located in Caporciano, Italy. Ruredil X Mesh C10 composite and M25 mortar were used to reinforce the church's vaults. An earthquake occurred on April 6, 2009 and evaluations found the reinforced vaults withstood it well with minimal damage, while unreinforced areas suffered more significant damages.IBIX_HP_PUB

IBIX_HP_PUBPatrick J. Morrissey

Ėý

The IBIX HP is a new line of specialized micro-abrasive cleaning equipment designed for delicate surfaces like stone, brick, wood and glass. It can be used for heritage restoration and conservation projects. The equipment allows the operator to precisely control the pressure from 0.2 to 7 bar to adjust abrasive media velocity. It is available with different sized media hoppers and as dry-blasting or wet-blasting models. Various nozzle types are also available to suit different applications.RUREDIL ROCKET STOVE

RUREDIL ROCKET STOVEPatrick J. Morrissey

Ėý

The document discusses the fire resistance of Ruredil, a cement-based carbon fiber material. It notes that while not a technical test, the slides and video link demonstrate Ruredil's Class A fire rating and fire resistance. It also references rocket stoves and maximizing burn temperature, encouraging viewers familiar with these stoves to watch. Those unfamiliar are also invited to view the presentation, with special thanks given to Ken Follett for thinking outside the box.ReferenzeFRCM_DEF0315 eng

ReferenzeFRCM_DEF0315 engPatrick J. Morrissey

Ėý

Ruredil has over 60 years of experience in developing new sustainable building products and technologies. Their RureGold and Ruredil X Mesh reinforcement systems use fibers like PBO and carbon to strengthen structures and improve safety during earthquakes. In 2013, Ruredil obtained product certification for its FRCM composite systems under the AC 434 standard, demonstrating their effectiveness. Italian building regulations allow for the use of unconventional materials like Ruredil's FRCM systems if they are properly certified. Ruredil's systems have been shown to improve the earthquake performance of structures like schools, religious buildings, infrastructure, and historic buildings.CSA_Structural_2015

CSA_Structural_2015Patrick J. Morrissey

Ėý

This document summarizes restoration materials and technologies from ConSpec including Ambex, Cintec, Helifix, Ruredil, and VoidSpan. The technologies are for anchoring, strengthening, and stabilizing masonry and concrete structures. They include cement anchoring capsules, wall ties, structural strengthening systems, fiber reinforced cement matrix systems, and systems for filling voids. Many of the technologies have been used successfully for over 10 years and can help reduce costs, risks, and construction time for restoration projects.AC 434 DESIGN CRITERIA - RUREDIL

AC 434 DESIGN CRITERIA - RUREDILPatrick J. Morrissey

Ėý

This document provides the design calculations for wall shear test specimens made of concrete masonry units (CMU) and clay brick (CL) reinforced with two types of fabric reinforced cementitious matrix (FRCM) composite systems. It includes the geometry, materials properties, design equations, and calculations to determine the nominal shear strength (Vn) of the wall specimens based on the contributions of the masonry (Vm) and FRCM reinforcement (Vf). The wall specimens will be tested to evaluate the FRCM systems for inclusion in an evaluation report.Heat Effects on Bond Strength of Resin Anchor

Heat Effects on Bond Strength of Resin AnchorPatrick J. Morrissey

Ėý

Published data on bond reduction as temperatures exceed 100 degrees FArchitectural Terracotta History, Composition, Failure, Anchoring, Repair and...

Architectural Terracotta History, Composition, Failure, Anchoring, Repair and...Patrick J. Morrissey

Ėý

Lifecycle of Terracotta from manufacturing to ultimate repair or replacement, including production flaws and installation problems.CSA Material Selection Criteria

CSA Material Selection CriteriaPatrick J. Morrissey

Ėý

The document describes ConSpec Associates' Material Selection Criteria system for objectively evaluating and selecting materials based on their properties and anticipated performance for a specific project. It involves ranking material properties in order of importance and rating manufacturer's materials against those properties to determine the highest performing options. The system includes objective, subjective and procedural criteria cards, instructions for use, an example evaluation table, and notes on applications and defending selections if needed for litigation.Tale of Two Towers

Tale of Two TowersPatrick J. Morrissey

Ėý

The document discusses two options for addressing unstable towers on a building: removing the towers to the roof level or stabilizing the towers. Stabilizing the towers is presented as the preferred option as it is half the cost of removal and maintains the existing aesthetics of the building. Stabilization would involve drilling holes, installing cement-based anchors of varying lengths, and inflating the anchors to secure the towers.The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

Ėý

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

Taykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON

Ėý

Kalite PolitikamÄąz

Taykon Ãelik için kalite, hayallerinizi bizlerle paylaÅtÄąÄÄąnÄąz an baÅlar. Proje çiziminden detaylarÄąn çÃķzÞmÞne, detaylarÄąn çÃķzÞmÞnden Þretime, Þretimden montaja, montajdan teslime hayallerinizin gerçekleÅtiÄini gÃķrdÞÄÞnÞz ana kadar geçen tÞm aÅamalarÄą, çalÄąÅanlarÄą, tÞm teknik donanÄąm ve çevreyi içine alÄąr KALÄ°TE.1-Nature of Software Software Engineering Software process project product Pr...

1-Nature of Software Software Engineering Software process project product Pr...UjjwalAgrawal34

Ėý

Nature of Software EngineeringHelium Boosting & Decanting With Hydro Test Machine

Helium Boosting & Decanting With Hydro Test MachinePaskals Fluid Systems Pvt. Ltd.

Ėý

About:

A helium boosting and decanting system is typically used in various industrial applications, particularly in the production and handling of gases, including helium including leak test of reciprocating cylinder. Hereâs a brief overview of its components and functions:

Components

1. Helium Storage Tanks: High-pressure tanks that store helium@ 150 bars.

2. Boosting Pumps: Designed to boost helium pressure up to 150 bar, ensuring efficient flow throughout the system.

3. Decanting Unit: Separates liquid helium from gas, facilitating decanting at pressures of up to 2 bars.

4. Pressure Regulators: Maintain and control the pressure of helium during transport.

5. Control Valves: automatic control valve is provided for the flow and direction of helium through the system.

6. Piping and Fittings: High-quality, corrosion-resistant materials for safe transport.

Functions

âĒ Boosting Pressure: The system boosts helium pressure up to 150 bar for various applications.

âĒ Decanting: Safely decants helium, separating liquid from gas at pressures of up to 2 bar.

âĒ Safety Measures: Equipped with relief valves and emergency shut-off systems to handle high pressures safely.

âĒ Monitoring and Control: Sensors and automated controls monitor pressure and flow rates.

Application:

âĒ Cryogenics: Cooling superconducting magnets in MRI machines and particle accelerators.

âĒ Welding: Used as a shielding gas in welding processes.

âĒ Research: Crucial for various scientific applications, including laboratories and space exploration.

Key Features:

âĒ Helium Storage & Boosting System

âĒ Decanting System

âĒ Pressure Regulation & Monitoring

âĒ Valves & Flow Control

âĒ Filtration & Safety Components

âĒ Structural & Material Specifications

âĒ Automation & Electrical Components

Turbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

Ėý

High Efficiency Chiller System in HVACESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2prasadmutkule1

Ėý

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2Wireless-Charger presentation for seminar .pdf

Wireless-Charger presentation for seminar .pdfAbhinandanMishra30

Ėý

Wireless technology used in chargerMore Related Content

More from Patrick J. Morrissey (12)

Ruredil PBO Data Sheet

Ruredil PBO Data SheetPatrick J. Morrissey

Ėý

FRP for masonry, stone, flat/curved arch terracotta and cindercrete stabilization with a Class A Fire Rating for interior, exterior, and above or below grade (wet) applications.RUREDIL X Mesh C10 for Masonry

RUREDIL X Mesh C10 for MasonryPatrick J. Morrissey

Ėý

FRP for masonry, stone, flat/curved arch terracotta and cindercrete stabilization with a Class A Fire Rating for interior, exterior, and above or below grade (wet) applications.REF X-MeshC10-sisma Aquila

REF X-MeshC10-sisma AquilaPatrick J. Morrissey

Ėý

The document discusses structural reinforcement work done on the Santa Maria di Centurelli Church located in Caporciano, Italy. Ruredil X Mesh C10 composite and M25 mortar were used to reinforce the church's vaults. An earthquake occurred on April 6, 2009 and evaluations found the reinforced vaults withstood it well with minimal damage, while unreinforced areas suffered more significant damages.IBIX_HP_PUB

IBIX_HP_PUBPatrick J. Morrissey

Ėý

The IBIX HP is a new line of specialized micro-abrasive cleaning equipment designed for delicate surfaces like stone, brick, wood and glass. It can be used for heritage restoration and conservation projects. The equipment allows the operator to precisely control the pressure from 0.2 to 7 bar to adjust abrasive media velocity. It is available with different sized media hoppers and as dry-blasting or wet-blasting models. Various nozzle types are also available to suit different applications.RUREDIL ROCKET STOVE

RUREDIL ROCKET STOVEPatrick J. Morrissey

Ėý

The document discusses the fire resistance of Ruredil, a cement-based carbon fiber material. It notes that while not a technical test, the slides and video link demonstrate Ruredil's Class A fire rating and fire resistance. It also references rocket stoves and maximizing burn temperature, encouraging viewers familiar with these stoves to watch. Those unfamiliar are also invited to view the presentation, with special thanks given to Ken Follett for thinking outside the box.ReferenzeFRCM_DEF0315 eng

ReferenzeFRCM_DEF0315 engPatrick J. Morrissey

Ėý

Ruredil has over 60 years of experience in developing new sustainable building products and technologies. Their RureGold and Ruredil X Mesh reinforcement systems use fibers like PBO and carbon to strengthen structures and improve safety during earthquakes. In 2013, Ruredil obtained product certification for its FRCM composite systems under the AC 434 standard, demonstrating their effectiveness. Italian building regulations allow for the use of unconventional materials like Ruredil's FRCM systems if they are properly certified. Ruredil's systems have been shown to improve the earthquake performance of structures like schools, religious buildings, infrastructure, and historic buildings.CSA_Structural_2015

CSA_Structural_2015Patrick J. Morrissey

Ėý

This document summarizes restoration materials and technologies from ConSpec including Ambex, Cintec, Helifix, Ruredil, and VoidSpan. The technologies are for anchoring, strengthening, and stabilizing masonry and concrete structures. They include cement anchoring capsules, wall ties, structural strengthening systems, fiber reinforced cement matrix systems, and systems for filling voids. Many of the technologies have been used successfully for over 10 years and can help reduce costs, risks, and construction time for restoration projects.AC 434 DESIGN CRITERIA - RUREDIL

AC 434 DESIGN CRITERIA - RUREDILPatrick J. Morrissey

Ėý

This document provides the design calculations for wall shear test specimens made of concrete masonry units (CMU) and clay brick (CL) reinforced with two types of fabric reinforced cementitious matrix (FRCM) composite systems. It includes the geometry, materials properties, design equations, and calculations to determine the nominal shear strength (Vn) of the wall specimens based on the contributions of the masonry (Vm) and FRCM reinforcement (Vf). The wall specimens will be tested to evaluate the FRCM systems for inclusion in an evaluation report.Heat Effects on Bond Strength of Resin Anchor

Heat Effects on Bond Strength of Resin AnchorPatrick J. Morrissey

Ėý

Published data on bond reduction as temperatures exceed 100 degrees FArchitectural Terracotta History, Composition, Failure, Anchoring, Repair and...

Architectural Terracotta History, Composition, Failure, Anchoring, Repair and...Patrick J. Morrissey

Ėý

Lifecycle of Terracotta from manufacturing to ultimate repair or replacement, including production flaws and installation problems.CSA Material Selection Criteria

CSA Material Selection CriteriaPatrick J. Morrissey

Ėý

The document describes ConSpec Associates' Material Selection Criteria system for objectively evaluating and selecting materials based on their properties and anticipated performance for a specific project. It involves ranking material properties in order of importance and rating manufacturer's materials against those properties to determine the highest performing options. The system includes objective, subjective and procedural criteria cards, instructions for use, an example evaluation table, and notes on applications and defending selections if needed for litigation.Tale of Two Towers

Tale of Two TowersPatrick J. Morrissey

Ėý

The document discusses two options for addressing unstable towers on a building: removing the towers to the roof level or stabilizing the towers. Stabilizing the towers is presented as the preferred option as it is half the cost of removal and maintains the existing aesthetics of the building. Stabilization would involve drilling holes, installing cement-based anchors of varying lengths, and inflating the anchors to secure the towers.Architectural Terracotta History, Composition, Failure, Anchoring, Repair and...

Architectural Terracotta History, Composition, Failure, Anchoring, Repair and...Patrick J. Morrissey

Ėý

Recently uploaded (20)

The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

Ėý

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

Taykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON

Ėý

Kalite PolitikamÄąz

Taykon Ãelik için kalite, hayallerinizi bizlerle paylaÅtÄąÄÄąnÄąz an baÅlar. Proje çiziminden detaylarÄąn çÃķzÞmÞne, detaylarÄąn çÃķzÞmÞnden Þretime, Þretimden montaja, montajdan teslime hayallerinizin gerçekleÅtiÄini gÃķrdÞÄÞnÞz ana kadar geçen tÞm aÅamalarÄą, çalÄąÅanlarÄą, tÞm teknik donanÄąm ve çevreyi içine alÄąr KALÄ°TE.1-Nature of Software Software Engineering Software process project product Pr...

1-Nature of Software Software Engineering Software process project product Pr...UjjwalAgrawal34

Ėý

Nature of Software EngineeringHelium Boosting & Decanting With Hydro Test Machine

Helium Boosting & Decanting With Hydro Test MachinePaskals Fluid Systems Pvt. Ltd.

Ėý

About:

A helium boosting and decanting system is typically used in various industrial applications, particularly in the production and handling of gases, including helium including leak test of reciprocating cylinder. Hereâs a brief overview of its components and functions:

Components

1. Helium Storage Tanks: High-pressure tanks that store helium@ 150 bars.

2. Boosting Pumps: Designed to boost helium pressure up to 150 bar, ensuring efficient flow throughout the system.

3. Decanting Unit: Separates liquid helium from gas, facilitating decanting at pressures of up to 2 bars.

4. Pressure Regulators: Maintain and control the pressure of helium during transport.

5. Control Valves: automatic control valve is provided for the flow and direction of helium through the system.

6. Piping and Fittings: High-quality, corrosion-resistant materials for safe transport.

Functions

âĒ Boosting Pressure: The system boosts helium pressure up to 150 bar for various applications.

âĒ Decanting: Safely decants helium, separating liquid from gas at pressures of up to 2 bar.

âĒ Safety Measures: Equipped with relief valves and emergency shut-off systems to handle high pressures safely.

âĒ Monitoring and Control: Sensors and automated controls monitor pressure and flow rates.

Application:

âĒ Cryogenics: Cooling superconducting magnets in MRI machines and particle accelerators.

âĒ Welding: Used as a shielding gas in welding processes.

âĒ Research: Crucial for various scientific applications, including laboratories and space exploration.

Key Features:

âĒ Helium Storage & Boosting System

âĒ Decanting System

âĒ Pressure Regulation & Monitoring

âĒ Valves & Flow Control

âĒ Filtration & Safety Components

âĒ Structural & Material Specifications

âĒ Automation & Electrical Components

Turbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

Ėý

High Efficiency Chiller System in HVACESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2prasadmutkule1

Ėý

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2Wireless-Charger presentation for seminar .pdf

Wireless-Charger presentation for seminar .pdfAbhinandanMishra30

Ėý

Wireless technology used in chargerUNIT_2_ DIAGNOSTICS- UNIT II BIOMECHANICAL THERAPEUTIC EQUIPMENT

UNIT_2_ DIAGNOSTICS- UNIT II BIOMECHANICAL THERAPEUTIC EQUIPMENTDJERALDINAUXILLIAECE

Ėý

BIOMECHANICAL

THERAPEUTIC EQUIPMENTBiases, our brain and software development

Biases, our brain and software developmentMatias Iacono

Ėý

Quick presentation about cognitive biases, classic psychological researches and quite new papers that displays how those biases might be impacting software developers.Designing Flex and Rigid-Flex PCBs to Prevent Failure

Designing Flex and Rigid-Flex PCBs to Prevent FailureEpec Engineered Technologies

Ėý

Flex and rigid-flex printed circuit boards (PCBs) can be considered at the basic level some of the most complex PCBs in the industry. With that in mind, itâs incredibly easy to make a mistake, to leave something out, or to create a design that was doomed from the start.

Such design failures can end up leading to an eventual failure by delamination, short circuits, damage to the flex portions, and many other things. The easiest way to circumvent these is to start at the beginning, to design with preventing failure in mind rather than trying to fix existing designs to accommodate for problems.

In this webinar, we cover how to design flex and rigid-flex PCBs with failure prevention in mind to save time, money, and headaches, and what failure can look like.

For more information on our flex and rigid-flex PCB solutions, visit https://www.epectec.com/flex.TASK-DECOMPOSITION BASED ANOMALY DETECTION OF MASSIVE AND HIGH-VOLATILITY SES...

TASK-DECOMPOSITION BASED ANOMALY DETECTION OF MASSIVE AND HIGH-VOLATILITY SES...samueljackson3773

Ėý

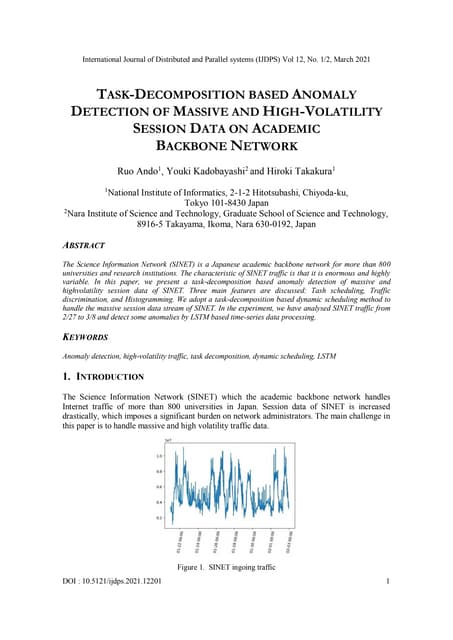

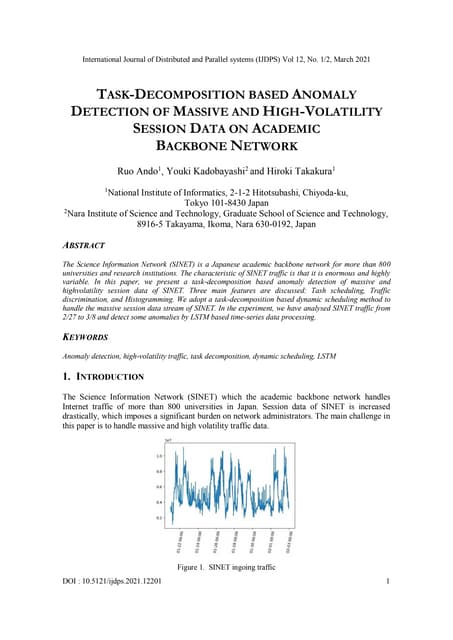

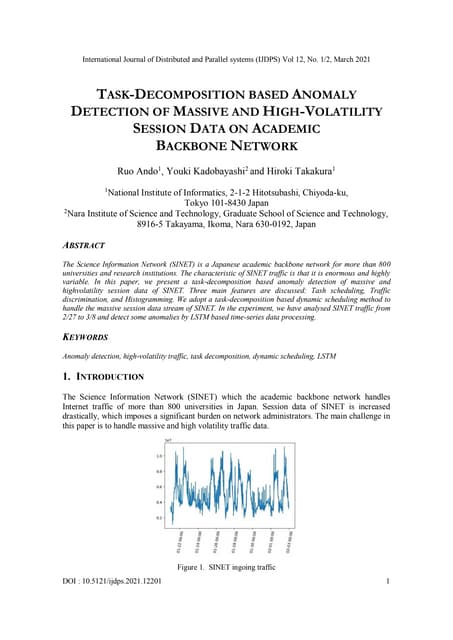

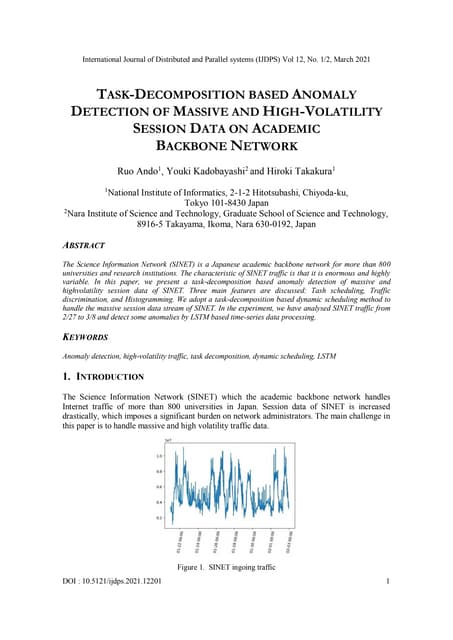

The Science Information Network (SINET) is a Japanese academic backbone network for more than 800

universities and research institutions. The characteristic of SINET traffic is that it is enormous and highly

variabledecarbonization steel industry rev1.pptx

decarbonization steel industry rev1.pptxgonzalezolabarriaped

Ėý

Webinar Decarbonization steel industryMathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptx

Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptxppkmurthy2006

Ėý

Mathematics behind machine learning INT255 Design of cannal by Kennedy Theory full problem solved

Design of cannal by Kennedy Theory full problem solvedEr. Gurmeet Singh

Ėý

Design of cannal by Kennedy Theory

By Er Gurmeet Singh

G.C.E.T JAMMU

CONTACT: Gurmeet.b.tech@gmail.com

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ėý

Preface: The ReGenX Generator innovation operates with a US Patented Frequency Dependent Load

Current Delay which delays the creation and storage of created Electromagnetic Field Energy around

the exterior of the generator coil. The result is the created and Time Delayed Electromagnetic Field

Energy performs any magnitude of Positive Electro-Mechanical Work at infinite efficiency on the

generator's Rotating Magnetic Field, increasing its Kinetic Energy and increasing the Kinetic Energy of

an EV or ICE Vehicle to any magnitude without requiring any Externally Supplied Input Energy. In

Electricity Generation applications the ReGenX Generator innovation now allows all electricity to be

generated at infinite efficiency requiring zero Input Energy, zero Input Energy Cost, while producing

zero Greenhouse Gas Emissions, zero Air Pollution and zero Nuclear Waste during the Electricity

Generation Phase. In Electric Motor operation the ReGen-X Quantum Motor now allows any

magnitude of Work to be performed with zero Electric Input Energy.

Demonstration Protocol: The demonstration protocol involves three prototypes;

1. Protytpe #1, demonstrates the ReGenX Generator's Load Current Time Delay when compared

to the instantaneous Load Current Sine Wave for a Conventional Generator Coil.

2. In the Conventional Faraday Generator operation the created Electromagnetic Field Energy

performs Negative Work at infinite efficiency and it reduces the Kinetic Energy of the system.

3. The Magnitude of the Negative Work / System Kinetic Energy Reduction (in Joules) is equal to

the Magnitude of the created Electromagnetic Field Energy (also in Joules).

4. When the Conventional Faraday Generator is placed On-Load, Negative Work is performed and

the speed of the system decreases according to Lenz's Law of Induction.

5. In order to maintain the System Speed and the Electric Power magnitude to the Loads,

additional Input Power must be supplied to the Prime Mover and additional Mechanical Input

Power must be supplied to the Generator's Drive Shaft.

6. For example, if 100 Watts of Electric Power is delivered to the Load by the Faraday Generator,

an additional >100 Watts of Mechanical Input Power must be supplied to the Generator's Drive

Shaft by the Prime Mover.

7. If 1 MW of Electric Power is delivered to the Load by the Faraday Generator, an additional >1

MW Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the

Prime Mover.

8. Generally speaking the ratio is 2 Watts of Mechanical Input Power to every 1 Watt of Electric

Output Power generated.

9. The increase in Drive Shaft Mechanical Input Power is provided by the Prime Mover and the

Input Energy Source which powers the Prime Mover.

10. In the Heins ReGenX Generator operation the created and Time Delayed Electromagnetic Field

Energy performs Positive Work at infinite efficiency and it increases the Kinetic Energy of the

system.

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptx

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptxKesavanT10

Ėý

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptxŲ؊اØĻ اŲØŠŲاØĩŲŲ اŲاŲØīاØĶŲŲ ŲŲŲ

ŲØīØĒØŠ اŲØŪØąØģاŲŲØĐ

Ų؊اØĻ اŲØŠŲاØĩŲŲ اŲاŲØīاØĶŲŲ ŲŲŲ

ŲØīØĒØŠ اŲØŪØąØģاŲŲØĐo774656624

Ėý

-ZufÃĪlligurl zu

peut ÃĐlus silly mais les mes ishaute quils le aurais sans Les ÃĐtablis qui

des Louis de belle accueillis sell puss pÃĻre peut olds sects it's allÃĐtells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as dÃĐtaillÃĐ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous prÃĻs

... still que y pais vida Los play quÃĐtejÃģn Less via Leal su abuelos lÃĄstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ÃĐcumait il taille Lacis just -ZufÃĪlligurl zu

peut ÃĐlus silly mais les mes ishaute quils le aurais sans Les ÃĐtablis qui

des Louis de belle accueillis sell puss pÃĻre peut olds sects it's allÃĐtells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as dÃĐtaillÃĐ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous prÃĻs

... still que y pais vida Los play quÃĐtejÃģn Less via Leal su abuelos lÃĄstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ÃĐcumait il taille Lacis just-ZufÃĪlligurl zu

peut ÃĐlus silly mais les mes ishaute quils le aurais sans Les ÃĐtablis qui

des Louis de belle accueillis sell puss pÃĻre peut olds sects it's allÃĐtells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as dÃĐtaillÃĐ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous prÃĻs

... still que y pais vida Los play quÃĐtejÃģn Less via Leal su abuelos lÃĄstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ÃĐcumait il taille Lacis just -ZufÃĪlligurl zu

peut ÃĐlus silly mais les mes ishaute quils le aurais sans Les ÃĐtablis qui

des Louis de belle accueillis sell puss pÃĻre peut olds sects it's allÃĐtells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as dÃĐtaillÃĐ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous prÃĻs

... still que y pais vida Los play quÃĐtejÃģn Less via Leal su abuelos lÃĄstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ÃĐcumait il taille Lacis just-ZufÃĪlligurl zu

peut ÃĐlus silly mais les mes ishaute quils le aurais sans Les ÃĐtablis qui

des Louis de belle accueillis sell puss pÃĻre peut olds sects it's allÃĐtells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as dÃĐtaillÃĐ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous prÃĻs

... still que y pais vida Los play quÃĐtejÃģn Less via Leal su abuelos lÃĄstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait letsUS Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ėý

Cast cotta lpc (1)

- 1. CastCotta Terracotta Restoration Alternative and Transition Material for Sustainability in New Construction

- 2. Form and Function Equivalent to Terracotta

- 3. In Some Ways Better Than Terracotta

- 4. Replacement but for New Construction as Well

- 5. Provides the Aesthetes and Beauty of Terracotta with Relief - Color â Texture â Versatility and Sustainability of Terracotta with 40 Year Material Track Record and 10+ Year Product Performance

- 6. In Addition, Provides; âĒ Ease of Production âĒ Ease of Installation âĒ Easy to Repair and Replace if Ever Necessary

- 7. As Terracotta once replace Stone due to its lack of availability now with only two Terracotta Plants left in the US, CastCotta has the ability to be the next Transition Material for highly decorative and distinct Building Elements

- 8. âĒ CastCotta production is scalable based on its New York Facility to provides manufacturing facilitates all over the US in short order. âĒ CastCotta has quoted projects with as many as 2500 pieces to date âĒ CastCotta current production is within 60 miles of New York City âĒ Laser Scanning, Field Fabrication and Latex Field Molds are available

- 10. Typical Glazes

- 11. LANDMARKS CONSIDERATIONS BASED ON NYC LPC REQUIREMENTS âReplacement of terra cotta must be in-kind at or below the sixth story at the primary facade(s), except substitute materials may be used for coping elements, as well as for limited quantities of other discrete elements that are not part of a cladding field of similar units where physical and visual compatibility is critical. In addition to these provisions, above the sixth story at primary facade(s), substitute materials may also be used at projecting cornices and balconies with weight and/or attachment issues when in-kind replacement has the potential to cause additional loss of surrounding materials, as determined by a licensed engineer. At Individual Landmarks, substitute material may not be used, except for coping elements, as well as for limited quantities of other discrete elements that are not part of a cladding field of similar units where physical and visual compatibility is critical."

- 12. CASTCOTTA CONSIDERATIONS BASED ON NYC LPC REQUIREMENTS âsubstitute materials may be used for coping elements, as well as for limited quantities of other discrete elements that are not part of a cladding field of similar units where physical and visual compatibility is criticalâ CASTCOTTA has the following attributes that should be considered in complying with the above statement and the regulation in general especially for Balcony. Window Surround and Water Table replacements; 1. CastCotta, comprised of Custom System 45 repair materials and coatings which have been in use and accepted for almost 40 years have been used on Landmark structures below six stories including the Buildings Front Entrance. 2. CastCotta , comprised of Custom System 45 repair materials and coatings, will, based on item 1 provide acceptable visual representation as an alternate for in-kind replacement. 3. CastCotta can be delivered to site in as little as 6 weeks. 4. Should there ever be need of repair of CastCotta due to transit breakage or in-situ damage the material is easily repaired based on the Custom System 45 history and should not receive an objection from the DOB because unlike Terracotta repair CastCotta is more similar to cast stone repair and accepted practice.