Casting 2012

- 2. Casting since about 4000 BC… 2 Ancient Greece; bronze statue casting circa 450 BC Iron works in early Europe, e.g. cast iron cannons from England circa 1543

- 3. Two Categories of Casting Processes 1. Expendable mold processes - mold is sacrificed to remove part 2. Permanent mold processes - mold is made of metal and can be used to make many castings

- 4. Casting Methods • Sand Casting High Temperature Alloy, Complex Geometry, Rough Surface Finish • Investment Casting High Temperature Alloy, Complex Geometry, Moderately Smooth Surface Finish • Die Casting High Temperature Alloy, Moderate Geometry, Smooth Surface

- 5. Sand Casting ÔÇó Uses sand to hold the desired shape to be cast ÔÇó Bonded with chemicals or clay with water or oil ÔÇó Many different types of sand casting

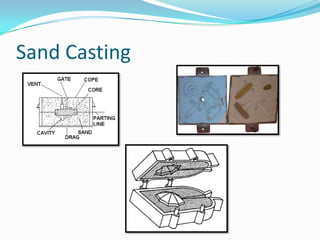

- 6. Sand Casting

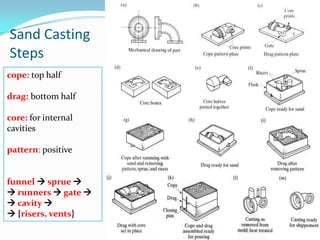

- 7. Sand Casting Steps cope: top half drag: bottom half core: for internal cavities pattern: positive funnel  sprue   runners  gate   cavity   {risers, vents}

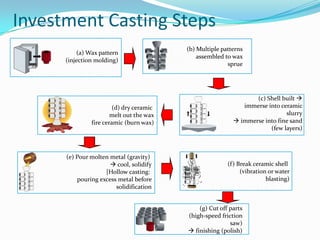

- 8. Investment Casting ÔÇó A refractory material (investment) is poured around or built up on a pattern ÔÇó The investment is hardened by drying or heating ÔÇó The pattern is removed by melting or burning ÔÇó Metal is poured into the resulting cavity

- 10. (a) Wax pattern (injection molding) (b) Multiple patterns assembled to wax sprue (c) Shell built  immerse into ceramic slurry  immerse into fine sand (few layers) (d) dry ceramic melt out the wax fire ceramic (burn wax) (e) Pour molten metal (gravity)  cool, solidify [Hollow casting: pouring excess metal before solidification (f) Break ceramic shell (vibration or water blasting) (g) Cut off parts (high-speed friction saw)  finishing (polish) Investment Casting Steps

- 11. Die Casting ÔÇó Huge numbers of small, light castings can be produced with great accuracy. ÔÇó Little surface finishing is required. ÔÇó Permanent mold (dies can be used over and over)

- 12. Die Casting

- 14. •Reference:  Metal Casting book  http://en.wikipedia.org