Casting & its types in metals

- 3. ŌĆó Casting is the process of producing metal/alloy component parts of desired shapes by pouring the molten metal/alloy into a prepared mold (of that shape) and then allowing the metal/alloy to cool and solidify. The solidified piece of metal/alloy is known as a CASTING or FOUNDRYŌĆØ.

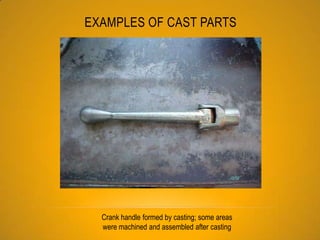

- 4. EXAMPLES OF CAST PARTS Crank handle formed by casting; some areas were machined and assembled after casting

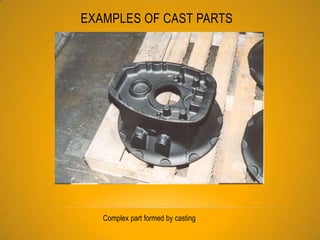

- 5. EXAMPLES OF CAST PARTS Complex part formed by casting

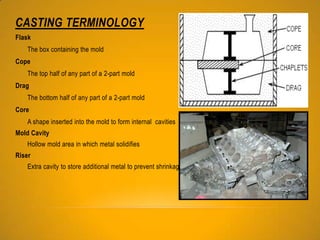

- 6. CASTING TERMINOLOGY Flask The box containing the mold Cope The top half of any part of a 2-part mold Drag The bottom half of any part of a 2-part mold Core A shape inserted into the mold to form internal cavities Mold Cavity Hollow mold area in which metal solidifies Riser Extra cavity to store additional metal to prevent shrinkage

- 7. Gating System Channels used to deliver metal into the mold cavity Pouring Cup The part of the gating system that receives poured metal Sprue Vertical channel Runners Horizontal channels Parting Line / Parting Surface Separate the cope and drag of a 2-part mold Draft Taper on a pattern that allows removal from the mold Casting The process and product of solidifying metal in a mold

- 8. CATEGORIES OF METAL CASTING PROCESSES 1. Expendable mold processes - mold is sacrificed to remove part TYPES: Sand Casting, Shell mold Casting,, Mold Casting, Investment Casting ŌĆó ŌĆó 2. Advantage: more complex shapes possible Disadvantage: production rates often limited by time to make mold rather than casting itself Permanent mold processes - mold is made of metal and can be used to make many castings TYPES:Die Casting, Permanent Mold Casting, Centrifugal Casting ŌĆó Advantage: higher production rates ŌĆó Disadvantage: geometries limited by need to open mold

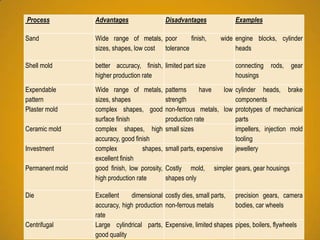

- 9. Process Advantages Sand Wide range of metals, poor finish, sizes, shapes, low cost tolerance Shell mold better accuracy, finish, limited part size higher production rate Expendable pattern Plaster mold Wide range of metals, sizes, shapes complex shapes, good surface finish complex shapes, high accuracy, good finish complex shapes, excellent finish good finish, low porosity, high production rate Ceramic mold Investment Permanent mold Die Centrifugal Disadvantages Examples wide engine blocks, cylinder heads connecting housings rods, gear patterns have low cylinder heads, brake strength components non-ferrous metals, low prototypes of mechanical production rate parts small sizes impellers, injection mold tooling small parts, expensive jewellery Costly mold, shapes only simpler gears, gear housings Excellent dimensional costly dies, small parts, precision gears, camera accuracy, high production non-ferrous metals bodies, car wheels rate Large cylindrical parts, Expensive, limited shapes pipes, boilers, flywheels good quality

- 10. IMPORTANT METAL CASTING METHODS ŌĆó Sand Casting ŌĆó Investment Casting High Temperature Alloy, Complex Geometry, Rough Surface Finish High Temperature Alloy, Complex Geometry, Moderately Smooth Surface Finish ŌĆó Die Casting High Temperature Alloy, Moderate Geometry, Smooth Surface

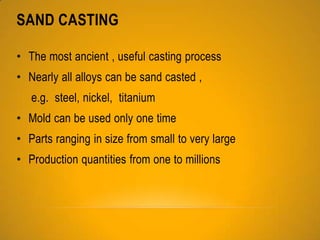

- 11. SAND CASTING ŌĆó The most ancient , useful casting process ŌĆó Nearly all alloys can be sand casted , e.g. steel, nickel, titanium ŌĆó Mold can be used only one time ŌĆó Parts ranging in size from small to very large ŌĆó Production quantities from one to millions

- 12. ŌĆó Sand casting typically has a low production rate. ŌĆó Use of a furnace, metal, pattern, and sand mold in this process

- 13. Sand Casting process cycle ŌĆó Mold-making A sand mold is formed by packing sand into each half of the mold. ŌĆó Clamping Binding of the both halves of molds ŌĆó Pouring Molten metal ladled and poured into the mold. ŌĆó Cooling The solidification and cooling of molten metal for a predetermined solidification time ŌĆó Removal/Shakeout After predetermined time has passed, breaking the mold ŌĆó Trimming Removing the extra parts called flash by cutting from casting

- 14. Factors effecting the quality of sand cast : ’āś Strength - Ability of the sand to maintain its shape. ’āś Permeability - Ability to allow venting of trapped gases through the sand .Permeability is determined by the size and shape of the sand grains. ’āś Thermal stability - Ability to resist damage, such as cracking, from the heat of the molten metal. ’āś Collapsibility - Ability of the sand to collapse, or more accurately compress, . ’āś Reusability - Ability of the sand to be reused for future sand molds.

- 15. ŌĆó Advantages : ’āś Can produce very large parts. ’āś Many material options. ’āś Low tooling and equipment cost. ’āś Scrap can be recycled. ’āś Short lead time possible. ŌĆó Disadvantages: ’āś Poor material strength. ’āś Poor surface finish and tolerance. ’āś Secondary machining often required. ’āś Low production rate. Aluminum piston for an internal combustion engine: as-cast and after machining. ’āś High labor cost. ŌĆó Applications: Engine blocks and manifolds, machine bases, gears, pulleys

- 16. INVESTMENT CASTING ŌĆó Investment casting is one of the oldest manufacturing processes ŌĆó molten metal is poured into an expendable ceramic mold ŌĆó The mold is formed by using a wax pattern ŌĆó Using ceramic slurry that hardens into the mold ŌĆó Investment casting also called "lost-wax casting" ŌĆó Lost -wax processes increases production time and cost

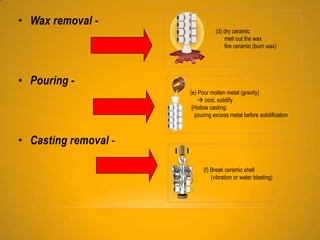

- 17. Investment Casting Process Cycle ŌĆó Pattern creation (a) Wax pattern (pattern creation) ŌĆó Mold creation (b) Multiple patterns assembled to wax sprue ŌĆó Immersing - (c) Shell built ’āĀ immerse into ceramic slurry ’āĀ immerse into fine sand (few layers)

- 18. ŌĆó Wax removal (d) dry ceramic melt out the wax fire ceramic (burn wax) ŌĆó Pouring (e) Pour molten metal (gravity) ’āĀ cool, solidify [Hollow casting: pouring excess metal before solidification ŌĆó Casting removal (f) Break ceramic shell (vibration or water blasting)

- 19. ŌĆó Advantages: ’āś Can form complex shapes ’āś Many material options ’āś High strength parts ’āś Excellent surface finish and accuracy ’āś Little need for secondary machining ŌĆó Disadvantages: ’āś Time Consuming process ’āś High labor cost ’āś High tooling cost ’āś Long lead time possible ŌĆó Applications: Turbine blades, pipe fittings, lock parts, hand tools, jewelry.

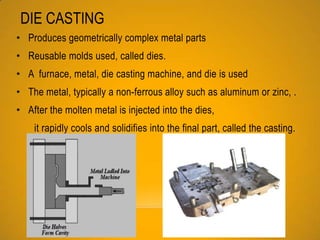

- 20. DIE CASTING ŌĆó Produces geometrically complex metal parts ŌĆó Reusable molds used, called dies. ŌĆó A furnace, metal, die casting machine, and die is used ŌĆó The metal, typically a non-ferrous alloy such as aluminum or zinc, . ŌĆó After the molten metal is injected into the dies, it rapidly cools and solidifies into the final part, called the casting.

- 21. Die casting process cycle ŌĆó Clamping - Preparation, binding and clamping of mold ŌĆó Injection Molten metal is transferred to the die ŌĆó Cooling Solidification and cooling of molten metal ŌĆó Ejection The removing of cast by hydraulic mechanism ŌĆó Trimming -. Cutting the extra metal by sawing

- 23. DIE CASTING EQUIPMENT ŌĆó Two types of die casting machines are :ŌĆó Hot chamber die casting machine ŌĆó Cold chamber die casting machine ŌĆó PARTS FORMED BY DIE CASTING

- 24. HOT-CHAMBER DIE CASTING ŌĆó Used for metal/alloys with low melting temperatures, such as zinc, tin, and lead. ŌĆó Clamping of the die ŌĆó Molten metal poured in a chamber ŌĆó Injecting the metal by forcing plunger ŌĆó Metal flows through a goose neck ŌĆó Low pressure required around 1000 - 5000 psi ŌĆó After the solidification , ejection of cast part by hydraulic system .

- 26. Hot chamber die casting process 1)Clamping. 2)Injection 3) Cooling 4) Ejection

- 27. Cold Chamber Die Casting ŌĆó Used for alloys with high melting temperatures e.g. aluminum ŌĆó Clamping the die ŌĆó Horizontally injection.. ŌĆó High Pressure is required around 2000 - 20000 psi. ŌĆó Solidification for predetermined time ŌĆó After solidification, the part can be ejected by the clamping unit.

- 29. Cold chamber die casting process