CBM Reservoir Simulation

- 1. CBM RESERVOIR SIMULATION BY JAMEEL AKBAR H.T.No.:12H11A27BH Department of Petroleum Engineering Al-Habeeb College of Engineering & Technology 1

- 2. CONTENT • Coal Bed Methane (CBM) – Introduction – Conventional v/s Unconventional Reservoir – Mechanism of gas flow – Langmuir Isotherm • Reservoir simulation – Introduction – Comet3 – Uses of Reservoir Simulation – My work • Results • Conclusion 2

- 3. Coal bed methane Introduction • Coal Bed Methane (CBM) is the gas which is created during the formation of coal and is trapped within a coal seam by formation water. • CBM is a form of natural gas that is trapped inside coal seams. • CBM is generated either from a biological process as a result of microbial action or from a thermal process as a result increasing heat with depth of coal. • The gas is stored in two ways within coal - The majority of gas is adsorbed on coal matrix. - Methane also occurs as free and dissolved gas in cleats (natural fractures) and pores within the coal. 3

- 4. • CBM is generally more than 95% methane and is often marketed as green fuel, as it contains no sulphur compounds such as hydrogen sulphide. • Ground water is associated with the gas - The hydrostatic pressure often serves to contain most of the sorbed gas in the coal. • CBM is chemically identical to other sources of gas, but is produced by Unconventional methods. 4

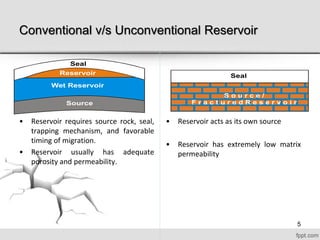

- 5. Conventional v/s Unconventional Reservoir • Reservoir requires source rock, seal, trapping mechanism, and favorable timing of migration. • Reservoir usually has adequate porosity and permeability. • Reservoir acts as its own source • Reservoir has extremely low matrix permeability SealReservoir Seal Source Wet Reservoir 5

- 6. Mechanism of gas flow 1. Desorption of the gas from the coal surface inside the micropores 2. Diffusion of the gas through the micropores 3. Darcy flow through the fracture network to the wellbore 6

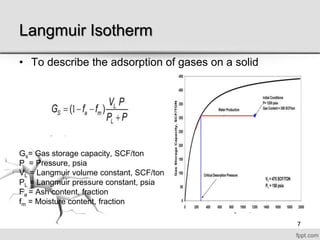

- 7. Langmuir Isotherm • To describe the adsorption of gases on a solid Gs= Gas storage capacity, SCF/ton P = Pressure, psia VL = Langmuir volume constant, SCF/ton PL = Langmuir pressure constant, psia Fa = Ash content, fraction fm = Moisture content, fraction 7

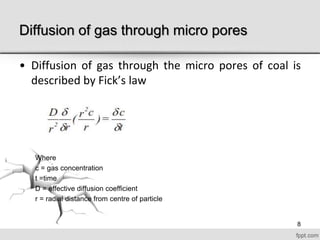

- 8. Diffusion of gas through micro pores • Diffusion of gas through the micro pores of coal is described by Fick’s law Where c = gas concentration t =time D = effective diffusion coefficient r = radial distance from centre of particle 8

- 9. Darcy’s flow through fractures • Flow of gas and water in the cleat or fracture system is described by Darcy’s law. q= -kA * (dP/dx) Where K= Permeability A= Area P= Pressure x= Thickness of the formation 9

- 10. Reservoir simulation • It is an area of reservoir engineering in which computer models are used to predict the flow of fluids (typically Oil, Gas & Water) through a porous media in order to more effectively develop and produce petroleum resources. • The tool used in this process, a reservoir simulator, is a set of simplified equations that describes flow in reservoirs. • The simplified equations in the simulator (material balance and Darcy’s Law) are applied to each of the many small elements of the reservoir model called grid blocks.

- 11. Reservoir simulation • Simulations using only one block to represent the reservoir are called tank models. Injection or production wells may be placed in these blocks corresponding to their location in the real reservoir. • Here we are using Comet3 reservoir simulator. 11

- 12. Comet -3 • COMET3 is a three-dimensional, three-component, two- phase, single, dual or triple porosity simulator for modeling gas and water production from desorption controlled reservoirs (coal and shale). • For modeling gas and water production from coal beds, COMET3 is used as a dual porosity. • COMET3 utilizes both Cartesian (x-y-z) and radial (r-θ-z) coordinate systems for multi-well problems. 12

- 13. • The reservoir or coal bed is at a constant uniform temperature. • A pseudo steady-state flow condition exists at all times between matrix and fractures 13

- 14. • The reservoir is divided into number of grid blocks. • Each gridblock in the simulator is assigned a set of reservoir properties, including thickness, permeability, porosity, etc. 14

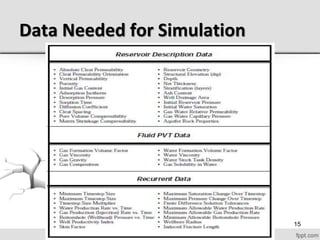

- 15. Data Needed for Simulation 15

- 16. Uses of reservoir simulation • Better understanding and management of reservoir • Optimization of well spacing • Field economics • Implementation in field development • History matching and Production forecasting with more degree of accuracy 16

- 17. My Work A single well data of 5 coal seams was taken and studied for the CBM parameters and was simulated as per the requirements 17

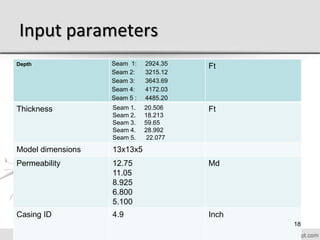

- 18. Input parameters Depth Seam 1: 2924.35 Seam 2: 3215.12 Seam 3: 3643.69 Seam 4: 4172.03 Seam 5 : 4485.20 Ft Thickness Seam 1. 20.506 Seam 2. 18.213 Seam 3. 59.65 Seam 4. 28.992 Seam 5. 22.077 Ft Model dimensions 13x13x5 Permeability 12.75 11.05 8.925 6.800 5.100 Md Casing ID 4.9 Inch 18

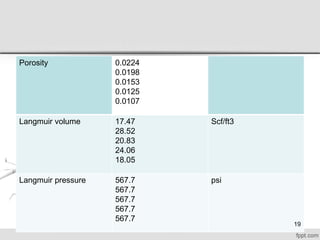

- 19. Porosity 0.0224 0.0198 0.0153 0.0125 0.0107 Langmuir volume 17.47 28.52 20.83 24.06 18.05 Scf/ft3 Langmuir pressure 567.7 567.7 567.7 567.7 567.7 psi 19

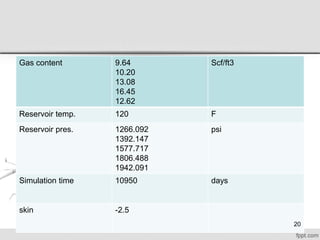

- 20. Gas content 9.64 10.20 13.08 16.45 12.62 Scf/ft3 Reservoir temp. 120 F Reservoir pres. 1266.092 1392.147 1577.717 1806.488 1942.091 psi Simulation time 10950 days skin -2.5 20

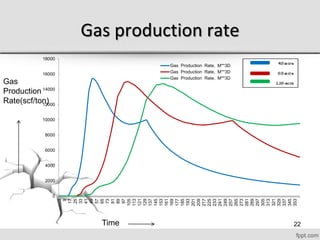

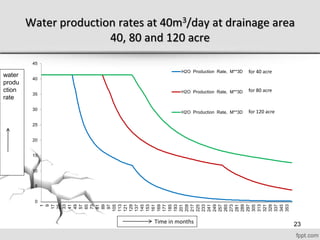

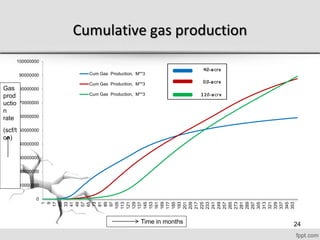

- 21. Results of the Simulation After running of simulation file we got desired parameters like Gas production rate, Water production rate. We illustrated one simulation file of 40, 80 & 120 acre of drainage area for production forecast and following graphs are plotted accordingly 21

- 22. Gas production rate 0 2000 4000 6000 8000 10000 12000 14000 16000 18000 1 9 17 25 33 41 49 57 65 73 81 89 97 105 113 121 129 137 145 153 161 169 177 185 193 201 209 217 225 233 241 249 257 265 273 281 289 297 305 313 321 329 337 345 353 Gas Production Rate, M**3D Gas Production Rate, M**3D Gas Production Rate, M**3D Time Gas Production Rate(scf/ton) 22

- 23. Water production rates at 40m3/day at drainage area 40, 80 and 120 acre water produ ction rate Time in months 0 5 10 15 20 25 30 35 40 45 1 9 17 25 33 41 49 57 65 73 81 89 97 105 113 121 129 137 145 153 161 169 177 185 193 201 209 217 225 233 241 249 257 265 273 281 289 297 305 313 321 329 337 345 353 H2O Production Rate, M**3D H2O Production Rate, M**3D H2O Production Rate, M**3D for 40 acre for 80 acre for 120 acre 23

- 24. Cumulative gas production 0 10000000 20000000 30000000 40000000 50000000 60000000 70000000 80000000 90000000 100000000 1 9 17 25 33 41 49 57 65 73 81 89 97 105 113 121 129 137 145 153 161 169 177 185 193 201 209 217 225 233 241 249 257 265 273 281 289 297 305 313 321 329 337 345 353 Cum Gas Production, M**3 Cum Gas Production, M**3 Cum Gas Production, M**3 Gas prod uctio n rate (scf/t on) Time in months 24

- 25. Conclusions • The Gas peak rate of 40 acre reaches early as compared to 80 acre followed by 120 acre. The reason behind this is that the reduction in the pressure causes the 40 acre well to achieve the early peak rate of gas production • 120 acre well spacing the peak rate of gas will come at later stage than the other two but the cumulative gas production of that well will be greater than the other two well spacing’s. • If the water production rate was increased , we will achieved an early peak rate of gas production but however there is a limiting factor of pumping capacity of pump which could slow down our water production rate and hence the gas production rate. 25

- 26. References 1. Coal bed methane-fundamental concept- K. Aminian, Petroleum &Natural Gas Engineering department West Verginia University. 2. A Guide to Coalbed Methane Reservoir Engineering 3. Smith, James T., Pressure Transient Testing: Design and Analysis, Lubbock, Texas (1987) . 4. Horne, Roland N., Modern Well Test Analysis, Petroway, Inc., Palo Alto, California (1990) . 5. Barrenblatt, G.E., I.P. Zheltov, and I.N. Kochina, “Basic Concepts in the Theory of Seepage of Homogeneous Fluids in Fissured Rocks,” J. Appl. Math. Mech, 24 (5), USSR (1960). 6. Warren, J.E. and P.J. Root, “Behaviour of Naturally Fractured Reservoirs,” Society of Petroleum Engineers Journal (September, 1963). 7. Mavor, M.J. and H. Cinco-Ley, “Transient Pressure behaviour of Naturally Fractured Reservoirs,” SPE Paper 7977, presented at the 1979 California Regional Meeting of the Society of Petroleum Engineers, Ventura, California (April 18-20, 1979). 8. Perrine, R.L., “Analysis of Pressure Build-up Curves,” Drilling and Production Practices, American Petroleum Institute (1956). 26

- 27. Questions? 27

- 28. Thank You 28