Centrifugal pumps

Download as PPTX, PDF8 likes8,812 views

Centrifugal pumps are dynamic machines that use centrifugal force to convert rotational kinetic energy to hydrodynamic energy. They have many applications including water supply and drainage. Key components include an impeller, casing, shaft, and diffuser. The impeller rotates and imparts kinetic energy on the fluid, increasing pressure and flow towards the outlet. Cavitation can occur if pressure drops too low and vapor bubbles form, undermining efficiency. Centrifugal pumps come in various types defined by factors like number of stages, impeller design, and position of inlets and outlets.

1 of 31

Downloaded 429 times

Recommended

pumps and centrifugal pump and their classifications

pumps and centrifugal pump and their classificationsTalha Hussain

Ėý

pump and its classifications

centrifugal pump and its classification and working and advantages and disadvantages

and applications of centrifugal pumpPumps and types of pumps

Pumps and types of pumpsMohammed Limdiwala

Ėý

the presentation includes basic ideas about water pumps, various terminology generally used for the pumps, classification of pumps and ideas about the types its construction and working PUMPS

PUMPSTamanash Pramanick

Ėý

Pumps are devices that use mechanical energy to increase the velocity, pressure, or elevation of liquids and gases. There are two main types of pumps: positive displacement pumps and dynamic pumps. Positive displacement pumps apply direct pressure on a liquid using a reciprocating piston or rotating components. Dynamic pumps use centrifugal force to generate high rotational velocities and convert the kinetic energy of liquids into pressure energy. Common positive displacement pump types include piston pumps, plunger pumps, and diaphragm pumps. Common dynamic pump types include centrifugal pumps which contain an impeller and casing. Proper consideration of factors like net positive suction head are important for pump selection and operation.Pump and Types Of Pumps

Pump and Types Of PumpsRahul Chaurasiya

Ėý

Pump and pumps classification.Introduction of Pumps.Applications of Pumps.Types of pump.Centrifugal Pump. Diaphragm pump.lobe pump.Positive displacement pump

Gear pump. Uses of pump.Pumps

PumpsAnkur Mahajan

Ėý

Pumps are mechanical devices that use external power to transfer fluids from one point to another. There are two main types of pumps: positive displacement pumps and rotodynamic pumps. Positive displacement pumps include reciprocating pumps, rotary lobe pumps, progressing cavity pumps, piston/plunger pumps, dosing pumps, and vacuum pumps. Rotodynamic pumps include centrifugal pumps. Each pump type has different characteristics that make it suitable for various fluid transfer applications.centrifugal pump ppt

centrifugal pump pptSujit Kumar Chaurasia

Ėý

introduction, construction, various types of classification, working, advantage, disadvantage, application of a centrifugal pumpSubmersible pump

Submersible pumpmehulomgupta

Ėý

The document discusses submersible pumps. It provides an introduction to pumps in general and describes the key types. It then focuses on submersible pumps, explaining their working principle, applications such as water wells and aquariums, advantages like efficiency and noise reduction, and disadvantages like shorter lifespan. The conclusion is that submersible pumps may be suitable for populated residential areas due to their quiet operation and low initial cost outweighing disadvantages.Basics of pump

Basics of pump Hammad Akber

Ėý

This Presentation is about working principle of Pumps.Basic Presentation regarding pumps , will definitely help beginners to learn pump types , their working , their parts etc.Submersible pump

Submersible pumpKrishna Vamsy

Ėý

The document summarizes the submersible pump. It describes how the first submersible oil pump was invented in 1928 and the first deep-well water pump was developed in the 1960s. A submersible pump consists of a centrifugal pump close-coupled to a submersible motor, pump bowl, motor assembly, discharge column, and head assembly. It is used for pumping water from deep tube wells and has applications in sewage, industrial pumping, oil wells, and sea water handling. The capacity is determined by the impeller and diffuser width, while pressure depends on impeller diameter, speed, and number of impellers. Advantages include use in deep wells and small diameters, while disadvantages include difficultyPumps

PumpsMahmudul Hasan

Ėý

A pump is a mechanical device that transfers rotational energy to liquid to move it from one place to another. There are two main types of pumps: dynamic and positive displacement. A reciprocating pump is a type of positive displacement pump that uses a piston or plunger to trap and move liquid. A rotary pump also positively displaces liquid but does so continuously rather than reciprocating. A centrifugal pump is a type of dynamic pump that uses a rotating impeller to accelerate liquid and convert kinetic energy to pressure energy to move the liquid.Centrifugal Pump

Centrifugal PumpMohammud Hanif Dewan M.Phil.

Ėý

The document discusses how centrifugal pumps work. It explains that fluid enters the impeller axially and is accelerated radially by centrifugal force, gaining pressure and velocity. The kinetic energy is partly converted to pressure energy in the volute casing. A centrifugal pump has a rotating impeller and stationary volute casing. Impellers can be open, semi-open, or enclosed, and pumps are classified by flow as radial, axial, or mixed. Multi-stage pumps contain multiple impellers to achieve higher pressures.Pump, its types and applications presentation

Pump, its types and applications presentationziaul islam

Ėý

This document discusses different types of pumps. It begins by defining a pump as a machine that converts mechanical energy into fluid energy by moving fluid from a region of low pressure to one of high pressure. There are two main types of pumps: positive displacement pumps and rotodynamic pumps. Positive displacement pumps work by trapping a fixed amount of fluid and forcing it into the discharge pipe. Rotodynamic pumps use rotational kinetic energy to increase the fluid's hydrodynamic energy. The document then discusses various sub-types of positive displacement pumps like gear pumps, screw pumps, and reciprocating pumps. It also covers different rotodynamic pump types such as centrifugal pumps, axial pumps, mixed-flow pumps, and turbine pumps. The documentBasics of Centrifugal Pump

Basics of Centrifugal PumpVikram Sharma

Ėý

Basics of centrifugal. Topics covered are operating principles, energy conversion, components in centrifugal pump, the concept of NPSH, pump rating calculation and affinity lawsReciprocating Pumps

Reciprocating PumpsNeeraj Gautam

Ėý

This document discusses reciprocating pumps. It begins by explaining that reciprocating pumps are positive displacement pumps that use a piston or plunger moving back and forth to displace water into a higher chamber. While formerly common, reciprocating pumps are now being replaced by centrifugal pumps for most industrial uses due to their higher costs and maintenance. The document then discusses the key components of reciprocating pumps including the cylinder, piston, connecting rod, crank, suction pipe, delivery pipe, and non-return valves. It explains the working principle of both single-acting and double-acting reciprocating pumps and how discharge is calculated. The document concludes by comparing reciprocating and centrifugal pumps.Pumps working principal

Pumps working principalRohit Sorte

Ėý

The document discusses different types of pumps used to transport liquids and gases. It describes pumps as mechanical devices that use pressure or suction to move fluids by forcing them in a specified direction. There are two main types of pumps - positive displacement pumps which deliver a fixed volume of fluid per cycle, and non-positive displacement pumps which do not control volume but can attain high pressures and flows. Examples of specific pump types discussed include centrifugal pumps, gear pumps, liquid ring pumps, screw pumps, piston pumps, and multistage centrifugal pumps. The document also addresses potential problems with pump operation like overloading or operating at excess speed.Centrifugal Pumps

Centrifugal PumpsHimanshi Gupta

Ėý

Centrifugal pumps are rotodynamic pumps that use a rotating impeller to increase the pressure of a liquid. The impeller spins and throws liquid outward via centrifugal force, increasing pressure. Key parts include the impeller, casing, suction and delivery pipes. Centrifugal pumps are classified based on impeller shape, working head, number of stages, flow direction, and number of suctions. They work by converting the kinetic energy of the liquid into pressure energy. The minimum speed required for startup depends on the manometric head. Cavitation can occur if the pressure drops below vapor pressure, forming bubbles that collapse and damage surfaces.Positive Displacement Pumps - Basic Principle

Positive Displacement Pumps - Basic PrincipleSahyog Shishodia

Ėý

Positive Displacement Pumps - Operation

This presentation gives a basic idea of Positive Displacement Pump Basic Principle of Operation.Centrifugal pump

Centrifugal pumpali dino

Ėý

This document discusses centrifugal pumps. It begins by defining pumps and their purpose of increasing fluid velocity, pressure, or elevation. It then classifies centrifugal pumps and describes their operation of converting motor energy into kinetic and potential energy of fluid flow using a rotating impeller. The key parts of centrifugal pumps are identified as the impeller, casing, suction pump, and discharge pump. The working principle is explained as fluid being accelerated outward by centrifugal force when the impeller rotates. Centrifugal pumps are commonly used for water supply, industry, and domestic applications due to their simplicity, low cost, and efficiency.Positive Displacement Pumps

Positive Displacement PumpsMohammud Hanif Dewan M.Phil.

Ėý

Positive displacement pumps move fluids by trapping a fixed volume and forcing that volume from the suction to discharge side. Reciprocating pumps, like piston pumps, use reciprocating motion powered by engines while rotary pumps use rotating components like gears or lobes. Piston pumps have two check valves and a reciprocating piston powered by translating rotary motion into linear motion. They can be direct or indirect acting, simplex or duplex, and single or double acting. Diaphragm pumps use a flexible diaphragm instead of pistons. Rotary pumps have gears, lobes, screws, cams, or vanes that rotate to trap and move fluid and include gear, lobe, screw, vane, and cam pumpspumps and its types-ppt

pumps and its types-pptDharmas India

Ėý

This document discusses different types of pumps, including their classifications, characteristics, applications, and performance. It describes hydrodynamic/non-positive displacement pumps, which use flow to transfer fluid at relatively low pressure and are generally used for low pressure, high volume applications. It also describes hydrostatic/positive displacement pumps, which have close-fitting components and can create high pressures, making them self-priming. Specific positive displacement pump types like gear, vane, piston and centrifugal pumps are examined in terms of their applications and operating principles. Pump efficiencies including volumetric, mechanical and overall efficiency are also covered.Introduction of pump

Introduction of pumpNur E Alam Siddike

Ėý

The document discusses different types of pumps. It defines a pump as a device that moves fluids through mechanical action. It then discusses where pumps are used, such as in factories, offices, homes, and power plants. The document classifies pumps based on their power source, either electrical or mechanical. It focuses on centrifugal pumps, describing their parts and working principle of using centrifugal force to pump fluid from the center to the outside of a circle. Advantages and disadvantages of centrifugal pumps are provided. Reciprocating and rotary pumps are also described along with their parts, types, advantages and disadvantages. The document concludes with discussing pump performance curves and defining pump efficiency.Basics Fundamentals and working Principle of Centrifugal Pump.

Basics Fundamentals and working Principle of Centrifugal Pump.SHASHI BHUSHAN

Ėý

Basics Fundamentals and working Principle of Centrifugal Pump. Centrifugal pumps are the rotodynamic machines that convert mechanical energy of shaft into kinetic and pressure energy of Fluid which may be used to raise the level of fluid. A centrifugal pump is named so, because the energy added by the impeller to the fluid is largely due to centrifugal effects.

Pumps and types of pumps in detail

Pumps and types of pumps in detailFARRUKH SHEHZAD

Ėý

The document discusses different types of pumps used in fluid transport systems. It describes positive displacement pumps which use a fixed volume cavity to trap and transport fluid with each cycle. Dynamic pumps are also discussed, which add momentum to fluid without a fixed volume. Centrifugal pumps are described in detail, with their construction, working principle, performance parameters and efficiency calculations explained. The key aspects covered are the use of impellers to impart energy and velocity to fluid which is then converted to pressure by the volute casing.Hydraulic ram

Hydraulic ramSubhash kumar

Ėý

The document discusses the hydraulic ram, which is a self-acting cyclic water pump powered by hydropower. It works on the principle of water hammer to lift a small quantity of water to a higher level using the force of a larger quantity of flowing water at a lower level, without any external power source. The hydraulic ram was invented in 1796 and has a simple design consisting mainly of a supply tank, supply pipe, valve chamber, waste valve, delivery valve, air vessel, and delivery pipe. It utilizes the kinetic energy and momentum of flowing water through its cyclic pumping process to efficiently transport water to higher elevations.Pumps Presentation.pdf

Pumps Presentation.pdfKAhmedRehman

Ėý

Centrifugal pumps work by using an impeller to increase the velocity and kinetic energy of a fluid. This increase in kinetic energy is then converted to pressure energy as the fluid passes through a volute casing, increasing the pressure. Centrifugal pumps have major components including a shaft, impeller, and volute casing. Radial pumps produce high pressure but low flow, while axial pumps operate at lower pressures but higher flow rates than radial pumps. Centrifugal pumps require priming to fill the impeller with liquid before startup.Pumps presentation

Pumps presentationarifsanghi786

Ėý

Pumps are mechanical devices that use kinetic energy to move fluids by decreasing pressure in the pump's suction and increasing pressure in the discharge. There are two main types of pumps: positive displacement pumps which move a fixed volume of fluid with each cycle, and centrifugal pumps which use an impeller to accelerate fluid and increase pressure. Common industrial pumps include centrifugal pumps like axial flow, mixed flow, and vertical turbine pumps as well as positive displacement pumps like reciprocating, screw, and gear pumps. Pumps have components like a casing, impeller, shaft, and seals and are classified according to their method of moving fluid.Pumps

PumpsNeeraj Lodhi

Ėý

A pump is a device that moves fluids or slurries through mechanical action. Pumps operate using various energy sources and come in different sizes, being used in applications like pumping water, fuel injection, oil/gas pumping, medical devices, and more. There are different types of pumps that operate based on different mechanisms, including dynamic pumps like centrifugal and axial pumps, positive displacement pumps like reciprocating, plunger, diaphragm, gear and peristaltic pumps, and rotary pumps. Each pump type has different configurations and is used for specific applications depending on factors like required pressure, flow rate, and properties of the fluid being pumped.Pitot tube

Pitot tubeTejas Solanki

Ėý

A pitot tube is a pressure measurement instrument used to determine fluid flow velocity. It was invented in the 18th century and modified in the 19th century. A pitot tube consists of a tube pointing directly into a fluid flow, where the stagnation pressure can be measured. The difference between the stagnation pressure and static pressure determines the fluid's rate of flow. Pitot tubes are commonly used in industry to measure velocities inside ducts and piping where other instruments cannot be used easily.Agen 159 lec 5

Agen 159 lec 5Md. Nurul Kadir

Ėý

This document provides an overview of centrifugal pumps, which are the most common type of pump used for agricultural irrigation, accounting for over 75% of installed pumps. It describes how centrifugal pumps work by using an impeller to impart kinetic energy to water and increase pressure. The main components are the rotating impeller coupled to a shaft, and stationary components like the casing. Impellers can be classified based on flow direction, number of suctions, and shape. Centrifugal pumps are also classified based on energy conversion type, number of stages, impeller type, axis of rotation, and drive method.More Related Content

What's hot (20)

Submersible pump

Submersible pumpKrishna Vamsy

Ėý

The document summarizes the submersible pump. It describes how the first submersible oil pump was invented in 1928 and the first deep-well water pump was developed in the 1960s. A submersible pump consists of a centrifugal pump close-coupled to a submersible motor, pump bowl, motor assembly, discharge column, and head assembly. It is used for pumping water from deep tube wells and has applications in sewage, industrial pumping, oil wells, and sea water handling. The capacity is determined by the impeller and diffuser width, while pressure depends on impeller diameter, speed, and number of impellers. Advantages include use in deep wells and small diameters, while disadvantages include difficultyPumps

PumpsMahmudul Hasan

Ėý

A pump is a mechanical device that transfers rotational energy to liquid to move it from one place to another. There are two main types of pumps: dynamic and positive displacement. A reciprocating pump is a type of positive displacement pump that uses a piston or plunger to trap and move liquid. A rotary pump also positively displaces liquid but does so continuously rather than reciprocating. A centrifugal pump is a type of dynamic pump that uses a rotating impeller to accelerate liquid and convert kinetic energy to pressure energy to move the liquid.Centrifugal Pump

Centrifugal PumpMohammud Hanif Dewan M.Phil.

Ėý

The document discusses how centrifugal pumps work. It explains that fluid enters the impeller axially and is accelerated radially by centrifugal force, gaining pressure and velocity. The kinetic energy is partly converted to pressure energy in the volute casing. A centrifugal pump has a rotating impeller and stationary volute casing. Impellers can be open, semi-open, or enclosed, and pumps are classified by flow as radial, axial, or mixed. Multi-stage pumps contain multiple impellers to achieve higher pressures.Pump, its types and applications presentation

Pump, its types and applications presentationziaul islam

Ėý

This document discusses different types of pumps. It begins by defining a pump as a machine that converts mechanical energy into fluid energy by moving fluid from a region of low pressure to one of high pressure. There are two main types of pumps: positive displacement pumps and rotodynamic pumps. Positive displacement pumps work by trapping a fixed amount of fluid and forcing it into the discharge pipe. Rotodynamic pumps use rotational kinetic energy to increase the fluid's hydrodynamic energy. The document then discusses various sub-types of positive displacement pumps like gear pumps, screw pumps, and reciprocating pumps. It also covers different rotodynamic pump types such as centrifugal pumps, axial pumps, mixed-flow pumps, and turbine pumps. The documentBasics of Centrifugal Pump

Basics of Centrifugal PumpVikram Sharma

Ėý

Basics of centrifugal. Topics covered are operating principles, energy conversion, components in centrifugal pump, the concept of NPSH, pump rating calculation and affinity lawsReciprocating Pumps

Reciprocating PumpsNeeraj Gautam

Ėý

This document discusses reciprocating pumps. It begins by explaining that reciprocating pumps are positive displacement pumps that use a piston or plunger moving back and forth to displace water into a higher chamber. While formerly common, reciprocating pumps are now being replaced by centrifugal pumps for most industrial uses due to their higher costs and maintenance. The document then discusses the key components of reciprocating pumps including the cylinder, piston, connecting rod, crank, suction pipe, delivery pipe, and non-return valves. It explains the working principle of both single-acting and double-acting reciprocating pumps and how discharge is calculated. The document concludes by comparing reciprocating and centrifugal pumps.Pumps working principal

Pumps working principalRohit Sorte

Ėý

The document discusses different types of pumps used to transport liquids and gases. It describes pumps as mechanical devices that use pressure or suction to move fluids by forcing them in a specified direction. There are two main types of pumps - positive displacement pumps which deliver a fixed volume of fluid per cycle, and non-positive displacement pumps which do not control volume but can attain high pressures and flows. Examples of specific pump types discussed include centrifugal pumps, gear pumps, liquid ring pumps, screw pumps, piston pumps, and multistage centrifugal pumps. The document also addresses potential problems with pump operation like overloading or operating at excess speed.Centrifugal Pumps

Centrifugal PumpsHimanshi Gupta

Ėý

Centrifugal pumps are rotodynamic pumps that use a rotating impeller to increase the pressure of a liquid. The impeller spins and throws liquid outward via centrifugal force, increasing pressure. Key parts include the impeller, casing, suction and delivery pipes. Centrifugal pumps are classified based on impeller shape, working head, number of stages, flow direction, and number of suctions. They work by converting the kinetic energy of the liquid into pressure energy. The minimum speed required for startup depends on the manometric head. Cavitation can occur if the pressure drops below vapor pressure, forming bubbles that collapse and damage surfaces.Positive Displacement Pumps - Basic Principle

Positive Displacement Pumps - Basic PrincipleSahyog Shishodia

Ėý

Positive Displacement Pumps - Operation

This presentation gives a basic idea of Positive Displacement Pump Basic Principle of Operation.Centrifugal pump

Centrifugal pumpali dino

Ėý

This document discusses centrifugal pumps. It begins by defining pumps and their purpose of increasing fluid velocity, pressure, or elevation. It then classifies centrifugal pumps and describes their operation of converting motor energy into kinetic and potential energy of fluid flow using a rotating impeller. The key parts of centrifugal pumps are identified as the impeller, casing, suction pump, and discharge pump. The working principle is explained as fluid being accelerated outward by centrifugal force when the impeller rotates. Centrifugal pumps are commonly used for water supply, industry, and domestic applications due to their simplicity, low cost, and efficiency.Positive Displacement Pumps

Positive Displacement PumpsMohammud Hanif Dewan M.Phil.

Ėý

Positive displacement pumps move fluids by trapping a fixed volume and forcing that volume from the suction to discharge side. Reciprocating pumps, like piston pumps, use reciprocating motion powered by engines while rotary pumps use rotating components like gears or lobes. Piston pumps have two check valves and a reciprocating piston powered by translating rotary motion into linear motion. They can be direct or indirect acting, simplex or duplex, and single or double acting. Diaphragm pumps use a flexible diaphragm instead of pistons. Rotary pumps have gears, lobes, screws, cams, or vanes that rotate to trap and move fluid and include gear, lobe, screw, vane, and cam pumpspumps and its types-ppt

pumps and its types-pptDharmas India

Ėý

This document discusses different types of pumps, including their classifications, characteristics, applications, and performance. It describes hydrodynamic/non-positive displacement pumps, which use flow to transfer fluid at relatively low pressure and are generally used for low pressure, high volume applications. It also describes hydrostatic/positive displacement pumps, which have close-fitting components and can create high pressures, making them self-priming. Specific positive displacement pump types like gear, vane, piston and centrifugal pumps are examined in terms of their applications and operating principles. Pump efficiencies including volumetric, mechanical and overall efficiency are also covered.Introduction of pump

Introduction of pumpNur E Alam Siddike

Ėý

The document discusses different types of pumps. It defines a pump as a device that moves fluids through mechanical action. It then discusses where pumps are used, such as in factories, offices, homes, and power plants. The document classifies pumps based on their power source, either electrical or mechanical. It focuses on centrifugal pumps, describing their parts and working principle of using centrifugal force to pump fluid from the center to the outside of a circle. Advantages and disadvantages of centrifugal pumps are provided. Reciprocating and rotary pumps are also described along with their parts, types, advantages and disadvantages. The document concludes with discussing pump performance curves and defining pump efficiency.Basics Fundamentals and working Principle of Centrifugal Pump.

Basics Fundamentals and working Principle of Centrifugal Pump.SHASHI BHUSHAN

Ėý

Basics Fundamentals and working Principle of Centrifugal Pump. Centrifugal pumps are the rotodynamic machines that convert mechanical energy of shaft into kinetic and pressure energy of Fluid which may be used to raise the level of fluid. A centrifugal pump is named so, because the energy added by the impeller to the fluid is largely due to centrifugal effects.

Pumps and types of pumps in detail

Pumps and types of pumps in detailFARRUKH SHEHZAD

Ėý

The document discusses different types of pumps used in fluid transport systems. It describes positive displacement pumps which use a fixed volume cavity to trap and transport fluid with each cycle. Dynamic pumps are also discussed, which add momentum to fluid without a fixed volume. Centrifugal pumps are described in detail, with their construction, working principle, performance parameters and efficiency calculations explained. The key aspects covered are the use of impellers to impart energy and velocity to fluid which is then converted to pressure by the volute casing.Hydraulic ram

Hydraulic ramSubhash kumar

Ėý

The document discusses the hydraulic ram, which is a self-acting cyclic water pump powered by hydropower. It works on the principle of water hammer to lift a small quantity of water to a higher level using the force of a larger quantity of flowing water at a lower level, without any external power source. The hydraulic ram was invented in 1796 and has a simple design consisting mainly of a supply tank, supply pipe, valve chamber, waste valve, delivery valve, air vessel, and delivery pipe. It utilizes the kinetic energy and momentum of flowing water through its cyclic pumping process to efficiently transport water to higher elevations.Pumps Presentation.pdf

Pumps Presentation.pdfKAhmedRehman

Ėý

Centrifugal pumps work by using an impeller to increase the velocity and kinetic energy of a fluid. This increase in kinetic energy is then converted to pressure energy as the fluid passes through a volute casing, increasing the pressure. Centrifugal pumps have major components including a shaft, impeller, and volute casing. Radial pumps produce high pressure but low flow, while axial pumps operate at lower pressures but higher flow rates than radial pumps. Centrifugal pumps require priming to fill the impeller with liquid before startup.Pumps presentation

Pumps presentationarifsanghi786

Ėý

Pumps are mechanical devices that use kinetic energy to move fluids by decreasing pressure in the pump's suction and increasing pressure in the discharge. There are two main types of pumps: positive displacement pumps which move a fixed volume of fluid with each cycle, and centrifugal pumps which use an impeller to accelerate fluid and increase pressure. Common industrial pumps include centrifugal pumps like axial flow, mixed flow, and vertical turbine pumps as well as positive displacement pumps like reciprocating, screw, and gear pumps. Pumps have components like a casing, impeller, shaft, and seals and are classified according to their method of moving fluid.Pumps

PumpsNeeraj Lodhi

Ėý

A pump is a device that moves fluids or slurries through mechanical action. Pumps operate using various energy sources and come in different sizes, being used in applications like pumping water, fuel injection, oil/gas pumping, medical devices, and more. There are different types of pumps that operate based on different mechanisms, including dynamic pumps like centrifugal and axial pumps, positive displacement pumps like reciprocating, plunger, diaphragm, gear and peristaltic pumps, and rotary pumps. Each pump type has different configurations and is used for specific applications depending on factors like required pressure, flow rate, and properties of the fluid being pumped.Pitot tube

Pitot tubeTejas Solanki

Ėý

A pitot tube is a pressure measurement instrument used to determine fluid flow velocity. It was invented in the 18th century and modified in the 19th century. A pitot tube consists of a tube pointing directly into a fluid flow, where the stagnation pressure can be measured. The difference between the stagnation pressure and static pressure determines the fluid's rate of flow. Pitot tubes are commonly used in industry to measure velocities inside ducts and piping where other instruments cannot be used easily.Similar to Centrifugal pumps (20)

Agen 159 lec 5

Agen 159 lec 5Md. Nurul Kadir

Ėý

This document provides an overview of centrifugal pumps, which are the most common type of pump used for agricultural irrigation, accounting for over 75% of installed pumps. It describes how centrifugal pumps work by using an impeller to impart kinetic energy to water and increase pressure. The main components are the rotating impeller coupled to a shaft, and stationary components like the casing. Impellers can be classified based on flow direction, number of suctions, and shape. Centrifugal pumps are also classified based on energy conversion type, number of stages, impeller type, axis of rotation, and drive method.Lect.9 centifugal pump ppt. 2021.pdf

Lect.9 centifugal pump ppt. 2021.pdffabmovieKhatri

Ėý

The document discusses centrifugal pumps. It describes how centrifugal pumps work by using centrifugal force to pump liquids. The key components are the impeller which rotates and converts energy to kinetic energy, and the volute or diffuser casing which converts kinetic energy to pressure. Common types are volute and diffuser pumps. The document provides details on pump components like casings, impellers, shafts, and operating principles like conversion of energy and priming. It also discusses performance characteristics curves.Centrifugal pumps

Centrifugal pumpsNanapu Mohan

Ėý

Hello everyone this is N Murali Mohan, working as a assistant professor in JNTUA college of engineering pulivendula, in this chapter covers the all topics, if any topics missing please inform I will correct and then upload.. thank you allPump installation and Maintenance.pdf

Pump installation and Maintenance.pdfhuzaifaali22

Ėý

The document provides information on pump types, components, operation, and installation. It defines a pump as a mechanical device that transfers fluid from one point to another. Two main categories of pumps are described: positive displacement pumps that have a fixed volume and centrifugal pumps with a variable flow/pressure relationship. The document outlines the components and operation of common pump types like reciprocating, rotary, and centrifugal pumps. It also discusses selecting a pump based on system requirements, installing the pump properly, and connecting piping and valves.Centrifugal pumps e_notes_dr_n_balasubra

Centrifugal pumps e_notes_dr_n_balasubraManoj Shukla

Ėý

1. Centrifugal pumps work by using centrifugal force to increase the pressure of a liquid. As the liquid moves through an impeller with curved vanes, it is pushed outward and its pressure increases.

2. Key components include an impeller, casing, suction and delivery pipes. Liquid enters the eye of the impeller and is flung outward, gaining pressure and velocity before exiting through the volute casing.

3. Advantages are low cost, high efficiency, uniform continuous flow. Centrifugal pumps are classified by design, number of impellers, entrances, shaft position, liquid handled and specific speed.Pumps

PumpsChirag Panchal

Ėý

The document discusses different types of pumps, including centrifugal and rotary pumps. It explains that centrifugal pumps use centrifugal force to raise water from a lower to higher level, while rotary pumps have vanes mounted on a rotor that rotates inside a cavity to pump fluids. The document also provides examples of common uses for different pumps and lists advantages such as low cost, maintenance, and space requirements for centrifugal pumps and the ability to handle high viscosity fluids for rotary pumps.Turbines and recipocating pumps and miscellaneous hydraulic machines

Turbines and recipocating pumps and miscellaneous hydraulic machinesMohit Yadav

Ėý

This document provides information about various topics related to hydraulic machines covered in a fluid mechanics project. It includes 3 sections: turbines, centrifugal pumps, and reciprocating pumps. For turbines, it discusses the basic working principles and types of turbines such as Pelton, Kaplan, and Francis turbines. It provides details on the components and working of each turbine. For centrifugal pumps, it explains the working principle and components like impeller, casing, and discusses concepts such as priming. It also includes the velocity triangle and equations for work done. A Brief Introduction on Pumps (Mechanical Aspect).ppt

A Brief Introduction on Pumps (Mechanical Aspect).pptKuldeepKamble10

Ėý

A Brief Introduction on Pumps (Mechanical Aspect).pptA Brief Introduction on Pumps (Mechanical Aspect).ppt

A Brief Introduction on Pumps (Mechanical Aspect).pptKuldeepKamble10

Ėý

A Brief Introduction on Pumps (Mechanical Aspect).pptCentrifugal & reciprocating pumps

Centrifugal & reciprocating pumpsvishalgohel12195

Ėý

1. The document presents information on centrifugal and reciprocating pumps, including their basic workings, components, uses, and efficiencies.

2. Centrifugal pumps use centrifugal force to accelerate and move fluid outwards from the center to increase pressure, while reciprocating pumps use pistons or plungers that move back and forth to displace fluid.

3. Key components of centrifugal pumps include casings, impellers, while reciprocating pumps have cylinders, pistons, valves. Both are used widely for irrigation, industry, buildings and other purposes.radial piston pump

radial piston pumpGAUTAM BUDDHA UNIVERSITY

Ėý

This document provides an overview of radial piston pumps. It defines a radial piston pump as a type of hydraulic pump where the working pistons extend radially from a central drive shaft. The document discusses the construction, working, properties, advantages, and applications of radial piston pumps. It notes that radial piston pumps can produce smooth flow under extreme pressure and are commonly used in machine tools, hydraulic systems, and the automotive industry.Pedal Powered Water Pump

Pedal Powered Water PumpNEERAJ KUMAR

Ėý

The document describes a major project submitted by six students to their lecturer on a pedal powered water pump. It includes a title page, declarations by the students and lecturer, acknowledgements, and a table of contents outlining what will be covered in the project report. Some of the key components to be discussed include the hand pump, pedal arrangement, rod, ball valve, pipe fittings and pressure gauges. The overall aim of the project is to design and build a water pump that can be operated by pedal power.Centrifugal pump

Centrifugal pumpSANT LONGOWAL INSTITUTE OF ENGINEERING AND TECHNOLOGY

Ėý

Centrifugal pumps work by using a rotating impeller to impart kinetic energy to liquid and convert it to pressure energy. The impeller forces liquid into a volute casing which converts the kinetic energy to pressure energy. Centrifugal pumps have simple construction, are low cost, require low maintenance, and are widely used to transport large volumes of liquids in industries like petroleum, power plants, and water treatment. Common problems include cavitation if the NPSH is too low and wear of impeller from suspended solids. Centrifugal pumps are effective, reliable, and efficient for pumping most liquids.Detailed presentation on pumps

Detailed presentation on pumpsAmmar Qazi

Ėý

Pumps are used to add energy to fluids (gases, liquids, or slurries) in order to produce flow or increase pressure. They can perform many different functions, including moving a fluid from one location to another, recirculating a fluid in a closed system, such as in a heating or cooling system, and providing pressure, such as in hydraulic systems. These functions are performed primarily by two different types of pumps: centrifugal and positive displacement.

Centrifugal pumps

Centrifugal pumpsEng-Mahmoud Sherif

Ėý

Centrifugal pumps work by using a rotating impeller to impart velocity energy to fluid and increase pressure. They consist of a casing and impeller on a shaft. As fluid enters the impeller eye, the impeller blades spin and eject fluid outward, increasing pressure. The volute collects and redirects the fluid, converting velocity energy to pressure. During operation, pressure imbalances across the impeller cause both radial and axial thrusts. Radial thrust is balanced through design of the casing and volute. Axial thrust is balanced through methods like balancing holes, wear rings, back vanes, or double suction impellers.Very basics of pumps

Very basics of pumpsFazal Babar

Ėý

The document provides an overview of centrifugal pumps. It defines what a pump is and explains that a centrifugal pump works by using centrifugal force to increase the pressure of a fluid. The key components of a centrifugal pump are then described in detail, including the casing, impeller, shaft, couplings, and bearings. Different types of impellers and casings are also discussed.Recently uploaded (20)

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3prasadmutkule1

Ėý

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3IoT-based-Electrical-Motor-Fault-Detection-System.pptx

IoT-based-Electrical-Motor-Fault-Detection-System.pptxatharvapardeshi03

Ėý

IoT-based-Electrical-Motor-Fault-Detection-System.pptxEnvironmental Product Declaration - Uni Bell

Environmental Product Declaration - Uni BellManishPatel169454

Ėý

The Uni-Bell PVC Pipe Association (PVCPA) has published the first North American industry-wide environmental product declaration (EPD) for water and sewer piping, and it has been verified by NSF Sustainability, a division of global public health organization NSF International.The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

Ėý

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

Unit 1- Review of Basic Concepts-part 1.pptx

Unit 1- Review of Basic Concepts-part 1.pptxSujataSonawane11

Ėý

DS, ADT, Algorithms, Asymptotic Notations are summarized. Cloud Cost Optimization for GCP, AWS, Azure

Cloud Cost Optimization for GCP, AWS, Azurevinothsk19

Ėý

Reduce Cloud Waste across AWS, GCP, Azure and Optimize Cloud Cost with a structured approach and improve your bottomline or profitability. Decide whether you want to outsource or manage it in house. Renewable-Energy-Powering-Mozambiques-Economic-Growth.pptx

Renewable-Energy-Powering-Mozambiques-Economic-Growth.pptxRofino Licuco

Ėý

Mozambique, a country with vast natural resources and immense potential, nevertheless faces several economic challenges, including high unemployment, limited access to energy, and an unstable power supply. Underdeveloped infrastructure has slowed the growth of industry and hampered peopleâs entrepreneurial ambitions, leaving many regions in the darkâliterally and figuratively.

https://www.rofinolicuco.net/blog/how-renewable-energy-can-help-mozambique-grow-its-economyWireless-Charger presentation for seminar .pdf

Wireless-Charger presentation for seminar .pdfAbhinandanMishra30

Ėý

Wireless technology used in chargerDefining the Future of Biophilic Design in Crete.pdf

Defining the Future of Biophilic Design in Crete.pdfARENCOS

Ėý

Biophilic design is emerging as a key approach to enhancing well-being by integrating natural elements into residential architecture. In Crete, where the landscape is rich with breathtaking sea views, lush olive groves, and dramatic mountains, biophilic design principles can be seamlessly incorporated to create healthier, more harmonious living environments.

GE 6B GT Ratcheting Animation- Hemananda Chinara.ppsx

GE 6B GT Ratcheting Animation- Hemananda Chinara.ppsxHemananda Chinara

Ėý

GE 6B Gas Turbine Ratcheting Mechanism Animation made by Hemananda Chinara, SIC, CPP, HPL.AIR FILTER system in internal combustion engine system.ppt

AIR FILTER system in internal combustion engine system.pptthisisparthipan1

Ėý

air filter system in ic engine TASK-DECOMPOSITION BASED ANOMALY DETECTION OF MASSIVE AND HIGH-VOLATILITY SES...

TASK-DECOMPOSITION BASED ANOMALY DETECTION OF MASSIVE AND HIGH-VOLATILITY SES...samueljackson3773

Ėý

The Science Information Network (SINET) is a Japanese academic backbone network for more than 800

universities and research institutions. The characteristic of SINET traffic is that it is enormous and highly

variableAI-Powered Power Converter Design Workflow.pdf

AI-Powered Power Converter Design Workflow.pdfAleksandr Terlo

Ėý

Blending human expertise with AI-driven optimization for efficient power converter design.Centrifugal pumps

- 1. CENTRIFUGAL PUMPS SUBMITTED TO- DR. H.C. THAKUR Submitted By- Satyajeet Pal Shubham Singh Shubhendu Subodh Contact No.- 09717146360 (SUBODH)

- 2. DEFINITION ïĩ Centrifugal Pumps are a sub-class of dynamic work absorbing turbo machinery. ïĩ Designed base on centrifugal force ïĩ It is used by the conversion of rotational kinetic energy to the hydrodynamic energy of fluid flow.

- 3. HISTORY ïĩ The first mechine catagrised a centrifugal pump was a mud lifting mechine. ïĩ which appeared as earlier 1475 by Italian Renaissance Engineer Francesco Di Giorgo Martini. ïĩ Scientist Denis papin and British Inventor John Appoid in 1851 developed a modern centrifugal pump.

- 4. Types of Centrifugal Pumps ïĩ Based on number of impeller/s in the pump: Single stage - pump has one impeller only; for low head service Two-stage - pump has two impellers in series; for medium head service Multi-stage - pump has three or more impellers in series; for high head service ïĩ Based on impeller suction: Single suction - pump with single suction impeller (impeller has suction cavity on one side only); simple design but impeller is subjected to higher axial thrust imbalance due to flow coming in on one side of impeller only. Double suction - pump with double suction impeller (impeller has suction cavities on both sides); Pump is considered hydraulically balanced but is susceptible to uneven flow on both sides of impeller if suction piping is not done properly.

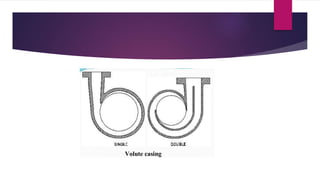

- 5. ïĩ Based on type of volute: Single volute - pump volute has single lip which is very easy to cast. Is usually used in small low capacity pumps where a double volute design is impractical due to relatively small size of volute passageway which make obtaining good quality commercial casting difficult. Pumps with single volute design have higher radial loads. Double volute - pump volute has dual lips located 180 degrees apart resulting in balanced radial loads; most centrifugal pumps are of double volute design.

- 7. ïĩ Based on nozzle location: End suction/top discharge - the suction nozzle is located at the end of, and concentric to, the shaft while the discharge nozzle is located at the top of the case perpendicular to the shaft. Pump is always of an overhung type and typically has lower NPSHR because the liquid feeds directly into the impeller eye. Top/top nozzles -the suction and discharge nozzles are located at the top of the case perpendicular to the shaft. Pump can either be overhung type or between-bearing type but is always a radially-split case pump. Side/side nozzles - the suction and discharge nozzles are located at the sides of the case perpendicular to the shaft. Pump can either be an axially or radially split case type.

- 8. ïĩ Based on shaft orientation: Horizontal - pump with shaft in horizontal plane; popular due to ease of servicing and maintenance. Vertical - pump with shaft in vertical plane; ideal when space is limited.

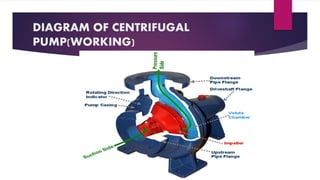

- 9. MAIN PARTS OF CENTRIFUGAL PUMP ïĩ Impeller ïĩCasing ïĩShaft ïĩDiffuser ïĩSealing Ring

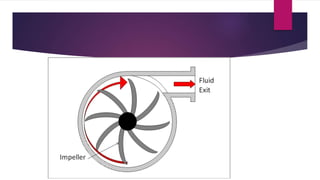

- 10. Impeller ïĩ An impeller is a rotating component of a Centrifugal pump. ïĩ It create suction through which the fluid is drawn. ïĩ Its made up of iron, steel,bronze, brass,aluminum or plastic. ïĩ Impellers are usually have an open inlet (called an eye) to accept incoming fluid,vanes to push the fluid radially.

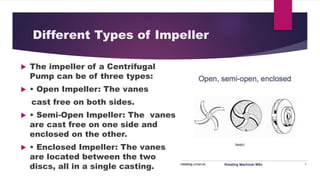

- 12. Different Types of Impeller ïĩ The impeller of a Centrifugal Pump can be of three types: ïĩ âĒ Open Impeller: The vanes cast free on both sides. ïĩ âĒ Semi-Open Impeller: The vanes are cast free on one side and enclosed on the other. ïĩ âĒ Enclosed Impeller: The vanes are located between the two discs, all in a single casting.

- 13. SEALING RING Sealing ring (leakage reduction ring) -Reduce the internal leakage -Delay the impeller and pump casing

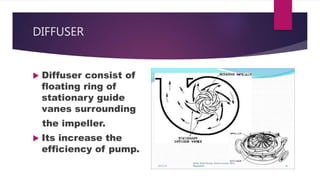

- 14. DIFFUSER ïĩ Diffuser consist of floating ring of stationary guide vanes surrounding the impeller. ïĩ Its increase the efficiency of pump.

- 15. CASING ïĩ The pumpâs casing houses the hole assembly and protects is from harm ïĩ The impellers are fitted inside the casings ïĩ It is important to reduce friction losses ïĩ Casings are generally of two types: ïĩ (1)volute casing ïĩ (2)circular casing

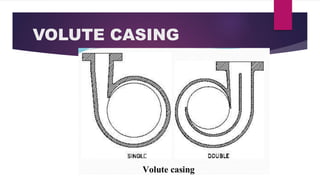

- 16. Volute casings ïĩ Volute casings build a higher head. ïĩ A volute is a curved funnel increasing in area to the discharge port ïĩ As the area of the cross-section increases, the volute reduces the speed of the liquid and increases the pressure of the liquid.

- 17. VOLUTE CASING

- 18. circular casings ïĩ circular casings are used for low head and high capacity. ïĩ Circular casing have stationary diffusion vanes surrounding the impeller periphery that convert velocity energy to pressure energy. ïĩ circular casings are divided in two way (1)Solid casing (2)split casing

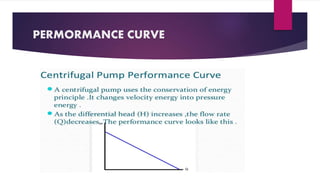

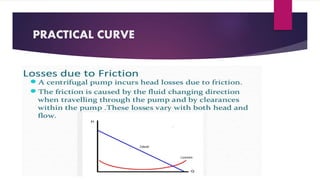

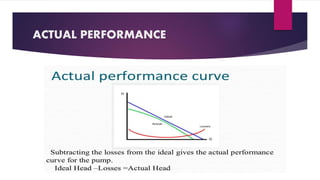

- 20. PRACTICAL CURVE

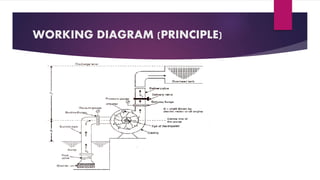

- 22. WORKING PRINCIPLE ïĩ Similar to all other pumps, the centrifugal pump also converts one form of energy into another form to operate for pumping fluid. ïĩ It principally takes mechanical energy from the motor assembled with the pump, and converts it into either kinetic energy or the potential energy of the fluid movement. ïĩ It absolutely depends upon the fluid as to what energy mechanical energy convert into. ïĩ The impeller, as indicated earlier, is available in both straight and curved blades/vanes. ïĩ The continuous rotation of the fluid creates a pressure within the impeller and this rise in pressure transfers some amount of energy to the discharge end too.

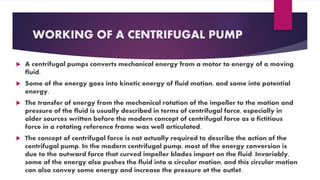

- 24. WORKING OF A CENTRIFUGAL PUMP ïĩ A centrifugal pumps converts mechanical energy from a motor to energy of a moving fluid. ïĩ Some of the energy goes into kinetic energy of fluid motion, and some into potential energy, ïĩ The transfer of energy from the mechanical rotation of the impeller to the motion and pressure of the fluid is usually described in terms of centrifugal force, especially in older sources written before the modern concept of centrifugal force as a fictitious force in a rotating reference frame was well articulated. ïĩ The concept of centrifugal force is not actually required to describe the action of the centrifugal pump. In the modern centrifugal pump, most of the energy conversion is due to the outward force that curved impeller blades impart on the fluid. Invariably, some of the energy also pushes the fluid into a circular motion, and this circular motion can also convey some energy and increase the pressure at the outlet.

- 26. PRACTICAL APPLICATIONS ïĩ To pump the general water supply. ïĩ To provide booster service ïĩ To pump the domestic water supply ïĩ To support the fire protection systems. ïĩ To provide sump drainage

- 28. Advantages ïĩ There are no drive seals, therefore the risk of leaks is completely eradicated. ïĩ This means that hazardous liquids can be pumped without spillages. ïĩ Less heat transfer from the motorâthe pump chamber is separated from the motor by an air gapÍū this provides a thermal barrier. ïĩ Complete separation of the liquid means that liquid cannot seep into the motor from the pump. ïĩ Reduced friction. ïĩ Pump has almost have 95% efficiency.

- 29. Disadvantages ïĩ Cannot be able to work high head. ïĩ Cannot deal with high viscous fluid. ïĩ Unexpected heavy load may cause the coupling to slip. ïĩ Ferrous particles in liquid are problematic when you are using magnetic drive. ïĩ Its one of the disadvantages is its relative poor suction power.

- 30. CAVITATION