Centrifugation

- 2. Contents 1. Definition 2. Classification 3. Composition 4. Relative force & application

- 3. Centrifugation ï§ Use of the centrifugal force for the separation of mixtures ï§ More-dense components migrate away from the axis of the centrifuge ï§ less-dense components of migrate towards the axis

- 4. Classification 75000rpm75000rpm 20000~25000rpm20000~25000rpm 3000rpm3000rpm Ultra- centrifuge High speed centrifuge Desk top centrifuge

- 5. Desk top clinical centrifuges ï§ Simplest ï§ Least expensive ï§ Maximum speed is below 3000rpm ï§ Ambient temperature

- 6. High-speed centrifuges ï§ Speeds of 20000 to 25000rpm ï§ Equipped with refrigeration equipment Refrigerated high-speed centrifuge Continuous flow centrifuge High speed centrifuges

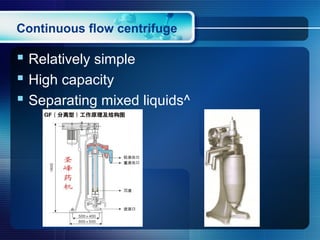

- 7. Continuous flow centrifuge ï§ Relatively simple ï§ High capacity ï§ Separating mixed liquids^

- 8. Refrigerated high-speed centrifuge ï§ Lower capacity ï§ Collect microorganisms O cellular debris O cells O large cellular organelles O ammonium sulfate precipitates O immunoprecipitates O viruses X small organells X

- 10. The ultracentrifuge ï§ Attain the speed of 75000rpm ï§ Isolate viruse DNA RNA protein

- 11. Composition ï§ Centrifuge consist of four parts: 1.Drive and speed control 2.Temperature control 3.Vacuum system 4.Rotors

- 12. Drive & Speed control ï§ Drive: water-cooled electric motor ï§ Speed control: 1.selected by rheostat 2.monitored with a tachometer

- 13. Overspeed system ï§ Prevent operation of a rotor above its maximum rated speed ï§ Consist of ^ 1.a ring of alternating reflecting and nonreflecting surfaces attached to the bottom of the rotor. 2.a small but intense point source of light 3.a photocell

- 14. Temperature control ï§ highspeed centrifuge: ïžplacing a thermocouple in the rotor chamber ïžmonitoring only the rotor chamber temperature ï§ Ultracentrifuge: ïžan infrared radiometric sensor placed beneath the rotor ïžcontinuously monitors the rotor temperature

- 15. Vacuum system ï§ The speed of centrifuge < 15000 to 20000rp Not required ï§ The speed of centrifuge > 4000rpm Required

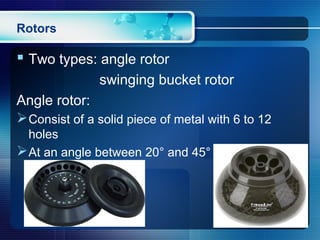

- 16. Rotors ï§ Two types: angle rotor swinging bucket rotor Angle rotor: ïConsist of a solid piece of metal with 6 to 12 holes ïAt an angle between 20° and 45°

- 17. Swinging bucket rotor: ïHang three to six free moving buckets

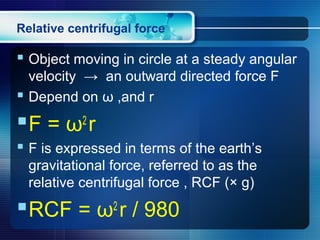

- 18. Relative centrifugal force ï§ Object moving in circle at a steady angular velocity â an outward directed force F ï§ Depend on Ï ,and r ï§F = Ï2 r ï§ F is expressed in terms of the earthâs gravitational force, referred to as the relative centrifugal force , RCF (à g) ï§RCF = Ï2 r / 980

- 19. ï§ To be of use, these relationships must be expressed in terms of ârevolutions per minuteâ , rpm ï§ Rpm values may be converted to radians Ï = Ï (rpm) /30 & F = Ï2 r â RCF = (Ï (rpm) /30)2 à r/ 302 /980 =(1.119 Ã10-5 )(rpm)2 r

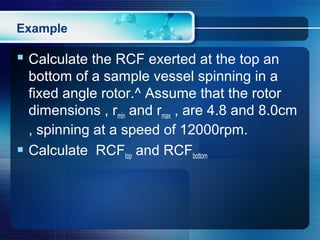

- 20. ï§So, RCF is related to r ï§The sample is located at a fixed distance r ï§The problem is illustrated in the following example

- 21. Example ï§ Calculate the RCF exerted at the top an bottom of a sample vessel spinning in a fixed angle rotor.^ Assume that the rotor dimensions , rmin and rmax , are 4.8 and 8.0cm , spinning at a speed of 12000rpm. ï§ Calculate RCFtop and RCFbottom

- 22. ï§ Centrifugal force exerted at the top and bottom of the sample tube differs by nearly twofold ï§ To account for this , RCF values may be expressed as an average RCF value(RCFave) RCFave = (1.119 Ã10-5 )(12000)2 6.4 =10313 à g

- 23. Application ï§ Zone Centrifugation or Sedimentation velocity ï§ Isopycnic Centrifugation or Sedimentation equilibrium

- 24. Sedimentation velocity ï§ v =dr / dt = ÎĶ(Ïp - Ïm) Ï2 r /f r(cm), the distance from the axis of rotation to the sedimenting particle or molecule ÎĶ(cm3 ), volume of the particle Ïp(g/cm3 ), the density of the particle Ï m(g/cm3 ), the density of the medium f(g/sec), the frictional coefficient v(cm/sec), the radial velocity of sedimentation of the particle

- 25. Sedimentation coefficient ï§ s = (dr / dt) âĒ (1 / Ï2 r) Or s = ÎĶ (Ïp-Ïm) f S(s), unit:10-13 seconds 18 Ã10-13 seconds = 18s

- 26. Frictional coefficient ï§ f = 6 Ïηrm rm (cm), the molecule or particle radius η(g/cmâĒsec) , the viscosity of the medium in poises ï§ So, the rate of sedimentation is governed by the size, shape, and density of the sedimenting particle or molecule, as well as by the viscosity and density of the medium

- 27. ï§ Most often the sedimentation coefficient is corrected to the value that would be obtained in a medium with a density and viscosity of water at 20â ï§ S20 ïž w = st,m âĒ ηt,m(Ïp- Ï20,w)/ η20,w (Ïp- Ït,m) st,m, the uncorrected sedimentation coefficient determined in medium m, and temperature t ηt,m , the viscosity of the medium at the temperature of centrifugation η20,w ,the viscosity of water at 20â Ïp ,the density of the particle or molecule in solution Ït,m , the density of the medium at the temperature of centrifugation Ï20,w , the density of water at 20â

- 28. Time ï§ s = (dr / dt) âĒ (1 / Ï2 r) â s = (lnrt âlnro) / (Ï2 (tt ât0)) â tt ât0 = 1/s âĒ (lnrt âlnro) / Ï2 =Ît rt , the radii at the top of the spinning centrifuge tube r0 , the radii at the bottom of the spinning centrifuge tube Ît is the time required to bring about total sedimentation or pelleting of the sedimenting species

- 29. The density gradient ï§ The solution is most dense at the bottom of the tube and decreases in density up to the top of the tube. ï§ Two major types of techniques are commonly used: 1.Zone centrifugation 2.Isopycnic centrifugation

- 30. Example^ ï§ One method for further purifying fractions is equilibrium density-gradient centrifugation, which separates cellular components according to their density at a high speed (about 40,000 rpm) for several hours

- 31. Testube

- 32. table Sedimentation velocity Sedimentation equilibrium synonym Zone centrifugation Isopycnic , equilibrium density- gradient centrifugation gradient Shallow, stabilizing â maximum gradient density below that of least dense sedimenting species Steep â maximum gradient density greater than that of most dense sedimenting species centrifugation Incomplete sedimentation , Short time , Low speed Complete sedimentation to equilibrium position, Prolonged time , High speed

- 33. Sedimentation velocity ï§ Maximum gradiet density < the least dense sedimenting species ï§ During centrifugation sedimenting material moves through the gradient at a rate determined by its sedimentation coefficient ï§ It is important to terminate centrifugation before the first species reaches the bottom of the tube ï§ This method works well for species that differ in size but not in density

- 34. Sums to be prepare

- 35. Sedimentation equilibrium ï§ Allowing the sedimenting species to move through the gradient until they reach a point ï§ no further sedimentation occurs because they are floating on a âcushionâ of material that has a density greater than their own ï§ Maximum gradient density > the most dense sedimenting species ï§ prolonged periods and at relatively higher speeds ï§ This technique is used to separate particles similar in size but of differing densities

- 36. SUN WEI Pharmacy of woosuk university sunwei880709@hotmail.com