Centrifugation.pptx

- 1. Centrifugation Ms. Sneha Anil Pachore Dept. of Pharmaceutics Asst. Professor Indira College of Pharmacy, Pune

- 2. • Centrifugation is a Unit operation employed for separating the constituents present in a dispersion with the aid of centrifugal force • Centrifuge is device for separating particles from a solution according to their size, shape, density, viscosity of the medium • Centrifugal force provides the driving force for the separation • It replaces gravitational forces operating during the sedimentation • The equipment used for the separation are known as centrifuges 12/9/2023 Sample Footer Text 2

- 3. • Applications of Centrifugation 1. Production of bulk drug • Centrifugation technique is used to separate crystalline drugs such as aspirin from the mother liquor • Production of biological products • Most of the proteinaceous drugs and macromolecules are present as colloidal dispersion in water • By normal method, it is difficult to produce them in large scale. Centrifugation is employed for separating the blood cells from blood 2. Biopharmaceutical analysis of drugs • Drugs present in the blood tissue fluids and urine are normally present in the form of colloidal dispersion • Centrifugation is used for separating the drugs • This method is essential for the evaluation of pharmacokinetic parameters and bioequivalence studies

- 4. 3. Evaluation of suspension and emulsion • Centrifugation method is used as a rapid empirical test parameter for the evaluation of suspension and emulsion. Normally, creaming is slow process in emulsions. • A stable emulsion should not show any signs of separation even after centrifuging at 2000-3000 revolution per minute at room temperature 4. Determination of molecular weight of colloids • Determination of molecular weight of a polymer is not possible by usual methods. • Ultra-centrifugation method are used for determination of molecular weight of serum albumin, insulin, methyl cellulose

- 5. • Principle of centrifugation • If particles size in the dispersions is 5 micro meter or less, they undergo Brownian Sediment under gravity • Therefore a stronger force, centrifugal force is applied in order to separate • Centrifugal Effect or relative Centrifugal Force (RCF) • The centrifugal operation is described by equations including the gravitational constant. • Consider a body of mass m Kg rotating in a circular path radius r meters at a velocity of v force acting on the body in a radial direction is given by: • Force acting in radial direction, • F=mv2/r …….. (1) • Where F=centrifugal force, N

- 6. • The same body is experiencing gravitational force (newton). It can be expressed as: • Gravitation force, G=mg …..(2) • Where g= acceleration due to gravity, m/s2 • The centrifugal effect is expressed as a ratio of centrifugal force to gravitational force. • In other words, centrifugal force, which is a number of time greater than the gravitation force • Separation power of centrifuge is expressed as a ratio of the centrifugal force to the gravitational acceleration. • This ratio may have a value as high as 104 • The centrifugal effect can be expressed as: • Centrifuge, C= force acting in radial direction/gravitational force • C= F/G

- 7. • But v = mπrn, Where n= speed of rotation (revolations per second of centrifuge). Substituting this in equation (3 yields) • C= (2πrn)2/ gr = 4π2 r2 n2/gr = 4π2 r2 n2/g ….(4) • Since 2r =d, where d- diameter of the rotation. Substituting the value in equation (4) gives: • C= 2π2dn2/ g ……….. (5) • The gravitational constant has a value of 9.807 m/s2, so that equation (5) can be simplified as: • Centrifugal effect =2.013n2 d ………….(6) • In the equation (6), n is expressed in s-1 and d is in metres • The measurement of d is made from the free surface of liquid (or from the tip of the tube) to the centre of a centrifuge and should be mentioned while reporting the centrifugal effect • From equation (5) and (6), it can be inferred that • Centrifugal effect α diameter • Centrifugal effect α (speed of rotation)2

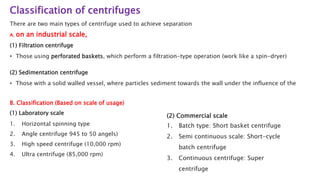

- 8. Classification of centrifuges There are two main types of centrifuge used to achieve separation A. on an industrial scale, (1) Filtration centrifuge • Those using perforated baskets, which perform a filtration-type operation (work like a spin-dryer) (2) Sedimentation centrifuge • Those with a solid walled vessel, where particles sediment towards the wall under the influence of the B. Classification (Based on scale of usage) (1) Laboratory scale 1. Horizontal spinning type 2. Angle centrifuge 945 to 50 angels) 3. High speed centrifuge (10,000 rpm) 4. Ultra centrifuge (85,000 rpm) (2) Commercial scale 1. Batch type: Short basket centrifuge 2. Semi continuous scale: Short-cycle batch centrifuge 3. Continuous centrifuge: Super centrifuge

- 9. 1. Perforated Basket Centrifuge Principle • It is a filtration centrifuge. The separation is through a perforated wall based on the solid and liquid phases • The bowl contains a perforated side wall • The liquid phase passes through the perforated wall, while solid phase is retained in the • The solid is removed after cutting the sediment by a blade after stopping the centrifuge

- 10. Construction • It consists of a stainless steel perforated basket (typically 1-2 m in diameter) lined with a filter cloth • The basket rotates at a speed which is typically < 25 s-1, higher speeds tending to stress the basket excessively • The product enters centrally and is thrown outwards by centrifugal force and held against the filter cloth • The filtrate is forced through the cloth and removed via the liquid outlet; the solid material is retained on the cloth • The cake can be washed if required by spraying water into the centrifuge 12/9/2023 Sample Footer Text 10

- 11. Working • The material is kept on a basket when the basket is stationary • The amount of material should be optimum, otherwise, during Centrifugation it puts a great material done to give even distribution • Power is applied to rotate the basket and maximum speed must be attained quickly • The basket runs at 1000 revolutions per minutes • The power require for running is small compared to the power require for starting and • During Centrifugation, the liquid passes through the perforated wall, while the solid phase leaves the basket and is collected at the outlet • The cake is then spun to dry as much as possible • Sometimes higher speeds are used so that the cake will be completely dried • After a definite period of time, the power is turned off. By applying a brake the Centrifuge is • The basket is brought to rest • The solid cake is cut using a blade and then unloaded manually

- 12. • Uses 1.Perforated basket Centrifuge is extensively used for separating crystalline drugs (such as is removed completely 2.It is also used for removing unwanted solids from a liquid. For example, precipitated 3.Sugar crystals are separated using perforated basket centrifuge • Advantages 1.The Centrifuge is very compact, and it occupies very little floor space 2.It can handle slurries with a high proportion of solid and even those having paste like 3.The final product has a very low moisture content 4.In this method, the dissolved solids are separated from the cake 5.The process is rapid

- 13. Disadvantages: • The entire cycle is complicated resulting in considerable labour costs. • It is a batch process. • If the machine is adapted for prolonged operation, there is considerable wear and tear of the equipment.

- 14. NON-PERFORATED BASKET CENTRIFUGE Principle: • This is a sedimentation centrifuge. • The separation is based on the difference in the densities of solid and liquid phases without a porous barrier. • The bowl contains a non-perforated side-wall. • During centrifugation, solid phase is retained on the sides of the basket, while the liquid remains at the top, which is removed by a skimming tube. Construction: • It consists of a basket, which may be made of steel or any other suitable metal. • The basket is suspended on vertical shaft and is driven by a motor using a suitable power system.

- 15. Working: • The suspension is fed continuously into the basket. • During centrifugation, solid phase is retained on the sides of the basket, while liquid remains on the top. • The liquid is removed over a weir or through a skimming tube. • When a suitable depth of solids has been deposited on the walls of the basket, the operation is stooped. • The solids are then scraped off by hand or using a scraper blade. Uses: Non-perforated basket centrifuge is useful when the deposited solids offer high resistance to the flow of liquid.

- 16. SEMI-CONTINUOUS CENTRIFUGE OR SHORT CYCLE AUTOMATIC BATCH CENTRIFUGE Principle: • It is a filtration centrifuge. • The separation is through a perforated wall based on the difference in the densities of solid and liquid phases. • The bowl contains a perforated side-wall. • During centrifugation, the liquid phase passes through the perforated wall, while solid phase retains in the bowl, the solid is washed and removed by cutting the sediment using a blade. • It is a short cycle automatic batch centrifuge

- 17. Construction: • It consists of a vertical perforated basket, which is supported from a horizontal shaft driven by a motor. • From the open side of the basket, provisions are made at the centre to introduce feed and wash pipe through horizontal tubes. • A feeler rides over the feed, which is connected to diaphragm valve through air supply. • The feeler controls the thickness of the feed. • Hydraulic cylinder attachment is made in such a manner that the discharge chute enters from the sides of basket, when discharge of crystals is desirable.

- 18. Working: • The perforated basket is allowed to rotate and slurry is introduced from the side pipe. • During centrifugation, the slurry passes through the perforated wall. • The solids are retained in the basket, while filtrate leaves the basket, which is collected at outlet. • Further, the cake is washed with water. • The wash escapes from the basket through the filtrate outlet • After achieving the desired thickness (50 to 70 millimetres), the feeler cuts off the air supply to a diaphragm valve that automatically shuts off the entry of slurry. • The hydraulic cylinder is actuated, which lifts the knife along with the discharge chute. • The knife does not cut the cake completely down to the screen, but leaves a layer of crystals that acts as a filter medium for further separation in the next cycle. • The residual crystals may be given a brief wash before starting the next cycle. • Therefore, the entire cycle is semiautomatic.

- 19. Advantages: 1. Short-cycle automatic batch centrifuge is used when solids can be drained fast from the bowl. Disadvantage: 1. During discharge, considerable breakage of crystals is possible. 2. Construction and functioning is complicated.

- 20. SUPERCENTRIFUGE Super centrifuge is a continuous centrifuge used for separating two immiscible liquid phases. Principle: • It is a sedimentation centrifuge. • The separation is based on the difference in the densities between two immiscible liquids. • Centrifugation is done in the bowl of small centrifuge. • During centrifugation, the heavier liquid is thrown against the wall, while the lighter liquid remains as an inner layer. • The two layers are simultaneously separated using modified weirs.

- 21. Construction: • It consists of a long hollow cylindrical bowl of small diameter. • It is suspended from a flexible spindle at the top and guided at the bottom by loose-fit bushing. • Two liquid outlets are provided at different heights at the top of the bowl, for simultaneous recovery of the separated liquids using modified weirs. 12/9/2023 Sample Footer Text 21

- 22. Working: • The centrifuge is allowed to rotate on its longitudinal axis at a high frequency usually about 2000 revolutions per minute with the help of drive-assembly. • The feed is introduced from the bottom of the centrifuge using a pressure system. • During centrifugation, two liquid phases separate based on the difference in their densities. • The heavier liquid is thrown against the wall, while the lighter liquid forms an inner layer. Both liquids rise to the top of the vertical bowl. • The liquid-liquid interface (the so-called neutral zone) is maintained by an hydraulic balance. These two layers are simultaneously separately removed from different heights through modified weirs. • Thus, the super centrifuge can work for continuous separation of immiscible liquid phases. Uses • It is used for separating liquid phases of emulsions in food and pharmaceuticals.