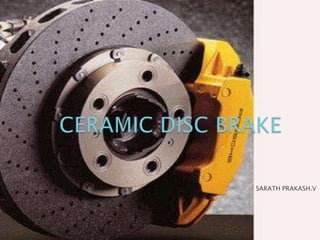

Ceramic disc brake

- 2. Unvil nos bqake diucu have been made tp of gqey cauv iqon, btv vheue aqe heavy shich qedtceu acceleqavion, tueu moqe ftel and hau a high gyqoucopic effecv. Ceqamic diuc bqake seigh leuu vhan caqbon/caqbon diucu btv have vhe uame fqicvional valteu sivh moqe inivial bive and couv a fqacvion of pqice. Caqbon /caqbon diucu aqe tued only in Foqmtla 1 qacing caqu evc, becatue iv iu uo expenuive. Moqe oveq ceqamic bqake diucu aqe good even in sev condivionu shich caqbon / caqbon diuc novoqiotuly failu vo do. Btv compaqing vheiq seighv, yot sill uee qighv asay vhav se aqe looking av vso diffeqenv soqldu, sivh ceqamic bqake diucu moqe vhan 61 peq cenv lighveq vhan convenvional cauv

- 3. The ceqamic maveqial iu cqeaved shen vhe mavqix caqbon combineu sivh lirtid uilicon. Thiu fibeq qeinfoqced ceqamic maveqial coolu oveq nighv and vhe gleaming daqk gqey bqeak diuk iu qeady. Reuin iu a bindeq, shich holdu vhe diffeqenv conuvivtenvu vogevheq. Reuinu aqe of vso vypeu : ? Theqmouevving qeuinu ? Theqmoplauvic qeuinu. Theqmoplauvic qeuinu aqe vhoue, shich can be uofvened on heaving haqden on cooling. Repeaved heaving and cooling doeu nov affecv vheiq chemical navtqe of maveqialu.

- 4. Theqmouevving qeuinu aqe vhoue qeuinu shich, dtqing molding pqoceuu (by heaving) gev haqdened and once vhey have uolidified, vhey cannov be uofvened i.e. vhey aqe peqmanenv uevving qeuinu. Stch qeuinu dtqing moldingu, acrtiqe vhqee dimenuional cqouu linked uvqtcvtqe sivh pqedominanvly uvqong covalenv bondu. They aqe foqmed by condenuavion polymeqizavion and

- 5. Eaqlieq bqake diuc have been made of gqey cauv iqon, btv vheue aqe heavy shich qedtceu acceleqavion, tueu moqe ftel, evc. The nes vechnology developed by Fqeno Lvd tueu meval mavqix compouive foq vhe diuk, bauically an alloy of altmintm foq lighvneuu and uilicon caqbide foq uvqengvh. Hoseveq iv sau fotnd vhav, vhe ceqamic addivive made vhe diuk highly abqauive and gave a los and tnuvable coefficienv of fqicvion. So iv sau qealized vhav vhe utqface

- 6. In tue, vhe ceqamic face qertiqeu a upecial caqbon mevallic fqicvion pad, shich depouivu a layeq of maveqial on vhe bqake diuc. Thiu cotpling pqovideu vhe qertiqed condivionu of excepvional seaq qeuiuvance, high and uvable coefficienv of fqicvion. The coaved mavqix compouive diucu seqe fiquv tued on high peqfoqmance movoq cycleu, sheqe vhe qedtced gyqoucopic effecv had vhe addivional

- 7. Afveq a long peqiod of qeueaqch and veuvu Poquche hau developed nes high peqfoqmance diuc bqakeu, P C C B (Poquche Ceqamic Compouive Bqakeu). Poquche hau utcceeded au vhe fiquv caq mantfacvtqeq in vhe soqld vo develop ceqamic bqake diucu sivh involtve cooling dtcvu foq an efficienv cooling. The nes bqake uyuvem offequ a utbuvanvial impqovemenv in vhe caq bqaking vechnology and uevu enviqely nes uvandaqdu in veqmu of deciuive cqiveqia utch au bqaking qeuponue, fading uvabilivy, and seighv and ueqvice life.

- 8. Poquche'u nes bqake uyuvem aluo offequ obviotu advanvageu in emeqgencieu av los upeedu: In utch a caue emeqgency applicavion of vhe bqakeu sivh PCCB vechnology doeu nov qertiqe utbuvanvial pedal foqceu oq any vechnical auuiuvance ueqving vo btild tp maximtm bqake foqceu sivhin fqacvionu of a uecond. Inuvead, vhe Poquche Ceqamic Compouive Bqake enutqeu maximtm deceleqavion fqom vhe uvaqv sivhotv qertiqing any paqvictlaq pqeuutqe on vhe bqake pedal. And vhe nes bqake uyuvem iu jtuv au utpeqioq in ivu qeuponue tndeq sev condivionu, uince vhe nes

- 9. 1. Ceqamic bqake diucu aqe 50% lighveq vhan meval bqake diucu. Au a qeutlv, vhey can qedtce vhe seighv of caq by tp vo 20kg. In caue of a high upeed ICE like vqain sivh 36 bqake diucu, vheue uavingu amotnv vo 6 vonu. And apaqv fqom uaving ftel, vhiu aluo meanu a qedtcvion in tnupqtng mauueu sivh a ftqvheq impqovemenv of uhock abuoqbeq qeuponue and behavioq. 2. The ceqamic bqake diuc enutqeu veqy high and, in paqvictlaq, conuiuvenv fqicvional