CH-3 WIND POWER Technology as a Renewable Energy

- 1. Wind Energy Technology Chapter-3 Prepared by: SSGP, Surat

- 2. INTRODUCTION ïĩ Winds are horizontal movement of AIR from an area of HIGH pressure(H) to an area of low pressure(L). ïĩ Wind energy is a kinetic energy associated with movement of large masses of air. ïĩ It is clean, cheap, and eco-friendly renewable source. ïĩ Wind energy is utilized as mechanical energy with the help of a wind turbine. ïĩ Moderate to high-speed winds, typically from 5m/s to about 25m/s are considered favorable for most wind turbines. ïĩ The electric power generation through wind was first proposed in Denmark in 1890

- 3. What Makes Wind ? ïĩ Wind energy is created when the atmosphere is heated unevenly by the Sun, some patches of air become warmer than others. ïĩ These warm patches of air rise, other air rushes in to replace them â thus, wind blows.

- 4. ïĩ The wind is a by-product of solar energy. Approximately 2% of the sun's energy reaching the earth is converted into wind energy. ïĩ The surface of the earth heats and cools unevenly, creating atmospheric pressure zones that make air flow from high- to low pressure areas. ïĩ circulation of widespread winds on a global basis, producing planetary winds or may have a limited influence in a smaller area to cause local winds.

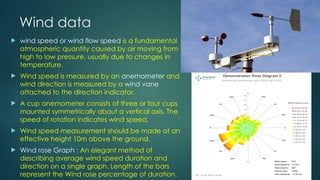

- 5. Wind data ïĩ wind speed or wind flow speed is a fundamental atmospheric quantity caused by air moving from high to low pressure, usually due to changes in temperature. ïĩ Wind speed is measured by an anemometer and wind direction is measured by a wind vane attached to the direction indicator. ïĩ A cup anemometer consists of three or four cups mounted symmetrically about a vertical axis. The speed of rotation indicates wind speed. ïĩ Wind speed measurement should be made at an effective height 10m above the ground. ïĩ Wind rose Graph : An elegant method of describing average wind speed duration and direction on a single graph. Length of the bars represent the Wind rose percentage of duration.

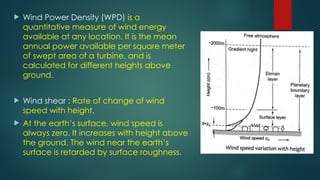

- 6. ïĩ Wind Power Density (WPD) is a quantitative measure of wind energy available at any location. It is the mean annual power available per square meter of swept area of a turbine, and is calculated for different heights above ground. ïĩ Wind shear : Rate of change of wind speed with height. ïĩ At the earthâs surface, wind speed is always zero. It increases with height above the ground. The wind near the earthâs surface is retarded by surface roughness.

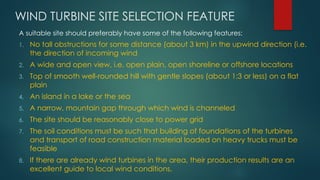

- 8. WIND TURBINE SITE SELECTION FEATURE A suitable site should preferably have some of the following features: 1. No tall obstructions for some distance (about 3 km) in the upwind direction (i.e. the direction of incoming wind 2. A wide and open view, i.e. open plain, open shoreline or offshore locations 3. Top of smooth well-rounded hill with gentle slopes (about 1:3 or less) on a flat plain 4. An island in a lake or the sea 5. A narrow, mountain gap through which wind is channeled 6. The site should be reasonably close to power grid 7. The soil conditions must be such that building of foundations of the turbines and transport of road construction material loaded on heavy trucks must be feasible 8. If there are already wind turbines in the area, their production results are an excellent guide to local wind conditions.

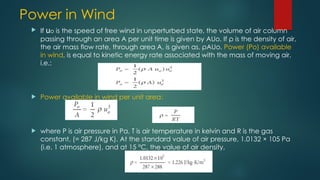

- 9. Power in Wind ïĩ If uo is the speed of free wind in unperturbed state, the volume of air column passing through an area A per unit time is given by AUo. If Ï is the density of air, the air mass flow rate, through area A, is given as, ÏAUo. Power (Po) available in wind, is equal to kinetic energy rate associated with the mass of moving air, i.e.: ïĩ Power available in wind per unit area: ïĩ where P is air pressure in Pa, T is air temperature in kelvin and R is the gas constant, (= 287 J/kg K). At the standard value of air pressure, 1.0132 à 105 Pa (i.e. 1 atmosphere), and at 15 °C, the value of air density,

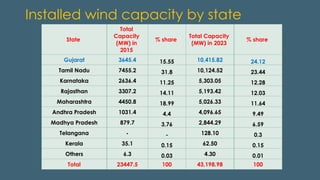

- 10. Installed wind capacity by state State Total Capacity (MW) in 2015 % share Total Capacity (MW) in 2023 % share Gujarat 3645.4 15.55 10,415.82 24.12 Tamil Nadu 7455.2 31.8 10,124.52 23.44 Karnataka 2636.4 11.25 5,303.05 12.28 Rajasthan 3307.2 14.11 5,193.42 12.03 Maharashtra 4450.8 18.99 5,026.33 11.64 Andhra Pradesh 1031.4 4.4 4,096.65 9.49 Madhya Pradesh 879.7 3.76 2,844.29 6.59 Telangana - - 128.10 0.3 Kerala 35.1 0.15 62.50 0.15 Others 6.3 0.03 4.30 0.01 Total 23447.5 100 43,198.98 100

- 11. Wind Turbine or Wind Mill ïĩ A windmill is defined as a machine that converts the kinetic energy of the wind into mechanical energy. ïĩ A wind turbine turns wind energy into electricity using the aerodynamic force from the rotor blades. ïĩ Wind turbines are the modern version of a windmill. Put simply, they use the power of the wind to create electricity. ïĩ The difference in air pressure across the two sides of the blade creates both lift and drag. ïĩ The force of the lift is stronger than the drag and this causes the rotor to spin.

- 12. Types of Wind Mills 1. According to orientation of rotor: a) Horizontal Axis (HAWT) b) Vertical Axis (VAWT) 2. According to useful electrical power output: a) Small output: up to 2 kW b) Medium output: 2 to 100 kW c) Large Output: more than 100 kW 3. According to types of rotor: a) Propeller Type- it is horizontal axis high speed rotor b) Multiple Blade Type- it is horizontal axis low speed rotor c) Savonius type- it is vertical axis rotor

- 13. 4. According to wind direction on rotor: a) Up wind rotor wind mill b) Down wind rotor wind mill 5. According to number of blades: a) Single blade b) Double blade c) Three blade d) Multi blade

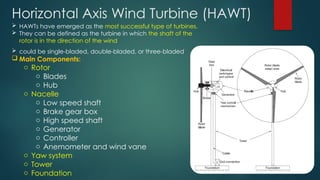

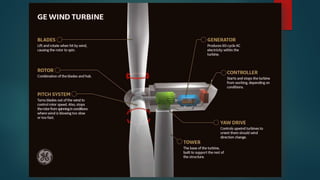

- 14. Horizontal Axis Wind Turbine (HAWT) ï HAWTs have emerged as the most successful type of turbines. ï They can be defined as the turbine in which the shaft of the rotor is in the direction of the wind ï could be single-bladed, double-bladed, or three-bladed ïą Main Components: o Rotor o Blades o Hub o Nacelle o Low speed shaft o Brake gear box o High speed shaft o Generator o Controller o Anemometer and wind vane o Yaw system o Tower o Foundation

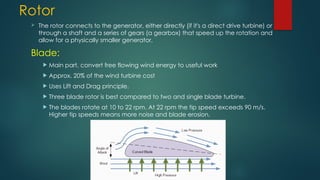

- 15. Rotor ï The rotor connects to the generator, either directly (if it's a direct drive turbine) or through a shaft and a series of gears (a gearbox) that speed up the rotation and allow for a physically smaller generator. Blade: ïĩ Main part, convert free flowing wind energy to useful work ïĩ Approx. 20% of the wind turbine cost ïĩ Uses Lift and Drag principle. ïĩ Three blade rotor is best compared to two and single blade turbine. ïĩ The blades rotate at 10 to 22 rpm. At 22 rpm the tip speed exceeds 90 m/s. Higher tip speeds means more noise and blade erosion.

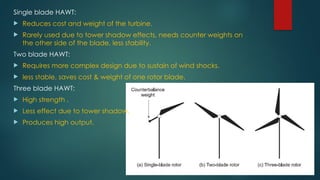

- 16. Single blade HAWT: ïĩ Reduces cost and weight of the turbine. ïĩ Rarely used due to tower shadow effects, needs counter weights on the other side of the blade, less stability. Two blade HAWT: ïĩ Requires more complex design due to sustain of wind shocks. ïĩ less stable, saves cost & weight of one rotor blade. Three blade HAWT: ïĩ High strength . ïĩ Less effect due to tower shadow. ïĩ Produces high output.

- 18. Hub ïĩ In simple designs, blades are directly bolted to hub. ïĩ In sophisticated designs they are bolted to the pitch mechanism, which adjust their angle of attack according to their wind speed. ïĩ The hub is fixed to the rotor shaft which derives the generator through a gear box.

- 19. Nacelle It is a cover housing that houses all of the generating components in a wind turbine, including the generator, gearbox, drive train, and brake assembly. Low speed shaft ïĩ The shaft from the hub to the gear box ïĩ Speed is typically between 40 to 400 rpm ïĩ Generator typically rotated at 1200 rpm to 1800 rpm Brake Gear box ïĩ Gear box increases the speed of the shaft ïĩ Meet the requirement of the generator High speed shaft ïĩ Gear box shaft is followed by the high speed shaft ïĩ Connects to generator

- 20. Braking mechanism ïĩ A mechanical drum brake is used to stop turbine in emergency situation. ïĩ This brake is also used to hold at rest for maintenance. Main shaft

- 21. Generator ïĩ Converts mechanical energy to electrical energy. which is approx. 34% of the wind turbine cost. ïĩ generate electricity through asynchronous machines that are directly connected with the electricity grid. ïĩ One end attached to the wind turbine, other end connected to the Electrical grid. ïĩ Require cooling system to prevent overheating. Controller ïĩ Starts when the machine at wind speed of about 4 m/s and shuts off the machines at about 25m/s , may damage wind turbine. ïĩ It gets wind speed data from the anemometer and accordingly.

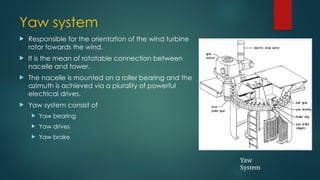

- 22. Yaw system ïĩ Responsible for the orientation of the wind turbine rotor towards the wind. ïĩ It is the mean of rotatable connection between nacelle and tower. ïĩ The nacelle is mounted on a roller bearing and the azimuth is achieved via a plurality of powerful electrical drives. ïĩ Yaw system consist of ïĩ Yaw bearing ïĩ Yaw drives ïĩ Yaw brake Yaw System

- 23. Yaw bearing ïĩ Can be of the roller or gliding type, servers as a rotatable connection between the tower and nacelle of the wind turbine. Yaw drive ïĩ Used to keep the rotor facing into the wind as the wind direction changes. ïĩ The yaw drives exist only on the active yaw system and are the mean of active rotation of the wind turbine nacelle . ïĩ Each yaw drives consists of powerful electric motor (usually AC) with its electric drive and a large gearbox , which increases the torque.

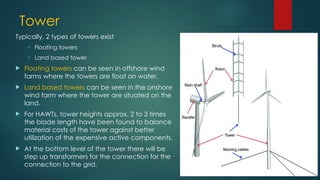

- 24. Tower Typically, 2 types of towers exist o Floating towers o Land based tower ïĩ Floating towers can be seen in offshore wind farms where the towers are float on water. ïĩ Land based towers can be seen in the onshore wind farm where the tower are situated on the land. ïĩ For HAWTs, tower heights approx. 2 to 3 times the blade length have been found to balance material costs of the tower against better utilization of the expensive active components. ïĩ At the bottom level of the tower there will be step up transformers for the connection for the connection to the grid.

- 25. Advantages of HAWT ï The output power is high as compared to the vertical axis wind turbine. ï The efficiency of a HAWT is high. ï It is less expensive than a VAWT (see following section). ï It is more consistent and its rotational speed is high. ï On variation in the wind shear, the tall tower captures more wind. ï Reliability is high. ï The blades of the turbine can be bent using a gearbox to get the best wind attack angle, which results in better performance under stormy conditions. ï The rotor can be tilted by the blades during storms.

- 26. Disadvantages of HAWT ïĩ HAWTs are available only in large sizes and are challenging to use in distributed generation. ïĩ As they are of large size and heavyweight, transportation from one place to another is difficult. ïĩ The mounting of a heavy generator and gearbox at the top of the tower requires a stronger structure, which increases the complexity and cost of the structure. ïĩ Installation and maintenance of a HAWT is a difficult process because of the tall tower and heavy turbines. ïĩ Noise from the HAWT is high compared to other wind turbines. ïĩ To design and manufacture a HAWT, heavy machinery is required.

- 27. HAWT Technological Evolution ïĩ Useful wind speeds-There is a range of wind speeds within which the rotor can move and function properly. ïĩ Lower limit - âCut-inâ = 4 m/s (approx. 14 km/h). With wind speeds below this value, it is not possible to activate the rotation of the blades and the rotor remains stationary. ïĩ Upper limit - âCut-offâ ~ 25 m/s (approx. 90 km/h). Above this speed, the rotor is stopped to avoid serious structural problems. ïĩ Wind limit value - âSurvival Speedâ, representing the maximum design wind speed which the structure of turbine & blades can withstand without incurring damage. This value varies depending on the type of wind turbine and generally is approx. 60m/s, (approx. 216 km/h).

- 28. Conversion efficiency : ïĩ Conversion of kinetic energy into electricity of modern-day wind machines is around 25%. ïĩ The maximum theoretical efficiency of a wind turbine system is defined by Betzâs law, which identifies the so-called âBetz limitâ corresponding to a maximum efficiency of 59%. Capacity factor: ïĩ Equivalent number of hours of operation (at the maximum rated system power) throughout the year.(8760 hours). ïĩ Capacity Factor values vary from 20% (1750 hours/ year at full power) to 40% (3500 hours/year at full power); ïĩ In certain exceptional cases it is possible to reach values close to 50% (4400 hours/year at full power). ïĩ In Italy the current Capacity Factor of the entire national wind farm is 25%, corresponding to approx. 2,200 hours per year of system operation at nominal power.

- 29. Vertical axis wind turbines (VAWT) ïĩ Vertical axis wind turbines (or VAWTs) have the main rotor shaft arranged vertically. ïĩ Darrieus designs are the most common VAWTs Main attractions of a VAWT are: ïĩ it can accept wind from any direction, eliminating the need of yaw control. ïĩ gearbox, generator etc. are located at the ground, thus eliminating the heavy nacelle at the top of the tower. This simplifies the design and installation of the whole structure, including tower. ïĩ the inspection and maintenance also gets easier and ïĩ it also reduces the overall cost.

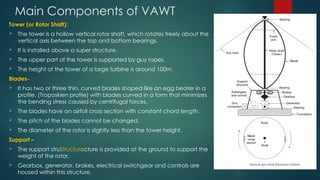

- 30. Main Components of VAWT Tower (or Rotor Shaft): ï The tower is a hollow vertical rotor shaft, which rotates freely about the vertical axis between the top and bottom bearings. ï It is installed above a super structure. ï The upper part of the tower is supported by guy ropes. ï The height of the tower of a large turbine is around 100m. Blades- ï It has two or three thin, curved blades shaped like an egg beater in a profile, (Troposkien profile) with blades curved in a form that minimizes the bending stress caused by centrifugal forces. ï The blades have an airfoil cross section with constant chord length. ï The pitch of the blades cannot be changed. ï The diameter of the rotor is slightly less than the tower height. Support â ï The support struStructurecture is provided at the ground to support the weight of the rotor. ï Gearbox, generator, brakes, electrical switchgear and controls are housed within this structure.

- 31. TYPES OF ROTORS 1. Cup type rotor 2. Savonius or S-rotor 3. Darrieus rotor 4. Musgrove rotor 5. Evans rotor

- 32. CUP TYPE ROTOR ïĩ The simplest being a three-or four-cup structure attached symmetrically to a vertical shaft. ïĩ The drag force on the concave surface of the cup facing the wind is more than that on the convex surface. As a result, structure starts rotating. Some lift force also helps rotation. ïĩ However, it cannot carry a load and therefore cannot used as power source. ïĩ The main characteristic of this rotor is that its rotational frequency is linearly related to wind speed. i.e., it is used for measuring the wind speed and the apparatus is known as CUP ANEMOMETER.

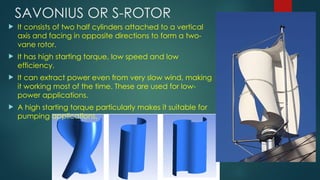

- 33. SAVONIUS OR S-ROTOR ïĩ It consists of two half cylinders attached to a vertical axis and facing in opposite directions to form a two- vane rotor. ïĩ It has high starting torque, low speed and low efficiency. ïĩ It can extract power even from very slow wind, making it working most of the time. These are used for low- power applications. ïĩ A high starting torque particularly makes it suitable for pumping applications.

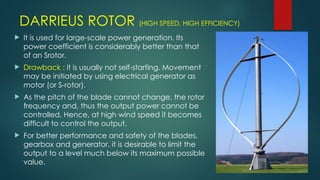

- 34. DARRIEUS ROTOR (HIGH SPEED, HIGH EFFICIENCY) ïĩ It is used for large-scale power generation. Its power coefficient is considerably better than that of an Srotor. ïĩ Drawback : it is usually not self-starting. Movement may be initiated by using electrical generator as motor (or S-rotor). ïĩ As the pitch of the blade cannot change, the rotor frequency and, thus the output power cannot be controlled. Hence, at high wind speed it becomes difficult to control the output. ïĩ For better performance and safety of the blades, gearbox and generator, it is desirable to limit the output to a level much below its maximum possible value.

- 35. MUSGROVE ROTOR ïĩ He suggested the use of H-shaped rotor where blades with a fixed pitch are attached vertically to a horizontal cross arm. ïĩ Power control is achieved by controlled folding of the blades. ïĩ Inclining the blades to the vertical provides an effective means of altering the blade angle of attack and hence controlling the power output.

- 36. EVANS ROTOR (GYRO MILL) ïĩ It is an improvement over H-shaped rotor. ïĩ Here, the rotor geometry remains fixed (blades remains straight) , but the blades are hinged on a vertical axis and the blade pitch is varied cyclically (as the blade rotates about the vertical axis) to regulate the power output. ïĩ But the need to vary the pitch cyclically through every rotor revolution introduces considerable mechanical complexity. ïĩ However, this enables it to self-start.

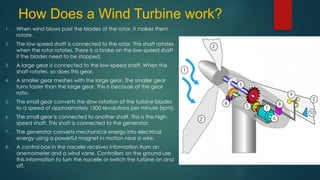

- 37. How Does a Wind Turbine work? 1. When wind blows past the blades of the rotor, it makes them rotate. 2. The low-speed shaft is connected to the rotor. This shaft rotates when the rotor rotates. There is a brake on the low-speed shaft if the blades need to be stopped, 3. A large gear is connected to the low-speed shaft. When the shaft rotates, so does this gear. 4. A smaller gear meshes with the large gear. The smaller gear turns faster than the large gear. This is because of the gear ratio. 5. The small gear converts the slow rotation of the turbine blades to a speed of approximately 1500 revolutions per minute (rpm). 6. The small gear is connected to another shaft. This is the high- speed shaft. This shaft is connected to the generator. 7. The generator converts mechanical energy into electrical energy using a powerful magnet in motion near a wire. 8. A control box in the nacelle receives information from an anemometer and a wind vane. Controllers on the ground use this information to turn the nacelle or switch the turbine on and off.

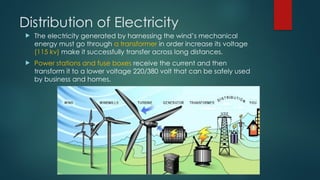

- 38. Distribution of Electricity ïĩ The electricity generated by harnessing the windâs mechanical energy must go through a transformer in order increase its voltage (115 kv) make it successfully transfer across long distances. ïĩ Power stations and fuse boxes receive the current and then transform it to a lower voltage 220/380 volt that can be safely used by business and homes.

- 39. Advantages of VAWT ïĩ The generator and gearbox can be placed on the ground ïĩ The structure is usually simpler. ïĩ You do not need a yaw (pointing) mechanism to turn the rotor against the wind. ïĩ These are easier for hobbyists to build â little detailed knowledge of aerodynamics is needed for simple designs.

- 40. Disadvantages of VAWT ïĩ These structures are low to the ground, where wind speeds are lowest. ïĩ The overall efficiency is much lower than horizontal axis machines. ïĩ Most vertical axis machines are not self starting. ïĩ Many vertical axis machines require guy wires which greatly increase the structural footprint. ïĩ Maintenance is usually more difficult. For example, replacement of the generator typically requires disassembly of the entire machine.

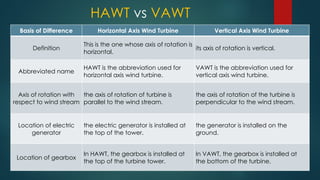

- 41. HAWT vs VAWT Basis of Difference Horizontal Axis Wind Turbine Vertical Axis Wind Turbine Definition This is the one whose axis of rotation is horizontal. its axis of rotation is vertical. Abbreviated name HAWT is the abbreviation used for horizontal axis wind turbine. VAWT is the abbreviation used for vertical axis wind turbine. Axis of rotation with respect to wind stream the axis of rotation of turbine is parallel to the wind stream. the axis of rotation of the turbine is perpendicular to the wind stream. Location of electric generator the electric generator is installed at the top of the tower. the generator is installed on the ground. Location of gearbox In HAWT, the gearbox is installed at the top of the turbine tower. In VAWT, the gearbox is installed at the bottom of the turbine.

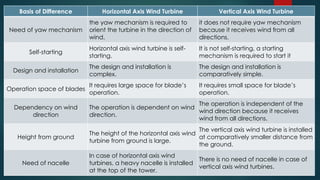

- 42. Basis of Difference Horizontal Axis Wind Turbine Vertical Axis Wind Turbine Need of yaw mechanism the yaw mechanism is required to orient the turbine in the direction of wind. it does not require yaw mechanism because it receives wind from all directions. Self-starting Horizontal axis wind turbine is self- starting. It is not self-starting, a starting mechanism is required to start it Design and installation The design and installation is complex. The design and installation is comparatively simple. Operation space of blades It requires large space for bladeâs operation. It requires small space for bladeâs operation. Dependency on wind direction The operation is dependent on wind direction. The operation is independent of the wind direction because it receives wind from all directions. Height from ground The height of the horizontal axis wind turbine from ground is large. The vertical axis wind turbine is installed at comparatively smaller distance from the ground. Need of nacelle In case of horizontal axis wind turbines, a heavy nacelle is installed at the top of the tower. There is no need of nacelle in case of vertical axis wind turbines.

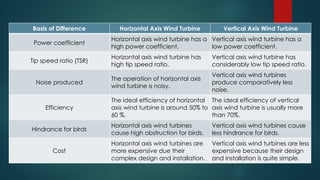

- 43. Basis of Difference Horizontal Axis Wind Turbine Vertical Axis Wind Turbine Power coefficient Horizontal axis wind turbine has a high power coefficient. Vertical axis wind turbine has a low power coefficient. Tip speed ratio (TSR) Horizontal axis wind turbine has high tip speed ratio. Vertical axis wind turbine has considerably low tip speed ratio. Noise produced The operation of horizontal axis wind turbine is noisy. Vertical axis wind turbines produce comparatively less noise. Efficiency The ideal efficiency of horizontal axis wind turbine is around 50% to 60 %. The ideal efficiency of vertical axis wind turbine is usually more than 70%. Hindrance for birds Horizontal axis wind turbines cause high obstruction for birds. Vertical axis wind turbines cause less hindrance for birds. Cost Horizontal axis wind turbines are more expensive due their complex design and installation. Vertical axis wind turbines are less expensive because their design and installation is quite simple.

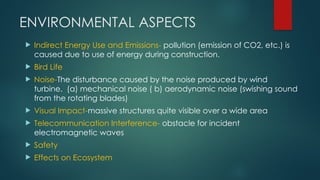

- 44. ENVIRONMENTAL ASPECTS ïĩ Indirect Energy Use and Emissions- pollution (emission of CO2, etc.) is caused due to use of energy during construction. ïĩ Bird Life ïĩ Noise-The disturbance caused by the noise produced by wind turbine. (a) mechanical noise ( b) aerodynamic noise (swishing sound from the rotating blades) ïĩ Visual Impact-massive structures quite visible over a wide area ïĩ Telecommunication Interference- obstacle for incident electromagnetic waves ïĩ Safety ïĩ Effects on Ecosystem

- 45. Advantages of wind power 1. The wind is free and with modern technology it can be captured efficiently. 2. Once the wind turbine is built the energy it produces does not cause green house gases or other pollutants. 3. Many people find wind farms an interesting feature of the landscape. 4. Wind turbines have a role to play in both the developed and third world. 5. Remote areas that are not connected to the electricity power grid can use wind turbines to produce their own supply.

- 46. Disadvantages of wind power 1. Many people feel that the countryside should be left untouched, without these large structures being built. The landscape should left in its natural form for everyone to enjoy. 2. Many people see large wind turbines as unsightly structures and not pleasant or interesting to look at. They disfigure the countryside and are generally ugly. 3. When wind turbines are being manufactured some pollution is produced. Therefore wind power does produce some pollution. 4. The strength of the wind is not constant and it varies from zero to storm force. This means that wind turbines do not produce the same amount of electricity all the time. There will be times when they produce no electricity at all. 5. Wind power must compete with other low-cost energy sources