Chapter 01 -Introduction of OSHA

- 1. Chapter 1: Introduction To OSHA

- 2. ïœ Define the concept of occupational safety and health. ïœ Explain the history of occupational safety and health. ïœ Explain the importance of safety in the workplace. ïœ Describe the major safety terminologies. ïœ Classify types of accident.

- 3. ïœ Occupational safety and health (OSH) is a basic human right for safety at workplace

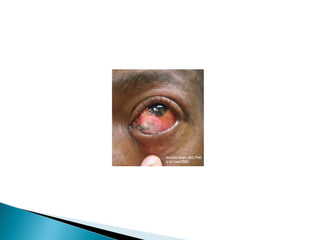

- 4. DONâT WATCH THIS IF YOU HAVE A WEAK HEART!

- 10. ïœ Accident prevention is an essential part of good management and workmanship ïœ Management and workers must cooperate ïœ Top management must take the lead ïœ A define and known safety and health policy ïœ Organization and resources to achieve policy ïœ Best available knowledge and methods

- 11. ïœ Until 1970, there were no national laws for safety and health hazards ïœ Several tragedies had occurred ⊠The 1911 Triangle Shirtwaist Company fire in New York City killed 146 of 500 employees ⊠Production for World War I caused a crisis in workplace safety and health conditions. ⊠By the 1960âs, 14,000 workers died every year and more than 2.2 million workers were not able to work from injuries and illnesses

- 12. ïœ The Era of Boiler Safety- Before 1914 ⊠Around 1890âs Perak state government elected a personnel expertise in steam boiler and was given a license as boiler surveyor

- 13. ïœ The era of machinery safety- 1914 to 1962 ⊠On 1 January 1914, all the steam boiler enactments was replaced with âMachinery Enactmentâ. ⊠The inspector inspects the steam boiler and any other machinery such as internal combustion engine, water turbine and any other auxiliary installation involved

- 14. ïœ The era of industrial safety- 1953 to 1967 ⊠All the machinery enactment used before 1953 was then replaced with Ordinal 1953. ⊠The role of an inspector has expanded from only inspecting the steam boiler to the safety of workers in factories that uses machinery.

- 15. ïœ The era of industrial safety and health- 1970 to 1994 ⊠Akta Kilang dan Jenteraâ (Factories and Machinery Act ) 1970 was approved by the parliaments. ⊠To solve all the shortcoming of the Machine Ordinal 1953, as the workers in a workplace without machine previously are now being protected under the new Acts.

- 16. ïœ The era of occupational safety and health- 1994 onwards ⊠Occupational Safety and Health Act (OSHA) was enacted in 1994 ⊠FMA 1967 emphasis on safety while OSHA 1994 emphasis on addressing health hazards in the workplace

- 17. ïœ Employees can remain motivated if they feel safe and happy ïœ Formation and implementation of safety programs that are meant to teach the employees to handle risks ïœ Violence at workplace

- 18. ïœ Accident- An unplanned unexpected event which may result in loss, injury or damage ïœ Code of Practice- A body of rules for Practical Guidance only and not having the force of law although failure to comply may be used in evidence in legal proceedings. ïœ Ergonomics- The study of relationship between workers and their occupation, equipment and environment and particularly, the application of anatomical, physiological and psychological knowledge to the problems arising there from.

- 19. ïœ Fire Precautions- The measures taken and the fire protection features provided in a building (e.g. design, systems, equipment and procedures) to minimize the risk to the occupants from and outbreak of fire. ïœ Fire Prevention- The concept of preventing outbreaks of fire, of reducing the risk of fire spreading and avoiding danger to persons and property from fire. ïœ First Aid- The skilled application of accepted principles of treatment on the occurrence of an accident or in the case of sudden illness, using facilities or materials available at the time.

- 20. ïœ Hazard- The exposed danger, a condition or practice with potential for loss. A situation that may give rise to personal injury or asset damage or both. ïœ Manual Handling- Any means of transporting or supporting a load manually. Lift, putting down, pushing, pulling, carrying or moving by hand of bodily force. ïœ Means of Escape- Structural means whereby a safe route is provided for persons to travel unaided from any point in a building to a place of safety

- 21. ïœ Near Miss- An incident, which does not show a visible result, but had the potential to do so. ïœ Policy- A statement of corporate intent, which will be adopted and pursued as advantageous or expedient. ïœ Qualified Worker- One who is accepted as having the necessary physical attributes, who possesses the required intelligence, training and education, and has acquired the necessary skill and knowledge to carry out the work in hand to satisfactory standards of safety, quantity and quality.

- 22. ïœ Reasonably Practicable - A computation made in which the quantum of risk is placed on one scale, and the disadvantages involved in the measure necessary of averting the risk is placed upon the other. A balance between: risk and cost, inconvenience, effect on production. ïœ Risk Assessment- A process where hazards are identified and risks evaluated, with the objective of eliminating or reducing the risks as low as reasonably practicable. ïœ Safety Audit- Monitoring of the implementation of a safety policy by subjecting each area of an activity to a systematic critical examination with the purpose of minimizing loss, and providing a quantified assessment of performance

- 23. ïœ Safety Inspection- Systematic assessment of safety standards for plant, place of work, working. Carried out by a manager and not a safety adviser/engineer. ïœ Safety Monitoring- Periodic checks on observance of corporate safety standards and procedures. ïœ Workplace- The workplace may be described as any place where people are at work

- 24. ïœ Accident happens mostly due by two major causes: ⊠Unsafe condition at the workplace ⊠Unsafe act done by a person or a group