class43-directdigitalandsupervisorycontrol-151123045624

- 1. All operatione ere perfotmed hlenually : Man Conttolled All Operations are performed automaticelly: Computer Couttolled Production Time Very High: Dne tri lot of time wnstagen during opecuti Productiou Time qiiite low: dne to removal of inefiicieot time eucii ss: repeated meastiremen Chip removal, Tool change over etc. Acciimcy Depends on Human Accuzacy doesn't depcads oa Humaa skill and hence unskilled person can aleo operete the machine once machine setting is over. Consistency in the quality of products cannot be achieved. Yields consisteni quality products. Complicated prof4e ma─Źhining vezy difEcelt to mqchine at even sometimcs impossible ta mu─ŹtdzŌĆóc. Can easily be machined because the movements of the machine is conttulled by o program. Introduction Difference Between Conventional & CNC M/cing

- 2. Very low flexibility or adaptability of new compouen*sormod5cmMne High flexibility for new components or modifications. Workpieee clamping and tool mounting methods quite slow in operation. Mochanicsd eyeteme are commonly used. Quiek aeting wotkpiece elamping and tool mounting methods adopted auch aa hydrsutic end pne tmatie ayatema. Not paasible. Consiatency in the cy─Źle time of pzaduct Manufactuzing eost quite ┼Šzigh. As q whole maaufacture of preducts at ┬½ reduced cost is possible. Low initial investments High initial inveetments One person can operate only one Machine ut a time One person can operate more than one euch machines ai a iime

- 3. DiCerence Between I>ithe & Stilling Lathe Two axis Machine extendable to $- Generally genemted. Principal Motions: Lon +u&nM (A) W Tmnsveme mve!oSToo! Rotational Motion of Workpiece about Z-axis Single Point Cursing tools are used. Consist of a turtet to accommodate number of tools. Upon indexing the turret the roofs are paeitioned to work the w/p the spindle. Three Axis Machine extendable to 6- axts. ┬Żlenerally flat or contoured surfaces are generated. Longitudinal (X), Transverse (Y) and Vertical (Z) trnvel of Workpiece RotRtiooal h4otion of Tool generally Z-axis Multiple point cutting tools are used. Consists of a ATC to accommodate number of tools. The tools are changed really usin a different mechanisms.

- 4. Lathe Milling W/p ie clamped either on a chuck or by a collect system. W/p is clamped on the machine bed in vise or ptoper fixturing arrangements. May have more than one spindle for May have more than one pallets for

- 5. ŌĆó INTRODUCTION ŌĆó FUNDAMENTAL PRINCIPLES ŌĆó INSTRUCTION

- 6. 1. INTRODUCTION ŌĆó Ways of Mach├»ning ŌĆó Parts of CNC Machine ŌĆó Working Methods of CNC

- 7. Ways of Machining ŌĆó Conventional or Traditional ŌĆó Numerical Control (NC) ŌĆó Computer Numerical Control (CNC)

- 8. Difficulties with Conventional System ŌĆó Complex shapes are difficult to machine ŌĆó Depends on the human skill ŌĆó Frequent & repeated measurements are required ŌĆó Difficult to achieve consistency in product quality ŌĆó High Changeover Time ŌĆó Less productive hours ŌĆó More scrap is generated

- 9. Current arket Deman ŌĆó High quality products 0 at 0 Lowest cost 0 in 0 Minimum time 0 with 0 wide range of variety

- 10. Parts of C/CNC Machine _ _ I ŌĆó ProgrammingUnit ŌĆó I I ŌĆó ŌĆó . I ŌĆó I I Cjy i i ŌĆó ŌĆó )ŌĆó Machi ŌĆóne Control UniŌĆó t .y I i . ŌĆó Machi . ne Tool Uni. t

- 11. Programming nit ŌĆó Programmer ŌĆó Computer system ŌĆó User Interface dev├»ce ŌĆó Data Storage and Transfer facility

- 12. achine Control nit ŌĆó Tape Reader ŌĆó Data Buffer ŌĆó Signal Output Channels to Machine Tool ŌĆó Feedback channels from the Machine Tool

- 13. Machine Tool ŌĆó Actuation System ŌĆöStepper motor/servomotor ŌĆöBall Screw & nut with support bearing Feed back devices on closed loop system ŌĆöLinear Bearing ŌĆó Tool & Work handling Devices ŌĆöAutomatic Tool Changers (ATCs) Turret Head ŌĆöAutomatic Pallet Changers ŌĆöHydraulic/Pneumatic Tool/Work Clamping System

- 14. Machine Tool ŌĆó Actuation System ŌĆöStepper motor/servomotor ŌĆöBall Screw & nut with support bearing Feed back devices on closed loop system ŌĆöLinear Bearing ŌĆó Tool & Work handling Devices ŌĆöAutomatic Tool Changers (ATCs) Turret Head ŌĆöAutomatic Pallet Changers ŌĆöHydraulic/Pneumatic Tool/Work Clamping System

- 15. 2. Fundamental Principles ŌĆó Coordinate System ŌĆó Longitudinal Motion ŌĆó Transverse Motion ŌĆó DimensioningSystem ŌĆó Absolute ŌĆó Incremental ŌĆó Mixed ŌĆó Reference System ŌĆó Machine Reference ŌĆó Work Reference

- 16. Instruction or program ŌĆó Introduction N 10 G 00 X 50.0 Z 25.0 ; Block No. G 00 Address Words End of Block Data Block

- 17. Fanuc Heidenhein Program Logic & Structure for the both the eyeiome are aame only the writing format ia Both uses G & M Codes for writing the pnogtems. Standard alot milling, pocket cycles not available. milling Ttiene cycles. available «e rim atandeid G-Code Siondard functions for mirroring, Corner wounding, corner chamfeziog etc Standard a able. functions for mirroring etc are Program number starts with the tetter Doesn't. Requires block termination or end of btock ' ; * Doesn't Requires '.' in the numerical such as 20.1$ or 28.0 values doesn't Compare & Contrast Fanuc & Heidenhain

- 18. Basic Program Structure ŌĆó Working unit ŌĆöMm: G71 ŌĆöInch: G70 ŌĆó Working Plane XY: G17 ŌĆöZX: G18 ŌĆöYZ: G19 ŌĆó Dimensioning method Absolute: G90 ŌĆöIncremental: G91

- 19. Simple Example Program (Absolute) % 101 G71 N05 G90 G17 N10 G30 X0 Y0 Z-10 N20 G31 X100 Y100 ZO N30 G99 T1 LOR5 N40 M06 T1 N50 M03 S2000 N60 G90 G00 X20 Y20 N62 G01 Z5 F250 N65 G01 Z O F100 N70 G01 Z-1 F50 N80 G01 X80 Y20F100 N90 Y80 X80 N100 X20 N110 Y20 N120 G00 Z5 3 M N1 0 0 20 60

- 20. Simple Example Program (Incremental) Oo102 G71 N05 G90 G17 N10 G30 X-50 Y-50 Z-10 N20 G31 X50 Y50 ZO N30 G99 T1 LO R3 N40 M06 T1 N50 M03 S2000 N60 G90 G00 X-40 Y0 Z10 N65 G01 ZO F500 N70 G01 Z-1 F50 N80 G91 Y-40 N90 X80 N100 Y80 N110 X-80 N120 Y-40 N130 G00 Z10 N140 M05

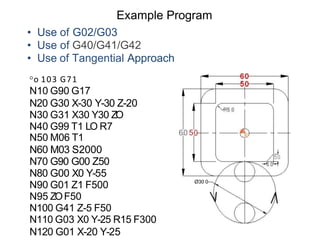

- 21. Example Program ŌĆó Use of G02/G03 ŌĆó Use of G40/G41/G42 ŌĆó Use of Tangential Approach O o 103 G71 N10 G90 G17 N20 G30 X-30 Y-30 Z-20 N30 G31 X30 Y30 ZO N40 G99 T1 LO R7 N50 M06 T1 N60 M03 S2000 N70 G90 G00 Z50 N80 G00 X0 Y-55 N90 G01 Z1 F500 N95 ZOF50 N100 G41 Z-5 F50 N110 G03 X0 Y-25 R15 F300 N120 G01 X-20 Y-25 6.0 5 ├ś30 0 50

- 22. N140 G98 L3 N15O G17 G91 Y-15 N133 GOOG90 Z+1 M99 N134 L3.2 N135 G98 L4 N136 G17 G91 X-15 N137 GOOG9O Z+1 M99 N134 L4.2 N140 GOOZ1 M99 N142 GOOZ10 N144 G98 LO N145 MOS N150 M30 N9999 %1005 G71 10 10 Contd..

- 23. Depth of Cut Increment Method %1002 G71 N100 G17 G90 N200 G30 X-45 Y-45 Z-15 N300 G31 X+4S Y+45 Z+0 N400 G99 T1 L+0 R+7 N500 G00 G40 G90 N600 T1 M06 N700 S1000 M03 N800 G00 X-S5 Y+0 Z+10 N900 Z+0 N1000 G98 L1 N1100 G01 G41 G91 Z-1 F100 N1200 G90 X-30 Y+0 F80 N1300 X-30 Y+20 0.0 10 .0

- 24. N14OO X-20 Y+30 N141O X2O Y3O N15OO GO2 X+30 Y+20 R+10 N16OO GO1 X3O Y-20 N170O GO2 X+20 Y-30 R+10 N180O GO1 X-20 Y-30 N185O X-30 Y-20 N186O X-30 Y0 N187O GOG4O X-55 YO N1900 L1.4 N2000 G98 LO N2100 G40 Z+20 N2200 M30 N9999 %1002 G71

- 25. Linear circular polar Method %1003 G71 N2O G17 N40 G17 G30 G9O X+0 Y+0 Z-10 N6O G31 G9O X+100 Y+100 Z+0 N8O G99 T1 L+0 R+3 N90 T1 N110 G01 M06 N120 S2000 N140 G01 M03 N18O G00 G90 X+20 Y+20 Z+5

- 26. N200 GO1 G90 Z-1 FSO N220 G9O I+20 J+20 G29 N240 G11 G90 R+80 H+45 F100 N260 G90 I+50 J+50 G29 N280 G12 G90 H-55 N300 GO7 G90 X+20 F60 N320 GOOG90 Z+5 N340 GO1 M30 N9999 %1003 G71

- 27. Writing Format: G83 P01.... P02.... PO3.... P04.... P05.... Where; P01: Setup Clearance P02: Total Depth P03: Pecking Depth P04: Dwell Time (in Sec nds) P05: Feed Rate P02 P01

- 28. %1005 G71 N05 G17 G90 N10 G30 X-45 Y-45 Z-15 N20 G31 X+45 Y+45 Z0 N30 G99 T1 L+0 R+4 N31M06 T1 N32 M03 S2000 N40 G90 G40 G00 X-40 Y-30 N45 G01 Z10 F800 N50 G01 Z3 F100 N60 G83 P01 -1 P02 -5 P03 -1P04 0.1P05 100 N65 Z1 M99 N70 G98 L1 N80 G17 X-40 Y30 G90 N90 G00 Z1 M99 N100 G98 L2 N110 G17 G91 G01 X10 F100 N120 G90 G00 Z1 M99 N130 L2.5

- 29. N140 G98 L3 N15O G17 G91 Y-15 N133 GOOG90 Z+1 M99 N134 L3.2 N135 G98 L4 N136 G17 G91 X-15 N137 GOOG9O Z+1 M99 N134 L4.2 N140 GOOZ1 M99 N142 GOOZ10 N144 G98 LO N145 MOS N150 M30 N9999 %1005 G71 10 10 Contd..

- 30. Writing Format G75 P01... P02 ... P03 ... P04 ... P05 ... P06 ... P07 ... P01: Setup Clearance P02: Total Depth P03: Peckng Depth P04: Feed Rate in Z-axis P05: 1st Side Length of Pocket P06: 2nd Side Length of Pocket P07: Feed Rate for Cutting G75 : Rectangular Pocket Milling Clockwise G76: Rectangular Pocket Milling Anti Clockwise

- 31. %1├”8o7l N05 G17 G90 N10 G30 X0 Yfi Z-I5 N20 G31 X+90 Y+90 ZO N30 G9S TI I.+0 R+3 N40 G4fi GS8 N50 5103SIS┼ÆI N60 G├╣0 X2OY2G NHS G0) Z10 F230 N├│8 G00 Z3 N70 G74 P0l ŌĆö 3P02ŌĆö 5P03ŌĆö 1P04 50P05 X+40 P06 Y+10 P07 100 NS0 G00 K3 hI99 N100 GS0 120J20GU R60H9 5199 Nll0 G00 Zl0 Nl2├╗ 6I├╝├╝ N1206130

- 32. G74 POI... B02 ... P03 ... P0l: Setup Clearance P02:Total Depth P03: Pecking Depth P04: Feed Rate in Z-axis POS: 1st Side I.ength of Slot P06: 2ŌĆóŌĆś Side I.enyth of Slot POS:Feed Rate for Cutting

- 33. %1├”8o7l N05 G17 G90 N10 G30 X0 Yfi Z-I5 N20 G31 X+90 Y+90 ZO N30 G9S TI I.+0 R+3 N40 G4fi GS8 N50 5103SIS┼ÆI N60 G├╣0 X2OY2G NHS G0) Z10 F230 N├│8 G00 Z3 N70 G74 P0l ŌĆö 3P02ŌĆö 5P03ŌĆö 1P04 50P05 X+40 P06 Y+10 P07 100 NS0 G00 K3 hI99 N100 GS0 120J20GU R60H9 5199 Nll0 G00 Zl0 Nl2├╗ 6I├╝├╝ N1206130

- 34. &rifing Format G├Ż8 X V'here, X is the name Gif ├”x├¼s ├¼n which mirroring wil├¼ take place %1010 G71 N05 G17 G90 N10 G17 G30 X-50 Y-50 Z-10 N20 G31 X+50 Y+50 Z+0 N30 G99 T1 L+0 R+3 N40 T1 M06 N40 G40 G90 N50 S1500 M03 N60 G90 X+0 Y+0 Z+5 N70 G98 L150 N80 G00 X+10 Y+10 N82 G01 Z+5 F500 N85 G01 ZO F100 N90 G01 Z-1 F50

- 35. N100 G01 X+20 Y+10 F100 N110 G01 X+20 Y+15 N112 X15 Y15 N114 Y25 N116 X30 N118 Y30 N120 X10 N122 Y10 N124 G O OZ+5 N140 G98 LO N150 G28 X L150 N160 G28 X Y L150 N170 G28 Y L150 N18O G O OZ+5 N200 M05 G O O220 N100 M30