Classification of machining processes (PT)

- 1. A.D.PATEL INSTITUTE OF TECHNOLOGY Presented By:- Group No.:- 1 Rudraraj Panchal (160010119050) Guided By:- Proff. S.B.Bhatia

- 3. MACHINING ’é¦ Machining is a processes in which a piece of raw material is cut into a desired final shape and size by a controlled material- removal process.

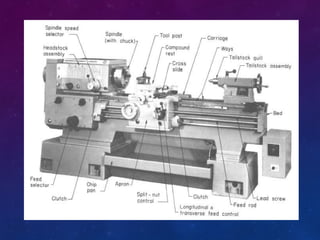

- 4. MACHINE TOOL ŌĆó A lathe is a machine tool which rotates the work piece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation with tools that are applied to the work piece to create an object which has symmetry about an axis of rotation.

- 6. MACHINING PROCESSES Include the following: ’ü▒ Safety Equipment ’ü« Metal removing process ’ü« Unwanted material -- chips or swarfs ’ü« Raw Work piece ’ü« Machine Tool ’ü« Machine Shop ’ü« Machinist

- 7. MATERIAL REMOVAL PROCESSES A combination of shaping operations, the common feature of which is removal of material from a work piece so the remaining part acquires the desired shape ŌĆóCategories: Traditional and non traditional processes Machining ŌĆō ItŌĆÖs a traditional material removal by a Mechanical Equipment and sharp cutting tool, e.g., turning, milling, drilling Abrasive processes ŌĆōmaterial removal by hard, abrasive particles, e.g., grinding ,sand blasting Non traditional processes - Non traditional processes-various energy forms other than sharp cutting tool to remove material, like chemicals ,laser water jet etc.

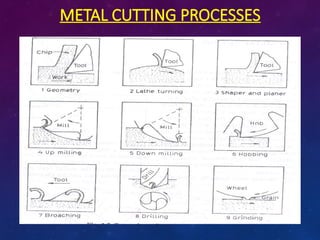

- 8. 16 MATERIAL REMOVAL PROCESSES(CONTD) Mechanical ’āś Single-point cutting ’é¦Turning ’é¦Planning and shaping ’āś Multi-point cutting ’é¦Milling ’é¦Drilling ’é¦Broaching ’é¦Sawing

- 9. 17 ’āś Abrasive machining ’é¦Grinding ’é¦Honing ’é¦Lapping ’é¦Abrasive jet machining ’é¦Sand blasting MATERIAL REMOVAL PROCESSES(CONTD)

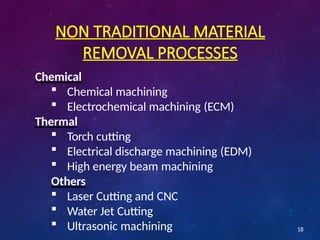

- 10. 18 Chemical ’é¦ Chemical machining ’é¦ Electrochemical machining (ECM) Thermal ’é¦ Torch cutting ’é¦ Electrical discharge machining (EDM) ’é¦ High energy beam machining Others ’é¦ Laser Cutting and CNC ’é¦ Water Jet Cutting ’é¦ Ultrasonic machining NON TRADITIONAL MATERIAL REMOVAL PROCESSES

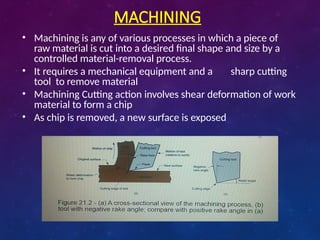

- 12. MACHINING ŌĆó Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. ŌĆó It requires a mechanical equipment and a sharp cutting tool to remove material ŌĆó Machining Cutting action involves shear deformation of work material to form a chip ŌĆó As chip is removed, a new surface is exposed

- 13. MACHINING OPERATIONS Some important machining operations: ŌĆó Turning ŌĆó Drilling ŌĆó Milling Lathe machine Other machining operations: ŌĆó Shaping and planing ŌĆó Broaching and hobbing ŌĆó Sawing and engraving

- 14. THANK YOU