Case Study - Lean Implementation (Manufacturing)

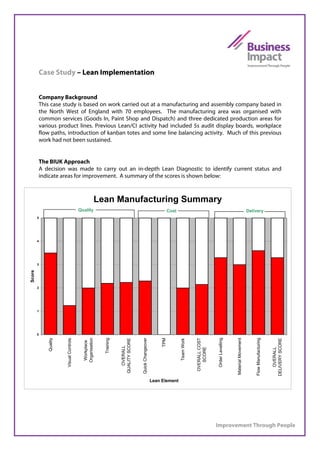

- 1. Case Study ŌĆō Lean Implementation Company Background This case study is based on work carried out at a manufacturing and assembly company based in the North West of England with 70 employees. The manufacturing area was organised with common services (Goods In, Paint Shop and Dispatch) and three dedicated production areas for various product lines. Previous Lean/CI activity had included 5s audit display boards, workplace flow paths, introduction of kanban totes and some line balancing activity. Much of this previous work had not been sustained. The BIUK Approach A decision was made to carry out an in-depth Lean Diagnostic to identify current status and indicate areas for improvement. A summary of the scores is shown below: Lean Manufacturing Summary Quality Cost Delivery 5 4 3 Score 2 1 0 Order Levelling Flow Manufacturing Training Quick Changeover Organisation Material Movement Quality TPM OVERALL COST QUALITY SCORE Visual Controls DELIVERY SCORE Team Work Workplace OVERALL SCORE OVERALL Lean Element Improvement Through People

- 2. An overall score of 51% was achieved against the fifty-five criteria with Quality and Cost scores being below average while Delivery was above average. When the above results were combined with detailed area-by-area observation, the following recommendations were made: ŌĆó re-instatement of the 5s programme with regular audits and responsibilities ŌĆó review of line side stock levels to create better flow and space utilisation ŌĆó consideration of the use of dedicated tool sets for assembly stations rather than several large tool boxes ŌĆó enhancement of the visual display/information available across all production areas, including real time performance display ŌĆó analysis of selected processes in terms of ŌĆśmudaŌĆÖ (the seven wastes) ŌĆó more involvement of all process personnel in improvement suggestions and actions (the ŌĆśeighthŌĆÖ waste) ŌĆó consideration of area requirements in terms of storage and visual control of stock ŌĆó use of basic SMED principles to reduce changeover times in the Paint Shop ŌĆó consideration of the calculation and use of takt time to balance and create flow where appropriate Implementation and Results Many of the recommendations above were implemented as part of a Business Improvement Techniques programme, with a substantial percentage of the workforce taking part. This resulted in many improvements that impacted on Quality, Cost and Delivery performance. The BIT programme having established a solid foundation for Continuous Improvement, BIUK consultants worked with the company to identify further improvement opportunities, two of which are outlined below. Order Entry Process A process mapping exercise identified major errors in the order entry process. These errors often resulted in lack of validation of customer required dates and impacted on production, delivery and work in process levels. A new procedure was developed that correctly validated customer delivery dates resulting in substantial savings on costs and improved customer service. Build to Order Analysis of current stock quantities revealed that many product lines were built in advance of customer orders. This resulted in a huge stock of kitted product that took up an entire storage unit. The solution was to identify and create Min/Max levels for key subassemblies and smaller unique parts. This resulted in customer orders being kitted within one day of receipt and the storage unit being surplus to requirements. Improvement Through People