Composite masonry

- 2. COMPOSITE MASONRY âĒ When walls are constructed with two or more types of building materials it is term as composite masonry. âĒ The composite masonry are adopted due to following reasons: 1.It reduces overall cost of construction. 2.This make the structure more durable by providing materials of better quality and good workmanship in the faces.

- 3. 3. It improves the appearance of the structure by concealing the inferior work. 4. It makes the used of locally available materials to obtain optimum economy.

- 5. COMPOSITE MASONRY: 1. Stone facing with brick backing. 2. Stone slab facing with brick backing. 3. Brick facing with concrete backing. 4. Ashlar facing with brick backing. 5. Ashlar facing with rubble backing.

- 6. STONE FACING WITH BRICK BACKING. âĒ In this type of composite masonry a wall is constructed in brick work and stones are provided on facing to appear if constructed in stone. âĒ It is adopted to improve the appearance of the structure at the lesser cost.

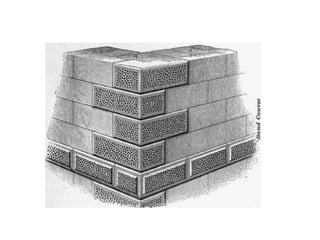

- 8. STONE SLAB FACING WITH BRICK BACKING: âĒ In this type of composite masonry a wall is constructed in brick work and stone slab are used in facing. âĒ The stone slab seldom exceed 5 to 10cm in thickness and are properly secured to the brick backing. âĒ The stone may be used natural or artificial.

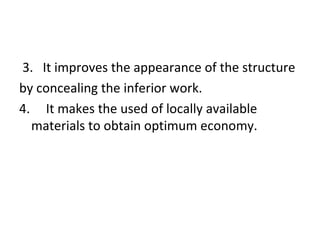

- 9. BRICK FACING WITH CONCRETE BACKING. âĒ In this type of construction bricks are used as facing material and concrete as backing . âĒ This type of construction is adopted to get the strength of concrete and the aesthetic of bricks .

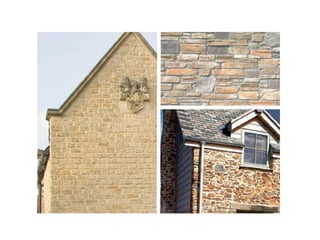

- 11. ASHLAR FACING WITH BRICK BACKING. âĒ In this type of composite masonry rough tooled and chamfered stones are provided in facing while brick work is provided in backing. âĒ It is preferable to use the height of ashlar as a multiple of brick thickness plus masonry joints .

- 13. ASHLAR FACING WITH RUBBLE BACKING. âĒ In this type of composite rough tooled and chamfered stones are provided in facing while rubble masonry in backing . âĒ This may reduce the cost of construction as the rubbles are available at a cheap rate.

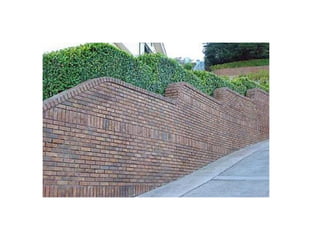

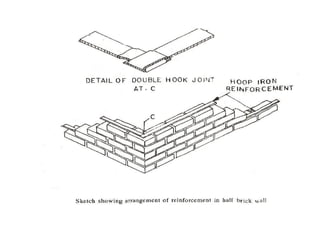

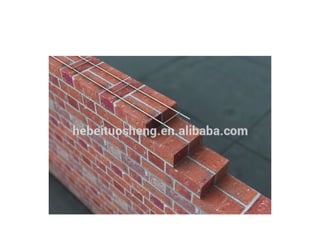

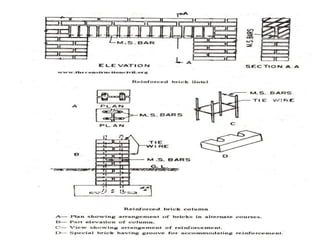

- 15. Reinforced Brick Masonry âĒ Brick work strengthened by introduction of mild steel flats, hoop iron, expanded mesh or bars is termed as reinforced brick masonry. This reinforced brick masonry is capable of resisting both compressive as well as tensile and shear stress. On account of its ability to resist lateral forces, reinforced brick masonry is extensively used in seismic areas. It is essential to use first class bricks (having crushing strength of 140 kg/sq. cm or more) and rich and dense cement mortar in the reinforced brick work. The reinforcement should be effectively bedded and surrounded with mortar cover of 15 to 25 cm. This is necessary to protect the reinforcement against corrosion.

- 18. âĒ Reinforced brick masonry is frequently adopted for the construct ion of retaining walls especially in places where exposed brick work is necessary from architectural considerations. âĒ Such a wall is made by using special bricks (having grooves for accommodating reinforcing bars) in cement mortar 1 : 3 and reinforced with vertical MS rounds placed near each face. Horizontal reinforcement in the form of steel meshed strips are also provided at every third or fourth course.