Composites

- 1. Hacettepe University/Department of Chemical Engineering 04.01.2014

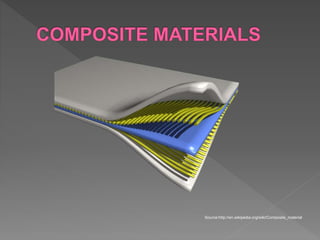

- 4. Matrix Phase:The matrix is the majority of the compositeâs volume.(First phase) Dispersed (reinforcing) phase:Which is embedded in the matrix in a discontinuous form. Source:http://www.mscsoftware.com/training_videos/patran/Reverb_help/index.html#page/Laminate%20Modeler/lam_tutorial.3.03.html

- 5. Metal Matrix Composites (MMC) Ceramic Matrix Composites (CMC) Polymer Matrix Composites (PMC)

- 6. Particulate Composites Fibrous Composites Laminate Composites

- 7. The 1500s B.C. when early Egyptians Source:http://www.ecotek.com.cy/blog/?view=day&blogDate=7/6/2 013 Source:http://aprilrocksthecasbah.blogspot.com/2009/11/rissani-to-fes.html

- 9. Mechanical Properties Modulus of Elasticity - Isostrain Loading Isostrain vs Isostress Source:http://resources.edb.gov.hk/~s1sci/R_S1Science/sp/en/syllabus/unit14/new/

- 10. Key Factors Influencing Process Selection: Number of parts required Matrix type Reinforcement type Shape & complexity of the product Size of the product Cost per unit part Dimensional accuracy & tolerances Appearance/finishing of the product Strength & stiffness Post processing/assembly techniques âĒPolimer Matrix âĒMetal Matrix âĒCeramic Matrix âĒParticulate âĒFibrous âĒLaminate

- 11. Hot-pressing method Powder metallurgy method Liquid metal impregnation method Electrodeposition Vapor deposition method Raw Material Method

- 12. Wet Layup Spray Lay up Resin Transfer Moulding â RTM Filament winding Pultrusion

- 13. Target productivities for composite manufacturing processes: http://www.azom.com/article.aspx?ArticleID=352

- 17. AdvantagesDisadvantages Weight ratio Tensile strength Toughness Better Performance Fatigue resistance Design flexibility Costs Manufacturing difficulties Repair Variability range Temperature issues Complex testing

- 18. Consequently; Composites are very oldest materials and can be found in natural forms. Composites have two or more different properties in one material and make our lives easier. Choosing of manufacturing process is depend on limitation of materials and types of materials.