Construction equipments

- 1. Construction Equipments Presented By, T. Manikandan B.tech., M.E., Asst. Prof. â Dept. of Civil Engineering, Sembodai Rukmani Varatharajan Engineering College, Sembodai â 614809.

- 2. Introduction âĒ In the case of huge construction projects Proper use of the appropriate equipment contributes to economy, quality, safety, speed and timely completion of a project. âĒ Equipment are use for highway projects, irrigation, buildings, power projects etc. âĒ 15-30% of total project cost has been accounted towards equipment and machinery

- 3. Classification of Construction Equipment ïž Earth-moving equipment ïž Hauling equipment ïž Hoisting equipment ïž Conveying equipment ïž Aggregate and concrete production equipment ïž Pile-driving equipment ïž Tunneling and rock drilling equipment ïž Pumping and dewatering equipment

- 4. Excavating and earth moving equipment ïžPower shovel ïž Back hoe ïž Drag line ïž Clam shell ïž Scrapers ïž Bull dozer.

- 5. Power shovel ïžTo excavate the earth and to load the trucks ïž capable of excavating all types of earth except hard rock ïž size varies from 0.375m3 to 5m3 ïž Suitable for close range of work ïž Capable of digging very hard materials ïž can remove big sized boulders ïž It is used in various types of jobs such as digging in gravel banks, clay pits, digging cuts in road works etc.

- 6. Back hoe ïžIt is used to excavate below the natural surface on which it rests. ïž Generally used to excavate trenches, pits for basements and also for grading works, which requires precise control of depths. ïž It is the most suitable machine for digging below the machine level, such as, trenches, footings, basements etc. ïž It can be efficiently used to dress or trim the surface avoiding the use of manual effort for dressing the excavated the surface.

- 7. Drag line ïž A dragline can dig and dump over larger distances than a shovel can do. ïž Drag lines are useful for digging below its track level and handling softer materials. ïžIt is the most suitable machine for dragging softer material and below its track level. ïž It is very useful for excavating trenches when the sides are permitted to establish their angle of repose without shoring. ïž It is mostly used in the excavation for canals and depositing on the embankment without hauling units.

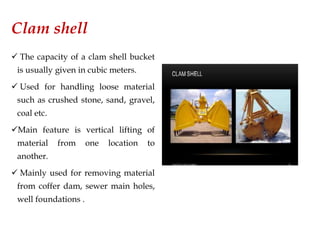

- 8. Clam shell ïž The capacity of a clam shell bucket is usually given in cubic meters. ïž Used for handling loose material such as crushed stone, sand, gravel, coal etc. ïžMain feature is vertical lifting of material from one location to another. ïž Mainly used for removing material from coffer dam, sewer main holes, well foundations .

- 9. Trenching machine ïžUsed for excavating trenches for laying pipelines, sewerage, cables etc ïž Operation is quick giving the required depth or width. ïž Two types of trenching machines are wheel type, ladder type.

- 10. Scrapers ïžUnique machine for digging and long-distance hauling of plough able materials. ïžself-operating machine, It is not dependent on other equipment. ïž Wheels of machine cause some compaction. ïžThe basic parts of scrapers are the bowl, apron and tail gate or ejector.

- 11. Bull dozer ïžFor spreading the earth fill. ïž For opening up pilot roads through mountainous and rocky terrains. ïž Clearing construction sites. ïžMaintaining haul roads Clearing land from the trees and stumps. ïžback-filling trenches at construction sites by dragging the earth from one place to another.

- 12. Earth compaction equipment ïžSmooth-wheel rollers. ïžPneumatic tyred rollers.

- 13. Smooth-wheel rollers ïžUsed for ordinary rolling work where deep compaction is not required. ïž These rollers may have one front and two rear wheels. ïž The rear wheels being usually larger in diameter and the front one being winder. ïžWeight of rollers may be increased by filling water or sand ballast in hollow cylinder. ïžThese rollers are effective in compacting granular soils, such as sand, gravel and crushed stone.

- 14. Pneumatic tyred rollers The use of a pneumatic roller (or rubber tire roller) is vital in the compaction process of asphalt paving as it is able to conform the surface being paved. In order to achieve the proper compaction and density of the asphalt and to ensure a long lasting, smooth pavement surface, the use of a rubber tire roller in the paving process is paramount.

- 15. Hauling Equipment ïžThe equipment used for transportation of material are known as hauling equipment or simply haulers. ïž Haulers may operate on the roadways or railways. It involve transportation of building materials, carriage and disposal of excavated earth haulage of heavy construction equipment. ïž These are classified on the basis of method of dumping the load: 1. Dump trucks Side or rear dump trucks Bottom dump trucks 2. Dumpers

- 16. Dump trucks ïžThere are two types (a) Side or rear dump trucks:- These trucks are suitable for use in hauling wet clay, sand, gravel, quarry rocks etc. (b)Bottom dump trucks:- These trucks are suitable for use in hauling free flowing material, such as gravel, dry earth, hard clay etc.

- 17. Dumpers ïž Loading, hauling and dumping is done very fast as compared to other equipment ïž Suitable for short hauls on rough roads, Specially where a shuttle movement is required.

- 18. Donât worry about failures, worry about the chance you miss when you donât even try it !! ThankYouAll!!