Construction Equipments and its Management

- 2. Importance of Construction Equipment - Construction equipment plays an important role in most construction projects. -to prepare the site, erect a building or bridge, or construct an airport runway - Commercial or residential contractors typically rely on renting or leasing equipment as needed, or they may choose to subcontract the work. - Decisions regarding the types and quantity of equipment to use on a project will greatly impact the project cost and duration.

- 3. - because of repeated use of many major pieces of equipment, heavy civil construction contractors often find it more cost- effective to own their own equipment and treat their equipment fleet as a profit center for their companies. - Consequently, the construction manager needs to select the equipment combination that yields the lowest production cost while achieving the desired productivity to enable meeting the contractual completion date.

- 4. Construction Equipment Management âĒ Equipment is a critical resource in the execution of most construction projects. âĒ As the equipment fleet may represent the largest long-term capital investment in many construction companies, equipment management decisions have significant impacts on the economic viability of these construction firms. âĒ Equipment must pay for itself by earning more for the contractor than it costs to purchase, own, and use it. âĒ Idle equipment is a drain on income â operating costs are earned only when the equipment is used, but ownership costs are earned irrespective of frequency of use.

- 5. âĒ Equipment productivity - The costs to be considered are the cost of owning, leasing, or renting the equipment and the costs of operating, maintaining, and repairing it. âĒ The effectiveness of a contractorâs preventive maintenance program will significantly influence equipment operating and repair costs. âĒ Contractors must continually evaluate their equipment fleets to determine when to acquire additional items, when to replace items, and when to dispose of items that are underutilized.

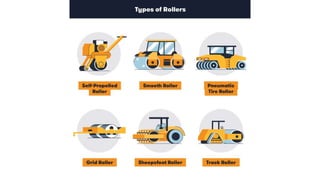

- 7. Roller

- 9. Trencher

- 10. Paver

- 11. The basic criteria that should be used in selecting equipment for specific tasks are: âĒ The capability of the equipment to perform the work. âĒ The capability of the equipment to perform effectively under the working conditions of the job site. âĒ The availability of the equipment, either from the contractorâs equipment fleet or from a rental or leasing agency. âĒ The reliability of the equipment and predicted maintenance requirements. âĒ The availability of parts and service support for the equipment. âĒ The capability of the equipment to perform multiple tasks on the project. âĒ Safety features available with the equipment. Selection of Equipment

- 12. âĒ Suitability for Job Conditions: The equipment must meet the requirement of the work, climate and working conditions. âĒ Size of the Equipment: Size of equipment should be such that it must be able to be used with other matching units. âĒ Standardization: It is better to have same type and size of equipment in the project. âĒ The Economical Aspects: While selecting the equipment, it should be considered that the cost of unit production should be minimum. âĒ Reliability of the Equipment: Equipment selected for the project must be reliable one.

- 13. âĒ Service Support: Service support should be available in the area of project where the equipment shall be used. Service after sales is a major criteria for selection of equipment. âĒ Operating Requirements: The equipment selected should be easy to operate and maintain, acceptable to the operator and should have lesser fuel consumption. âĒ Past performance: If the equipment being purchased is of new make and model, it is desirable to enquire about its performance from other users, who are using this make and model.

- 14. FORECASTING EQUIPMENT REQUIREMENT Following are the main points planner has to decide in equipment planning Working Shifts: By increasing the number of shifts we can reduce the number of equipment required, as the same equipment can be used in second and third shift. Number and Size of Equipments: For deciding the number and size of the equipments following factors should be considered. ïķ Quantum of work, ïķ Working days available for completion of project. ïķ Number of shifts planned. Matching Units: The number and size of the matching equipment should be planned for each activity, keeping in view that complete matching set must be utilized at the maximum and combination must be optimum. EQUIPMENT MANAGEMENT IN CONSTRUCTION PROJECTS

- 15. Procurement Scheduling : Procurement scheduling is done considering procurement time required and time when equipment is required. Workshop and Stores Planning: While planning for the purchase of equipments, it is necessary to plan for the workshop and stores for carrying out the repair and maintenance. Man power planning: Planning for manpower in order to operate the equipment and to carry out the repair and maintenance is also necessarily be done sufficiently in advance. Site Conditions: The type of equipment selected mainly depends upon soil available, and valley conditions, surface and strata where work is to be carried out. EQUIPMENT MANAGEMENT IN CONSTRUCTION PROJECTS

- 16. âĒ Different type of soil needs different amount of effort. âĒ Reduction of horse power of engine due to altitude. âĒ Time spent on servicing and inspection varies with the working conditions. âĒ Output of the equipment also depends upon the operator's efficiency. âĒ Output of dumper etc. depends on the condition of haul road. âĒ Time spent on the unproductive works. âĒ Changing weather conditions are responsible for variation in output. âĒ Capacities of the matching machineries working in the same group. Output and Capacity of Equipment Output of the equipment varies with various conditions. Following are some of them: EQUIPMENT MANAGEMENT IN CONSTRUCTION PROJECTS

- 17. MAINTENANCE MANAGEMENT Every machine is thoroughly tested and inspected by the manufacturers before selling. When used it is subjected to wear and tear, hence proper attention should be given to protect the machine and its components from unnecessary wear and thus protect them from failures. A proper attention means lubrication, cleaning, timely inspection and systematic maintenance. Maintenance means efforts directed towards the upkeep and the repair of that machine.

- 18. A. Repair Maintenance can be followed for non-critical equipment, and where failures are unpredicted. B. Corrective Maintenance should be adopted for frequently failing components. C. Preventive Maintenance (planned or scheduled or systematic maintenance). Periodic inspection or checking at the pre-decided frequency helps to find out the reasons leading to break down and to rectify them when they are in minor (or initial) stages.

- 21. Cost of Owning Plant, equipment, and tools used in construction operations are priced in the following three categories in the estimate: 1. Small tools and consumables: Hand tools up to a certain value together with blades, drill bits, and other consumables used in the project are priced as a percentage of the total labor price of the estimate. 2. Equipment usually shared by a number of work activities: These kinds of equipment items are kept at the site over a period of time and used in the work in progress. 3. Equipment used for specific tasks: These are capital items and used in projects such as digging trench or hoisting material into specified slots. This equipment is priced directly against the take-off quantities for the Project it is to be used on. The equipment is not kept on-site for extended periods - the equipment is shipped to the site, used for its particular task, and then immediately shipped back to its original location.

- 22. Total equipment costs comprise two separate components: ownership costs and operating costs. Except for the one-time initial capital cost of purchasing the machine, ownership costs are fixed costs that are incurred each year, regardless of whether the equipment is operated or idle. Operating costs are the costs incurred only when the equipment is used. Each cost has different characteristics of its own and is calculated using different methods.

- 23. OWNERSHIP COST Ownership costs are fixed costs. Almost all of these costs are annual in nature and include: . Initial capital cost . Depreciation . Investment (or interest) cost . Insurance cost . Taxes . Storage cost

- 24. INITIAL COST On an average, initial cost makes up about 25% of the total cost invested during the equipmentâs useful life. This cost is incurred for getting equipment into the contractorâs yard, or construction site, and having the equipment ready for operation. Many kinds of ownership and operating costs are calculated using initial cost as a basis, and normally this cost can be calculated accurately. Initial cost consists of the following items: . Price at factory (âđ) extra equipment (âđ) sales tax . Cost of shipping . Cost of assembly and erection

- 25. DEPRECIATION Depreciation represents the decline in market value of a piece of equipment due to age, wear, deterioration, and obsolescence. Depreciation can result from: . Physical deterioration occurring from wear and tear of the machine . Economic decline or obsolescence occurring over the passage of time In the appraisal of depreciation, some factors are explicit while other factors have to be estimated. Generally, the asset costs are known which include: âĒ Initial cost: The amount needed to acquire the equipment âĒ Useful life: The number of years it is expected to be of utility value âĒ Salvage value: The expected amount the asset will be sold at the end of its useful life

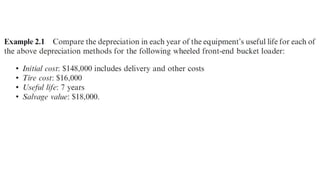

- 26. Among many depreciation methods, the straight-line method, double-declining balance method, and sum-of-yearsâ-digits method are the most commonly used in the construction equipment industry

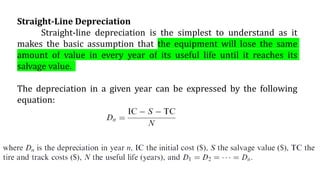

- 27. Straight-Line Depreciation Straight-line depreciation is the simplest to understand as it makes the basic assumption that the equipment will lose the same amount of value in every year of its useful life until it reaches its salvage value. The depreciation in a given year can be expressed by the following equation:

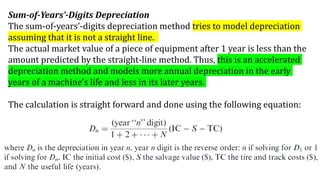

- 28. Sum-of-Yearsâ-Digits Depreciation The sum-of-yearsâ-digits depreciation method tries to model depreciation assuming that it is not a straight line. The actual market value of a piece of equipment after 1 year is less than the amount predicted by the straight-line method. Thus, this is an accelerated depreciation method and models more annual depreciation in the early years of a machineâs life and less in its later years. The calculation is straight forward and done using the following equation:

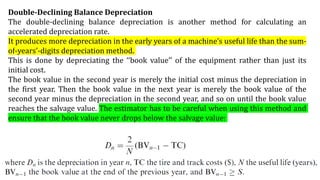

- 29. Double-Declining Balance Depreciation The double-declining balance depreciation is another method for calculating an accelerated depreciation rate. It produces more depreciation in the early years of a machineâs useful life than the sum- of-yearsâ-digits depreciation method. This is done by depreciating the ââbook valueââ of the equipment rather than just its initial cost. The book value in the second year is merely the initial cost minus the depreciation in the first year. Then the book value in the next year is merely the book value of the second year minus the depreciation in the second year, and so on until the book value reaches the salvage value. The estimator has to be careful when using this method and ensure that the book value never drops below the salvage value: