Continuous Improvement Strategy

- 1. Business Excellence throughĪŁ Operational Excellence.ĪŁ a Continuous Improvement Strategy Craig Marton

- 2. food for thought ..ĪŁ the systems that deliver value to our customers are perfectly designed to achieve the results we get. - Unknown (but someone pretty bright)

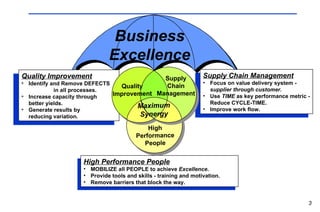

- 3. Quality Improvement Identify and Remove DEFECTS in all processes. Increase capacity through better yields. Generate results by reducing variation. High Performance People MOBILIZE all PEOPLE to achieve Excellence . Provide tools and skills - training and motivation. Remove barriers that block the way. Supply Chain Management Focus on value delivery system - supplier through customer. Use TIME as key performance metric - Reduce CYCLE-TIME. Improve work flow. High Performance People Quality Improvement Business Excellence Supply Chain Management Maximum Synergy

- 4. CUSTOMER First ..... the EXTERNAL Dimension Constancy of Purpose .....the LEADERSHIP Dimension Everyone Involved .....the PEOPLE Dimension Decisions Based on Facts .....the KNOWLEDGE Dimension Process Focused .....the SYSTEMS Dimension Continuous Improvement .....the LEARNING Dimension Values of a High Performance Organization...

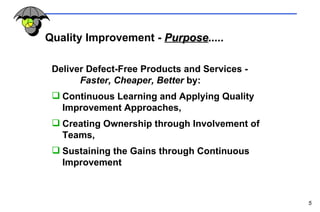

- 5. Quality Improvement - Purpose ..... Deliver Defect-Free Products and Services - Faster, Cheaper, Better by: Continuous Learning and Applying Quality Improvement Approaches, Creating Ownership through Involvement of Teams, Sustaining the Gains through Continuous Improvement

- 6. THE GOALS OF QUALITY IMPROVEMENT: Improved Customer Satisfaction Defect Reduction Yield Improvement Higher Operating Income Improved, Predictable Capability Quality Improvement Goals Are Directly and Quantifiably Linked to those of the Business. Constant Process Measurement Defeat the Competition Gain Market share Stay in Business

- 7. A SUMMARY OF THE IMPROVEMENT METHOD Phase 4: Sustain Phase 3: Transform Phase 2: Evaluate Phase 1: Gather o Project Definition o Establish Process Capability o Map the Process o Verification of Measurement Systems o Project Review (Phase 1) o Study Response Variables o Evaluate Input Variables o Short List of Input Variables o Project Review (Phase 2) o Determine Critical Inputs o Define Mathematical Model o Short List of Critical Input Variables o Project Review (Phase 4) o Optimize Critical Inputs o Monitor Output / Control Inputs o Sustain the Gain / Update Quality System Final Report & Evaluation Celebration plus... Project Application plus... Project Application plus... Project Application plus... Project Application

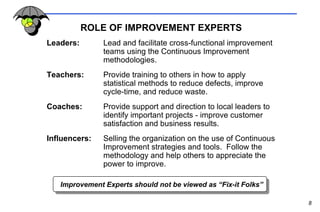

- 8. ROLE OF IMPROVEMENT EXPERTS Leaders: Lead and facilitate cross-functional improvement teams using the Continuous Improvement methodologies. Teachers: Provide training to others in how to apply statistical methods to reduce defects, improve cycle-time, and reduce waste. Coaches: Provide support and direction to local leaders to identify important projects - improve customer satisfaction and business results. Influencers: Selling the organization on the use of Continuous Improvement strategies and tools. Follow the methodology and help others to appreciate the power to improve. Improvement Experts should not be viewed as Ī░Fix-it FolksĪ▒

- 9. Process Owners Must Own the Processes GATHER EVALUATE TRANSFORM SUSTAIN IMPROVEMENT EXPERTS PROCESS OWNERS INVOLVEMENT TIME

- 10. According to CSC Index, 73% of all change efforts FAIL. Successful Change Requires: Technical Solutions + Buy-In By Key Stakeholders = Effective Change Results Business Excellence is a journey of change..... Having Good Technical Solutions is the EASY part. Good, Buy-In Strategy is KEY.

- 11. Some Precepts for Developing a Good Buy-In Strategy..... Have well grounded, widely understood Vision and Strategies. What gets measured, gets done; what gets rewarded, stays done. High levels of trust and commitment must be achieved through involvement. Roles and accountabilities must be clarified throughout the change process - don't just expect people to know what to do. Listen carefully to key stakeholders, and satisfy their needs. Over-communication is impossible. Never underestimate individual resistance to change. Systems are getting what they were designed to get. Only management can change the systems.

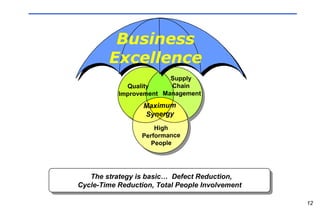

- 12. The strategy is basicĪŁ Defect Reduction, Cycle-Time Reduction, Total People Involvement Quality Improvement High Performance People Supply Chain Management Maximum Synergy Business Excellence

- 13. Operating Results Opportunity Analysis and Prioritization Resource Availability Improvement Process Skill Assessment Resource Prioritization Safety, Quality, Throughput and Cost Data

- 14. Operating Results Gather Data Evaluate Data Prioritize Opportunities Improve Process Sustain Improvements Continuous Improvement