Cooling system

- 1. TRACTOR COOLING SYSTEM BY,

- 2. Defination :- The system which control engine temperature is known as cooling system. :-Fuel is burnt inside cylinder of I.C.engine to produce power. :- The temperature produced on power stroke of an engine can be as high as 1600 dc and this is greater than melting point of engine part. :- Therefore to cool engine, cooling system is introduced.

- 3. .To maintain optimum temperature of engine for efficient operation. . To maintain lubricant property of oil inside the engine cylinder for normal function. .To protect engine component from high temp.

- 4. Bad effect of high temperature of engine:- • cylinder and piston may expand to such a extent that the piston would seize in cylinder and stop the engine. • lubricating quality of the oil inside of the cylinder would be distroyed due to high temperature and their may not be sucking of air in the cylinder. • preignition of fuel mixture would take place and would cause engine knocking as well as loss of power.

- 6. Air cooled engines are those engine in which heat is conducted from the working components of the engine to the atmosphere directly.

- 7. Principle of air cooling system:- 1)Cylinder of an air cooled engine has fins to increase the area of contact of air for speedy cooling. 2) The fins metallic ridges which are form during casting of cylinder and cylinder head.

- 9. AdvAntAges of Air cooling system -It is more simple in design & construction. Water jacket, radiator, thermostat, water pump, hose pipe, etc. are not needed. -It is more compact -It is comparatively lighter in weight disAdvAntAges -There is uneven cooling of engine parts -Engine temperature is generally high during working period.

- 10. -Engines using water is cooling medium is called water cooled engine. -The liquid is circulate round the cylinder to absorb heat form cylinder walls. -In general water is used as cooling liquid.

- 11. 1. open jAcket or hopper method:- • In this method hopper or jacket containing water which is surround the engine cylinder. • As the engine is continuously operate water start boiling replace the cold water. • Drain plug is provided in this method for removing the water.

- 12. 2. Thermosiphon meThod:- • In this method radiator, water jacket, temperature gauge hose connection. • The water which is surround the cylinder is lighter due its hotness. • And then that hot water goes to radiator and cold water goes back to the engine cylinder block.

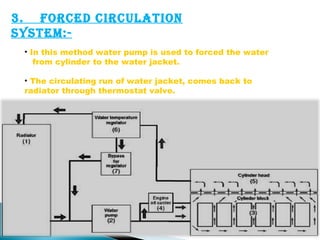

- 13. 3. Forced circulaTion sysTem:- • In this method water pump is used to forced the water from cylinder to the water jacket. • The circulating run of water jacket, comes back to radiator through thermostat valve.

- 14. componenT oF waTer cooling sysTem

- 15. waTer pump • It is centrifugal type pump casing an impeller mounted on the shaft. •Water pump is mounted at the front end of the cylinder block.

- 16. radiaTor It is a device used for cooling the circulating water in engine.

- 17. Fan :- Fan is used to provide strong draft of air through radiator to improve engine cooling

- 18. Water jacket •Water jacket are cored around the engine cylinder So that water can be circulate freely around the cylinder •

- 19. thermostate valve • it is control valve used in the cooling system to control the flow of water when activated by temperature signal.

- 20. Radiator cap N Hose pipe Fan belt

- 21. cooling system troubles •Due to poor cooling system following problems 1)Overheating 2)Slow warm up of engine •Accumalation of rust and scale in the radiator • •Defective hose pipe •Defective thermostat •Defective water pump • Loose fan belt

- 22. care and maintenance -Fresh water should be filled in radiator. -Checking of hose pipe. -Checking of tension of fan belt. -Very hot engines should never be filled with cold water.

- 23. TTHHAANNKK you