Corrcon

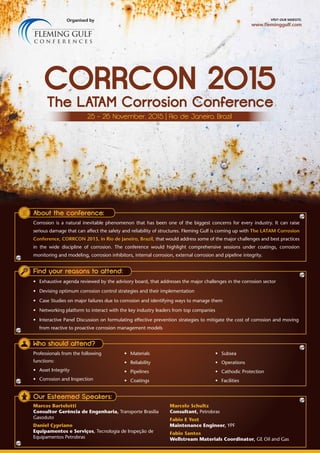

- 1. Our Esteemed Speakers: Marcos Bartelotti Consultor Gerência de Engenharia, Transporte Brasilia Gasoduto Daniel Cypriano Equipamentos e Serviços, Tecnologia de Inspeção de Equipamentos Petrobras Marcelo Schultz Consultant, Petrobras Fabio E Yost Maintenance Engineer, YPF Fabio Santos Wellstream Materials Coordinator, GE Oil and Gas Professionals from the following functions: • Asset Integrity • Corrosion and Inspection • Materials • Reliability • Pipelines • Coatings • Subsea • Operations • Cathodic Protection • Facilities Corrosion is a natural inevitable phenomenon that has been one of the biggest concerns for every industry. It can raise serious damage that can affect the safety and reliability of structures. Fleming Gulf is coming up with The LATAM Corrosion Conference, CORRCON 2015, in Rio de Janeiro, Brazil, that would address some of the major challenges and best practices in the wide discipline of corrosion. The conference would highlight comprehensive sessions under coatings, corrosion monitoring and modeling, corrosion inhibitors, internal corrosion, external corrosion and pipeline integrity. • Exhaustive agenda reviewed by the advisory board, that addresses the major challenges in the corrosion sector • Devising optimum corrosion control strategies and their implementation • Case Studies on major failures due to corrosion and identifying ways to manage them • Networking platform to interact with the key industry leaders from top companies • Interactive Panel Discussion on formulating effective prevention strategies to mitigate the cost of corrosion and moving from reactive to proactive corrosion management models About the conference: Find your reasons to attend: Who should attend? CORRCON 2015 The LATAM Corrosion Conference 25 - 26 November, 2015 | Rio de Janeiro, Brazil visit our website: www.fleminggulf.com Organised by

- 2. 25th November 2015 7:30 Registration and Coffee 8:20 Welcome by Fleming Gulf 8:25 Opening remarks from the Chair Corrosion - Monitoring, Modeling and Control 9:00 Corrosion control of reinforced concrete structures in marine environment • Causes of corrosion in reinforced concrete structures • Different types of corrosion: Crevice, Pitting • Understanding the corrosion mechanism of reinforced steel • Using cathodic protection to control corrosion 9:30 Latest on-line and real time technology for corrosion monitoring • Advancements in corrosion monitoring technology • Investigation of information on corrosion and pitting • Key benefits of the technology 10:00 Monitoring and control strategies for corrosion under insulation (CUI) • Risk based inspection (RBI) Technique for monitoring CUI • Prevention and mitigation of CUI- current methods used • Design considerations for preventing CUI • Monitoring techniques for CUI- Linear Polarization Resistance, Electrochemical Impedance Spectroscopy, Electrochemical Noise, Zero Resistance Ammetry 10:30 Modeling and projection of the corrosion rates of stainless steel in marine environments • Corrosion rate calculation • Discussing the material selection model • Comparing the experimental and theoretical corrosion rates 11:00 Networking Break and Refreshment Corrosion Inhibitors 12:00 Corrosion Inhibitors for Flow Induced Localized Corrosion (FILC) • Study of the initiation of the Flow Induced Localized Corrosion • How corrosion inhibitors mitigate corrosion caused by flowing media? • Understanding the mechanism of drag reducing properties of corrosion inhibitors • How the inhibitors prevent the initiation of FILC? • Mitigating flow induced localized corrosion by corrosion inhibitors • Relevance of drag reduction effect by corrosion inhibitors • Case studies of FILC inhibition in CO2 and H2S Systems • Understanding the mechanism of drag reduction effect 12:30 Corrosion in above the gas storage tanks and its mitigation through Volatile Corrosion Inhibitors (VCI) • Introduction to volatile corrosion inhibitors • Evaluating the effectiveness of VCIs • VCI application on above ground storage tanks in conjunction with cathodic protection 13:00 Eco-friendly corrosion inhibitors for metals and alloys • Case studies of application of Eco-friendly corrosion inhibitors and their performance • Estimating the toxicity of corrosion inhibitors and their impact over environment • Using natural products and synthetic compounds as corrosion inhibitors 13:30 Lunch Break Internal Corrosion 15:00 Best practices to monitor, analyze and mitigate internal corrosion in wells and pipeline systems • Common factors of internal corrosion and their effects: H2S, CO2, water stagnation, bacteria • Pitting corrosion and its mechanism • Best practices for mitigation of internal corrosion in the design phase and operational phase • Corrosion mitigation techniques like Pigging, Batch/ Continuous Corrosion Inhibition, Biocides • Identifying the best ways to monitor, analyze and mitigate internal corrosion • Monitoring techniques for early detection of internal corrosion • Case studies on mitigation of internal corrosion • Integrity management of internal corrosion 15:30 Internal corrosion in slurry pipeline carrying iron- ore and phosphate • Internal abrasion problems in the slurry pipeline • Electrochemical techniques used for determining corrosion of slurry pipelines • Corrosion control methods to be adopted • Corrosion inhibition in slurry pipelines 16:00 Panel Discussion: Formulating effective prevention strategies to mitigate the cost of corrosion in long run • Impact of corrosion and the damage caused to different industries • Discussing the successful real time examples of effective strategies incorporated that helped in cost reduction • Defining optimum corrosion management practices 17:00 Closing remarks from the Chairman 17:10 Networking Reception Speakers and delegates are cordially invited to Networking Cocktail Reception End of Conference Day One Day 1 Booking Line: tel: + 91 20 6607 0064, fax: + 91 20 6607 0061 email: ruchi.nema@fleminggulf.com, www.fleminggulf.com

- 3. 26th November 2015 8:00 Registration and Coffee 8:50 Opening Remarks from the Chairman Coatings 9:00 Corrosion control of FPSOs by using coating in conjunction with cathodic protection systems • Opting a suitable coating system • Corrosion prevention for FPSO Tanks and Top side equipments • Adopting a well defined inspection program for achieving performance • Application of Galvanic anodes or impressed current type cathodic protection 9:30 Health and Safety Issues in Coating Application and Removal • Brief synopsis about health and safety issues in the coatings industry • Common safety measures • Respiratory Hazards and understanding Respiratory Protection Standards • Fundamentals of environmental protection standards • Protection from exposure during paint removal operations 10:00 Dealing with Cathodic Disbondment • Determining the factors that affect the Cathodic Disbondment • Analysis of Cathodic Disbondment Testing • Overview of Cathodic Disbondement Resistance Mechanisms 10:30 Leak detection systems for underground pipelines and storage tanks • Detection of breakdowns due to internal and external coating failures • Tank Leak Detection: Secondary containment with interstitial monitoring, Automatic Tank Gauging Systems, Vapor Monitoring, Statistical Inventory Reconciliation • Leak Detection System for underground pipelines 11:00 Coffee Break and Networking External Corrosion 11:30 Analysis, monitoring and mitigation of stray current corrosion • Causes of stray current corrosion from DC transit systems • Effects of rail and utility-pipe corrosion caused by stray currents • Corrosion rates of different metals affected by stray current corrosion • Measures to be taken to control stray current • Different techniques to avoid stray corrosion 12:00 Atmospheric Corrosion of carbon steel in different environmental conditions • Mechanism of atmospheric corrosion on carbon steel • Determining the corrosion rates of carbon steel in different environments • Factors and variables in atmospheric corrosion 12:30 The effects of Microbial Influenced Corrosion (MIC) on engineering metals • Understanding the mechanism of Microbial Corrosion in aqueous environment • Study of adhesion of microbes to the metal surface • Types of bacteria responsible for corrosion • Electrochemical techniques for the inspection of of bacterial corrosion 13:00 Lunch Break Pipeline Integrity 14:30 Performing Close Interval Potential Survey (CIPS) and Direct Current Voltage Gradient (DCVG) for enhancing pipeline integrity • Brief overview of CIPS and DCVG techniques • Advantages and Disadvantages of performing CIPS and DCVG together • Calculating the %IR for combined CIPS and DCVG • Case Study of using Combined CIPS and DCVG 15:00 Maintaining the integrity of Flexible Pipes • Causes of damage and failure of Flexible Pipes • Understanding the structural layers of the Flexible Pipes • Flexible pipes integrity management strategies • Latest Inspection and Monitoring techniques used • How to deal with the corrosion of the tensile and pressure armors of Flexible Pipe? 15:30 Subsea Corrosion Management and Inspection • Managing the integrity of offshore assets • Challenges in inspecting pipelines and their repair • Discussing the latest corrosion monitoring techniques • Material selection for subsea assets 16:00 Panel Discussion: Creating a proactive corrosion strategy for avoiding failures • Moving from reactive to proactive model for avoiding failures • Latest advancements in the corrosion monitoring, inspection, modeling and control • Examples of some disasters and lessons learned 17:00 Closing remarks from the Chairman 17:15 Close of the conference and Farewell Networking Coffee I would like to thank everyone who has helped with the research and organization of this event, specially the Advisory Council and Speakers for their support and commitment. Ruchi Nema | Conference Producer ruchi.nema@fleminggulf.com Day 2 Booking Line: tel: + 91 20 6607 0064, fax: + 91 20 6607 0061 email: ruchi.nema@fleminggulf.com, www.fleminggulf.com