Cp114451

- 1. DEPARTMENT OF MECHANICAL ENGINEERING ACADEMIC YEAR:2018-19(EVEN) Subject Code ME8493 L P T C Subject Title THERMAL ENGINEERING-I 3 0 0 3 Year / Dept / Sem II / Mechanical Engineering /IV Regulation Year 2017 Faculty Name / Desg / Mr.K.MUTHU/ Assistant Professor / Mechanical Engineering Course Prerequisite To integrate the concepts, laws and methodologies from the first course in thermodynamics into analysis of cyclic processes Course Objectives (CO) CO 1: To integrate the concepts, laws and methodologies from the first course in thermodynamics into analysis of cyclic processes. CO 2: To apply the thermodynamic concepts into various thermal application like IC engines, Steam. CO 3: To study and performance about Turbines, Compressors and Refrigeration and Air conditioning systems Expected Course Outcome (ECO) Upon the completion of this course the students will be able to CO1:Apply thermodynamic concepts to different air standard cycles and solve problems. CO2: Solve problems in single stage and multistage air compressors CO3: Explain the functioning and features of IC engines, components and auxiliaries. CO4:Calculate performance parameters of IC Engines. CO5:Explain the flow in Gas turbines and solve problems. Programme Educational Objective (PEO) PEO1: The Graduates of Mechanical Engineering would develop continual receptiveness for scientific and engineering knowledge by self-learning and face the arriving challenges in their field. PEO2: The Graduates of Mechanical Engineering would have been trained with a range of knowledge to analytically integrate the fundamentals and new concepts from engineering practices to create optimized solutions/products for the real life issues. PEO3:The Graduates of Mechanical Engineering would excel in communication, vocabulary with interpersonal skills as professional engineers. SRI VIDYA COLLEGE OF ENGINEERING & TECHNOLOGY COURSE PLAN Doc.Ref:SVME02 Revision: Date:

- 2. Mapping of CO & PO(Specify the PO’s) - (Fill the col.s with the legend given below) PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 CO1 3 2 1 - - - 1 1 - - 1 2 CO2 1 3 3 2 1 - - - - 1 - 1 CO3 1 2 3 1 2 - - 1 2 1 1 1 CO4 1 1 2 1 - - 1 - 1 2 - - CO5 2 1 1 2 1 1 1 1 1 - - - Bridging the Curriculum Gap (Additional Topics beyond syllabus / Seminars / Assignments) BCG1:Engineering applications of thermal engineering. BCG2:Working principles of I.C Engines. BCG3:Basic concepts of Air compressor, turbines, R&AC Related Website URLs W1: http://www.aerostudents.com/files/aerodynamicsC/basicConcepts.pdf W2: http://www.nptel.iitm.ac.in/syllabus/112103021/ (i.c.engines) W3: http://www.potto.org/gasDynamics/node165.php(nozzles & turbines) W4: http://en.wikipedia.org/wiki/air conditioning (R& AC) Related Video Course Materials (min. 4 no.s) V1: http://www.youtube.com/watch?v=CWy1277574E(gas power cycles) V2: http://www.youtube.com/watch?v=CWy127trek(ic engines) V3: https://www.youtube.com/watch?v=cq6N657GFJ (Compressors) Text books T1:.Rajput. R. K., “Thermal Engineering” S.Chand Publishers, 2000 T2: Kothandaraman.C.P.,Domkundwar. S,Domkundwar. A.V., “A course in thermal Engineering", Fifth Edition, ”DhanpatRai& sons , 2002 Reference Books R1:Sarkar, B.K,”Thermal Engineering” Tata McGraw-Hill Publishers, 2007 R2:Arora.C.P, ”Refrigeration and Air Conditioning ,” Tata McGraw-Hill Publishers 1994 R3:Ganesan V..” Internal Combustion Engines” , Third Edition, Tata Mcgraw- Hill 2007 R4: Rudramoorthy, R, “Thermal Engineering “,Tata McGraw-Hill, New Delhi,2003 R5: Ramalingam. K.K., "Thermal Engineering", SCITECH Publications (India) Pvt. Ltd., 2009. Prepared by Approved by Signature Name Mr. K.MUTHU Mr. P. SURESH KUMAR Designation Assistant Professor / Mechanical HOD (Mechanical)

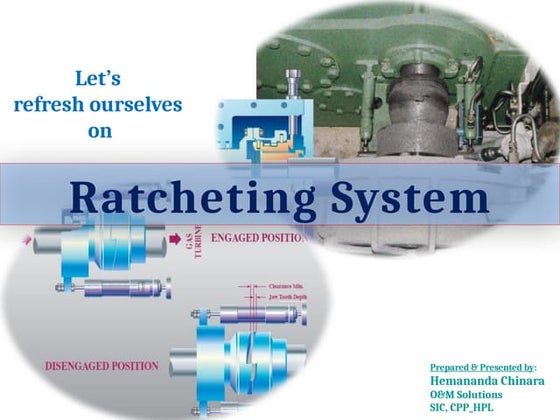

- 3. ME8493 THERMAL ENGINEERING-I OBJECTIVES:  To integrate the concepts, laws and methodologies from the first course in thermodynamics into analysis of cyclic processes.  To apply the thermodynamic concepts into various thermal application like IC engines, Steam.  Turbines, Compressors and Refrigeration and Air conditioning systems (Use of standard refrigerant property data book, Steam Tables, Mollier diagram and Psychrometric chart permitted) UNIT I GAS AND STEAM POWER CYCLES 9 Air Standard Cycles – Otto, Diesel, Dual, Brayton – Cycle Analysis, Performance and Comparison– Rankine, reheat and regenerative cycle. UNIT II RECIPROCATING AIR COMPRESSOR 9 Classification and comparison, working principle, work of compression – with and without clearance, Volumetric efficiency, Isothermal efficiency and Isentropic efficiency. Multistage air compressor with Intercooling. Working principle and comparison of Rotary compressors with reciprocating air compressors. UNIT III INTERNAL COMBUSTION ENGINES AND COMBUSTION 9 IC engine – Classification, working, components and their functions. Ideal and actual : Valve and port timing diagrams, p-v diagrams- two stroke & four stroke, and SI & CI engines – comparison. Geometric, operating, and performance comparison of SI and CI engines. Desirable properties and qualities of fuels. Air-fuel ratio calculation – lean and rich mixtures. Combustion in SI & CI Engines – Knocking – phenomena and control. UNIT IV INTERNAL COMBUSTION ENGINE PERFORMANCE AND SYSTEMS 9 Performance parameters and calculations. Morse and Heat Balance tests. Multipoint Fuel Injection system and Common Rail Direct lnjection systems. Ignition systems – Magneto, Battery and Electronic. Lubrication and Cooling systems. Concepts of Supercharging and Turbocharging – Emission Norms. UNIT V GAS TURBINES 9 Gas turbine cycle analysis – open and closed cycle. Performance and its improvement – Regenerative, Intercooled, Reheated cycles and their combinations. Materials for Turbines. TOTAL:45PERIODS

- 4. OUTCOMES: Upon the completion of this course the students will be able to CO1 Apply thermodynamic concepts to different air standard cycles and solve problems. CO2 Solve problems in single stage and multistage air compressors CO3 Explain the functioning and features of IC engines, components and auxiliaries. CO4 Calculate performance parameters of IC Engines. CO5 Explain the flow in Gas turbines and solve problems. TEXT BOOKS: 1. Kothandaraman.C.P., Domkundwar. S,Domkundwar. A.V., “A course in thermal Engineering”, Fifth Edition, ”Dhanpat Rai & sons , 2016 2. Rajput. R. K., “Thermal Engineering” S.Chand Publishers, 2017 REFERENCES: 1. Arora.C.P, ”Refrigeration and Air Conditioning ,” Tata McGraw-Hill Publishers 2008 2. Ganesan V..” Internal Combustion Engines” , Third Edition, Tata Mcgraw-Hill 2012 3. Ramalingam. K.K., “Thermal Engineering”, SCITECH Publications (India) Pvt. Ltd., 2009. 4. Rudramoorthy, R, “Thermal Engineering “,Tata McGraw-Hill, New Delhi,2003 5. Sarkar, B.K,”Thermal Engineering” Tata McGraw-Hill Publishers, 2007

- 5. SRI VIDYA COLLEGE OF ENGINEERING & TECHNOLOGY COURSE PLAN Doc.Ref:SVME02 Revision: Date: S.No Topic Name Book Page no Mode of delivery No of hrs Cumulative hrs Unit I – Gas and Steam Power Cycles 1 Basics of thermodynamics T2 1-33 BB 1 1 2 Introduction, Air standard cycles – Otto cycle – Air standard efficiency, mean effective pressure, Characteristics & applications T2 538-544 BB 2 3 3 Diesel cycle – Air standard efficiency, mean effective pressure, Characteristics & applications T2 551-552 BB 2 5 4 Dual cycle – Air standard efficiency, mean effective pressure, Characteristics & applications T2 556-564 BB 2 7 5 Brayton cycle – Air standard efficiency, Characteristics & applications T2 567-568 BB 1 8 6 Rankine cycle T2 545-551 BB 2 10 7 Reheat cycle T2 553-556 BB 1 11 8 Regenerative cycle T2 558-563 BB 1 12 Unit II – Reciprocating Air Compressor 9 Classification and comparison, working principle, T2 676-678 BB &PPT 2 14 10 work of compression –with and without clearance, T2 678-680 BB& OHP 3 17 11 Volumetric efficiency, Isothermal efficiency and Isentropic efficiency. T2 682-685 OHP 2 19 12 Multistage air compressor with Inter-cooling. T2 690-699 OHP 2 21 13 Working principle and comparison of Rotary compressors with reciprocating air compressors T2 717-725 BB &OHP 3 24 Unit III – Internal Combustion Engines and Combustion 15 IC engine – Classification, working, components and their functions. T2 588-589 BB 2 26 16 Ideal and actual : Valve and port timing diagrams, T2 602-603 BB 1 27 17 p-v diagrams- two stroke & four stroke T2 603-606 BB 2 29 18 SI & CI engines – comparison. Geometric, operating, and performance comparison of SI and CI engines. T2 608-625 BB 2 32

- 6. 19 Desirable properties and qualities of fuels. Air-fuel ratio calculation – lean and rich mixtures. T2 632-640 BB 2 34 20 Combustion in SI & CI Engines – Knocking – phenomena and control. T2 623-627 BB 2 36 Unit IV – Internal Combustion Engines Performance and Systems 22 Performance parameters and calculations. Morse and Heat Balance tests. T2 632-634 BB 3 39 23 Multipoint Fuel Injection system and Common Rail Direct injections systems. T2 612-614 BB 2 41 24 Ignition systems – Magneto, Battery and Electronic. T2 615-618 BB 2 43 25 Lubrication and Cooling systems. T2 623-626 BB 2 45 26 Concepts of Supercharging and Turbo charging – Emission Norms. T2 630-632 BB 3 48 Unit V – Gas Turbines 28 Gas turbine cycle analysis T2 754-758 PPT 2 50 29 Open and closed cycle. T2 760-763 BB 2 52 30 Performance and its improvement – Regenerative, Intercooled, T2 768-771 BB 3 55 31 Reheated cycles and their combinations. T2 778-781 BB 3 58 32 Materials for Turbines. T2 762-765 PPT 2 60 Prepared by Approved by Signature Name Mr. K.MUTHU Mr.P.SURESH KUMAR Designation Assistant Professor / Mechanical HOD (Mechanical)

![[IJET-V1I6P8] Authors: Priyanka Bonde ,R.R.Borase,J.G.Patil](https://cdn.slidesharecdn.com/ss_thumbnails/ijet-v1i6p8-151213093225-thumbnail.jpg?width=560&fit=bounds)