Custom roll forming machine

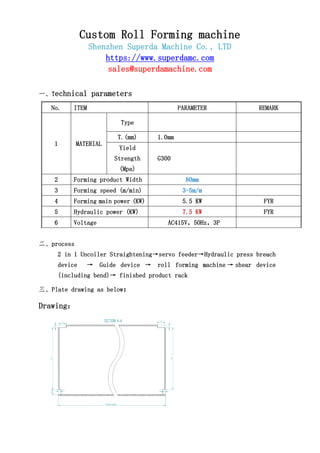

- 1. Custom Roll Forming machine Shenzhen Superda Machine Co., LTD https://www.superdamc.com sales@superdamachine.com õĖĆŃĆüTechnical parameters No. ITEM PARAMETER REMARK 1 MATERIAL Type T.(mm) 1.0mm Yield Strength (Mpa) G300 2 Forming product Width 80mm 3 Forming speed (m/min) 3-5m/m 4 Forming main power (KW) 5.5 KW FYR 5 Hydraulic power (KW) 7.5 KW FYR 6 Voltage AC415V’╝ī50Hz’╝ī3P õ║īŃĆüprocess 2 in 1 Uncoiler StraighteningŌåÆservo feederŌåÆHydraulic press breach device ŌåÆ Guide device ŌåÆ roll forming machine ŌåÆ shear device (including bend)ŌåÆ finished product rack õĖēŃĆüPlate drawing as below’╝Ü Drawing’╝Ü

- 2. Õøø’╝īMachines List Photo just for reference õ║ī’╝ē’╝ī Servo Feeder 3.1 Max. feeding width:200mm 3.2 Feeding thickess: 0.4-1.6mm 3. 3 Motor , 0.85’╝½’╝Ę(Yaskawa) Photo just for reference õĖĆ’╝ē2 in 1 Uncoiler straightener 1ŃĆü Type’╝ÜManual Expansion 2ŃĆüParameter 1’╝ēPassive discharge 2’╝ē Coil weight’╝Ü< 2T 3’╝ēCoil inner D.’╝ÜŽå450mm-Žå530mm 4’╝ēMax. Width.200mm 5) Thickness .0.4-1.6mm 6) Straightener roller :7 pcs 8) Power.1.5kw

- 3. õĖē’╝ē’╝ī Hydraulic hole punching system 3.1 Function’╝ÜHydraulic punch breach (Mould 1 set) 3.2 Structure: set the length, automatic length measurement, automatic positioning reaches the set distance stop action , hydraulic cylinder driven punching die, stamping automatic shutdown. 3.3 Hydraulic system working pressure’╝Ü16MPa 3.4 Hydraulic station’╝Ü7.5KW’╝ł Hydraulic punch hole/shear use same station’╝ē Õøø’╝ē Guide device õ║ö’╝ēMain Forming machines 6.1 Forming Roller’╝Ü10 stations’╝īand add Rub-roll, To make sure the surface profile no scratches. 6.2 Side Panel’╝ÜT.18mm ,A3 steel Heavy duty ŃĆé 6.3 Rolling speeding: 3-5 m/minŃĆé 6.4 Roller material’╝Ü#45’╝īoverall quenching, hardness HRC55-60 Ōäā. 6.5 Motor power’╝Ü5.5KWŃĆé 6.6 Main Roller ’╝Ü’┐Ā65mm’╝ī45 #ŃĆé 6.7 Equipment base: 400 H type using welded steel plate.

- 4. 6.8 Transmission: chain drive. 6.9 Security: across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operator safety. And other gear in the chain and the staff could easily lead to injury transmission section covered with protective cover, to ensure the safety of workers. Photo just for reference ÕģŁ’╝ēŃĆüHydraulic Follow shear Follow shear Knife material’╝ÜCr12’╝īquenching hardness of up to HRC56-58 degrees. Õģ½’╝ēŃĆüFlat collect rack

- 5. ÕŹü’╝ēŃĆüElectrical control system The entire line imported PLC control, LCD touch screen, man-machine interface. People interact with the PLC. Operator setting the program to run automatically (programmable control) and control process monitoring, production line operator control and modify the control parameters, and real-time monitoring the equipment status & parameters and fault indication. Workpiece length digital setting, adjustable length can be adjustable as well. Real-time monitoring of equipment operating status and fault indication. Operation manual / automatic two styles. With manual and automatic switching function: In the manual mode, can be stand-alone operation, easy maintenance; In automatic mode, carry out full production run, in order to start; across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operating personnel Safety. ** The main components of the brand: PLC control system: Delta Encoder: Omron Touch screen: Weinview Some components are Schneider brand devices.

- 6. Devices’╝Ü No. Machine name QTY REMARK 1 Uncoiler straightener 1 2 Servo Feeder 1 3 Hydraulic machine 1 With mould 4 Guide device 1 5 Forming machine 1 7 Follow Shear 1 Including knife 8 Collect rack 1 9 Control system 1 ’╝órand No. Name manufacturer 1 Motor & Reducer Domestic brands 2 The main key bearing Domestic brands 4 PLC Systems Delta 5 Low-voltage electrical Schneider 6 Encoder Omron 7 touch screen Veinview 8 Hydraulic system Domestic brands Custom roll forming machine blog