Cutting Machine of Garments Sector

Download as PPTX, PDF6 likes2,785 views

This document discusses various methods of cutting fabric for garment production. It describes fully manual cutting using scissors, manually operated power knives like straight knives and band knives, and computerized cutting methods. Specific cutting tools are explained, including their features, working principles, advantages and disadvantages. Key cutting methods covered are straight knives, band knives, round knives, die cutting, notchers, and drill cutting machines. The goal of the document is to provide an overview of fabric cutting techniques used in the garments industry.

1 of 20

Downloaded 103 times

Recommended

fabric spreading

fabric spreading Farhan ullah baig

╠²

The document discusses various aspects of fabric spreading including types of spreads, spreading methods, quality considerations, and equipment used. It describes manual spreading using two people versus semi-automatic spreading carriages. Automatic spreaders can load fabric rolls, control tension, and cut fabric ends automatically. Quality depends on defects, tension, flatness, ply alignment, and static electricity. Setup involves preparing orders, tables, and machines. Spreading surfaces include pin tables, vacuum tables, and air flotation tables. Control devices manage tension while positioning devices monitor alignment. End treatment devices catch or cut fabric at the ends.Stitches and seam analysis of a polo t shirt

Stitches and seam analysis of a polo t shirtUniversity of Southern California

╠²

This document analyzes the stitches and seams used in a men's t-shirt. It identifies the garment parts and provides details on the brand, size, fabric, and needle used. For each garment part, including the collar, placket, label, sleeves, hem, and side seams, it lists the stitch type and sewing machine used, as well as an alternative option. In total, it examines the construction of the t-shirt and the specific stitches for attaching each component.Fusing machinery and equipments

Fusing machinery and equipmentsAstha Vishwakarma

╠²

This document provides an overview of fusible interlinings, including the base materials, resins, coating methods, fusing methods, requirements, advantages, machinery, quality control, brands, and problems. It discusses the key components of fusible interlinings - the base material (woven, knitted, or non-woven), thermoplastic resin, and coating. It also describes different types of resins, methods of applying the resin coating, and means of fusing using presses. Quality control and selecting the appropriate fusible interlining for the application is also covered at a high level.U 4 cutting technology

U 4 cutting technology kibrom G

╠²

The document provides information about the cutting department processes at Aksum University's Textile Engineering department. It describes the standard operating procedures, including:

1) Receiving markers from the pattern department and cutting ratios from management.

2) Receiving fabric from the store and spreading it on cutting tables.

3) Placing markers on the fabric lay and cutting panels according to the marker. Numbering, bundling, inspecting, and replacing defective parts before sending cut panels to sewing.

It then discusses factors that influence marker efficiency such as fabric characteristics, pattern piece shapes, and grain line orientation. Different marker planning and fabric spreading methods - manual, semi-automatic, and fully automated - are alsoCUTTING DEPARTMENT OF APPAREL INDUSTRY.

CUTTING DEPARTMENT OF APPAREL INDUSTRY.DKHUSHI

╠²

cutting department of apparel industry.

types of cutting machineries. methods of cutting , spreading types of spreading, methods of spreading, marker production types of markers, marker making, bundling, fusing department, machines used for fusing, types of fusing materials, #apparel industry #cuttingdepartment Fabric spreading

Fabric spreadingMohaiminul Islam Nishad

╠²

This presentation was made to have an elaborate sense of fabric spreading. Different types of fabric spreading and the pros and cons of different fabric spreading is illustrated into the presentation.Cutting department

Cutting departmentManuja Madhushan

╠²

The document discusses the cutting department process in the apparel industry. It involves cutting pattern pieces from fabrics according to a marker and issue plan. Cutting is the decisive first stage that must be done accurately as mistakes are difficult to rectify. Processes include marker making, fabric spreading, cutting, numbering, checking, sorting, and bundling. Inspections ensure proper marker placement, shading, table marks, and tension. Factors like fabric type and thickness, design, and tools used affect the cutting method which can be manual, powered knife, or computerized.Fabric Spreading and Cutting Machines

Fabric Spreading and Cutting MachinesAsif Ahmed TONMOY

╠²

This document discusses fabric spreading and cutting machines used in the garment manufacturing process. It describes the marker and marker planning process used to optimize fabric utilization. It then explains different types of fabric spreading including manual, semi-automatic, and fully automatic methods. Key equipment for spreading such as tables, fabric loaders, and weights are identified. Finally, the document outlines various cutting machines from manual scissors to semi-automatic and fully-automatic computerized cutting machines. Precautions for each stage of spreading and cutting are also provided.Straight knife cutting machine

Straight knife cutting machineBangladesh University Of Business & Technology

╠²

The document discusses a straight knife cutting machine commonly used in garment factories in Bangladesh. It has a motorized blade that cuts fabric according to patterns. The main parts are the base plate, pressure foot, motor stand, sharp belt, pinion shaft, lever, and knife. It can cut a high depth of fabric in a single pass. Proper maintenance, including lubrication and inspection, is important to ensure the long and safe working of the machine. Potential issues include risks of damage from the high-speed blade and motor weight causing knife deflection.Spreading and cutting machines

Spreading and cutting machinesKundan Ganvir

╠²

Fabric Spreading and Cutting Machines. Manual fabric spreading, Semi-automatic fabric spreading, fully automatic spreading machines. What is cutting of fabric? Manual cutting machines, semi-automatic cutting machines, computerized cutting machinesPresentation on Textile Pressing

Presentation on Textile PressingAmanuzzaman Aman

╠²

This document discusses different types of pressing used in the garments industry. It begins by defining pressing as applying heat and pressure to remove creases from cloth or garments. There are five categories of pressing based on the garment type and material: no pressing, minimum pressing, under pressing, final pressing, and permanent pressing. The document then describes the objectives and types of different pressing equipment used, including irons, steam presses, steam air finishing machines, and steam tunnels.Interlining Procedure (Types & Methods)

Interlining Procedure (Types & Methods)ABU TALEB TARAQUE

╠²

This document discusses different types of interlinings used in garment construction and their application methods. There are two main types of interlinings - sewn and fusible. Fusible interlinings are attached using heat and pressure to fuse a resin coating. The document describes various fusible interlining materials and coating types, as well as advantages of fusible interlinings over sewn for mass production. Flat bed and continuous machines are introduced as methods to fuse interlinings, with different heating, pressure and speed controls for each. Quality control factors like temperature, pressure and bonding strength are also outlined.Band-knife

Band-knifeseuakash

╠²

Band knife cutting machines use an endless loop blade similar to a band saw to cut fabric and other materials. There are vertical and horizontal band knife machines depending on the material. Vertical machines use narrower blades for better accuracy while cutting foam. Horizontal machines have wider blades for materials like leather and foam. Band knife machines provide accurate cuts and can cut intricate patterns compared to other cutting machines. They require less minimum cutting allowance than die cutters and are faster and less labor intensive than other options.Fabric Cutting

Fabric CuttingSalim Azad

╠²

This document provides information about different cutting methods and knives used in fabric cutting. It introduces various fully manual and computerized cutting methods, including straight knives, round knives, band knives, die cutting, notchers, drills, laser cutting, water jet cutting, and plasma torch cutting. For each method, it describes the features, working principles, advantages, and disadvantages. The document is presented by a group of students and contains their names and student IDs.stitch classification

stitch classificationBGMEA University of Fashion & Technology (BUFT)

╠²

The document traces the history and development of the sewing machine from its earliest inventions in the late 18th century to modern computer-controlled machines. Key developments include the first patent for a sewing machine design by Thomas Saint in 1791; the lock stitch invention by Walter Hunt in 1833; Isaac Singer's invention of the rotary sewing machine in 1851, which combined elements of prior machines; and the introduction of the first electric sewing machines by Singer in 1889. The document provides details on various stitch types and their classifications, including lock stitch, chain stitch, and cover stitch. It discusses the applications and advantages of different stitch techniques.Fabric Spreading

Fabric SpreadingAshenafi Solomon

╠²

The document discusses different types of fabric packaging and spreading methods. It describes 5 types of piece goods packaging: 1) open face rolled, 2) tubular knitted fabric rolled, 3) folded fabric rolled, 4) folded fabrics, and 5) velvet-hanging. It also discusses various methods of fabric spreading including manual, semi-automatic, and fully automated spreading. Key aspects of spreading like fabric lays, splicing, and types of spreading tables including pin tables, air floatation tables, turntable tables, and vacuum tables are summarized. Quality requirements for defect-free spreading such as ply alignment, tension, and elimination of static electricity are also covered.Warp knitting

Warp knittingRasminThahaniZ

╠²

Warp knitting is a method of knitting where loops are formed vertically along the length of fabric from warp yarns. There are several types of warp knitting including tricot, raschel, and milanese knits. Tricot knits use compound needles and are used for fabrics like lingerie, loungewear, and uniforms. Raschel knits use latch needles and heavier yarns, producing more textured fabrics for applications like carpets, home textiles, and outerwear. Milanese knits form diagonal patterns and are often made from filament yarns into lightweight fabrics.Knitting technology

Knitting technologyAboni Knit Wear Ltd ( Babylon Group)

╠²

Dear Viewers ,

Good News to you.

Here I Attach a Assignment To you. Its helped to u make a Assignment in Knit Technology.

Tnx to all. Jacquad shedding

Jacquad sheddingNafiz Antu

╠²

This presentation summarizes the Jacquard shedding mechanism. It introduces the four presenters and provides background on the Jacquard loom, which can produce complex woven designs through individual control of warp threads. The presentation then covers the scope of Jacquard shedding, including its ability to control thousands of yarns and produce intricate designs. It also classifies different types of Jacquard looms based on their lifting capacity, design capacity, shed formation, and other features. Key aspects of the single lift Jacquard mechanism are explained. Advantages and disadvantages of the Jacquard loom conclude the presentation.Derivatives of Twill Weave

Derivatives of Twill Weave fahim zauwad

╠²

Twill weave is a kind of weave that repeat on three or more ends and picks and produces diagonal line on the face of fabric.

In a regular twill the diagonal line or twill line produces at 45 degree angle with the horizontal.

Concept:

The most characteristic of twill is that they have diagonal lines on the cloth.

Overlock Machines

Overlock Machinesnagarajbhat27

╠²

The document describes an overlock machine, which is a specialized sewing machine used to finish fabric edges and seams. It can produce stitches at speeds up to 5000 stitches per minute. The overlock machine makes stitches using 1-5 threads depending on the number of needles and loopers. Common stitch types include 3-thread, 4-thread, and 5-thread overlocks. Key features of the overlock machine include its differential feed system and ability to stretch stitching up to 300%. Problems with thread chains are addressed through the use of a backlatcher or chain cutting device.Knitting needles

Knitting needles Jijo Mathew

╠²

This document discusses three main types of knitting needles: bearded needles, latch needles, and compound needles. Bearded needles are the simplest and cheapest type, made from a single piece of metal with a fixed hook. Latch needles are more complex but self-acting, with a movable latch that opens and closes to form loops. Compound needles have a separate sliding element that works with an open hook to form loops without straining the yarn. The document provides details on the features, parts, advantages, and limitations of each needle type.Single needle lock stitch machine

Single needle lock stitch machineBangladesh University Of Business & Technology

╠²

This document provides an overview of single needle lock stitch sewing machines. It begins with a brief history of sewing machines and their development. It then discusses the specific type of single needle lock stitch machine, including its characteristics, features, parts, functions of parts, specifications of some models, maintenance, setting, replacement, and precautions. The key points covered are that a single needle lock stitch machine uses one needle to create a lock stitch, has various components like the needle, bobbin, feed dog, and requires proper maintenance, setting, and replacement of parts over time.Stitch and it's classification (part 1)

Stitch and it's classification (part 1)Md Shamsuzzaman Rasel

╠²

The topic stitch has been divided into 3 part. Here is the first part. Stay connected for the rest of the part. Basic informartion of knitting

Basic informartion of knittingAboni Knit Wear Ltd ( Babylon Group)

╠²

Here I write some important topics. It is very helpful to a Textile Student. I think If u Study it u will learn basic knowledge about knitting Technology.Fabric cutting

Fabric cuttingFarhan ullah baig

╠²

Cutting is the process of separating fabric into precise pattern pieces. Accurate cutting facilitates sewing while inaccurate cutting can cause fitting issues. Factors that influence cutting accuracy include marker lines, cutting technique, pitch, fabric movement, and equipment condition. Cutting is done using hand shears, portable straight/round knives, stationary band knives/dies, or automatic laser/waterjet systems. Proper cutting sets up quality sewing and assembly.Garment finishing

Garment finishingRajeev Sharan

╠²

The document discusses various garment finishing processes and equipment. It describes spotting processes that use hazardous chemicals and safer alternatives. It also covers folding, packing, hanging, pressing and finishing of different garments using specialized machines like shirt folders, steam irons, and finishers tailored for different garment types. Safety features of folding equipment like jam prevention systems are highlighted.fabric length,width & thickness_8.6.2020.pptx

fabric length,width & thickness_8.6.2020.pptxssuser94922c

╠²

Fabric dimensional properties include length, width, and thickness. Length is measured end to end along the selvedge using a table, scale, or trumeter machine. Width is measured perpendicular to the length between the selvedges, taking multiple measurements and calculating the mean. Thickness is measured using devices like the Reynolds tester that apply a known pressure between parallel plates and measure the distance between them. Proper sampling, conditioning, and multiple measurements are important to obtain accurate fabric dimensions. Fabric cutting Machine

Fabric cutting MachineMd. Mazadul Hasan Shishir

╠²

This document provides an overview of various fabric cutting methods used in the garment industry. It begins with an introduction to the purpose of fabric cutting and requirements for cutting. It then describes several cutting methods including manual (hand scissors, power knives), computerized (computer-controlled knife cutting, laser beam cutting, water jet cutting, plasma torch cutting), and their advantages and disadvantages. Popular garment cutting machine manufacturers are listed at the end.Fabric Cutting

Fabric CuttingSalim Azad

╠²

This document provides information about different cutting methods and knives used in fabric cutting. It introduces various fully manual and computerized cutting methods, including hand scissors, straight knives, band knives, round knives, die cutting, notcher cutting machines, drill cutting machines, and computer controlled knife cutting, laser beam cutting, water jet cutting, and plasma torch cutting. For each method, it describes the features, working principle, advantages, and disadvantages. It also lists the names and student IDs of the group members who prepared the presentation.More Related Content

What's hot (20)

Straight knife cutting machine

Straight knife cutting machineBangladesh University Of Business & Technology

╠²

The document discusses a straight knife cutting machine commonly used in garment factories in Bangladesh. It has a motorized blade that cuts fabric according to patterns. The main parts are the base plate, pressure foot, motor stand, sharp belt, pinion shaft, lever, and knife. It can cut a high depth of fabric in a single pass. Proper maintenance, including lubrication and inspection, is important to ensure the long and safe working of the machine. Potential issues include risks of damage from the high-speed blade and motor weight causing knife deflection.Spreading and cutting machines

Spreading and cutting machinesKundan Ganvir

╠²

Fabric Spreading and Cutting Machines. Manual fabric spreading, Semi-automatic fabric spreading, fully automatic spreading machines. What is cutting of fabric? Manual cutting machines, semi-automatic cutting machines, computerized cutting machinesPresentation on Textile Pressing

Presentation on Textile PressingAmanuzzaman Aman

╠²

This document discusses different types of pressing used in the garments industry. It begins by defining pressing as applying heat and pressure to remove creases from cloth or garments. There are five categories of pressing based on the garment type and material: no pressing, minimum pressing, under pressing, final pressing, and permanent pressing. The document then describes the objectives and types of different pressing equipment used, including irons, steam presses, steam air finishing machines, and steam tunnels.Interlining Procedure (Types & Methods)

Interlining Procedure (Types & Methods)ABU TALEB TARAQUE

╠²

This document discusses different types of interlinings used in garment construction and their application methods. There are two main types of interlinings - sewn and fusible. Fusible interlinings are attached using heat and pressure to fuse a resin coating. The document describes various fusible interlining materials and coating types, as well as advantages of fusible interlinings over sewn for mass production. Flat bed and continuous machines are introduced as methods to fuse interlinings, with different heating, pressure and speed controls for each. Quality control factors like temperature, pressure and bonding strength are also outlined.Band-knife

Band-knifeseuakash

╠²

Band knife cutting machines use an endless loop blade similar to a band saw to cut fabric and other materials. There are vertical and horizontal band knife machines depending on the material. Vertical machines use narrower blades for better accuracy while cutting foam. Horizontal machines have wider blades for materials like leather and foam. Band knife machines provide accurate cuts and can cut intricate patterns compared to other cutting machines. They require less minimum cutting allowance than die cutters and are faster and less labor intensive than other options.Fabric Cutting

Fabric CuttingSalim Azad

╠²

This document provides information about different cutting methods and knives used in fabric cutting. It introduces various fully manual and computerized cutting methods, including straight knives, round knives, band knives, die cutting, notchers, drills, laser cutting, water jet cutting, and plasma torch cutting. For each method, it describes the features, working principles, advantages, and disadvantages. The document is presented by a group of students and contains their names and student IDs.stitch classification

stitch classificationBGMEA University of Fashion & Technology (BUFT)

╠²

The document traces the history and development of the sewing machine from its earliest inventions in the late 18th century to modern computer-controlled machines. Key developments include the first patent for a sewing machine design by Thomas Saint in 1791; the lock stitch invention by Walter Hunt in 1833; Isaac Singer's invention of the rotary sewing machine in 1851, which combined elements of prior machines; and the introduction of the first electric sewing machines by Singer in 1889. The document provides details on various stitch types and their classifications, including lock stitch, chain stitch, and cover stitch. It discusses the applications and advantages of different stitch techniques.Fabric Spreading

Fabric SpreadingAshenafi Solomon

╠²

The document discusses different types of fabric packaging and spreading methods. It describes 5 types of piece goods packaging: 1) open face rolled, 2) tubular knitted fabric rolled, 3) folded fabric rolled, 4) folded fabrics, and 5) velvet-hanging. It also discusses various methods of fabric spreading including manual, semi-automatic, and fully automated spreading. Key aspects of spreading like fabric lays, splicing, and types of spreading tables including pin tables, air floatation tables, turntable tables, and vacuum tables are summarized. Quality requirements for defect-free spreading such as ply alignment, tension, and elimination of static electricity are also covered.Warp knitting

Warp knittingRasminThahaniZ

╠²

Warp knitting is a method of knitting where loops are formed vertically along the length of fabric from warp yarns. There are several types of warp knitting including tricot, raschel, and milanese knits. Tricot knits use compound needles and are used for fabrics like lingerie, loungewear, and uniforms. Raschel knits use latch needles and heavier yarns, producing more textured fabrics for applications like carpets, home textiles, and outerwear. Milanese knits form diagonal patterns and are often made from filament yarns into lightweight fabrics.Knitting technology

Knitting technologyAboni Knit Wear Ltd ( Babylon Group)

╠²

Dear Viewers ,

Good News to you.

Here I Attach a Assignment To you. Its helped to u make a Assignment in Knit Technology.

Tnx to all. Jacquad shedding

Jacquad sheddingNafiz Antu

╠²

This presentation summarizes the Jacquard shedding mechanism. It introduces the four presenters and provides background on the Jacquard loom, which can produce complex woven designs through individual control of warp threads. The presentation then covers the scope of Jacquard shedding, including its ability to control thousands of yarns and produce intricate designs. It also classifies different types of Jacquard looms based on their lifting capacity, design capacity, shed formation, and other features. Key aspects of the single lift Jacquard mechanism are explained. Advantages and disadvantages of the Jacquard loom conclude the presentation.Derivatives of Twill Weave

Derivatives of Twill Weave fahim zauwad

╠²

Twill weave is a kind of weave that repeat on three or more ends and picks and produces diagonal line on the face of fabric.

In a regular twill the diagonal line or twill line produces at 45 degree angle with the horizontal.

Concept:

The most characteristic of twill is that they have diagonal lines on the cloth.

Overlock Machines

Overlock Machinesnagarajbhat27

╠²

The document describes an overlock machine, which is a specialized sewing machine used to finish fabric edges and seams. It can produce stitches at speeds up to 5000 stitches per minute. The overlock machine makes stitches using 1-5 threads depending on the number of needles and loopers. Common stitch types include 3-thread, 4-thread, and 5-thread overlocks. Key features of the overlock machine include its differential feed system and ability to stretch stitching up to 300%. Problems with thread chains are addressed through the use of a backlatcher or chain cutting device.Knitting needles

Knitting needles Jijo Mathew

╠²

This document discusses three main types of knitting needles: bearded needles, latch needles, and compound needles. Bearded needles are the simplest and cheapest type, made from a single piece of metal with a fixed hook. Latch needles are more complex but self-acting, with a movable latch that opens and closes to form loops. Compound needles have a separate sliding element that works with an open hook to form loops without straining the yarn. The document provides details on the features, parts, advantages, and limitations of each needle type.Single needle lock stitch machine

Single needle lock stitch machineBangladesh University Of Business & Technology

╠²

This document provides an overview of single needle lock stitch sewing machines. It begins with a brief history of sewing machines and their development. It then discusses the specific type of single needle lock stitch machine, including its characteristics, features, parts, functions of parts, specifications of some models, maintenance, setting, replacement, and precautions. The key points covered are that a single needle lock stitch machine uses one needle to create a lock stitch, has various components like the needle, bobbin, feed dog, and requires proper maintenance, setting, and replacement of parts over time.Stitch and it's classification (part 1)

Stitch and it's classification (part 1)Md Shamsuzzaman Rasel

╠²

The topic stitch has been divided into 3 part. Here is the first part. Stay connected for the rest of the part. Basic informartion of knitting

Basic informartion of knittingAboni Knit Wear Ltd ( Babylon Group)

╠²

Here I write some important topics. It is very helpful to a Textile Student. I think If u Study it u will learn basic knowledge about knitting Technology.Fabric cutting

Fabric cuttingFarhan ullah baig

╠²

Cutting is the process of separating fabric into precise pattern pieces. Accurate cutting facilitates sewing while inaccurate cutting can cause fitting issues. Factors that influence cutting accuracy include marker lines, cutting technique, pitch, fabric movement, and equipment condition. Cutting is done using hand shears, portable straight/round knives, stationary band knives/dies, or automatic laser/waterjet systems. Proper cutting sets up quality sewing and assembly.Garment finishing

Garment finishingRajeev Sharan

╠²

The document discusses various garment finishing processes and equipment. It describes spotting processes that use hazardous chemicals and safer alternatives. It also covers folding, packing, hanging, pressing and finishing of different garments using specialized machines like shirt folders, steam irons, and finishers tailored for different garment types. Safety features of folding equipment like jam prevention systems are highlighted.fabric length,width & thickness_8.6.2020.pptx

fabric length,width & thickness_8.6.2020.pptxssuser94922c

╠²

Fabric dimensional properties include length, width, and thickness. Length is measured end to end along the selvedge using a table, scale, or trumeter machine. Width is measured perpendicular to the length between the selvedges, taking multiple measurements and calculating the mean. Thickness is measured using devices like the Reynolds tester that apply a known pressure between parallel plates and measure the distance between them. Proper sampling, conditioning, and multiple measurements are important to obtain accurate fabric dimensions.Similar to Cutting Machine of Garments Sector (20)

Fabric cutting Machine

Fabric cutting MachineMd. Mazadul Hasan Shishir

╠²

This document provides an overview of various fabric cutting methods used in the garment industry. It begins with an introduction to the purpose of fabric cutting and requirements for cutting. It then describes several cutting methods including manual (hand scissors, power knives), computerized (computer-controlled knife cutting, laser beam cutting, water jet cutting, plasma torch cutting), and their advantages and disadvantages. Popular garment cutting machine manufacturers are listed at the end.Fabric Cutting

Fabric CuttingSalim Azad

╠²

This document provides information about different cutting methods and knives used in fabric cutting. It introduces various fully manual and computerized cutting methods, including hand scissors, straight knives, band knives, round knives, die cutting, notcher cutting machines, drill cutting machines, and computer controlled knife cutting, laser beam cutting, water jet cutting, and plasma torch cutting. For each method, it describes the features, working principle, advantages, and disadvantages. It also lists the names and student IDs of the group members who prepared the presentation.Fabric cutting

Fabric cuttingSyed Ferdous Mahmud

╠²

The document discusses various methods of fabric cutting used in the garment industry. It describes the key steps in the fabric cutting process and requirements for accurate cutting. Several cutting methods are outlined, including manual cutting with scissors or power knives, as well as computerized cutting using knives, lasers, water jets, or plasma torches. The advantages and disadvantages of each method are provided.Atm jury slide

Atm jury slideIrshad Ansari

╠²

This document discusses various levels of technology used for fabric cutting in the textile industry, from fully manual to computerized methods. It describes the features, advantages, and disadvantages of different cutting methods including scissor cutting, straight knife cutting, round knife cutting, die cutting, band knife cutting, notcher cutting, drill cutting, computer controlled knife cutting, laser beam cutting, water jet cutting, and plasma torch cutting. It provides an example return on investment calculation for an automatic fabric spreader. The document aims to explain the technology levels and evaluate the value of different fabric cutting equipment options.Fabric Cutting

Fabric CuttingFaisal Ahmed Bappi

╠²

The document discusses various methods of fabric cutting used in the garment industry. It describes manual cutting using hand scissors, and semi-automatic and automatic methods like straight knife cutting, band knife cutting, round knife cutting, die cutting, drill cutting, water jet cutting, laser cutting, and plasma torch cutting. For each method, it provides details on features, advantages, and disadvantages. The key requirements for fabric cutting are outlined as precision of cut, clean edges, infused edges, and support of the fabric lay.Cutting technology in garment industry

Cutting technology in garment industrySwarnim Singh

╠²

Cutting is an important pre-production process that separates fabric parts precisely according to a pattern. There are manual, semi-automatic, and fully automatic cutting machines. Manual machines like scissors are used for small runs while automatic machines like computer-controlled knives cut large volumes quickly and consistently. Future innovations could automate the entire cutting process using roller cutters and feedback systems to reduce costs and improve efficiency.Cutting

CuttingPartho Biswas

╠²

Cutting involves separating garment pieces from fabric according to a pattern. It requires precision and clean edges. Common cutting methods include manual scissors, straight knives (most common), and computerized techniques like laser cutting. Straight knife machines work by using an electric motor to power a reciprocating blade, guided by an operator. Factors like fabric type, accuracy needs, volume, and time constraints determine the best cutting method. Potential issues like fused edges can be addressed through techniques like lubricating the blade or reducing cutting speed.Cutting

CuttingVipul Bhatia

╠²

Different types of cutting equipment are used in garment manufacturing including manual scissors, power knives like straight knives and band knives, and computerized methods. Straight knives can cut fabric stacks of higher heights efficiently but require skill. Band knives cut small parts precisely but fabric must be cut in bundles. Computer controlled knife cutting provides the most accurate cuts at high speeds by moving a knife over fabric held down by bristles. Laser cutting allows very fast single ply cuts but is not suitable for multi-layer fabrics or synthetics.GFD 312: MASS PRODUCTION TECHNIQUES AND PRACTICES

GFD 312: MASS PRODUCTION TECHNIQUES AND PRACTICES09197914524

╠²

FABRIC SPREADING AND CUTTING including its objective, definition, kinds,and requirements of Spreading and Cutting.175035 apparel lab 03

175035 apparel lab 03Mahbubay Rabbani Mim

╠²

This lab report summarizes an experiment comparing a straight knife cutting machine and round knife cutting machine. The straight knife machine uses a straight blade to cut large pieces of fabric and has high productivity. It can cut straight and curved lines. The round knife machine uses an octagonal blade and is better for cutting gentle curves and small pieces. Key differences are that the straight knife can cut fabric at any angle while the round knife cuts at 90 degrees. Regular maintenance like grinding and lubricating the blades is important for both machines.175035 apparel lab 03

175035 apparel lab 03Mahbubay Rabbani Mim

╠²

This lab report summarizes the student's study of straight knife and round knife cutting machines. The straight knife machine uses a straight blade to cut large pieces and curves, while the round knife machine uses a round blade and is better for small-scale cutting and gentle curves. Key differences are that the straight knife can cut fabrics from any angle, has higher productivity, but requires more skill, while the round knife is easier to use but can only cut at 90 degree angles. Both machines require regular blade sharpening and cleaning to maintain optimal performance.Presentation on Garments Cutting

Presentation on Garments CuttingAmanuzzaman Aman

╠²

The document discusses cutting in the garments industry. It covers the cutting process, requirements for accurate cutting, different cutting methods including manual and computerized, and various cutting machines used such as straight knife cutters, round knife cutters, and band knife cutters. It also discusses quality control processes for the cutting section to ensure accurate cutting of garment pieces.Cutting Machines

Cutting MachinesMd. Mazadul Hasan Shishir

╠²

The document discusses various techniques for cutting fabric pieces for garment making, including manual cutting, straight knife cutting machines, band knife cutting machines, round knife cutting machines, die cutters, water jet cutting, and laser cutting. It provides details on the components, operation, advantages and disadvantages of each cutting technique. Straight knife cutters can cut many fabric layers at once but carry risks of deflection and accidents. Band knife cutters cut with high accuracy but require fabric to be bundled and have high wastage. Round knife cutters are suitable for smaller productions. Die cutters provide accurate cuts for mass production. Water jet and laser cutting produce less heat but have limitations in the materials they can cut.Cutting

CuttingAhmad Sakib

╠²

The document discusses various techniques for cutting fabric pieces for garment making, including manual cutting, straight knife cutting machines, band knife machines, round knife machines, die cutters, water jet cutting, and laser cutting. It provides details on the components, operation, advantages and disadvantages of each cutting technique. Cutting is an important step in garment production used to separate fabric parts according to pattern pieces. Precision and clean cuts are required.Welcome to my presentation on cutting machine

Welcome to my presentation on cutting machineFama6797

╠²

This presentation provides an overview of cutting machines used in garment production. It introduces different cutting techniques, including manual cutting with scissors, powered knives, and computerized methods. Specific machine types are described, such as straight knife cutters, band knife cutters, and round, die, and notcher cutters. The objectives of cutting are to separate fabric parts according to a pattern's dimensions for garment assembly. Precision, clean edges, and unfolded fabric are important for achieving cutting goals.Computerized cutting machine

Computerized cutting machineMd. Reajul islam

╠²

Shakib Khan presented on computerized cutting machines. He discussed that cutting is a necessary step in garment production to separate fabric pieces according to a marker. There are manual, semi-automatic, and computerized cutting methods. Computerized knife cutting machines cut fabric according to a computer program without needing a marker, using an oval steel blade that moves precisely. Laser beam cutting machines cut fabric using a high-powered laser beam in a fine spot, controlled by a computer, cutting at 13 meters per minute. Computerized cutting machines provide accurate, high-speed cutting but have high initial and maintenance costs and require skilled operators.SPME 1.pptx

SPME 1.pptxKartikChopra29

╠²

Sportswear sewing uses fabrics like stretch knits and water-repellent nylons. Interfacings like stretch interfacing and bias tapes are used rarely and help avoid stretching. There are several techniques used in cutting and spreading fabrics including using a rolling rack or turntable to spread fabrics under tension for different modes. Cutting is done on machines like band knives, hot notchers, or lasers to accurately separate pieces while transferring marks. Proper bundling, shade separation and work ticketing is done after cutting before pieces are sent for sewing.(Sir Ashraful Alam) Full PDF Apparel Manufacturing I Sheet Part-2

(Sir Ashraful Alam) Full PDF Apparel Manufacturing I Sheet Part-2Md Rakibul Hassan

╠²

(Ashraful Alam) Full PDF Apparel Manufacturing I Sheet Part-2 | Full PDF Apparel Manufacturing Sheet Part-2Apparel i (term final)

Apparel i (term final)MohammadAshraful4

╠²

This file contains Apparel Spreading & Cutting section as well as the use of computer in apparel manufacturing.Presentation on fabric cutting

Presentation on fabric cuttingUsamaBinShahid2

╠²

The document discusses different types of fabric cutting machines used in the garments industry. It begins by defining fabric cutting as accurately separating fabric parts from a spread according to a pattern's dimensions. There are three main types of cutting machines: manual (using scissors), semi-automatic (like straight knife cutters), and fully automatic (laser cutters, water jet, plasma torch). The key requirements for cutting are precision, clean edges, supported fabric, and minimized waste. Semi-automatic machines like straight knife cutters are versatile and affordable but pose risks, while automatic machines provide fast, consistent cutting but are more expensive. Overall cutting machines are important for efficient, accurate production in the apparel industry.Recently uploaded (20)

Air pollution is contamination of the indoor or outdoor environment by any ch...

Air pollution is contamination of the indoor or outdoor environment by any ch...dhanashree78

╠²

Air pollution is contamination of the indoor or outdoor environment by any chemical, physical or biological agent that modifies the natural characteristics of the atmosphere.

Household combustion devices, motor vehicles, industrial facilities and forest fires are common sources of air pollution. Pollutants of major public health concern include particulate matter, carbon monoxide, ozone, nitrogen dioxide and sulfur dioxide. Outdoor and indoor air pollution cause respiratory and other diseases and are important sources of morbidity and mortality.

WHO data show that almost all of the global population (99%) breathe air that exceeds WHO guideline limits and contains high levels of pollutants, with low- and middle-income countries suffering from the highest exposures.

Air quality is closely linked to the earthŌĆÖs climate and ecosystems globally. Many of the drivers of air pollution (i.e. combustion of fossil fuels) are also sources of greenhouse gas emissions. Policies to reduce air pollution, therefore, offer a win-win strategy for both climate and health, lowering the burden of disease attributable to air pollution, as well as contributing to the near- and long-term mitigation of climate change.

Multi objective genetic approach with Ranking

Multi objective genetic approach with Rankingnamisha18

╠²

Multi objective genetic approach with Ranking decarbonization steel industry rev1.pptx

decarbonization steel industry rev1.pptxgonzalezolabarriaped

╠²

Webinar Decarbonization steel industryStructural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...

Structural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...slayshadow705

╠²

This presentation provides an in-depth analysis of structural quality control in the KRP 401600 section of the Copper Processing Plant-3 (MOF-3) in Uzbekistan. As a Structural QA/QC Inspector, I have identified critical welding defects, alignment issues, bolting problems, and joint fit-up concerns.

Key topics covered:

Ō£ö Common Structural Defects ŌĆō Welding porosity, misalignment, bolting errors, and more.

Ō£ö Root Cause Analysis ŌĆō Understanding why these defects occur.

Ō£ö Corrective & Preventive Actions ŌĆō Effective solutions to improve quality.

Ō£ö Team Responsibilities ŌĆō Roles of supervisors, welders, fitters, and QC inspectors.

Ō£ö Inspection & Quality Control Enhancements ŌĆō Advanced techniques for defect detection.

¤ōī Applicable Standards: GOST, KMK, SNK ŌĆō Ensuring compliance with international quality benchmarks.

¤ÜĆ This presentation is a must-watch for:

Ō£ģ QA/QC Inspectors, Structural Engineers, Welding Inspectors, and Project Managers in the construction & oil & gas industries.

Ō£ģ Professionals looking to improve quality control processes in large-scale industrial projects.

¤ōó Download & share your thoughts! Let's discuss best practices for enhancing structural integrity in industrial projects.

Categories:

Engineering

Construction

Quality Control

Welding Inspection

Project Management

Tags:

#QAQC #StructuralInspection #WeldingDefects #BoltingIssues #ConstructionQuality #Engineering #GOSTStandards #WeldingInspection #QualityControl #ProjectManagement #MOF3 #CopperProcessing #StructuralEngineering #NDT #OilAndGasTaykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON

╠²

Kalite Politikam─▒z

Taykon ├ćelik i├¦in kalite, hayallerinizi bizlerle payla┼¤t─▒─¤─▒n─▒z an ba┼¤lar. Proje ├¦iziminden detaylar─▒n ├¦├Čz├╝m├╝ne, detaylar─▒n ├¦├Čz├╝m├╝nden ├╝retime, ├╝retimden montaja, montajdan teslime hayallerinizin ger├¦ekle┼¤ti─¤ini g├Črd├╝─¤├╝n├╝z ana kadar ge├¦en t├╝m a┼¤amalar─▒, ├¦al─▒┼¤anlar─▒, t├╝m teknik donan─▒m ve ├¦evreyi i├¦ine al─▒r KAL─░TE.How to Build a Maze Solving Robot Using Arduino

How to Build a Maze Solving Robot Using ArduinoCircuitDigest

╠²

Learn how to make an Arduino-powered robot that can navigate mazes on its own using IR sensors and "Hand on the wall" algorithm.

This step-by-step guide will show you how to build your own maze-solving robot using Arduino UNO, three IR sensors, and basic components that you can easily find in your local electronics shop.Industrial Valves, Instruments Products Profile

Industrial Valves, Instruments Products Profilezebcoeng

╠²

WeŌĆÖre excited to share our product profile, showcasing our expertise in Industrial Valves, Instrumentation, and Hydraulic & Pneumatic Solutions.

We also supply API-approved valves from globally trusted brands, ensuring top-notch quality and internationally certified solutions. LetŌĆÖs explore valuable business opportunities together!

We specialize in:

ŌĆó Industrial Valves (Gate, Globe, Ball, Butterfly, Check)

ŌĆó Instrumentation (Pressure Gauges, Transmitters, Flow Meters)

ŌĆó Pneumatic Products (Cylinders, Solenoid Valves, Fittings)

As authorized partners of trusted global brands, we deliver high-quality solutions tailored to meet your industrial needs with seamless support.Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptx

Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptxppkmurthy2006

╠²

Mathematics behind machine learning INT255 Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

╠²

Optimal use of resources, including energy, is one of the most important principles in modern and sustainable agricultural systems. Exergy analysis and life cycle assessment were used to study the efficient use of inputs, energy consumption reduction, and various environmental effects in the corn production system in Lorestan province, Iran. The required data were collected from farmers in Lorestan province using random sampling. The Cobb-Douglas equation and data envelopment analysis were utilized for modeling and optimizing cumulative energy and exergy consumption (CEnC and CExC) and devising strategies to mitigate the environmental impacts of corn production. The Cobb-Douglas equation results revealed that electricity, diesel fuel, and N-fertilizer were the major contributors to CExC in the corn production system. According to the Data Envelopment Analysis (DEA) results, the average efficiency of all farms in terms of CExC was 94.7% in the CCR model and 97.8% in the BCC model. Furthermore, the results indicated that there was excessive consumption of inputs, particularly potassium and phosphate fertilizers. By adopting more suitable methods based on DEA of efficient farmers, it was possible to save 6.47, 10.42, 7.40, 13.32, 31.29, 3.25, and 6.78% in the exergy consumption of diesel fuel, electricity, machinery, chemical fertilizers, biocides, seeds, and irrigation, respectively. The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

╠²

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

╠²

Cutting Machine of Garments Sector

- 2. FABRIC CUTTING ’ü▒To make a complete garments, cutting is necessary. It means to cut out the garment pieces from lays of the fabric with the help of cutting templates. In garments industries fabric is cut from lay and spreading with accuracy and properly which is termed as fabric cutting. ŌĆó Object: ’üČTo separate fabric parts from the spread of the lay according to the dimension of the marker ŌĆó Requirements Of Cutting: ’āś Precession of cut ’āś Clean edge ’āś Infused edge ’āś Consistency in cutting ’āś Support of the lay

- 3. TYPES OF CUTTING METHOD ’ü▒ Fully Manual ’üČ Hand operated scissor ’ü▒ Manually Operated Power Knife ’üČ Straight knife ’üČ Band knife ’üČ Round knife ’üČ Die cutting ’üČ Notcher ’üČ Drill ’ü▒ Computerized Methods Of Fabric Cutting ’üČ Computer controlled knife cutting ’üČ Cutting by Laser beam ’üČ Cutting by Water jet ’üČ Cutting by Plasma torch

- 4. HAND OPERATED SCISSOR ŌĆó Features: ’āś First & oldest method of fabric cutting ’āś Used for cutting one or two plies of fabric ’āś Available to cut the fabric from left to right or right to left ’āś Can be cut by scissor ’āś Needs more time & contain high cost ’āś Used in tailoring & household purpose to cut fabric

- 5. STRAIGHT KNIFE ŌĆó Features: ’üČ The elements of straight knife consists of: 1. An electric motor 2. Stand 3. A base plate usually on rollers 4. Handle 5. Knife 6. Knife Guard 7. Wheel ’üČ Knife is driven by electric power ’üČ Grinding wheel is present to sharp the knife during cutting ’üČ Blade edge: straight edge, wave edge, saw edge, serrated edge ’üČ Straight edge is mostly used ’üČ Blade stroke 2.5 to 4.5 cm ’üČ Can cut heavy fabric such as canvas & denim

- 6. STRAIGHT KNIFE ŌĆó Working Principal: ’ü▒Two kind of powers are required to operate a Straight Knife ’üČMotor power drive the reciprocating knife ’üČOperator power drives the knife through the lay ’ü▒The motor power needed is determined by ’üČHeight of the lay ’üČConstruction of the fabric ’üČCurvature of the line being cut ’üČStroke of the blade ’ü▒Greater power of the motor, greater blade movement to cut the fabric

- 7. STRAIGHT KNIFE ŌĆó Advantage: ’ü▒Comparatively cheap & transferred easily from one place to another place ’ü▒Higher lay of fabric can be cut easily ’ü▒Round corner can be cut more precisely then even round knife ’ü▒Production speed is very good & fabric can be cut from any angle ŌĆó Disadvantage: ’ü▒Some time deflection may occur due to the weight of the motor ’ü▒Knife deflection is high in risk, when lay height is too high ’ü▒Sometime accident may happen

- 8. DIFFERENT TYPES OF KNIFE ’üČRound Knife: ’üČStraight Knife: Wave knife Straight knife Notch knife

- 9. BAND KNIFE ŌĆó Features: ’ü▒Band knife comprises a series of three or more pulleys, powered by electric motor ’ü▒Cutting knife is endless in shape & flexible ’ü▒Blade is usually narrower then on a straight knife ’ü▒This method m/c is stationary but fabric is moveable ’ü▒This is like saw mill cutter

- 10. BAND KNIFE Advantage: ’ü▒Used when a higher standard of cutting accuracy is required ’ü▒Extensively used to cut very sharp corners small parts such as collars & cuff ’ü▒Used more in menŌĆÖs wear than ladies wear ’ü▒Intensively risk of accident is low ’ü▒Possible to cut 90╦Ü angle of the fabric Disadvantage: ’ü▒Work load is high as m/c is stationary & fabric is moveable ’ü▒Not suitable for cutting large amount of garments parts ’ü▒Not possible to cut fabric directly ’ü▒Fabric wastage is high ’ü▒Power loss is high

- 11. ROUND KNIFE ŌĆó Features: ’ü▒Element of round knife: ’üČBase plate & Electric motor ’üČHandle for the cutter to direct the blade ’üČRotating circular blade ’ü▒Blade diameter varies from 6-20 cm ’ü▒Blade is circular ’ü▒Blade is driven by electric power ’ü▒Circular knife is driven by 1000-3500 cm ŌĆó

- 12. ROUND KNIFE ’ü▒Advantage: Suitable for single ply cutting as well as multi-layers (say 20- 30 layers) ’ü▒Suitable for small scale cutting ’ü▒Suitable gentle curve cutting ’ü▒Easy to operate ’ü▒Useful for cutting layer parts of a garments Disadvantage: ’ü▒Not suitable for cutting very curve lines in higher no. of lays ’ü▒Not suitable for higher production ’ü▒Possibility of accident is high ’ü▒Difficult to cut small component ’ü▒Needs skilled operator

- 13. DIE CUTTING ŌĆó Features: ’ü▒Mainly two types of die cuttings are available namely: Presses & Clickers ’ü▒Main parts of all die cutting m/c are Blade, Ram Head, Die, Motor & Operating System of Ram ’ü▒Die is made by metallic strip ’ü▒Most useful to cut sharp & small parts

- 14. DIE CUTTING Working Principal: ’ü▒Die is prepared with metal strip according to the shape of pattern ’ü▒Die press generally has a cutting die just penetrates the cutting pad in order that the fibers of the lowest ply are completely separated ’ü▒For die cutting, the spreader spreads a lay to the required placement of dies ’ü▒The spread is cut into sections to allow transport to the cutting pad ’ü▒The gap between two dies 2-3 mm are placed when die is taken to cut fabric lay

- 15. DIE CUTTING ŌĆó Advantage: ’ü▒Extensively used to cut sharp corners of small parts of dress accurately ’ü▒Most useful to cut at any shape or any angle ’ü▒Comparatively less time required ’ü▒Best method of cutting knitted fabric ŌĆó Disadvantage: ’ü▒Fabric loss is high due to the need of block of fabric lay ’ü▒High labor cost ’ü▒To change the style quickly is impossible ’ü▒Difficult to cut large components of dress

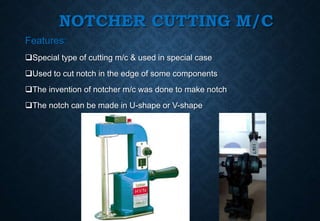

- 16. NOTCHER CUTTING M/C Features: ’ü▒Special type of cutting m/c & used in special case ’ü▒Used to cut notch in the edge of some components ’ü▒The invention of notcher m/c was done to make notch ’ü▒The notch can be made in U-shape or V-shape

- 17. NOTCHER CUTTING M/C Advantage: ’ü▒Special type of cutting m/c & used in special case ’ü▒Useful to cut small notch to the fabric ’ü▒Most useful to make consistency in notching Disadvantage: ’ü▒Only used to make notch ’ü▒Thermoplastic fiber can not cut by this m/c ’ü▒Time loss ’ü▒Use of the m/c is limited

- 18. DRILL CUTTING M/C Features: ’ü▒Needed to mark on the end of components of dresses especially for pocket & dart setting ’ü▒This m/c contains a motor, base plate, drill, & spirit level ’ü▒For tightly woven fabric, making of hole by drill is permanent for long ’ü▒In hypodermic drill some color is sprayed along with the hole so that it can easy to find the marked place

- 19. DRILL CUTTING M/C Advantage: ’ü▒Needed to mark on the end of components of dresses especially for setting pocket & dart ’ü▒Make the hole permanently for long time Disadvantage: ’ü▒Only used for making hole in the fabric especially for setting pocket & dart ’ü▒For loose woven fabric it can not make the hole permanently for long time