CV Anca Beatrice Deatcu E

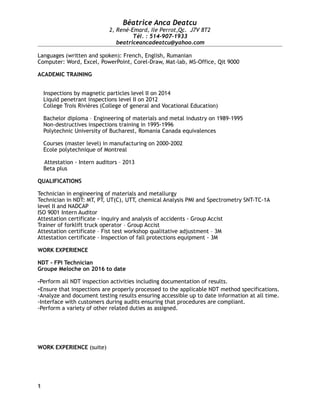

- 1. Béatrice Anca Deatcu 2, René-Emard, Ile Perrot,Qc. J7V 8T2 Tél. : 514-907-1933 beatriceancadeatcu@yahoo.com Languages (written and spoken): French, English, Rumanian Computer: Word, Excel, PowerPoint, Corel-Draw, Mat-lab, MS-Office, Qit 9000 ACADEMIC TRAINING Inspections by magnetic particles level II on 2014 Liquid penetrant inspections level II on 2012 College Trois Rivières (College of general and Vocational Education) Bachelor diploma – Engineering of materials and metal industry on 1989-1995 Non-destructives inspections training in 1995-1996 Polytechnic University of Bucharest, Romania Canada equivalences Courses (master level) in manufacturing on 2000-2002 Ecole polytechnique of Montreal

Attestation - Intern auditors – 2013 Beta plus

QUALIFICATIONS

Technician in engineering of materials and metallurgy

Technician in NDT: MT, PT, UT(C), UTT, chemical Analysis PMI and Spectrometry SNT-TC-1A level II and NADCAP ISO 9001 Intern Auditor

Attestation certificate - inquiry and analysis of accidents - Group Accist Trainer of forklift truck operator – Group Accist Attestation certificate – Fist test workshop qualitative adjustment – 3M Attestation certificate – Inspection of fall protections equipment - 3M WORK EXPERIENCE NDT - FPI Technician Groupe Meloche on 2016 to date -Perform all NDT inspection activities including documentation of results. -Ensure that inspections are properly processed to the applicable NDT method specifications. -Analyze and document testing results ensuring accessible up to date information at all time. -Interface with customers during audits ensuring that procedures are compliant. -Perform a variety of other related duties as assigned. WORK EXPERIENCE (suite) 1

- 2. Béatrice Anca Deatcu 2, René-Emard, Ile Perrot,Qc. J7V 8T2 Tél. : 514-907-1933 beatriceancadeatcu@yahoo.com Quality, Safety, SNT-Tc-1A Coordinator and NDT technician (non-destructive testing) Mequaltech on 2010-2015 -Answer to the external customer’s audits, and to the audits of certification ISO 9001: 2008 -Audit the conformity of the company operations and indicate nonconformities -Develop and implement improved NDT techniques following customer guidelines and requirements. -Plan and coordinate the process of formations and advances trainings of the technicians -Revise the inspections procedures -Manage the Health-Safety and forklift truck operators training of the employees -Make the fit tests to every employee -Health and Safety audits of conformities on the site -Proceed to non-destructive testing by liquid penetrant, magnetic particles, ultrasounds and phased - Array -Make chemical analyses PMI and by portable Spectrometry -Surveillance of construction sites at SUNCOR, VALERO, SHELL, Produis de papier Resolu, etc. WORK EXPERIENCE (suite) Manager

REITMANS Inc. Canada, Montreal and West of the Island on 2005-2010 -Manage the employees, the human resources, the sales and the operations -Realize the marketing according to the plans supplied by the head office -Form the new employees and the futures managers

- Offer a good customer service

Technical representative and sales

BOLADESIGN Canada, Ile Bizard on 2002 – 2005 -Meet customers and offer personalized conceptions (designs) of lettering -Negotiate contracts and conclude the orders of lettering -Design signs by computer -Make and install signs -Customer service

Engineer in engineering of materials and metals industry S.C. COMOTI S.A, Bucharest, Romania on 1995-1999 -Survey the process of the heat treatments -Assure the quality controls and he conformity of the operations -Draft technical reports -Execute the destructive and non-destructive testing -Metallography -Prepare solutions of chemical attacks -Survey the manufacturing of metal parts realised by the externals suppliers

2