CV_Arindam_Roy_SIMS

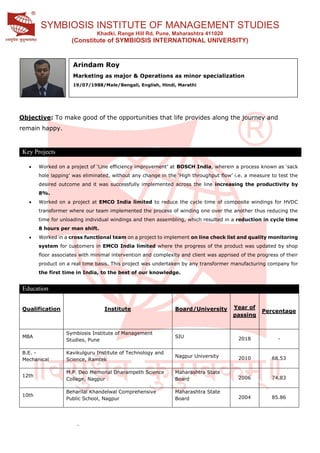

- 1. SYMBIOSIS INSTITUTE OF MANAGEMENT STUDIES Khadki, Range Hill Rd, Pune, Maharashtra 411020 (Constitute of SYMBIOSIS INTERNATIONAL UNIVERSITY) Objective: To make good of the opportunities that life provides along the journey and remain happy.  Worked on a project of ‘Line efficiency improvement’ at BOSCH India, wherein a process known as ‘sack hole lapping’ was eliminated, without any change in the ‘High throughput flow’ i.e. a measure to test the desired outcome and it was successfully implemented across the line increasing the productivity by 8%.  Worked on a project at EMCO India limited to reduce the cycle time of composite windings for HVDC transformer where our team implemented the process of winding one over the another thus reducing the time for unloading individual windings and then assembling, which resulted in a reduction in cycle time 8 hours per man shift.  Worked in a cross functional team on a project to implement on line check list and quality monitoring system for customers in EMCO India limited where the progress of the product was updated by shop floor associates with minimal intervention and complexity and client was apprised of the progress of their product on a real time basis. This project was undertaken by any transformer manufacturing company for the first time in India, to the best of our knowledge. . Education Qualification Institute Board/University Year of passing Percentage MBA Symbiosis Institute of Management Studies, Pune SIU 2018 - B.E. - Mechanical Kavikulguru Institute of Technology and Science, Ramtek Nagpur University 2010 68.53 12th M.P. Deo Memorial Dharampeth Science College, Nagpur Maharashtra State Board 2006 74.83 10th Beharilal Khandelwal Comprehensive Public School, Nagpur Maharashtra State Board 2004 85.86 Key Projects Arindam Roy Marketing as major & Operations as minor specialization 19/07/1988/Male/Bengali, English, Hindi, Marathi

- 2. SYMBIOSIS INSTITUTE OF MANAGEMENT STUDIES Khadki, Range Hill Rd, Pune, Maharashtra 411020 (Constitute of SYMBIOSIS INTERNATIONAL UNIVERSITY) A) Senior Engineer - Manufacturing - Diesel Systems division, Nasik April 2015 – February 2016 1. Responsible for manufacturing of conventional nozzle body parts. 2. Handled internal and external grinding of conventional nozzle bodies across eight different processes. 3. Responsible for in process quality control, Shop 5S, quality and productivity improvement projects. 4. Responsible for line balancing and handling soft man power issues across the shop floor. 5. Daily responsibilities include detailed analysis of man power and machine productivity, resource and capacity utilization and coordination with various departments for smooth operation of the shop floor. A) Engineer (Manufacturing) - Transformer division, EMCO Limited October 2013 to April 2015 1. Independently handled a team of 30 personnel per shift and ensured smooth operation of manufacturing of power transformers; monitored process activities for the production of power transformer windings and “phase assembly (nesting)” up to 315 MVA/400 KV range. 2. Successfully achieved lead time reduction of 33% across all segments (average) of power transformer windings & phase assembly (nesting). 3. Leader of “Quality circle” team in company; implemented various continuous improvement projects. 4. Part of production team that manufactured 315 MVA/400 KV transformer which successfully passed the “Dynamic short circuit test” at KEEMA, Netherlands. B) Assistant Engineer (Manufacturing) – Transformer division, EMCO Limited April 2011 to September 2013 C) Engineer Trainee (Business Development + Transformer manufacturing) July 2010 to March 2011 1. Handled responsibility of business development activities for establishment of 660 MW thermal power plant. 2. Coordinated with various government agencies, district administration and non-government organizations for early and smooth approvals and clearances. 3. Successfully completed environmental public hearing in a record period of two and a half months. 4. Distinguished efforts towards handling special projects for Teams / Business units as per requirement. 5. Reduced the pre project cycle time from 20 weeks to 8 weeks. 6. Learned basics of transformer manufacturing and had on job shop supervision experience as part of training. 1. ERP – SAP (Production Planning (PP) Module) 2. Maynard Operation Sequence Technique (MOST) 3. Computer Aided Design software UGS NX-5 4. MS Office  Member of the Institute social responsibility team ‘Pranay’ which successfully completed sharing “Sharing Happiness Campaign – Kavach” i.e. clothes donation, Independence day celebration with under privileged children of society and blood donation campaign in college  Executive coordinator of TEDx series of talks (marketing team) for Symbiosis International University, Kirkee Work Experience Computer Proficiency Extra-Curricular Activities