Dairy Plant Modivas KP Project LQ

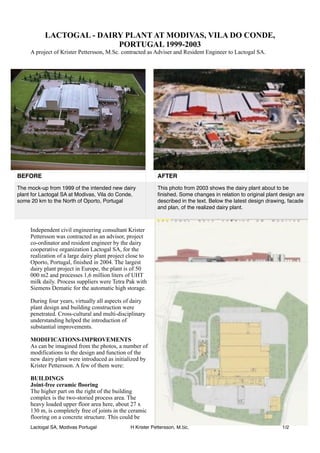

- 1. LACTOGAL - DAIRY PLANT AT MODIVAS, VILA DO CONDE, PORTUGAL 1999-2003 A project of Krister Pettersson, M.Sc. contracted as Adviser and Resident Engineer to Lactogal SA. ! Independent civil engineering consultant Krister Pettersson was contracted as an advisor, project co-ordinator and resident engineer by the dairy cooperative organization Lactogal SA, for the realization of a large dairy plant project close to Oporto, Portugal, finished in 2004. The largest dairy plant project in Europe, the plant is of 50 000 m2 and processes 1,6 million liters of UHT milk daily. Process suppliers were Tetra Pak with Siemens Dematic for the automatic high storage. During four years, virtually all aspects of dairy plant design and building construction were penetrated. Cross-cultural and multi-disciplinary understanding helped the introduction of substantial improvements. MODIFICATIONS-IMPROVEMENTS As can be imagined from the photos, a number of modifications to the design and function of the new dairy plant were introduced as initialized by Krister Pettersson. A few of them were: !BUILDINGS Joint-free ceramic flooring The higher part on the right of the building complex is the two-storied process area. The heavy loaded upper floor area here, about 27 x 130 m, is completely free of joints in the ceramic flooring on a concrete structure. This could be /1 2H Krister Pettersson, M.Sc,Lactogal SA, Modivas Portugal BEFORE AFTER The mock-up from 1999 of the intended new dairy plant for Lactogal SA at Modivas, Vila do Conde, some 20 km to the North of Oporto, Portugal This photo from 2003 shows the dairy plant about to be ’¼ünished. Some changes in relation to original plant design are described in the text. Below the latest design drawing, facade and plan, of the realized dairy plant. Text

- 2. achieved by casting the heavy-duty concrete slab with a methodology avoiding the need of expansion or construction joints producing only micro-cracks in the concrete. Then a combination of ceramic tiles and fixing compound was carefully chosen for certain flexibility with the aim of resisting the small movements in the micro-cracks of the concrete. The resulting joint-free flooring is highly appreciated for hygiene, resistance and easy maintenance. !Building shell Apart from the new color (Swedish Falu-red was such a fresh contrast to the surrounding green nature, said the architect, Mr. Brito) the photos show that the inclinations of the various roofs have been increased and some of the height differences between building parts eliminated. Much of the roof drainage is centralized to one single, large roof drainage canal This means that the risk for rain- water leakage has been reduced and maintenance facilitated, as a number of risky joints and water accumulations on the roofs have disappeared. !EXTERNALAREAS Water supply for the dairy plant processes is mainly obtained from own, drilled wells on the land, also a few below the proper buildings. !Large amounts of rainwater from the roofs and hardened areas must be led away to recipients. Originally, very large diameter drainage pipes were planned for this purpose. !Krister could, however, introduce a more environmentally friendly design by building three large rain-water dams on the ground to serve the double purpose of reservoirs and infiltration dams. !With these reservoir dams, rainwater pipe dimensions could be much reduced. A certain infiltration of rain and superficial water would help replenish groundwater wells and the dams would serve also for watering and fire water supply. Finally an environmentally healthier and more diversified landscaping would be more agreeable to both beast and man. kp@gransloskompetens.se +46 76 2797885 Krister Pettersson /2 2H Krister Pettersson, M.Sc,Lactogal SA, Modivas Portugal