Dark Room Construction

- 1. DARK ROOM & PITFALLS OF IMAGING Dr.Tarique Ajij Junior Resident, Department of Radio- Diagnosis, Medical College, Kolkata

- 2. DARK ROOM CONSTRUCTION âĒ A Dark room is a room, from which normal light is excluded. âĒ It is made completely dark to allow the processing of light sensitive photographic materials.

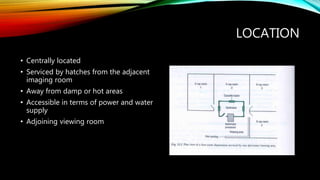

- 3. LOCATION âĒ Centrally located âĒ Serviced by hatches from the adjacent imaging room âĒ Away from damp or hot areas âĒ Accessible in terms of power and water supply âĒ Adjoining viewing room

- 4. HATCHES âĒ Hatches are designed to transfer film cassettes to and from the dark room without radiation light entering âĒ It consist of metallic structures with a lead lining to provide x ray shielding. âĒ They are typically wall mounted and include automatic interlocks that close one door when other is opened. âĒ It is also used for the temporary storage of loaded cassettes.

- 5. SIZE âĒ Minimum floor area of 10 sq meter âĒ Ceiling height of 2.5 - 3 meter âĒ Size may be reduced depending upon the department needs

- 6. RADIATION PROTECTION âĒ Walls adjacent to the radiographic room should be shielded with correct thickness of the lead all the way to the ceiling âĒ In the interests of both darkroom staff and film material alike âĒ 1.6 mm lead is mostly used

- 7. FLOORS âĒ Non-porous flooring âĒ Non-slip flooring âĒ Chemical resistant âĒ Stain proof âĒ Durable & easy to maintain âĒ Light coloured (low-light working conditions) âĒ Asphalt tiles âĒ Porcelain tiles âĒ Clay tiles âĒ Plastic tiles may be used in the dry dark-rooms

- 8. WALLS/CEILING âĒ Light in colour to reflect as much light as possible onto the working surface âĒ Easy to wipe or clean âĒ Covered with chemical resistant materials âĒ Special paints, varnish, ceramic or plastic wall

- 9. VENTILATION AND HEATING âĒ Satisfactory working conditions for the staff âĒ Good film handling and storage conditions âĒ Efficient automatic processor performance âĒ Relative humidity is maintained at around 40-60 % âĒ Room temperature maintained between 18-20 degree celsius âĒ A minimum of 10 air changes per hour âĒ All of these conditions can be achieved by using a good air-conditioning system âĒ Alternatively, fairly satisfactory ventilation can be achieved by using an extractor fan sited higher than and diagonally opposite a second fan, the latter being so placed as to obtain fresh and filtered air from outside.

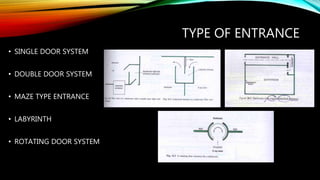

- 10. TYPE OF ENTRANCE âĒ SINGLE DOOR SYSTEM âĒ DOUBLE DOOR SYSTEM âĒ MAZE TYPE ENTRANCE âĒ LABYRINTH âĒ ROTATING DOOR SYSTEM

- 11. ROTATING DOOR SYSTEM âĒ Most efficient but most expensive type. âĒ Composed of two black cylinders. âĒ The outer is fixed. âĒ Inner is the revolving door with only one opening.

- 12. FIRE SAFETY âĒ Ideally, all darkrooms should be provided with an alternative exit, which should be indicated clearly and left unobstructed at all times

- 13. DARK ROOM ILLUMINATION âĒ WHITE LIGHTING âĒ SAFELIGHTING

- 14. WHITE LIGHTING âĒ For inspection & maintenance of cassettes & screens âĒ Cleaning of work surfaces âĒ Servicing of equipment âĒ Sited close to the ceiling âĒ Moderate in intensity âĒ (60w tungsten, 30w fluorescent ) âĒ Preferably centrally placed âĒ More than one switch preferable âĒ Identification of respective switches is important

- 15. SAFE LIGHTING DIRECT SAFE LIGHTING âĒ Light from safe lamp directly falls onto the work surface âĒ Eg. Beehive safelamp âĒ Minimum distance of 1.2 m from the working surface âĒ Best for loading & unloading areas

- 16. SAFE LIGHTING INDIRECT SAFE LIGHTING âĒ Directs the light towards the ceiling which reflects light back into the room âĒ Is intended to provide general illumination of the dark room âĒ Suspended atleast 2.1 m above floor level

- 17. SAFE LAMP FOR BOTH DIRECT & INDIRECT ILLUMINATION

- 18. SAFE LIGHT FILTERS âĒ Sheet of gelatin dyed to the appropriate colour and sandwiched between two sheets of glass for protection âĒ Used in conjunction with a 25 W lamp âĒ Extremes of heat and temperature deteriorates the filter gelatin âĒ Should be cleaned periodically

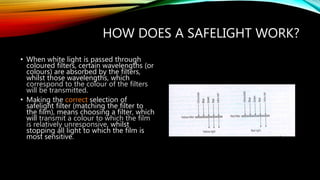

- 19. HOW DOES A SAFELIGHT WORK? âĒ When white light is passed through coloured filters, certain wavelengths (or colours) are absorbed by the filters, whilst those wavelengths, which correspond to the colour of the filters will be transmitted. âĒ Making the correct selection of safelight filter (matching the filter to the film), means choosing a filter, which will transmit a colour to which the film is relatively unresponsive, whilst stopping all light to which the film is most sensitive.

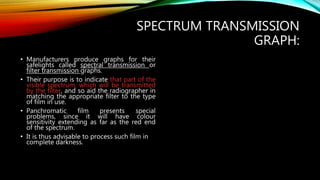

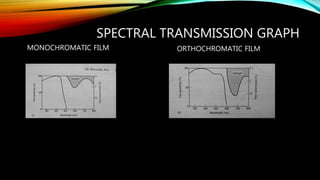

- 20. SPECTRUM TRANSMISSION GRAPH: âĒ Manufacturers produce graphs for their safelights called spectral transmission or filter transmission graphs. âĒ Their purpose is to indicate that part of the visible spectrum, which will be transmitted by the filter, and so aid the radiographer in matching the appropriate filter to the type of film in use. âĒ Panchromatic film presents special problems, since it will have colour sensitivity extending as far as the red end of the spectrum. âĒ It is thus advisable to process such film in complete darkness.

- 21. SPECTRAL TRANSMISSION GRAPH MONOCHROMATIC FILM ORTHOCHROMATIC FILM

- 22. IN SHORT!! âĒ AMBER âBLUE LIGHT SENSITIVE FILM(400-450nm) âĒ REDâGREEN LIGHT SENSITIVE FILM ORTHOCHROMATIC(500- 550nm) âĒ TOTAL DARKNESS FOR PANCHROMATIC FILM (1200nm)

- 23. HOW SAFE IS SAFE LIGHTING? âĒ No safe lighting is completely safe; all films will become significantly fogged if exposed to safelights for long enough. âĒ This is because safelight filters are not perfect absorbers of the undesirable wavelengths and, in truth, all films have some sensitivity to all wavelengths. âĒ Thus, the intensity of illumination and the film-handling time must be kept to a minimum if significant fogging is not to occur.

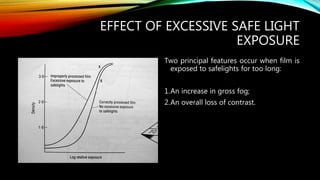

- 24. EFFECT OF EXCESSIVE SAFE LIGHT EXPOSURE Two principal features occur when film is exposed to safelights for too long: 1.An increase in gross fog; 2.An overall loss of contrast.

- 25. DARK ROOM EQUIPMENTS âĒ Automatic processor âĒ Manual process unit âĒ Processing chemicals âĒ Hangers for suspending film âĒ Cassette âĒ Film storage hopper âĒ Loading bench âĒ Cupboards

- 28. PROCESSING TANKS FOUR tanks in the processing procedure. âĒ DEVELOPER âĒ RINZING âĒ FIXER âĒ WASHING

- 29. PROCESSING TANKS Universally used tank sizes: âĒ 1 gallon âĒ 2 gallon âĒ 3 gallon âĒ 5 gallon âĒ 10 gallon 1 GALLON=4.5 LITRES âĒ Processing tanks are made up of stainless steel to avoid erosion. âĒ The width of the tank may vary according to the capacity of the tank.

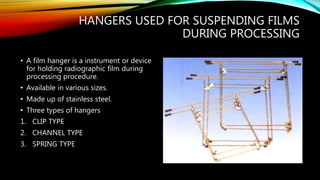

- 31. HANGERS USED FOR SUSPENDING FILMS DURING PROCESSING âĒ A film hanger is a instrument or device for holding radiographic film during processing procedure. âĒ Available in various sizes. âĒ Made up of stainless steel. âĒ Three types of hangers 1. CLIP TYPE 2. CHANNEL TYPE 3. SPRING TYPE

- 32. CASSETTES âĒ A radiographic film cassette is a rectangle or square plastic or metallic container used to hold x ray film (exposed or unexposed) and intensifying screens in close and uniform contact with one another.

- 33. CASSETTE SIZE âĒ DIFFERENT CASSETTE SIZES âĒ 17 x 14 inches âĒ 15 x 12 âĒ 14 x 14 âĒ 12 x 12 âĒ 12 x 10 âĒ 10 x 8 âĒ 12 x 6 (OPG)

- 34. USES OF CASSETTES 1. Hold intensifying screen and protect them from damage. 2. Exclude all light from entering the cassette and fogging the film. 3. Maintain a close and uniform contact between the screen and film. 4. Exclude dust and dirt from the sensitive films. 5. Act as a medium from exposure up to further processing of film.

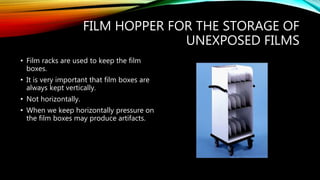

- 35. FILM HOPPER FOR THE STORAGE OF UNEXPOSED FILMS âĒ Film racks are used to keep the film boxes. âĒ It is very important that film boxes are always kept vertically. âĒ Not horizontally. âĒ When we keep horizontally pressure on the film boxes may produce artifacts.

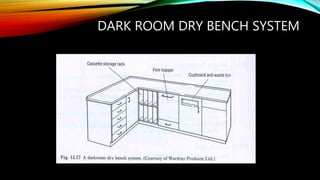

- 36. DARK ROOM DRY BENCH SYSTEM

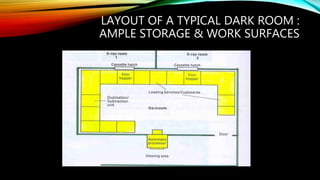

- 37. LAYOUT OF A TYPICAL DARK ROOM : AMPLE STORAGE & WORK SURFACES

- 38. HEALTH AND SAFETY IN THE PROCESSING AREA âĒ ELECTRICAL SAFETY âĒ GENERAL SAFETY âĒ CHEMICAL SAFETY

- 39. ELECTRICAL SAFETTY âĒ All electrical equipments to be sited well away from sinks & manual processing units âĒ Adequate earthing of all electrical appliances âĒ No trailing cables from appliances âĒ Pull-cord switching for lights

- 40. GENERAL SAFETY MEASURES âĒ The maximum level of safe lighting consistent with film sensitivity âĒ Adequate ventilation âĒ Second exits for fire safety

- 41. CHEMICAL HAZARDS âĒ Processing chemicals contain many toxic substances and must always be handled with care. âĒ Staff should always be aware of the harmful effects of exposure to the chemistry its fumes through inhalation, ingestion or skin contact. âĒ All staff involved with the handling of film chemistry should be regularly advised to read product labels and mixing instructions before handling solutions. âĒ Safety glasses, facemask, rubber gloves and plastic apron should be available within the processing area for each procedure.

- 42. PITFALLS OF SCREEN FILM RADIOGRAPHY

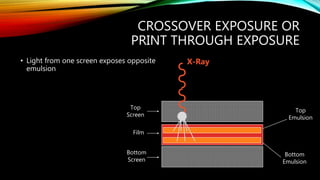

- 43. CROSSOVER EXPOSURE OR PRINT THROUGH EXPOSURE âĒ Light from one screen exposes opposite emulsion Top Screen Bottom Screen Bottom Emulsion Top Emulsion Film X-Ray

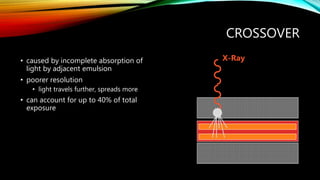

- 44. CROSSOVER âĒ caused by incomplete absorption of light by adjacent emulsion âĒ poorer resolution âĒ light travels further, spreads more âĒ can account for up to 40% of total exposure X-Ray

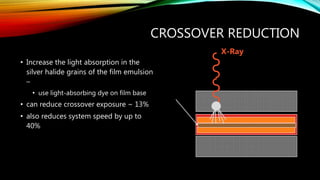

- 45. CROSSOVER REDUCTION âĒ Increase the light absorption in the silver halide grains of the film emulsion â âĒ use light-absorbing dye on film base âĒ can reduce crossover exposure ~ 13% âĒ also reduces system speed by up to 40% X-Ray

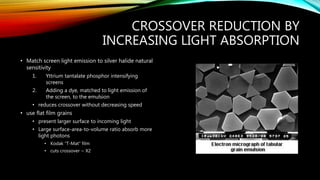

- 46. CROSSOVER REDUCTION BY INCREASING LIGHT ABSORPTION âĒ Match screen light emission to silver halide natural sensitivity 1. Yttrium tantalate phosphor intensifying screens 2. Adding a dye, matched to light emission of the screen, to the emulsion âĒ reduces crossover without decreasing speed âĒ use flat film grains âĒ present larger surface to incoming light âĒ Large surface-area-to-volume ratio absorb more light photons âĒ Kodak âT-Matâ film âĒ cuts crossover ~ X2

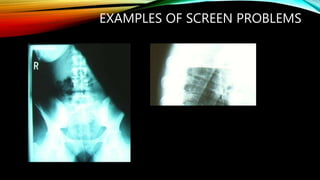

- 47. EXAMPLES OF SCREEN PROBLEMS

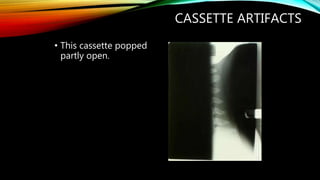

- 48. CASSETTE ARTIFACTS âĒ This cassette popped partly open.

- 49. CASSETTE ARTIFACTS âĒ Dirty screens will appear as white spots on the film. âĒ This film also has some static electricity artifacts.

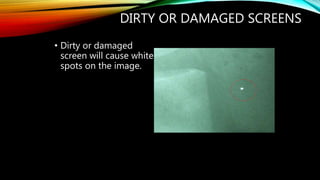

- 50. CASSETTE ARTIFACT DIRTY SCREENS âĒ Dirty or damaged screens will cause white spots on the image.

- 51. DIRTY OR DAMAGED SCREENS âĒ Dirty or damaged screen will cause white spots on the image.

- 52. DIRTY & DAMAGED SCREENS ï― The white spots on this film are the result of damaged or worn out screens. ï― Never use alcohol or detergents to clean screens.

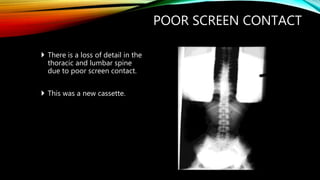

- 53. POOR SCREEN CONTACT ï― There is a loss of detail in the thoracic and lumbar spine due to poor screen contact. ï― This was a new cassette.