Defect analysis of garment manufacturing

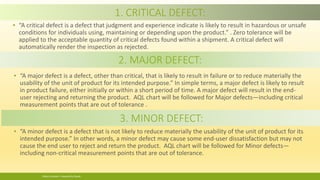

- 2. DEFECTS ARE CLASSIFIED INTO THREE MAIN CATEGORIES: - ‚ñ™ Critical Defects ‚ñ™ Major Defects ‚ñ™ Minor Defects 3. Minor Defect 2. Major Defect 1. Critical Defect Defect Analysis. Prepared by Rupak

- 3. 1. CRITICAL DEFECT: ▪ “A critical defect is a defect that judgment and experience indicate is likely to result in hazardous or unsafe conditions for individuals using, maintaining or depending upon the product.” . Zero tolerance will be applied to the acceptable quantity of critical defects found within a shipment. A critical defect will automatically render the inspection as rejected. 2. MAJOR DEFECT: ▪ “A major defect is a defect, other than critical, that is likely to result in failure or to reduce materially the usability of the unit of product for its intended purpose.” In simple terms, a major defect is likely to result in product failure, either initially or within a short period of time. A major defect will result in the end- user rejecting and returning the product. AQL chart will be followed for Major defects—including critical measurement points that are out of tolerance . ▪ “A minor defect is a defect that is not likely to reduce materially the usability of the unit of product for its intended purpose.” In other words, a minor defect may cause some end-user dissatisfaction but may not cause the end user to reject and return the product. AQL chart will be followed for Minor defects— including non-critical measurement points that are out of tolerance. 3. MINOR DEFECT: Defect Analysis. Prepared by Rupak

- 4. Coming soon Coming soonSlub -A short, thick place in the yarn or an extra piece of yarn woven into the fabric. 1 Coming soon2 3 Defect Classification Lists – Woven Fabric Defects